Comprehensive Guide to New Holland LS55 Parts Diagram

In the realm of machinery maintenance, comprehending the intricate relationships between various components is crucial. Each element plays a vital role in the overall functionality, and recognizing how they interact can significantly enhance operational efficiency. This section delves into the essential aspects of equipment schematics, highlighting the importance of familiarizing oneself with the layout and connection of individual parts.

By gaining insights into the arrangement and specifications of these components, users can better address issues that may arise during usage. This knowledge empowers operators to make informed decisions regarding repairs and upgrades, ensuring longevity and reliability in their equipment. The visual representation of these assemblies serves as a valuable resource for anyone looking to optimize their machinery performance.

Whether you’re a seasoned technician or a novice in the field, understanding these illustrations provides a foundation for effective maintenance practices. The clarity that comes from studying the arrangement of components not only aids in troubleshooting but also fosters a deeper appreciation for the machinery itself.

Understanding New Holland LS55 Components

Familiarizing oneself with the individual elements of machinery is crucial for effective operation and maintenance. Each component plays a vital role in ensuring the equipment functions optimally, contributing to overall efficiency and longevity.

Key components can be categorized as follows:

- Engine Assembly: This is the heart of the machine, responsible for providing power and drive.

- Hydraulic System: Essential for the movement and control of attachments, enabling various tasks to be performed seamlessly.

- Transmission: This system manages the transfer of power from the engine to the wheels, influencing speed and torque.

- Frame Structure: The robust skeleton that supports all other components, ensuring stability and durability under load.

Each of these categories contains numerous specific parts that must work harmoniously. Understanding their function can lead to more informed decisions regarding repairs and upgrades.

- Regular Maintenance: Familiarity with components aids in identifying wear and tear early.

- Enhanced Performance: Knowing how parts interact helps optimize machine operation.

- Cost-Effectiveness: Insight into component health can prevent costly breakdowns.

In summary, a comprehensive grasp of machinery components not only improves operational effectiveness but also empowers users to take proactive steps in maintenance and performance enhancement.

Importance of Parts Diagrams

Understanding the layout of components is crucial for effective maintenance and repair. Clear illustrations enable users to identify and locate each element, ensuring efficient troubleshooting and minimizing downtime. When one is familiar with the configuration, the process becomes more straightforward and less prone to error.

Enhanced Efficiency

Utilizing visual aids significantly boosts productivity. Technicians can quickly find the necessary components, leading to faster repairs and smoother operations. This visual representation reduces guesswork, allowing for a more systematic approach to addressing issues.

Informed Decision-Making

Comprehensive visuals facilitate better understanding of machinery. By examining the arrangement of elements, users can make informed decisions regarding replacements or upgrades, ultimately contributing to the longevity and performance of equipment.

Key Features of LS55 Model

This section explores the distinctive attributes that set this model apart in its category. By examining its design, functionality, and user-friendly characteristics, we gain insight into what makes it a preferred choice among operators.

Exceptional Maneuverability

The compact structure enhances its agility, allowing for seamless navigation in tight spaces. This feature is crucial for tasks that require precision and control.

Robust Performance

Equipped with a powerful engine, it delivers outstanding lifting capacity and speed, making it suitable for various applications. Reliability and efficiency are paramount in maximizing productivity.

Common Issues with LS55 Parts

Understanding the frequent challenges associated with various components can significantly enhance maintenance and operational efficiency. Users often encounter several common obstacles that may affect performance and reliability.

Wear and Tear: Over time, certain elements may experience deterioration, leading to reduced functionality. Regular inspections can help identify these issues early.

Misalignment: Components can become misaligned due to improper installation or heavy use, causing operational inefficiencies and potential damage. Ensuring proper alignment is crucial for optimal performance.

Fluid Leaks: Leaks can occur in hydraulic systems, which may compromise effectiveness. Timely detection and repair are essential to prevent further complications.

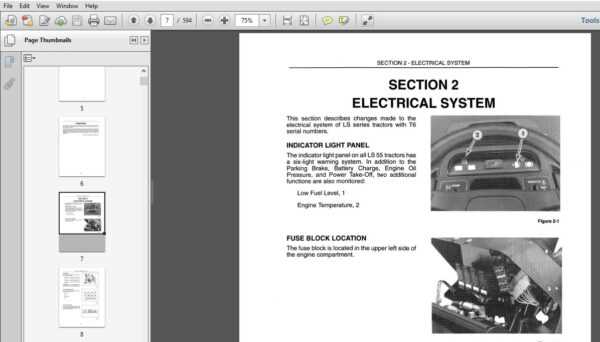

Electrical Failures: Issues with wiring and connections can lead to malfunctioning systems. Routine checks of electrical components can help maintain smooth operation.

Corrosion: Exposure to elements can result in rust and corrosion, weakening parts and impacting overall functionality. Protective measures can extend the life of critical components.

Where to Find Replacement Parts

Locating components for machinery maintenance is essential for ensuring optimal performance and longevity. A variety of sources can provide the necessary items to keep your equipment in top shape. Below are some reliable avenues to explore when searching for replacements.

- Authorized Dealers: Visiting authorized dealerships guarantees access to original items. These locations often have knowledgeable staff who can assist in identifying the correct components.

- Online Retailers: Numerous e-commerce platforms specialize in machinery components. Websites often feature extensive catalogs and customer reviews to aid in selection.

- Local Auto Parts Stores: Many local stores stock a range of items and can order specific components if they aren’t readily available.

- Salvage Yards: Salvage yards can be treasure troves for used items. This option is often more affordable and environmentally friendly.

- Manufacturer Websites: Directly visiting the manufacturer’s website may provide access to an online catalog and purchase options for required items.

- Forums and Online Communities: Engaging with online forums dedicated to machinery enthusiasts can yield valuable recommendations on where to find specific components.

By exploring these options, you can efficiently locate the necessary items to keep your equipment running smoothly.

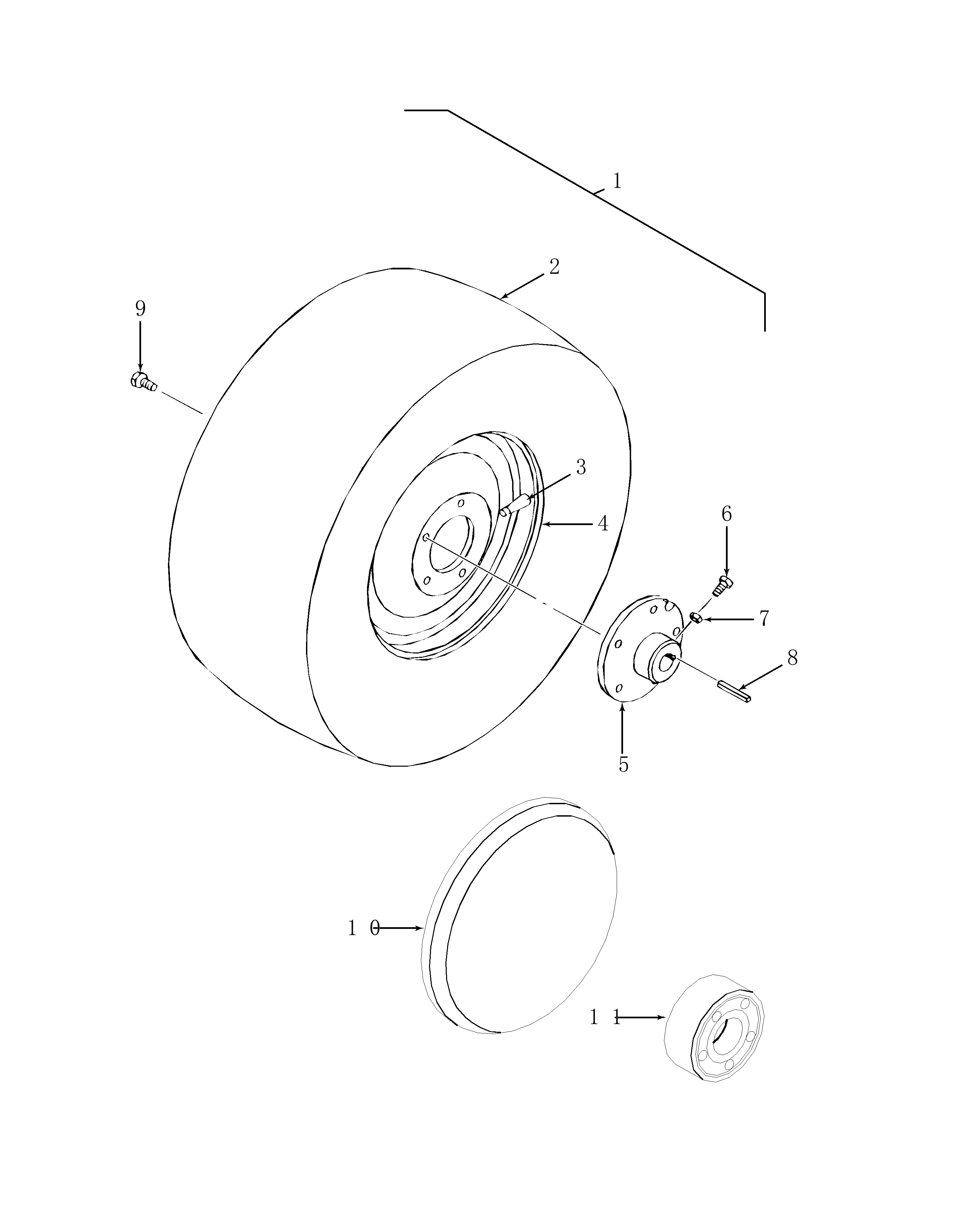

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual guides offer a detailed overview of various components, making it easier to identify, order, and replace items as needed. Familiarity with these graphics can significantly streamline your workflow and enhance your overall efficiency.

Breaking Down the Illustration

Start by examining the overall layout. Each section typically represents a different area of the machinery, allowing you to focus on specific components. Look for labeled parts that provide clarity on what each piece is and its function within the system.

Utilizing the Legend

Most visuals include a legend or key that explains symbols and numbers used in the representation. This guide is invaluable for deciphering what each item is, ensuring you can accurately reference and procure the correct components. Pay close attention to these details, as they can prevent costly mistakes during repairs.

By mastering the skill of interpreting these technical visuals, you will enhance your ability to maintain equipment efficiently and effectively.

Benefits of OEM vs Aftermarket Parts

When it comes to choosing components for machinery, the decision often revolves around the source of those components. Understanding the advantages of each option can significantly impact performance and longevity.

Original Equipment Manufacturer (OEM) components are specifically designed to meet the exact specifications of the original machinery. This ensures optimal compatibility and reliability, often resulting in enhanced performance. Additionally, using OEM parts typically comes with a warranty, providing peace of mind for the owner.

On the other hand, aftermarket alternatives can offer cost savings and a wider range of choices. These parts might enhance performance in specific applications and can often be readily available, making them a convenient option for some users. However, it’s crucial to consider the quality and reliability of these components, as they can vary significantly.

Ultimately, the choice between OEM and aftermarket components will depend on individual needs, budget, and the desired performance outcomes. Careful consideration of the benefits can lead to a more informed decision, ensuring the best fit for your machinery.

Maintenance Tips for LS55 Owners

Proper upkeep is essential for ensuring the longevity and performance of your equipment. Regular attention to various components can prevent breakdowns and enhance efficiency, making it crucial for operators to follow systematic maintenance practices.

Regular Inspections

Conduct thorough checks on all major systems, including hydraulic and electrical components. Identifying wear and tear early can save you from costly repairs later. Always refer to your manual for specific guidelines.

Fluid Management

Maintaining proper fluid levels is vital for optimal functionality. Regularly check and change hydraulic fluid, engine oil, and coolant as recommended. Neglecting these tasks can lead to severe performance issues.

Identifying Parts by Serial Number

Understanding how to pinpoint components using their unique identifiers is crucial for effective maintenance and repairs. This method ensures compatibility and enhances the efficiency of the equipment.

Why Serial Numbers Matter

Serial numbers provide specific information that can aid in identifying and sourcing the correct items. Here are some key points:

- Uniqueness: Each identifier is distinct to a particular item.

- Traceability: Helps track the history and specifications of the component.

- Manufacturer Reference: Facilitates communication with suppliers and service centers.

How to Use Serial Numbers Effectively

To make the most of serial numbers, follow these steps:

- Locate the serial number on the equipment.

- Consult the manufacturer’s catalog or website.

- Cross-reference the number with the required specifications.

- Contact support if additional information is needed.

Cost Considerations for Repairs

When addressing the financial aspects of machinery maintenance, several factors come into play that can significantly influence overall expenses. Understanding these elements is crucial for effective budgeting and planning.

Labor costs often represent a substantial portion of repair expenses. Depending on the complexity of the task, hiring skilled technicians can be necessary, impacting your budget accordingly. Additionally, parts prices vary widely based on quality and availability, making it essential to research options thoroughly.

Furthermore, diagnostic fees may arise, especially if the issue is not immediately apparent. This can lead to unexpected expenditures that should be factored into your overall repair strategy. Finally, consider the downtime associated with repairs, as prolonged inoperability can lead to lost productivity and revenue.

Customer Reviews on LS55 Parts

This section highlights the experiences and insights shared by users regarding components for the machine. Feedback from customers can provide valuable perspectives on quality, reliability, and performance.

Here are some common themes found in customer reviews:

- Quality: Many users praise the durability and construction of the components.

- Performance: Several reviews highlight how replacements enhance the overall functionality of the equipment.

- Compatibility: Customers often discuss the seamless integration of these components with their machines.

Overall, user feedback reflects a mix of satisfaction and areas for improvement:

- Some customers report exceptional experiences with longevity.

- Others suggest improvements in customer service and availability.

- A few reviews mention the importance of accurate specifications when ordering.

Resources for Further Information

This section provides a curated selection of resources aimed at enhancing your understanding and knowledge of machinery components and their specifications. Whether you are a novice or an experienced technician, these tools will prove invaluable in your research and maintenance efforts.

Online Forums and Communities

Participating in online forums can connect you with fellow enthusiasts and professionals. Engaging in discussions will allow you to delve into shared experiences and gather insights that can aid in troubleshooting and repairs.

Manufacturer Manuals and Guides

Consulting official manuals is crucial for obtaining accurate information about your equipment. These documents often contain the ultimate details regarding assembly, maintenance, and operational guidelines, ensuring optimal performance.