Understanding the Honda BF20 Parts Diagram for Effective Maintenance

The functionality of any marine motor relies heavily on its intricate assembly of components. Each element plays a crucial role in ensuring smooth operation and optimal performance. For enthusiasts and technicians alike, having a clear visual representation of these elements can significantly enhance maintenance and repair efforts.

In this section, we will delve into the essential parts that make up a specific outboard model, providing insights into their arrangement and interconnections. By familiarizing yourself with this layout, you can better understand how each piece contributes to the engine’s overall efficiency.

Additionally, recognizing the various components allows for more informed decisions when it comes to repairs and upgrades. Whether you’re troubleshooting an issue or planning enhancements, knowledge of the internal structure can be invaluable. Let’s explore the critical elements that keep your marine vessel powered and ready for adventure.

Understanding Honda BF20 Parts Diagram

When maintaining or repairing an outboard motor, having a clear visual representation of its components is essential. This illustration serves as a roadmap, guiding users through the intricate network of elements that ensure the smooth operation of the engine. By comprehending the layout and function of each segment, one can effectively identify issues and perform necessary interventions.

Familiarity with the schematic not only enhances troubleshooting skills but also aids in ordering the right components when replacements are needed. Each element, from the propeller to the cooling system, plays a vital role in the overall performance. Understanding how these parts interact can lead to improved maintenance practices and prolonged durability.

Moreover, a detailed overview helps both novice and experienced users navigate the complexities of their machinery with confidence. By investing time in studying these illustrations, individuals can ensure their engine remains in optimal condition, ultimately enhancing their boating experience.

Importance of a Parts Diagram

Understanding the intricate components of any machinery is crucial for effective maintenance and repair. A visual representation that outlines each element not only enhances comprehension but also streamlines the troubleshooting process. By utilizing such illustrations, users can easily identify and locate specific pieces, ensuring that repairs are conducted efficiently and accurately.

Moreover, having a clear schematic can save both time and resources. When individuals know exactly what they are dealing with, they can quickly source the necessary items or make informed decisions regarding replacements. This clarity helps to minimize downtime, which is essential in both personal and professional contexts.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Visual aids simplify complex structures, making them easier to grasp. |

| Efficient Troubleshooting | Quick identification of components aids in faster problem resolution. |

| Cost-Effectiveness | Informed decisions on replacements reduce unnecessary expenditures. |

| Time Savings | Minimized downtime allows for better productivity and performance. |

In conclusion, a well-structured visual reference is an invaluable tool for anyone involved in the upkeep of machinery. It fosters better understanding, facilitates effective repairs, and ultimately contributes to the longevity of the equipment.

Common Components of Honda BF20

Understanding the essential elements of an outboard motor is crucial for maintenance and repair. Each component plays a vital role in ensuring optimal performance and reliability. Familiarity with these elements helps users troubleshoot issues and enhances overall functionality.

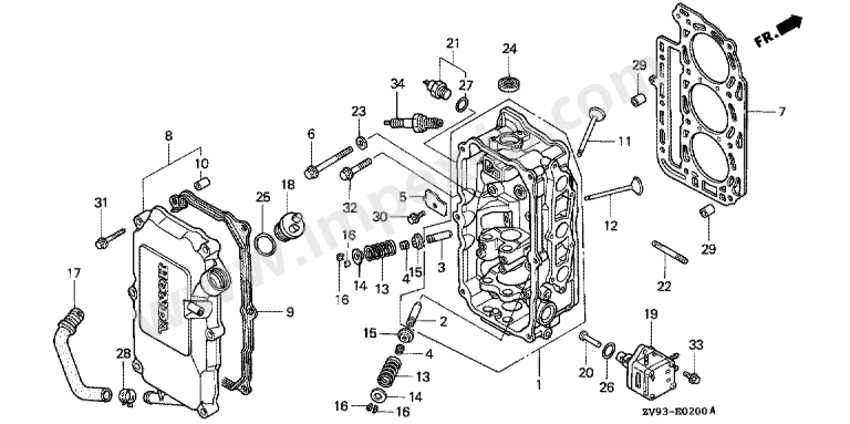

Powerhead is the heart of the engine, where fuel combustion occurs. This assembly typically includes the cylinders, crankshaft, and ignition system, all working in unison to generate power.

Gearcase houses the drivetrain and allows for the transfer of power from the engine to the propeller. It contains the gears and bearings necessary for adjusting speed and direction.

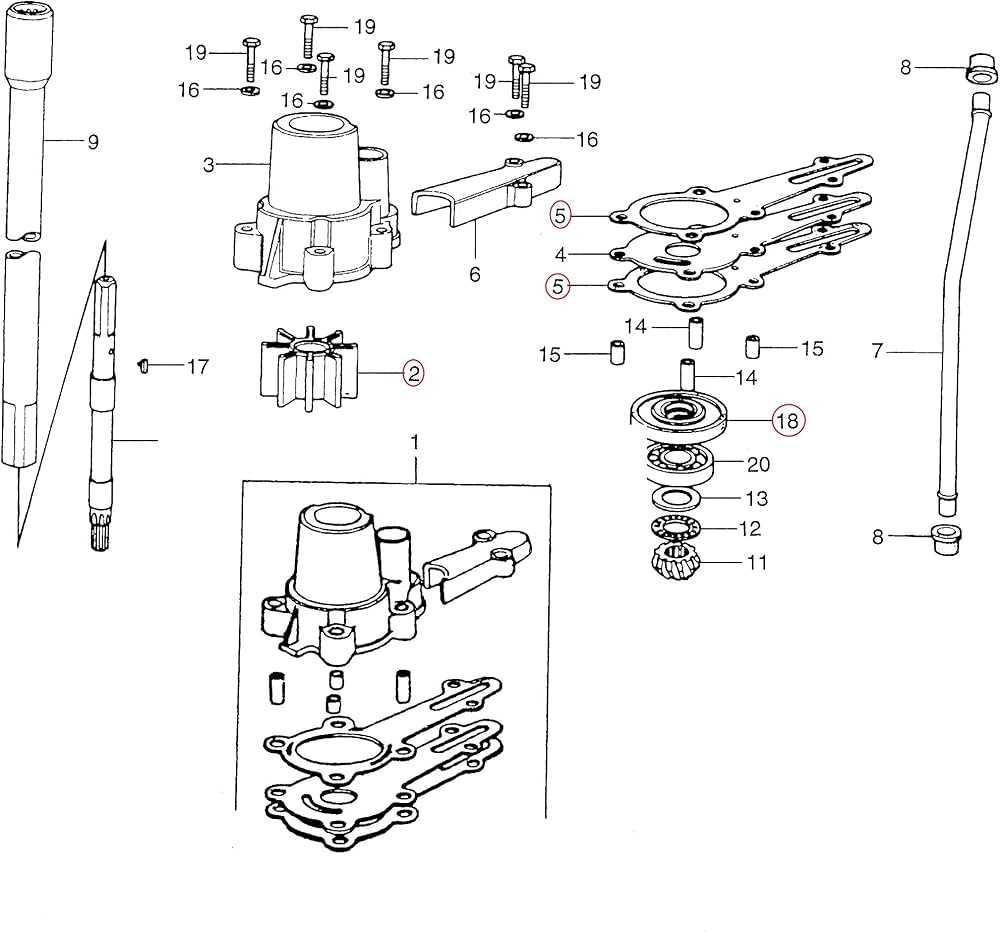

Cooling system is critical for maintaining optimal operating temperatures. It often consists of water intake, pump, and various hoses that circulate coolant to prevent overheating.

Fuel system includes components such as the fuel tank, lines, and carburetor or injectors, ensuring a steady supply of fuel to the engine for efficient operation.

Steering system enables maneuverability and control, incorporating mechanisms that connect the motor to the boat’s helm, allowing for precise navigation.

Electrical system comprises wiring, battery, and various electrical components that provide power for ignition, lights, and instrumentation, ensuring safe and efficient operation.

Being knowledgeable about these core components not only aids in routine maintenance but also empowers users to address potential issues proactively, ultimately prolonging the lifespan of their outboard motor.

How to Read the Diagram

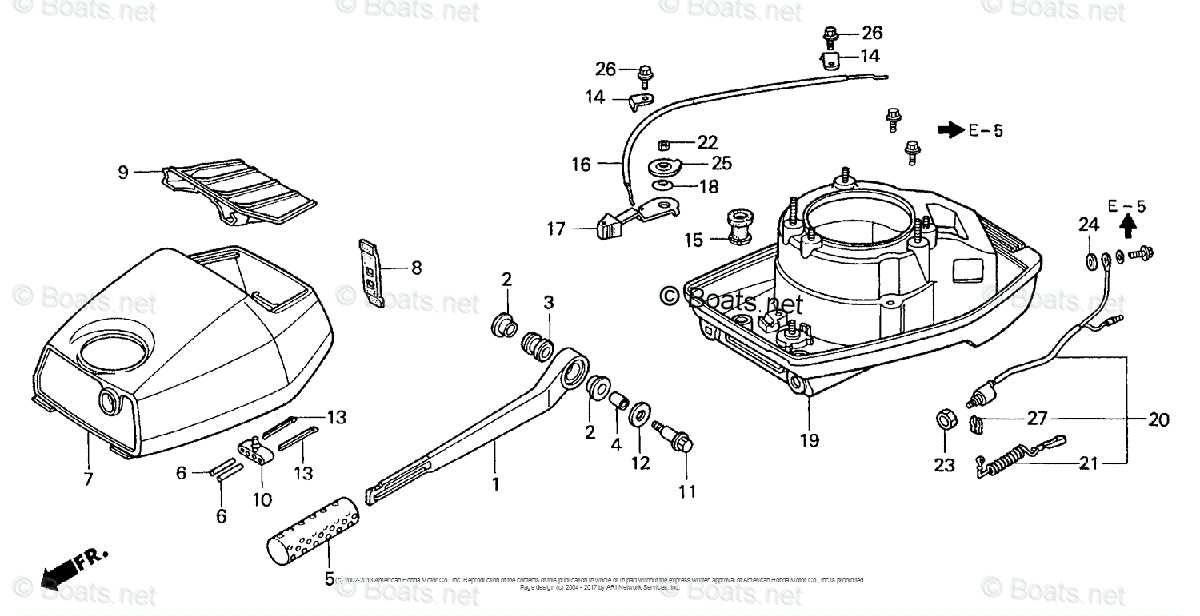

Understanding a visual representation of components is essential for effective maintenance and repairs. Such illustrations serve as a roadmap, guiding users through various elements and their relationships within a mechanical system. Familiarizing oneself with the structure and symbols used can significantly enhance the troubleshooting process.

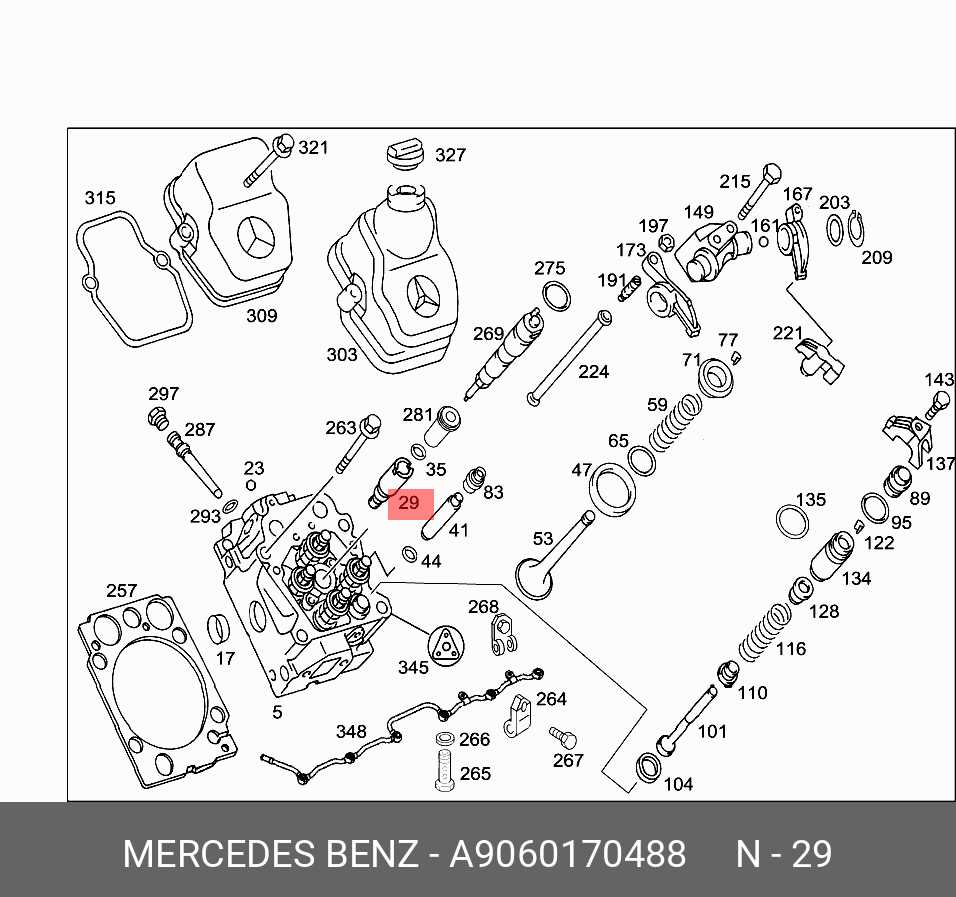

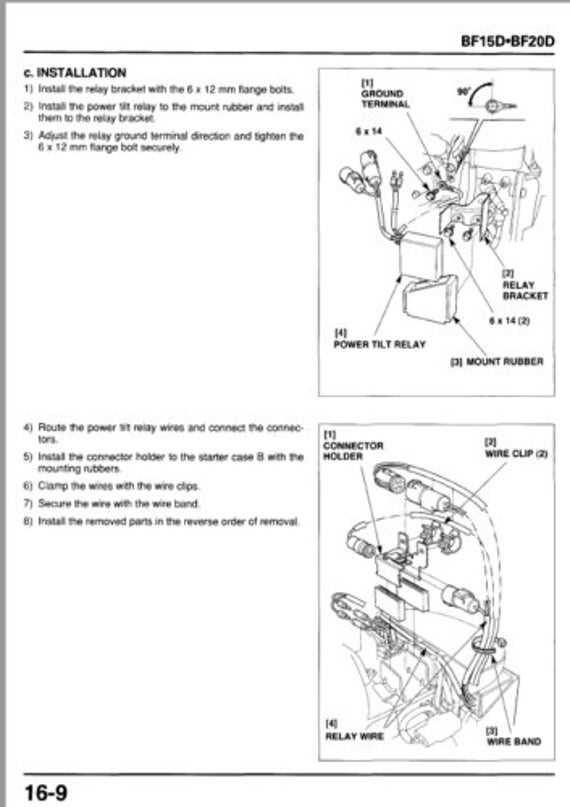

Start by identifying the legend or key, which explains the symbols and notations utilized in the illustration. This section is crucial for interpreting the meaning behind each symbol accurately. Pay attention to different types of lines, as they often indicate connections, movements, or electrical pathways.

Next, examine the layout carefully. Components are usually organized in a logical manner, often reflecting their physical arrangement in the actual assembly. Note any groupings or sections that represent specific functions or systems. Understanding these clusters can help in pinpointing issues or determining what parts need attention.

Additionally, take note of any numbers or labels accompanying the components. These often correlate with reference numbers in manuals or catalogs, facilitating easy ordering or inquiry about specific items. By following these steps, you will be better equipped to navigate through the illustration and tackle any tasks that arise.

Identifying Key Parts Easily

Understanding the essential components of machinery is crucial for efficient maintenance and repair. Familiarizing oneself with the layout and functions of various elements not only simplifies the troubleshooting process but also enhances overall operational knowledge. This section aims to guide users in recognizing critical components effectively.

Common Components Overview

Each machine is composed of several vital elements that work in harmony. Recognizing these parts allows for quicker assessments during inspections or repairs. Below is a brief overview of frequently encountered components:

| Component | Description |

|---|---|

| Engine | The powerhouse responsible for generating motion. |

| Propeller | Converts engine power into thrust for movement. |

| Fuel System | Stores and supplies fuel to the engine. |

| Cooling System | Maintains optimal operating temperature of the engine. |

Tips for Quick Identification

To streamline the process of identifying these key components, consider the following strategies:

- Utilize labeled images or charts for reference.

- Familiarize yourself with the function of each part.

- Keep a maintenance log to track issues and repairs.

Replacement Parts for Honda BF20

Maintaining a marine engine requires access to reliable components that ensure optimal performance and longevity. For enthusiasts and professionals alike, knowing the right substitutions is essential for seamless operation. This section will delve into the necessary components that support the functionality of your outboard motor, emphasizing quality and compatibility.

Essential Components are crucial for any engine’s efficiency. Items such as fuel filters, propellers, and spark plugs should be checked regularly to avoid performance issues. Choosing high-quality alternatives can lead to significant improvements in fuel efficiency and overall power output.

Another aspect to consider is the availability of service kits. These kits often include a range of items needed for routine maintenance, simplifying the upkeep process. Ensuring that all elements work in harmony contributes to a smoother experience on the water.

Wear and Tear is inevitable in any mechanical system. Regularly replacing items such as gaskets and seals can prevent leaks and other complications. By being proactive, boaters can avoid costly repairs and extend the lifespan of their engines.

Lastly, always consult with a trusted supplier or technician to ensure that the replacements are suited for your specific model. Proper guidance will aid in making informed choices, ultimately leading to a more reliable and enjoyable boating experience.

Maintenance Tips for Honda BF20

Regular upkeep is essential for ensuring the longevity and optimal performance of your outboard motor. By adhering to a consistent maintenance schedule and following best practices, you can prevent issues before they arise and enjoy reliable operation throughout the season. Here are some key recommendations to keep in mind.

Routine Checks

Performing routine inspections can help identify potential problems early. Check the following components regularly:

| Component | Recommended Frequency |

|---|---|

| Oil Level | Before each use |

| Fuel System | Monthly |

| Cooling System | Seasonally |

| Battery Condition | Monthly |

Seasonal Maintenance

At the beginning and end of each boating season, thorough maintenance is crucial. Consider these tasks:

- Change the engine oil and replace the filter.

- Inspect and clean the propeller.

- Check the anodes for wear and replace if necessary.

- Flush the cooling system to prevent saltwater corrosion.

Finding OEM vs. Aftermarket Parts

When maintaining or repairing machinery, choosing the right components is crucial for optimal performance and longevity. Two primary options are available: original equipment manufacturer (OEM) items and aftermarket alternatives. Each has its unique characteristics, benefits, and potential drawbacks that can significantly influence your decision-making process.

OEM components are made by the same manufacturer that produced the original items for the machinery. They typically offer a perfect fit and reliability, as they adhere to the exact specifications set forth during the manufacturing process. On the other hand, aftermarket options are produced by third-party companies, often designed to meet or exceed the standards of OEM components, while sometimes providing cost savings.

| Criteria | OEM Components | Aftermarket Alternatives |

|---|---|---|

| Quality | High, often meeting strict manufacturer standards | Varies, can be high or low depending on the brand |

| Cost | Generally more expensive | Typically less expensive, providing budget-friendly options |

| Availability | May have limited availability, depending on the model | Usually widely available through various retailers |

| Warranty | Often comes with a manufacturer warranty | Warranties can vary; some may offer limited coverage |

In conclusion, selecting between OEM and aftermarket options requires careful consideration of your specific needs, budget, and preferences. Evaluating these factors will help ensure that you make an informed decision that aligns with your goals for performance and maintenance. Understanding the differences between these two types of components can significantly enhance your experience and the longevity of your equipment.

Where to Purchase Spare Parts

Finding quality components for your marine engine is essential for maintaining optimal performance and longevity. There are various sources to consider, each offering different advantages depending on your specific needs and preferences.

Authorized Dealers

Visiting authorized dealers ensures you receive genuine items that meet the manufacturer’s standards. These outlets often provide expert advice and a comprehensive range of products tailored to your model, making them a reliable option for those seeking original equipment.

Online Retailers

The internet has made it easier than ever to find a vast selection of components. Numerous online platforms specialize in marine equipment, often featuring competitive pricing and user reviews. When purchasing online, always verify the seller’s reputation and ensure that the items match your specifications.

Diagram Comparison with Other Models

This section aims to provide insights into the structural differences and similarities found in various engine configurations. By analyzing the layout of components across different models, one can better understand the design evolution and functional enhancements that have occurred over time.

| Model | Component Layout | Notable Features |

|---|---|---|

| Model A | Compact arrangement with integrated cooling | Enhanced fuel efficiency, lightweight design |

| Model B | Extended component spacing for maintenance | Improved accessibility, rugged construction |

| Model C | Modular components for easy upgrades | Customizable options, higher power output |

Understanding these variations is crucial for users looking to optimize performance or maintain their machinery effectively. Each model presents unique advantages that cater to specific operational needs.

Common Issues with Honda BF20

Engines designed for marine applications can encounter various challenges over time. Understanding these frequent problems can help in maintaining optimal performance and prolonging the lifespan of the unit. Common complaints from users often revolve around mechanical failures, fuel issues, and electrical system malfunctions.

Mechanical Failures

One of the most reported issues involves the lower unit’s gear case. Users may experience difficulties with shifting or unusual noises, often indicative of wear and tear. Regular inspections and timely lubrication can mitigate these issues. Additionally, overheating is a concern; ensuring proper cooling system function is crucial to avoid engine damage.

Fuel System Problems

Fuel delivery issues can also arise, particularly with clogged filters or stale gasoline. It is essential to replace fuel filters regularly and use fresh fuel to prevent performance drops. Water contamination in the fuel system is another common issue, leading to misfiring and operational instability. Regular checks and maintenance can help keep the fuel system functioning smoothly.

Repair vs. Replace: Making Decisions

When faced with a malfunctioning device, the choice between fixing it or opting for a new one can be daunting. This decision often hinges on various factors, including cost, efficiency, and long-term benefits. Understanding these elements can help streamline the process and lead to a more informed conclusion.

Several considerations should be taken into account when evaluating whether to repair or replace:

- Cost Analysis: Assess the financial implications of both options. Repairing may be less expensive upfront, but consider potential future repairs.

- Frequency of Issues: If the equipment has a history of recurring problems, replacement might be the more practical choice.

- Age of the Item: Older models may have outdated technology, making replacement more appealing for better performance and features.

- Environmental Impact: Think about sustainability. Repairing can reduce waste, while replacing may involve disposing of old units.

- Usage Needs: Evaluate how often the item is used. For infrequent use, repairs might suffice, while daily use might justify a replacement.

Ultimately, the decision to repair or replace should be based on a careful evaluation of these factors. Making the right choice can lead to enhanced performance and satisfaction in the long run.

Resources for Honda BF20 Owners

For enthusiasts and users of a specific model of outboard engine, having access to the right information and tools is crucial for optimal performance and maintenance. A wealth of resources exists to assist owners in ensuring their equipment runs smoothly, offering everything from technical guides to community support.

Online Forums and Communities: Engaging with fellow users in online forums can provide invaluable insights. These platforms allow owners to share experiences, troubleshooting tips, and maintenance advice, creating a supportive network.

Official Manufacturer Resources: The manufacturer’s website often hosts a treasure trove of information, including user manuals, maintenance schedules, and safety guidelines. This can be a first-stop resource for anyone looking to understand their engine better.

Repair Shops and Service Centers: Local service centers specializing in marine engines can offer professional advice and repairs. Building a relationship with a trusted technician can be beneficial for regular maintenance and any unforeseen issues.

Video Tutorials: Many enthusiasts post instructional videos online, covering everything from basic upkeep to complex repairs. These visual aids can make the learning process more accessible and engaging for those who prefer hands-on guidance.

Parts Suppliers: Knowing where to source high-quality components is essential for repairs and upgrades. Numerous retailers, both online and in-store, cater specifically to marine engines, ensuring that owners have access to the necessary materials.

Maintenance Checklists: Creating or finding a detailed checklist for routine upkeep can help owners stay organized and proactive. Regular inspections and maintenance can significantly extend the lifespan of the engine.