Comprehensive Parts Diagram for Honda HRS216

In the world of outdoor equipment, comprehending the various elements that comprise a lawn maintenance machine is essential for effective upkeep and repair. Each segment plays a critical role in ensuring optimal performance, making it vital to familiarize oneself with their functions and interrelations. This knowledge empowers users to maintain their machines efficiently and troubleshoot any issues that may arise.

From the engine to the cutting mechanisms, every piece has its unique contribution to the overall functionality of the equipment. Recognizing these individual components can simplify the process of diagnosing problems and executing repairs. Furthermore, understanding how each part interacts with others aids in achieving a well-functioning system, leading to enhanced longevity and reliability.

This section aims to provide a comprehensive overview of the essential components, highlighting their specific roles and significance. By delving into the intricacies of these elements, users can gain valuable insights that will enhance their experience and proficiency in managing their lawn care tasks.

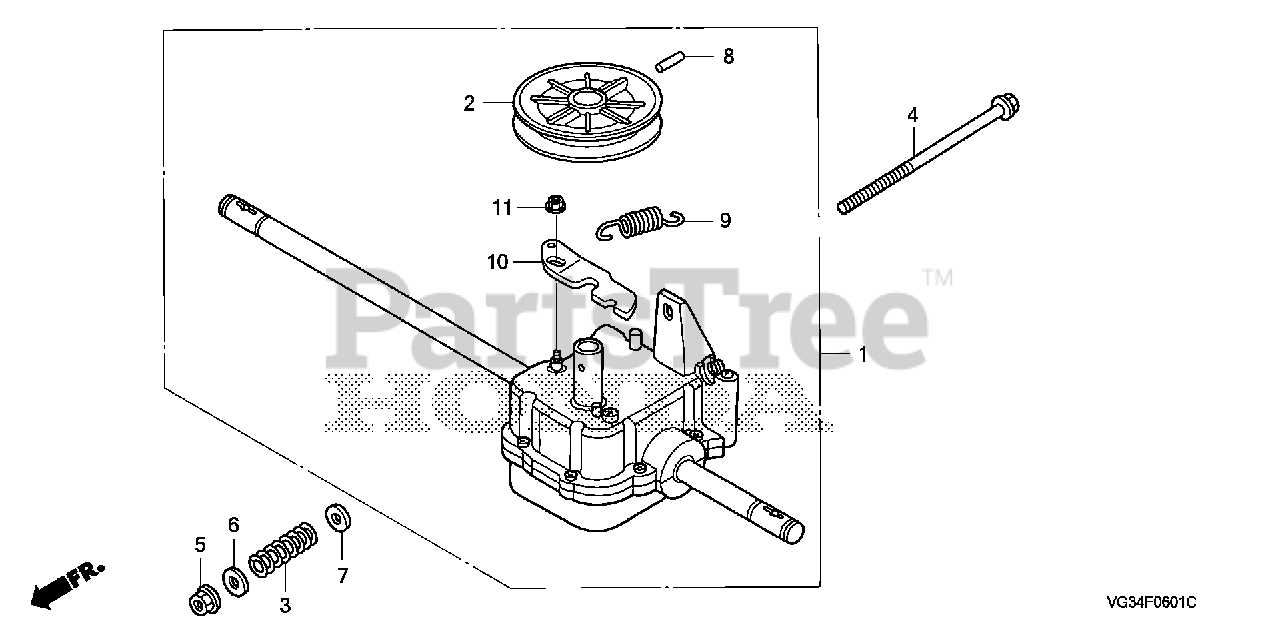

This section delves into the essential elements of a lawn maintenance machine, emphasizing their roles and significance in ensuring optimal performance. Understanding these vital parts enhances the overall user experience and aids in effective maintenance and troubleshooting.

Main Elements

The primary components are designed to work together seamlessly, allowing the equipment to operate efficiently. Each part plays a specific role, contributing to the overall functionality and reliability of the device.

| Component | Function |

|---|---|

| Engine | Provides the necessary power to drive the machine and its various functions. |

| Cutting Blade | Responsible for trimming grass to the desired height, ensuring a neat appearance. |

| Chassis | Houses and protects internal components while providing stability during operation. |

| Wheels | Facilitate movement across different terrains, allowing for easy maneuverability. |

| Fuel Tank | Stores the fuel required to power the engine for extended periods. |

Supporting Elements

In addition to the main components, various supporting parts contribute to the efficiency and user-friendliness of the machine. Recognizing these can enhance operational understanding and performance.

Maintenance Tips for Lawn Mowers

Regular upkeep is essential for ensuring the longevity and optimal performance of your grass-cutting equipment. Proper maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By following a few straightforward practices, you can keep your mower running smoothly throughout the cutting season.

Routine Inspection

Conducting frequent checks can help identify potential issues before they escalate. Here are some key areas to focus on:

- Examine the blades for wear or damage; sharp blades ensure a clean cut.

- Inspect the air filter and clean or replace it as needed to promote airflow.

- Check the fuel system for leaks or clogs, ensuring proper fuel delivery.

- Look for signs of rust or corrosion on metal components.

Seasonal Maintenance Tasks

At the start and end of each season, specific tasks can greatly extend the life of your machinery:

- Change the oil regularly to keep the engine lubricated.

- Sharpen or replace the cutting blades to maintain efficiency.

- Clean the deck to prevent grass build-up that can hinder performance.

- Store the machine in a dry place to protect it from the elements.

Common Replacement Parts Explained

Understanding the essential components of a lawn maintenance machine can greatly enhance its longevity and performance. Regular maintenance often requires replacing certain elements that endure wear and tear over time. This section provides insight into the most frequently changed items and their significance in ensuring optimal functionality.

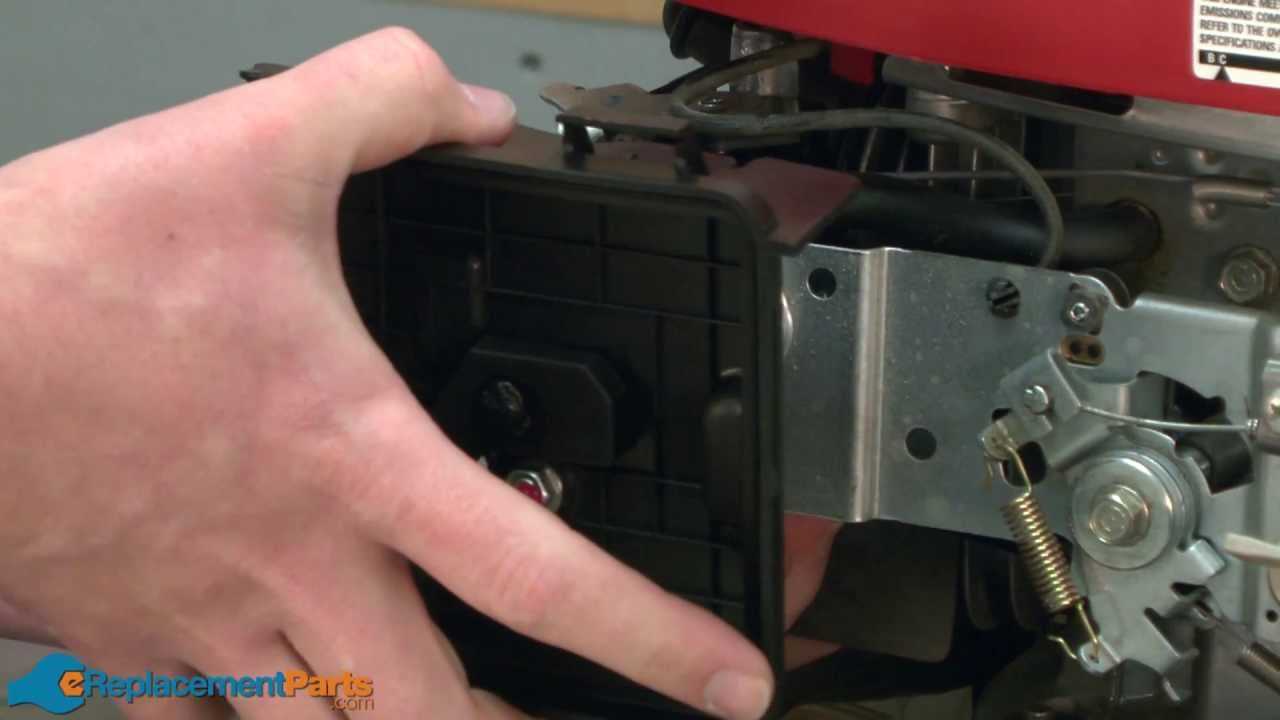

Air Filters

Air filters play a crucial role in maintaining engine performance by preventing dirt and debris from entering the combustion chamber. Over time, these filters can become clogged, leading to decreased efficiency and increased fuel consumption. Regular replacement ensures that the engine receives a clean supply of air, promoting better performance and longevity.

Blades

The blades of a mowing machine are essential for achieving a clean cut and a well-manicured lawn. Dull or damaged blades can lead to uneven cutting and may stress the engine. Routine inspection and replacement of blades are vital to maintaining a pristine appearance for your lawn and improving the overall health of the grass.

Understanding Engine Assembly Details

Exploring the intricacies of power unit assembly is crucial for both enthusiasts and professionals alike. This segment delves into the essential components and their configurations, shedding light on how they work together to ensure optimal performance and reliability. A thorough understanding of these elements is vital for effective maintenance and troubleshooting.

Key Components of the Power Unit

The assembly of a power unit comprises several fundamental elements, each playing a pivotal role in its overall functionality. Familiarizing oneself with these parts can enhance the effectiveness of repairs and upgrades.

| Component | Description |

|---|---|

| Cylinder | The chamber where combustion occurs, driving the piston. |

| Piston | A cylindrical component that moves up and down within the cylinder, converting energy from combustion into mechanical motion. |

| Crankshaft | Transforms linear motion from the piston into rotational motion, ultimately powering the machine. |

| Camshaft | Regulates the timing of valve openings and closings, playing a vital role in engine breathing. |

| Valves | Control the intake of air-fuel mixture and exhaust of combustion gases, critical for maintaining engine efficiency. |

Assembly Considerations

Proper assembly of these components is essential for achieving desired performance levels. Factors such as torque specifications and alignment play significant roles in ensuring that the power unit operates smoothly and efficiently. Regular inspections and maintenance of these parts can prevent common issues and prolong the life of the machinery.

Identifying Blades and Cutting Mechanism

Understanding the components involved in the cutting mechanism is essential for efficient operation and maintenance of lawn care equipment. This section focuses on the identification of various cutting elements and their functions, ensuring optimal performance during use.

The cutting system consists of several key parts, each playing a vital role in achieving a clean and even cut. Familiarizing oneself with these components can help in troubleshooting and replacements when necessary.

- Blades: The primary tool for cutting grass, these can vary in design depending on the specific type of machinery. Common types include:

- Rotary Blades: Circular blades that rotate to slice through grass.

- Reel Blades: A series of sharp blades that work in a scissor-like motion.

- Deck: This is the housing that contains the blades. Its design influences the efficiency of the cutting process and affects grass discharge.

- Spindle: A crucial component that holds the blades in place and allows them to rotate smoothly. Proper spindle maintenance is necessary to avoid damage to the blades.

- Adjustable Height Settings: Many models feature adjustable settings that allow users to modify the cutting height for different grass types and conditions.

Regular inspection of these elements ensures they remain sharp and functional. It is advisable to replace any worn or damaged parts promptly to maintain cutting efficiency and extend the lifespan of the equipment.

Wiring System and Electrical Parts

The wiring framework and electrical components play a crucial role in the overall functionality of any machinery. A well-designed electrical layout ensures seamless operation and communication between various parts, contributing to the device’s efficiency and reliability. Understanding the intricacies of these systems helps in troubleshooting, maintenance, and optimization.

Key Electrical Components

At the heart of the electrical setup are essential components such as motors, switches, and connectors. Each part serves a distinct purpose and works in harmony with others. For instance, the motor is responsible for driving movement, while switches facilitate control over various functions. The connectors ensure secure electrical connections, preventing potential issues arising from loose or damaged links.

Importance of Proper Wiring

Proper wiring is fundamental to the safe and efficient operation of the device. It minimizes the risk of electrical shorts and enhances performance by providing consistent power supply. Regular inspections and maintenance of the wiring system are vital to identify any wear or damage, allowing for timely repairs and ensuring longevity.

Fuel System Components and Diagrams

The fuel delivery mechanism is a crucial aspect of any internal combustion engine, ensuring the proper supply of fuel for optimal performance. This section explores the various elements involved in this system, providing a detailed overview of their functions and interconnections. Understanding these components is essential for diagnosing issues and performing maintenance effectively.

Key Elements of the Fuel Delivery Mechanism

- Fuel Tank: The storage unit for the fuel, designed to withstand pressure and prevent leakage.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine, often powered by an electric motor.

- Fuel Filter: A critical component that removes impurities and contaminants from the fuel before it reaches the engine.

- Fuel Lines: These conduits transport the fuel throughout the system, connecting various components.

- Carburetor or Fuel Injector: Responsible for mixing air and fuel in the correct proportions for combustion.

Overview of the Fuel System Layout

Understanding the arrangement and connection of these components aids in troubleshooting and repair. Here is a simplified sequence of fuel flow:

- The fuel is drawn from the tank by the pump.

- It passes through the filter to eliminate any foreign particles.

- The filtered fuel travels through the lines to the carburetor or injector.

- The mixture of air and fuel is prepared for entry into the combustion chamber.

This knowledge not only facilitates effective maintenance but also enhances the overall longevity of the equipment.

How to Order Replacement Parts

When it comes to maintaining outdoor equipment, acquiring suitable components is essential for optimal performance. Understanding the process of ordering these necessary items can save both time and money, ensuring that your machine remains in top condition. By following a few simple steps, you can streamline the acquisition of the required elements without hassle.

Start by identifying the specific components needed for your device. Consult the user manual or any reference materials to ascertain the correct specifications. This ensures that you are looking for the right items, preventing any confusion during the ordering process.

Next, visit reputable retailers or online platforms that specialize in outdoor machinery components. Many websites offer comprehensive catalogs, allowing you to search for the items based on model numbers or descriptions. It is advisable to compare prices and availability across multiple sources to secure the best deal.

Once you have located the desired components, proceed to place your order. Be sure to double-check the details, such as quantities and shipping options, before finalizing the transaction. Keeping a record of your order confirmation can be helpful for tracking purposes.

Lastly, after receiving the components, inspect them for any discrepancies or damages. This step ensures that you received the correct items and can address any issues promptly. Following these guidelines will facilitate a smooth experience in obtaining the necessary replacements for your outdoor machinery.

DIY Repair Guide for Users

This section aims to empower users to effectively troubleshoot and repair their equipment with confidence. By following a systematic approach, individuals can identify issues, replace components, and maintain optimal performance, ensuring longevity and reliability.

Identifying Common Issues

Begin by observing the machinery during operation. Unusual noises, vibrations, or performance inconsistencies often indicate underlying problems. Keeping a log of these observations can help pinpoint specific malfunctions, making the repair process more efficient.

Replacement of Components

Once issues are identified, the next step is to replace faulty components. Research compatible parts and gather necessary tools for the task. Always prioritize safety by disconnecting power sources before starting repairs. Familiarize yourself with the installation process through manuals or online tutorials to ensure correct assembly.

Safety Precautions During Maintenance

Ensuring safety while performing maintenance tasks is essential for protecting both the individual and the equipment. Adhering to proper safety protocols minimizes the risk of accidents and injuries. Awareness of potential hazards and the implementation of preventive measures are critical components of effective upkeep.

Before starting any maintenance procedure, it is vital to wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. This gear provides a barrier against physical hazards and harmful substances. Additionally, working in a well-ventilated area reduces the risk of inhaling fumes or dust generated during maintenance activities.

Always disconnect power sources and remove any fuel before beginning work on the machinery. This step prevents accidental starts and potential injuries. Familiarize yourself with the specific components of the equipment and refer to the manufacturer’s guidelines for maintenance procedures. Keeping tools organized and in good condition can also help avoid mishaps and ensure efficiency during maintenance tasks.

Finally, it is important to remain focused and avoid distractions while working. Taking breaks and maintaining a clean workspace contribute to a safer environment. By following these precautions, individuals can effectively minimize risks and ensure a successful maintenance experience.