Understanding the Parts Diagram for 1997 Honda CR-V

Exploring the intricacies of a classic sport utility vehicle can reveal a wealth of information about its construction and functionality. This exploration not only enhances one’s knowledge of automotive engineering but also assists in effective maintenance and repair tasks. Knowing the layout of various elements can make a significant difference when tackling issues that may arise over time.

Every vehicle consists of numerous components that work in harmony to deliver a seamless driving experience. From the engine and transmission to the electrical systems and body framework, understanding how these pieces interconnect is crucial. A clear representation of these elements can serve as a valuable reference for enthusiasts and professionals alike.

By familiarizing oneself with the arrangement of these parts, one can easily identify potential problem areas, streamline repairs, and enhance overall vehicle performance. This knowledge empowers individuals to take a proactive approach to maintenance, ensuring longevity and reliability in their automotive adventures.

Understanding the 1997 Honda CR-V

This section delves into the characteristics and components of a compact SUV that gained popularity in the late 90s. Known for its reliability and versatility, this vehicle has become a favored choice for both urban and off-road adventures. An examination of its structure and features reveals the engineering behind its enduring appeal.

Key Features

Among the standout attributes are its spacious interior and efficient fuel consumption. The design emphasizes practicality, making it suitable for families and individuals alike. The incorporation of advanced safety measures for its time also contributed to its strong reputation in the automotive market.

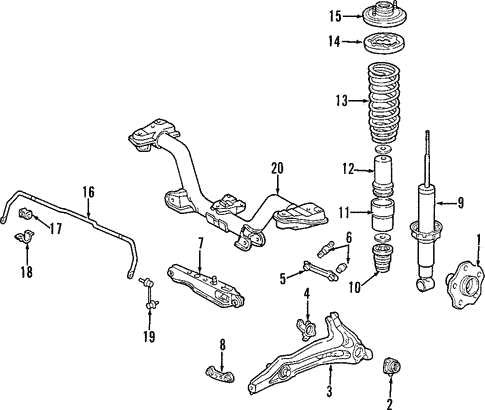

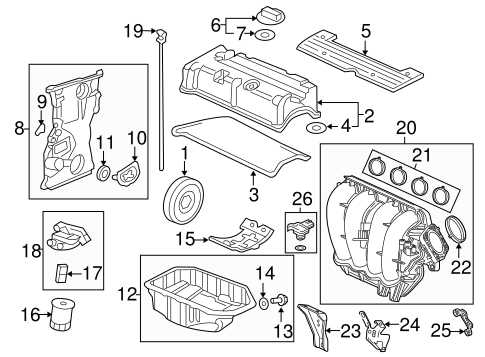

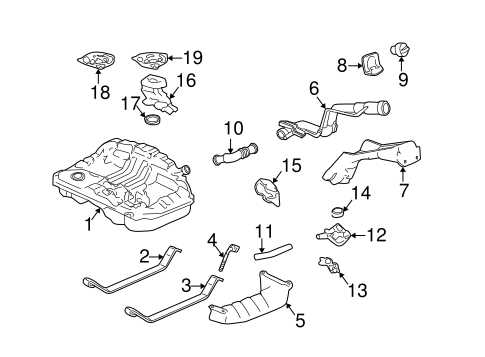

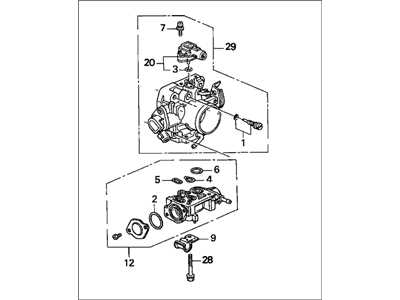

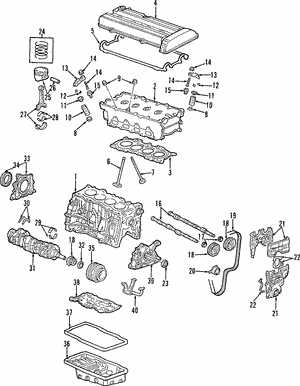

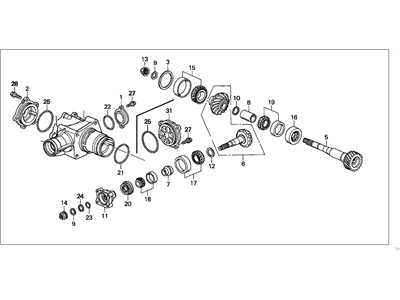

Component Overview

Understanding the various elements that make up this vehicle enhances the overall ownership experience. Each system, from the engine to the suspension, plays a crucial role in performance and handling. Familiarity with these components can assist in maintenance and troubleshooting, ensuring longevity and reliability.

Key Features of the 1997 Model

This vehicle stands out for its blend of functionality and comfort, making it a popular choice among enthusiasts and everyday drivers alike. It offers a well-rounded experience, combining reliability with practicality.

Interior Comfort

The cabin is designed to provide ample space, ensuring a comfortable ride for all passengers. Features such as adjustable seating and a user-friendly dashboard layout enhance the overall experience.

Performance and Handling

Equipped with a robust engine, this model delivers impressive power while maintaining fuel efficiency. The all-wheel-drive system enhances traction and stability, making it suitable for various driving conditions.

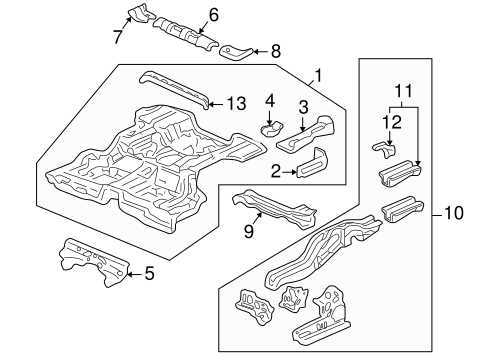

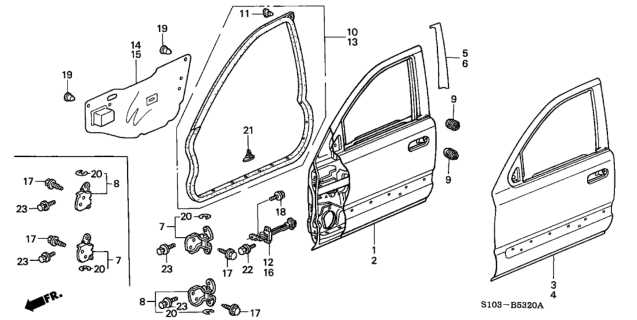

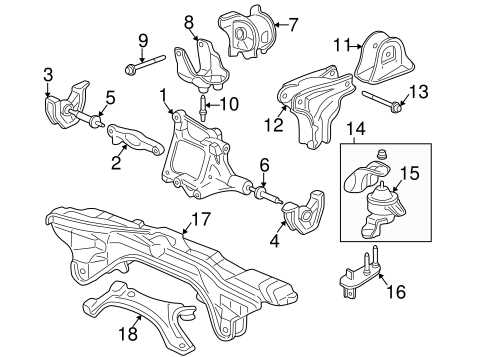

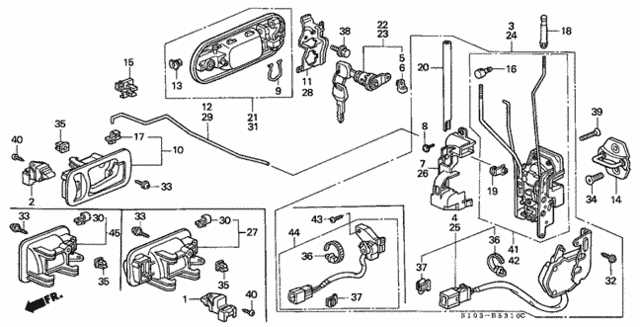

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of mechanical systems. These illustrations serve as essential tools for both professionals and enthusiasts, aiding in the identification, maintenance, and repair of various elements within a vehicle.

Enhanced Understanding

Having a clear visual reference allows individuals to grasp the arrangement and interconnections of different parts. This comprehension is vital for diagnosing issues, performing repairs, and ensuring that all components function harmoniously.

Streamlined Repair Process

Utilizing these visual aids significantly expedites the repair process. Technicians can quickly locate specific elements, reducing the time spent on troubleshooting. Moreover, the accuracy in reassembly is improved, leading to fewer mistakes and enhanced reliability of the vehicle.

In summary, effective visual guides not only facilitate better understanding but also enhance the efficiency of maintenance tasks, ultimately contributing to the longevity and performance of automotive systems.

Where to Find Official Diagrams

Accessing accurate schematics for vehicle components is essential for effective repairs and maintenance. Understanding where to locate these resources can significantly enhance your ability to service your automobile.

Here are several reliable sources to consider:

- Manufacturer’s Website: The official site often provides downloadable resources, including detailed schematics and manuals specific to your model.

- Online Automotive Forums: Communities dedicated to car enthusiasts frequently share links and files, helping each other with various repairs and modifications.

- Repair Manuals: Purchasing comprehensive guides from reputable publishers can offer extensive visual references and instructions for your vehicle.

- Local Dealerships: Authorized dealerships can provide physical or digital copies of official diagrams, ensuring you receive the most accurate information.

- Automotive Parts Stores: Some parts suppliers offer access to schematics as part of their customer service, aiding you in identifying the necessary components.

By exploring these avenues, you can efficiently locate the official schematics you need to keep your vehicle in optimal condition.

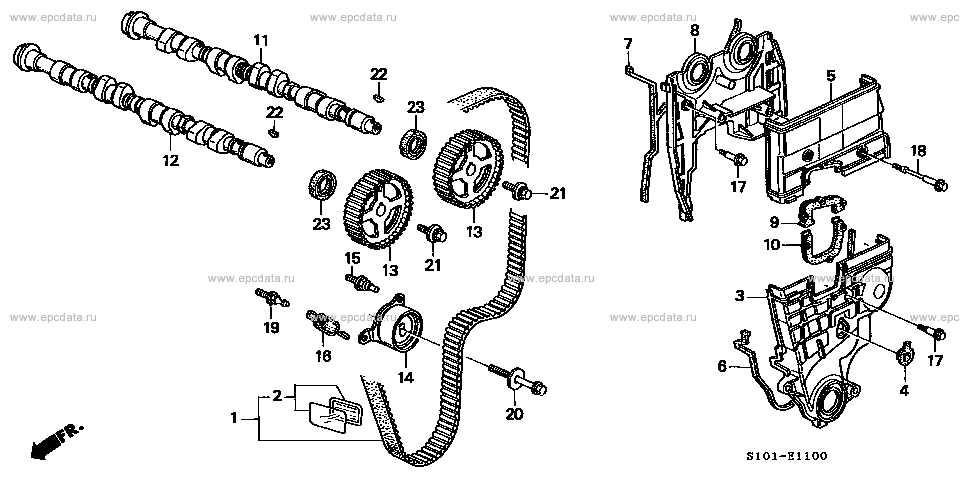

Commonly Replaced Components

Understanding the frequently swapped elements in vehicles can enhance maintenance efficiency and improve performance. Certain components tend to experience wear over time, making them prime candidates for replacement. This section explores those essential parts that often require attention to ensure optimal functionality.

Key Components to Monitor

Several items within the system are notorious for their tendency to fail or degrade, necessitating timely replacements. Regular inspection of these components can prevent unexpected breakdowns.

| Component | Symptoms of Wear | Recommended Replacement Interval |

|---|---|---|

| Brake Pads | Squeaking or grinding noises | 30,000 – 70,000 miles |

| Battery | Difficulty starting the engine | 3 – 5 years |

| Timing Belt | Engine misfiring or odd noises | 60,000 – 100,000 miles |

Conclusion

Regularly assessing these components can lead to a more reliable and enjoyable driving experience. By addressing these common issues proactively, vehicle owners can avoid more significant problems down the road.

Tools Needed for Repairs

When it comes to maintaining and fixing vehicles, having the right equipment is essential for achieving optimal results. A well-equipped workspace not only enhances efficiency but also ensures safety during the repair process. Understanding the tools required can greatly simplify tasks and contribute to a smoother experience.

Essential Tools

The following is a list of indispensable instruments for automotive repairs:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening fasteners. |

| Wrench Set | Used for gripping and turning nuts and bolts. |

| Screwdriver Set | For driving screws of various types. |

| Pliers | Essential for gripping and bending materials. |

| Torque Wrench | Ensures proper tightness of fasteners. |

Additional Accessories

In addition to basic tools, consider these accessories to enhance your repair capabilities:

| Accessory | Function |

|---|---|

| Jack and Jack Stands | For lifting the vehicle safely. |

| Work Light | Illuminates the workspace for better visibility. |

| Magnetic Tray | Keeps small parts organized and within reach. |

| Mechanic’s Creeper | Facilitates movement under the vehicle. |

Maintenance Tips for Longevity

Ensuring your vehicle remains reliable and efficient requires consistent care and attention. By following a few essential practices, you can significantly enhance the lifespan of your automobile while optimizing its performance.

Regular Inspections

Routine checks are crucial. Focus on fluid levels, tire pressure, and brake functionality. Identifying potential issues early can save you from costly repairs in the future. Consider scheduling these inspections every few months.

Quality Components

When replacing parts, always opt for high-quality alternatives. Investing in durable components not only improves performance but also reduces the likelihood of future problems. Remember, a well-maintained system is the ultimate key to longevity.

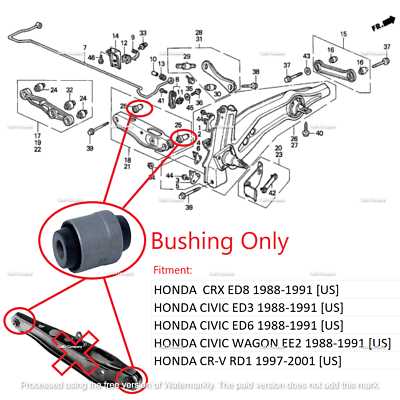

Identifying OEM vs Aftermarket Parts

When maintaining or upgrading a vehicle, understanding the distinction between original equipment manufacturer components and those produced by third-party suppliers is crucial. Each type offers unique benefits and considerations that can significantly impact performance, reliability, and cost.

OEM components are designed and produced by the same manufacturer that created the vehicle. They ensure compatibility and uphold the original quality standards, making them a safe choice for those seeking to maintain the factory specifications.

In contrast, aftermarket options are made by independent companies and may vary widely in quality and price. While some aftermarket products can enhance performance or reduce expenses, others might compromise durability or fit. It’s essential to research and choose wisely when exploring these alternatives.

Ultimately, the decision between OEM and aftermarket depends on individual priorities, such as budget, desired quality, and specific vehicle requirements. Evaluating both choices can help owners make informed decisions that align with their automotive needs.

Common Issues with the 1997 CR-V

Vehicles of this particular model year often experience several recurring problems that owners should be aware of. These issues can affect performance, reliability, and overall driving experience. Addressing them promptly can help maintain the vehicle’s longevity and functionality.

Engine and Transmission Problems

One of the most frequently reported challenges involves the engine and its components. Many drivers notice a decline in power, which may stem from worn spark plugs or a clogged fuel filter. Additionally, the automatic transmission can exhibit symptoms such as slipping or rough shifting, often due to low fluid levels or mechanical wear.

Suspension and Steering Concerns

Another area of concern includes the suspension and steering systems. Drivers may experience excessive noise while driving over bumps, indicating potential wear in the shocks or struts. Moreover, alignment issues can lead to uneven tire wear and affect handling, necessitating regular inspections to ensure safety on the road.

Being aware of these common challenges can help owners take proactive measures to keep their vehicles in optimal condition.

Online Resources for Repair Guides

In the age of digital information, accessing repair manuals and guides has become easier than ever. Numerous online platforms provide valuable resources for enthusiasts and professionals alike, enabling users to troubleshoot, repair, and maintain their vehicles with confidence. These resources often include detailed instructions, diagrams, and even video tutorials, catering to a wide range of skill levels.

Comprehensive Online Manuals

Websites dedicated to automotive repair often host extensive databases of manuals. These platforms allow users to search for specific models and access information such as service schedules, maintenance tips, and repair procedures. By utilizing these comprehensive online manuals, individuals can effectively diagnose issues and find step-by-step solutions.

Video Tutorials and Forums

In addition to written guides, video tutorials offer a visual approach to understanding complex repairs. Platforms like YouTube feature countless channels run by experienced mechanics who share their expertise through engaging content. Furthermore, online forums provide a community-driven space where users can ask questions, share experiences, and find advice from fellow car enthusiasts, enhancing the overall learning experience.

Benefits of Using Diagrams for Repairs

Utilizing visual representations during repair tasks offers numerous advantages that can significantly enhance the efficiency and accuracy of the process. These illustrations provide a clear understanding of complex systems, allowing individuals to identify components and their relationships more easily.

One major benefit is the simplification of intricate procedures. By breaking down tasks into visual steps, mechanics and DIY enthusiasts can follow along without confusion. This clarity reduces the likelihood of errors, which can lead to costly mistakes or further damage.

Additionally, diagrams serve as valuable reference tools that can be consulted repeatedly throughout the repair process. This ensures that technicians stay on track and adhere to best practices, ultimately resulting in a higher quality of work. The ability to visualize parts and their locations fosters a deeper understanding of the overall system, enhancing both learning and problem-solving skills.

Moreover, using illustrations can save time. Technicians can quickly locate the necessary components and understand how they fit together, expediting the repair process. This efficiency is especially beneficial in professional settings, where time equates to money.

In conclusion, leveraging visual aids during maintenance and repair tasks not only enhances comprehension but also promotes accuracy, saves time, and improves overall outcomes. Embracing these resources is a smart approach for anyone looking to undertake mechanical work.