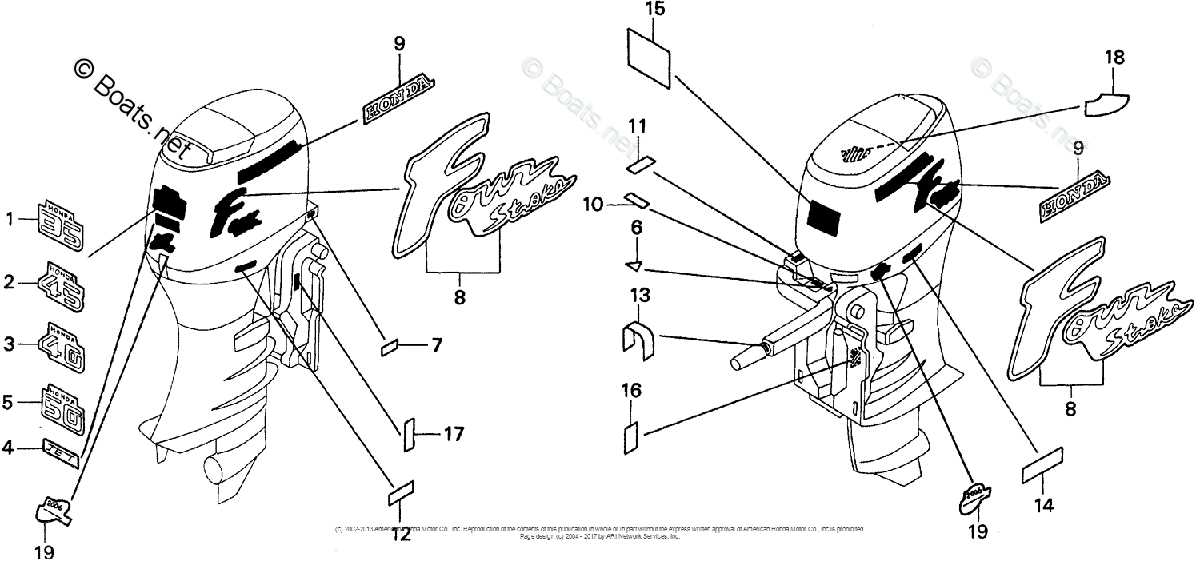

Honda BF50 Parts Diagram Overview

In the realm of marine propulsion, having a clear grasp of the arrangement and function of various elements is essential for maintenance and troubleshooting. A well-structured visual representation can greatly enhance the understanding of how each piece interacts within the system. This knowledge is invaluable for both enthusiasts and professionals in ensuring optimal performance and longevity of the equipment.

By exploring the intricate relationships between the various components, individuals can develop a deeper appreciation for the engineering that goes into these powerful machines. Each segment plays a vital role, and recognizing how they fit together enables effective repairs and replacements. Whether it’s for routine maintenance or unexpected repairs, familiarity with the layout simplifies the process and minimizes potential errors.

Additionally, for those involved in repair services or DIY projects, a comprehensive visual guide serves as a crucial reference. It provides insights into the assembly and disassembly processes, ensuring that all tasks are executed with precision. Such resources not only streamline workflows but also foster a greater sense of confidence in handling complex repairs.

Overview of Honda BF50 Components

This section delves into the essential elements that make up a specific outboard motor model, emphasizing the critical functions and interrelationships among various components. Understanding these key parts is crucial for effective maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Main Elements

The outboard engine consists of several significant components, each playing a vital role in its operation. The powerhead houses the engine and the ignition system, generating the necessary power for propulsion. Meanwhile, the gearcase connects to the propeller, converting the rotational force from the engine into thrust. Additionally, the fuel system is responsible for delivering the proper mixture of fuel and air to the engine for efficient combustion.

Auxiliary Features

In addition to the main elements, various auxiliary features contribute to the overall functionality of the motor. The cooling system prevents overheating by circulating water around the engine. Furthermore, the control mechanisms, including throttle and gear shifters, allow the operator to regulate speed and direction effectively. Together, these components ensure a seamless operation and a reliable experience on the water.

Understanding Engine Assembly Parts

The assembly of a motor is a complex structure composed of various components, each contributing to its overall functionality. Familiarizing oneself with these elements is crucial for effective maintenance and troubleshooting. Each part plays a significant role in the operation of the engine, ensuring that it runs smoothly and efficiently.

Main Components of the Assembly

The main elements involved in the motor’s assembly include several key components. Understanding their functions helps in diagnosing issues and ensuring proper performance.

| Component | Description |

|---|---|

| Cylinder Block | The core structure housing the cylinders, where combustion occurs. |

| Pistons | Components that move up and down within the cylinders, converting combustion energy into mechanical energy. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion to drive the output. |

| Camshaft | Controls the timing of valve openings and closings, critical for the engine’s breathing. |

Importance of Each Component

Each element in the engine’s assembly contributes to its efficiency and performance. Regular inspection and understanding of these parts can prevent potential failures and enhance longevity. Knowledge of how these components interact helps users maintain their motor effectively.

Key Accessories for Engine Model BF50

In this section, we explore essential add-ons and supplementary components that enhance the performance and functionality of your BF50 engine. These accessories are designed to optimize operation, improve efficiency, and ensure reliable performance in various marine environments.

| Accessory | Description |

|---|---|

| Propeller | Enhances propulsion efficiency and maneuverability, available in various pitches and materials. |

| Water Pump Kit | Ensures proper cooling system functionality, essential for maintaining optimal engine temperature. |

| Control Box | Facilitates smooth throttle and gear shifting operations, crucial for responsive handling. |

| Fuel Tank | Provides ample fuel storage capacity, available in different sizes to suit your boating needs. |

| Remote Steering Kit | Enables convenient steering control from a distance, enhancing ease of navigation. |

Each of these accessories plays a vital role in optimizing the performance and operational versatility of your marine engine, ensuring a seamless boating experience tailored to your specific requirements.

Identifying Electrical System Elements

In this section, we delve into understanding the crucial components that make up the electrical system of the BF50. We explore the fundamental elements responsible for powering and controlling various functions of the marine engine.

Power Distribution Components

Key components involved in distributing electrical power throughout the system include connectors, cables, and junction points. These components ensure that electricity flows efficiently to where it’s needed, supporting the engine’s operation and auxiliary systems.

Sensor and Control Elements

Within the electrical system, sensors play a vital role in monitoring engine performance and environmental conditions. They relay crucial data to control units, enabling precise adjustments to optimize efficiency and reliability.

Understanding these elements is essential for maintaining and troubleshooting the electrical system, ensuring the BF50 operates smoothly and reliably in various marine environments.

Fuel System Component Breakdown

In this section, we delve into the intricate components that make up the fuel delivery system of this marine engine. Understanding these elements is crucial for maintaining optimal performance and efficiency.

Fuel Tank

- Reservoir that stores the fuel supply for the engine.

- Usually located at the rear or center of the vessel.

- Constructed from durable materials to withstand marine conditions.

Fuel Lines

- Conduits that transport fuel from the tank to the engine.

- Made of flexible, high-grade tubing to ensure consistent flow.

- Equipped with fittings and connectors for secure attachment.

These components work together seamlessly to deliver fuel efficiently, ensuring the engine operates smoothly throughout its performance range.

Cooling System Parts Explained

In this section, we delve into the components crucial for maintaining optimal operating temperatures in the engine. Understanding these elements ensures efficient performance and longevity.

1. Heat Dissipation Mechanisms

Efficient cooling involves mechanisms that dissipate excess heat generated during engine operation. These components work synergistically to regulate temperatures within safe limits.

2. Circulation Components

Key to the cooling system are components that facilitate fluid circulation. They ensure uniform distribution of coolant throughout critical areas, preventing overheating and ensuring consistent performance.

Propulsion Mechanism Insights

In this section, we delve into the intricate workings that drive the movement of marine vessels, focusing on the essential components that propel them through water. Understanding the underlying mechanisms involved in generating thrust is crucial for appreciating the efficiency and performance of modern propulsion systems.

Key Components

Propulsion systems typically consist of several key elements that collaborate to convert energy into forward motion. These include the driving force generators, mechanisms for directional control, and ancillary devices that optimize efficiency.

| Component | Description |

|---|---|

| Propeller | The primary component responsible for thrust generation, utilizing rotating blades to push water backwards. |

| Gearbox | Transfers power from the engine to the propeller shaft, adjusting rotational speed for optimal efficiency at different boat speeds. |

| Thrust Vectoring Mechanism | Controls the direction of thrust output, crucial for steering and maneuvering the vessel. |

Efficiency Considerations

Efficiency in propulsion systems is influenced by factors such as hull design, engine power output, and the hydrodynamic interaction between the vessel and water. Engineers continuously refine these systems to maximize performance while minimizing fuel consumption and environmental impact.

Maintenance Items for Longevity

Ensuring the durability and performance of your marine engine involves regular attention to essential components that sustain optimal operation over time. By prioritizing routine care and upkeep, you can significantly extend the lifespan of critical engine systems and associated elements.

Engine Lubrication

Effective lubrication management remains fundamental to safeguarding internal components from excessive wear and friction. Regular inspection and timely replacement of lubricants are crucial to maintaining smooth operation and preventing potential breakdowns.

Electrical System Integrity

Reliable electrical function is imperative for modern marine engines, influencing ignition, monitoring, and auxiliary systems. Periodic assessment and maintenance of wiring, connections, and battery health uphold operational reliability and safety standards.

Common Replacement Parts Overview

In the world of marine engines, ensuring optimal performance often requires the timely replacement of essential components. Understanding the typical items that may need to be swapped out is crucial for maintaining efficiency and longevity. Below, we delve into several commonly replaced elements that play a pivotal role in the functionality of these machines.

Key Components to Monitor

Among the vital elements, the fuel filter serves as a primary barrier against impurities that could compromise engine performance. Regular replacement is advisable to maintain a clean fuel system. Additionally, the water pump is integral for cooling; over time, wear and tear can diminish its effectiveness, necessitating prompt attention.

Maintenance Essentials

Routine inspections should also focus on spark plugs, which are critical for ignition. Worn or fouled plugs can lead to misfires and reduced power. Another essential component is the impeller, responsible for ensuring proper water flow. Keeping a close eye on these components can help prevent unexpected breakdowns and enhance overall reliability.

Tools Needed for Repairs

When it comes to maintaining and fixing various machinery, having the right instruments is essential for achieving successful outcomes. Whether you are performing routine maintenance or tackling more complex repairs, a well-equipped toolkit can make the process smoother and more efficient.

Essential Instruments

Below is a list of fundamental tools that are commonly used in the repair of outboard motors. These instruments facilitate various tasks, ensuring that repairs are conducted safely and effectively.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening nuts and bolts. |

| Screwdriver Set | For driving screws in different sizes and types. |

| Socket Set | For quick removal and installation of fasteners. |

| Torque Wrench | For applying the correct torque to fasteners. |

| Pliers | For gripping, bending, and cutting wire or small parts. |

Additional Equipment

Besides the essential tools, having some additional equipment can enhance your repair capabilities. Items like a multimeter for electrical diagnostics, a fuel line removal tool, and a workbench with a vice can prove invaluable during repairs.

Assembly and Disassembly Techniques

Understanding effective methods for assembling and disassembling mechanical components is essential for maintaining and servicing equipment. Proper techniques ensure that each element fits correctly and functions optimally, reducing wear and prolonging the lifespan of the system.

Before starting the process, it is crucial to gather all necessary tools and equipment. A well-organized workspace enhances efficiency and minimizes the risk of losing small components. Additionally, having a clear plan or reference guide can significantly streamline the process, ensuring that no steps are overlooked.

During disassembly, care should be taken to avoid damaging any parts. Gently loosening fasteners in a systematic order prevents unnecessary strain. It is advisable to keep track of how components are arranged to facilitate easier reassembly later. Using containers to store small pieces can help maintain organization and prevent confusion.

When assembling, follow the reverse order of disassembly. Apply appropriate torque specifications to fasteners to ensure a secure fit without over-tightening, which can lead to damage. Regularly checking alignment and fit as components are joined can help identify potential issues before they become problematic.

Finally, performing a thorough inspection after assembly is vital. Testing the functionality of the system and ensuring that all parts operate smoothly will confirm that the assembly was successful and that the equipment is ready for use.

Parts Ordering and Compatibility Tips

When it comes to acquiring components for your watercraft engine, understanding the essentials of ordering and ensuring compatibility is crucial for effective maintenance and optimal performance. Here are some valuable insights to help streamline the process.

Before placing an order, it is essential to identify the specific requirements of your engine. This includes understanding the model, year, and any unique specifications that may influence compatibility. Proper research can prevent potential issues and ensure you receive the correct items.

| Tip | Description |

|---|---|

| Check Manufacturer’s Website | Visit the official site to access comprehensive information on components, including specifications and compatibility details. |

| Consult User Manuals | Refer to the manual for your engine, which typically contains crucial information regarding compatible components and maintenance procedures. |

| Use OEM Components | Original equipment manufacturer items are often the best choice for ensuring compatibility and maintaining performance standards. |

| Seek Expert Advice | Don’t hesitate to contact professionals or local dealerships for guidance on parts and their suitability for your specific model. |

| Read Reviews | Research customer feedback on various suppliers and components to gauge their reliability and compatibility. |

Following these guidelines can significantly enhance your experience in sourcing components and help maintain the longevity and efficiency of your watercraft engine.