Comprehensive Guide to New Holland TD5050 Parts Diagram

The efficiency of modern farming equipment relies heavily on its intricate assembly of various elements. Each component plays a crucial role in ensuring optimal performance and durability. By gaining insight into these individual parts, operators can better maintain their machinery and troubleshoot any issues that may arise.

Exploring the layout of these components allows for a comprehensive understanding of their interconnections and functionalities. With a detailed overview, users can identify the specific areas that require attention or replacement, thus enhancing the longevity of their equipment. Knowledge of each element’s position and role is invaluable for effective upkeep.

In this guide, we will delve into the essential features and configurations of agricultural machinery, providing clarity on how to navigate the complexities of these powerful tools. By familiarizing oneself with the structure, operators can ensure that their equipment remains in peak condition and continues to support their agricultural endeavors.

Understanding New Holland TD5050 Parts

Gaining insight into the components of agricultural machinery is crucial for effective maintenance and operation. This knowledge not only ensures optimal performance but also prolongs the lifespan of the equipment. Recognizing the various elements and their functions helps users address issues promptly and maintain productivity.

Each component plays a vital role in the overall functionality of the machine, influencing aspects such as efficiency, power delivery, and ease of use. Familiarity with these elements allows for informed decision-making when it comes to repairs and upgrades.

| Component | Description |

|---|---|

| Engine | Drives the entire system, providing the necessary power for operations. |

| Transmission | Transfers power from the engine to the wheels, enabling movement and speed control. |

| Hydraulics | Facilitates lifting and moving heavy loads, enhancing functionality in various tasks. |

| Chassis | The structural framework that supports all other components and provides stability. |

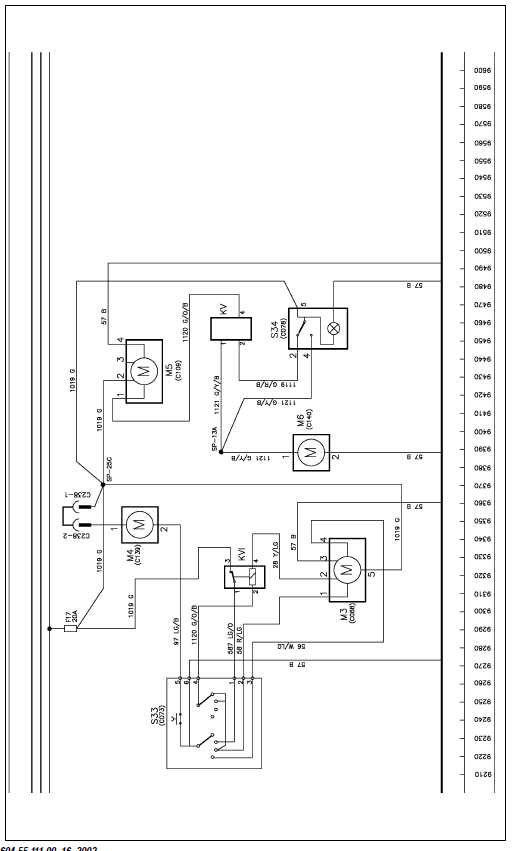

| Electrical System | Controls various functions, including starting the engine and operating lights and signals. |

Understanding these essential elements allows operators to optimize their machinery’s performance and ensure it operates smoothly across diverse tasks. Regular maintenance and checks can mitigate common issues, leading to more efficient agricultural practices.

Importance of Accurate Parts Diagrams

Detailed schematics play a crucial role in the maintenance and repair of machinery. They serve as essential tools for technicians and operators, providing a clear visual representation of components and their relationships within a system.

Here are several reasons why precision in these illustrations is vital:

- Efficiency in Repairs: Accurate visuals enable quick identification of parts, reducing downtime during maintenance.

- Enhanced Understanding: Clear schematics help users grasp the overall layout and function of the machinery, fostering better troubleshooting.

- Safety: Properly labeled components ensure that repairs are conducted safely, minimizing the risk of accidents.

- Cost-Effectiveness: Knowing exactly what parts are needed prevents unnecessary purchases, leading to savings in both time and money.

In conclusion, the significance of precise illustrations cannot be overstated. They facilitate smoother operations and support effective maintenance practices, ultimately contributing to the longevity of the equipment.

Common Parts and Their Functions

Understanding the essential components of agricultural machinery is crucial for effective operation and maintenance. Each element plays a specific role in ensuring that the equipment functions smoothly and efficiently. Below is an overview of key components commonly found in tractors, along with their respective functions.

Key Components

- Engine: This is the powerhouse of the machine, converting fuel into mechanical energy to drive various systems.

- Transmission: Responsible for transferring power from the engine to the wheels, allowing for speed and torque adjustments.

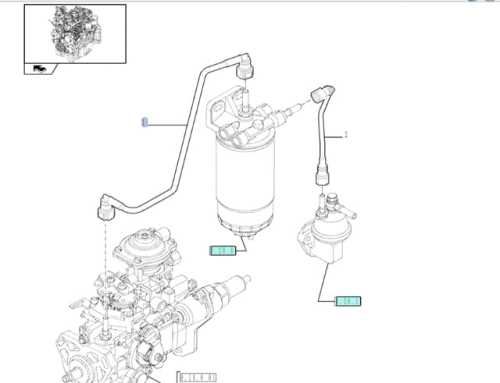

- Hydraulic System: Facilitates the operation of various attachments and implements by converting fluid power into mechanical force.

- Steering Mechanism: Allows the operator to guide the vehicle with precision, ensuring maneuverability in various terrains.

- Chassis: The framework that supports all other components, providing structural integrity and stability.

Additional Important Elements

- Electrical System: Powers lights, gauges, and other electronic features, playing a vital role in operation and safety.

- Cooling System: Maintains optimal operating temperature by dissipating heat generated by the engine.

- Fuel System: Stores and delivers fuel to the engine, ensuring efficient combustion and power generation.

- Brake System: Provides stopping power, enhancing safety during operation and transport.

- Tires: Impact traction and stability, allowing for effective movement across different surfaces.

Each component is interdependent, highlighting the importance of regular maintenance and familiarity with their functions for optimal performance.

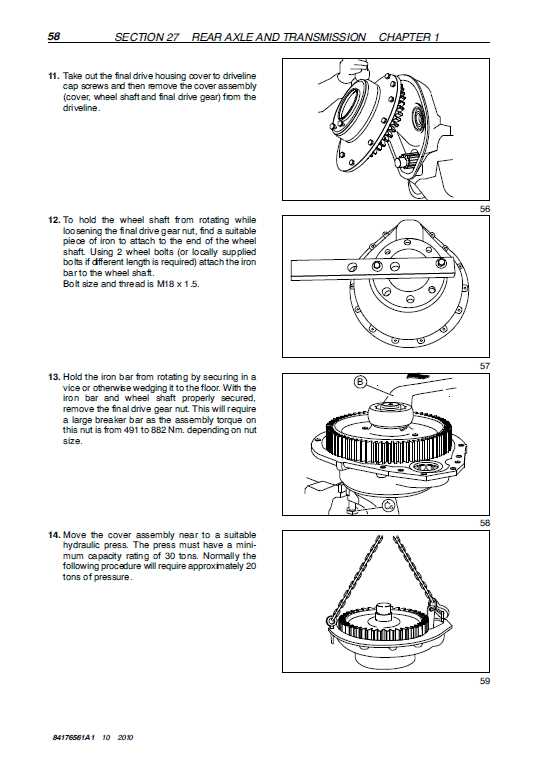

How to Read Parts Diagrams

Understanding visual schematics is crucial for effective maintenance and repair of machinery. These illustrations provide a comprehensive view of components, enabling users to identify and locate individual pieces accurately. By mastering this skill, one can enhance their troubleshooting efficiency and streamline the replacement process.

Familiarize Yourself with Symbols

Every schematic uses specific symbols to represent various elements. Familiarizing yourself with these representations will help you grasp the layout quickly. Pay attention to legends or keys that explain the symbols used, ensuring you can interpret the visuals effectively.

Follow the Flow of Assembly

Typically, these illustrations are organized to show the assembly sequence. Tracing the flow from one component to another will provide insight into how parts connect and function together. This understanding can be pivotal for successful repairs and upgrades.

Where to Find Replacement Parts

Finding suitable components for your agricultural machinery is essential for maintaining optimal performance. Whether you are dealing with repairs or upgrades, knowing where to source high-quality items can save time and ensure reliability. Here are several effective options to consider when searching for replacements.

- Authorized Dealers: These establishments often provide original components that meet the manufacturer’s specifications. It’s a reliable option for quality assurance.

- Online Retailers: Numerous e-commerce platforms specialize in machinery supplies. A quick search can yield a variety of choices, often with customer reviews to guide your decision.

- Local Supply Stores: Many towns have shops that focus on agricultural tools and equipment. Visiting these stores can provide immediate access to necessary items.

- Salvage Yards: For those looking for cost-effective solutions, salvage yards may have used components in good condition. It’s a sustainable option that can yield valuable finds.

- Trade Shows and Expos: Attending industry events can connect you with suppliers and manufacturers directly. This is an excellent way to discover new products and network with other professionals.

By exploring these avenues, you can efficiently locate the right components to keep your equipment in top shape. Always prioritize quality and compatibility to ensure the best performance from your machinery.

Maintenance Tips for TD5050 Components

Proper upkeep of machinery components is essential for ensuring longevity and optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency and safety during operation. Here are some essential tips to keep in mind.

Routine Inspections

- Check for any visible signs of wear or damage.

- Inspect fluid levels and ensure they are within the recommended range.

- Look for leaks in hoses and connections.

Cleaning and Lubrication

- Regularly clean components to remove dirt and debris.

- Apply appropriate lubricants to moving parts to reduce friction.

- Follow manufacturer guidelines for lubrication intervals and types.

By implementing these strategies, operators can significantly improve the reliability and functionality of their equipment, ultimately leading to better performance in the field.

Identifying Wear and Tear Issues

Recognizing signs of degradation in machinery is crucial for maintaining optimal performance and longevity. Regular inspections can reveal critical issues that, if left unaddressed, may lead to significant operational problems.

Common Signs of Wear

- Unusual noises during operation

- Visible cracks or damage on components

- Fluid leaks in various areas

- Overheating during use

Inspection Techniques

- Conduct visual assessments regularly.

- Listen for abnormal sounds when machinery is in operation.

- Monitor performance metrics to detect inconsistencies.

- Check fluid levels and conditions frequently.

Aftermarket Parts vs. OEM Options

When it comes to machinery maintenance and repair, the choice between original manufacturer components and alternative solutions can significantly impact performance and costs. Each option presents its own advantages and challenges, influencing both short-term fixes and long-term reliability.

Original components are designed specifically for particular models, ensuring perfect compatibility and adherence to manufacturer standards. However, they often come with a higher price tag. On the other hand, alternative solutions offer a broader range of options, potentially at a lower cost, but may vary in quality and compatibility.

- Advantages of OEM Components:

- Guaranteed compatibility with specific machinery models.

- Typically backed by manufacturer warranties.

- Consistent quality assurance and performance standards.

- Disadvantages of OEM Components:

- Higher costs compared to alternatives.

- Limited availability in some markets.

- Advantages of Aftermarket Solutions:

- Often more affordable than original components.

- Wide variety of options and brands to choose from.

- Potential for improved performance features or enhancements.

- Disadvantages of Aftermarket Solutions:

- Variable quality and reliability among different manufacturers.

- Risk of incompatibility with specific machinery models.

- Limited or no warranties offered.

Ultimately, the choice between these options depends on individual needs, budget constraints, and the specific requirements of the machinery involved. Understanding the implications of each choice can help ensure optimal performance and durability.

Cost Considerations for Parts Replacement

When it comes to maintaining machinery, evaluating expenses associated with component swaps is crucial. Understanding the financial implications helps ensure informed decisions that balance performance and budget constraints.

Several factors influence the overall costs of component replacements:

- Quality of Components: Opting for original or high-quality replacements may involve a higher initial investment but can lead to greater longevity and reduced need for future replacements.

- Labor Costs: Depending on whether the work is done in-house or by a professional, labor fees can significantly impact the total expenditure.

- Availability: Components that are hard to find may come at a premium, while readily available options could offer savings.

- Shipping and Handling: If sourcing from distant suppliers, additional costs may arise from shipping, which should be factored into the overall budget.

Ultimately, a strategic approach to assessing these elements can lead to cost-effective solutions while ensuring the machinery operates efficiently. Regular evaluations and maintenance can also help in anticipating potential expenses, reducing the likelihood of emergency replacements.

Tools Required for Repairs

When undertaking maintenance or repairs on machinery, having the right instruments is essential for efficiency and safety. A well-equipped toolbox not only simplifies the process but also ensures that tasks are completed effectively. Identifying and gathering the necessary tools ahead of time can significantly enhance the overall repair experience.

Key instruments typically include wrenches, screwdrivers, pliers, and socket sets, which cover a wide range of applications. Additionally, specialized tools may be required for more intricate tasks, ensuring that every component can be addressed with precision. Having a comprehensive selection at hand will allow for smoother operation and help avoid delays.

Moreover, safety equipment, such as gloves and goggles, is crucial to protect against potential hazards during repairs. Investing in quality tools not only extends their lifespan but also improves the quality of work done. Therefore, meticulous planning regarding the required instruments can lead to optimal outcomes and enhanced performance of the machinery.

Ensuring Compatibility with Your Tractor

When it comes to maintaining and enhancing your agricultural machinery, ensuring that every component works seamlessly with your specific model is crucial. Selecting the right elements not only improves performance but also extends the lifespan of your equipment. This section will guide you through the essential considerations for achieving optimal compatibility.

Key Factors to Consider

- Model Specifications: Always refer to your tractor’s manual for detailed specifications. This includes dimensions, engine type, and other essential details that dictate which components will fit and function correctly.

- Quality Standards: Opt for components that meet industry standards. High-quality parts tend to offer better performance and durability.

- Manufacturer Recommendations: Consult the manufacturer’s recommendations for compatible accessories. They often provide lists or guides to help you select appropriate items.

Testing for Fit

- Physical Inspection: Before installation, inspect both the part and the tractor for any signs of incompatibility.

- Trial Fit: If possible, conduct a trial fitting of the component to ensure it aligns correctly without any modifications.

- Seek Expert Advice: When in doubt, reach out to professionals or forums dedicated to agricultural machinery for insights on compatibility issues.