Understanding the Honda Tiller FC600 Parts Diagram

When maintaining your gardening equipment, having a clear visual representation of its individual elements can significantly simplify the process. A well-structured illustration can serve as a valuable reference for identifying and understanding the different sections of your machinery. This knowledge is essential for effective upkeep and troubleshooting.

In the world of horticultural tools, familiarity with each part enhances the user experience, enabling you to operate your device more efficiently. From the engine to the tines, recognizing how everything fits together allows for better maintenance practices. This insight can also help in sourcing replacements when needed.

By delving into the specifics of the machinery, you can not only extend its lifespan but also ensure optimal performance in your gardening tasks. Mastering the anatomy of your cultivator is a fundamental step toward achieving successful results in your outdoor endeavors.

Understanding Honda FC600 Tiller

When it comes to gardening and landscaping, having the right equipment is crucial for achieving optimal results. This particular model stands out for its efficiency and reliability in soil preparation. Users appreciate its design, which is tailored for ease of use and maneuverability, making it a popular choice among both amateurs and professionals.

Key Features

This robust machine is equipped with a powerful engine, providing the necessary torque to break up tough soil. Its adjustable settings allow for various depths, ensuring that users can customize their approach based on specific gardening needs. Additionally, the lightweight frame facilitates transport and storage, enhancing convenience.

Maintenance Tips

Proper upkeep is essential for longevity. Regularly checking the engine oil, air filter, and tines ensures optimal performance. Furthermore, keeping the exterior clean helps prevent rust and wear, ensuring that the equipment remains in peak condition for years to come. Following the manufacturer’s guidelines for maintenance will lead to a more satisfying experience and better results in your gardening endeavors.

Key Features of Honda FC600

This remarkable gardening machine is designed to enhance efficiency and ease in soil cultivation. Its advanced engineering and thoughtful design provide users with the ability to tackle various landscaping tasks effectively. This section highlights the essential characteristics that make it a preferred choice for both amateur and professional gardeners.

Powerful Performance

Equipped with a robust engine, this equipment ensures reliable operation even in challenging conditions. The powerful motor delivers consistent torque, allowing users to work through tough soil effortlessly. Exceptional torque not only improves productivity but also reduces strain on the operator.

User-Friendly Design

The ergonomic design of this tool enhances user comfort and control. Features like adjustable handles and lightweight construction allow for easy maneuverability and operation over extended periods. Simplicity in design also facilitates quick setup and maintenance, making it accessible for all skill levels.

Importance of Proper Maintenance

Regular upkeep of any machinery is crucial for its longevity and optimal performance. Neglecting maintenance can lead to decreased efficiency, increased wear and tear, and potential failures that can be costly and time-consuming to repair.

Benefits of Routine Care

- Enhanced Efficiency: Well-maintained equipment operates more smoothly and effectively.

- Extended Lifespan: Regular checks and servicing can significantly prolong the life of the machinery.

- Cost Savings: Preventive measures help avoid expensive repairs and replacements in the long run.

- Safety Assurance: Proper maintenance reduces the risk of accidents and malfunctions, ensuring safe operation.

Key Maintenance Practices

- Regular Inspections: Frequent checks can identify potential issues before they escalate.

- Cleaning: Keeping components free from debris and dirt promotes better functionality.

- Lubrication: Ensuring moving parts are properly lubricated minimizes friction and wear.

- Replacement of Worn Parts: Timely substitution of damaged or worn components is essential for reliable performance.

Common Issues with Honda Tillers

When it comes to cultivating soil, several challenges can arise that may hinder performance and efficiency. Understanding these common problems can help users maintain their equipment in optimal condition and address any issues swiftly.

1. Engine Starting Problems

Difficulty in starting the engine is a frequent complaint among users. This issue can stem from a variety of factors, including fuel quality, spark plug conditions, or issues with the ignition system. Regular maintenance and timely inspections can significantly reduce the chances of encountering this problem.

2. Uneven Tilling

Achieving uniform soil preparation can sometimes be challenging. Factors such as improper depth settings, worn blades, or uneven terrain can lead to inconsistent results. Ensuring that blades are sharp and properly aligned is essential for effective operation.

3. Overheating

Overheating can occur due to insufficient lubrication or blocked air vents. This can lead to reduced performance and potential engine damage. Keeping the machine clean and regularly checking oil levels can help prevent overheating issues.

4. Vibration and Noise

Excessive vibration or noise during operation can indicate mechanical issues, such as misaligned components or worn parts. Addressing these concerns promptly can enhance performance and extend the lifespan of the equipment.

5. Fuel System Issues

Problems within the fuel system, such as clogged filters or lines, can impede performance. Regularly checking and cleaning the fuel system components can prevent these complications and ensure smooth operation.

By being aware of these common issues, users can take proactive measures to maintain their equipment, ensuring reliable performance for all gardening and landscaping needs.

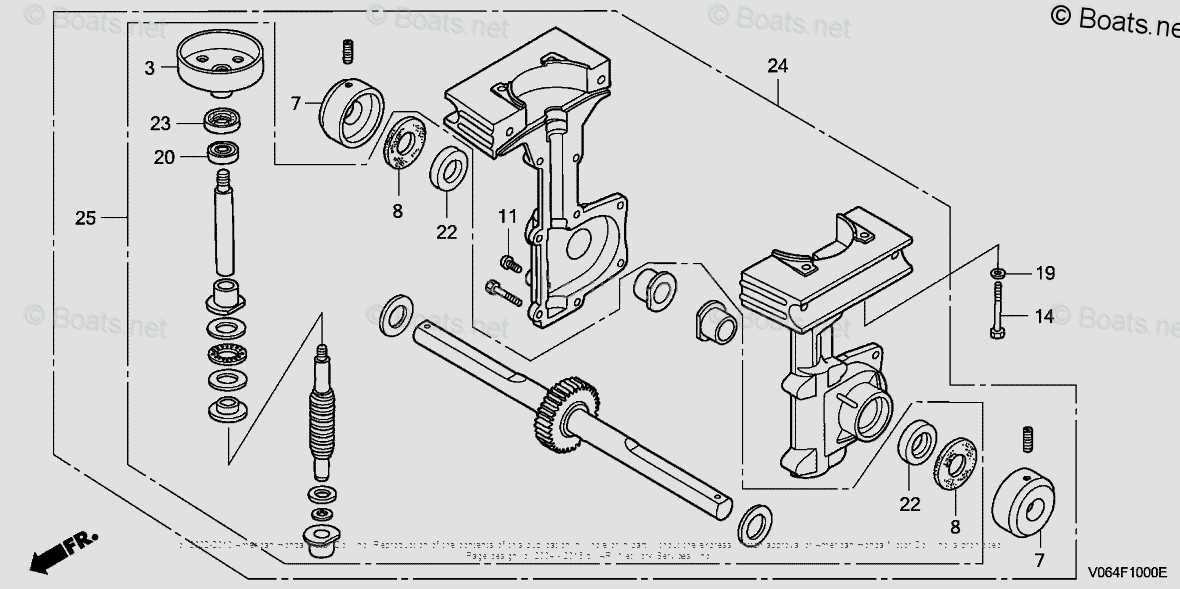

Overview of Parts and Components

This section provides a comprehensive understanding of the various elements that make up the machine. Each component plays a vital role in ensuring the effective operation and longevity of the equipment. Familiarity with these elements is essential for maintenance and repair, allowing users to keep their tools in optimal condition.

Main Assembly

The main assembly serves as the core framework, providing structural support and housing for internal mechanisms. It includes vital parts such as the engine mount and drive system, which are crucial for the overall functionality of the device. Understanding the layout of this assembly can help users identify any potential issues during troubleshooting.

Attachments enhance the versatility of the machine, allowing it to perform various tasks. These can include different types of blades or additional implements tailored for specific applications. Being aware of the available accessories enables users to maximize their equipment’s capabilities and adapt it for different gardening needs.

How to Access the Parts Diagram

Gaining insight into the components of your equipment can greatly enhance your maintenance and repair experience. Understanding how to locate and interpret these visual guides is essential for efficient servicing. This section outlines the steps you need to take to find the necessary illustrations that detail each element of your machine.

Step 1: Begin by visiting the official website of the manufacturer. Most companies provide a dedicated section for support, where you can find various resources, including visual aids for different models.

Step 2: Utilize the search function to enter the specific model you are interested in. This will help you narrow down the results to find the relevant illustrations quickly.

Step 3: Look for links labeled as “Service Manuals” or “Repair Guides.” These documents often include the comprehensive visuals you need, alongside detailed explanations.

Step 4: If available, consider downloading the PDF version of the manual. This format typically allows for easier navigation and can be accessed offline for convenience.

Step 5: For further assistance, you can explore online forums or communities dedicated to your equipment. Many enthusiasts share valuable insights and may provide direct links to the illustrations you seek.

By following these steps, you can efficiently locate and utilize the visual references that will aid you in understanding the structure and functionality of your machine.

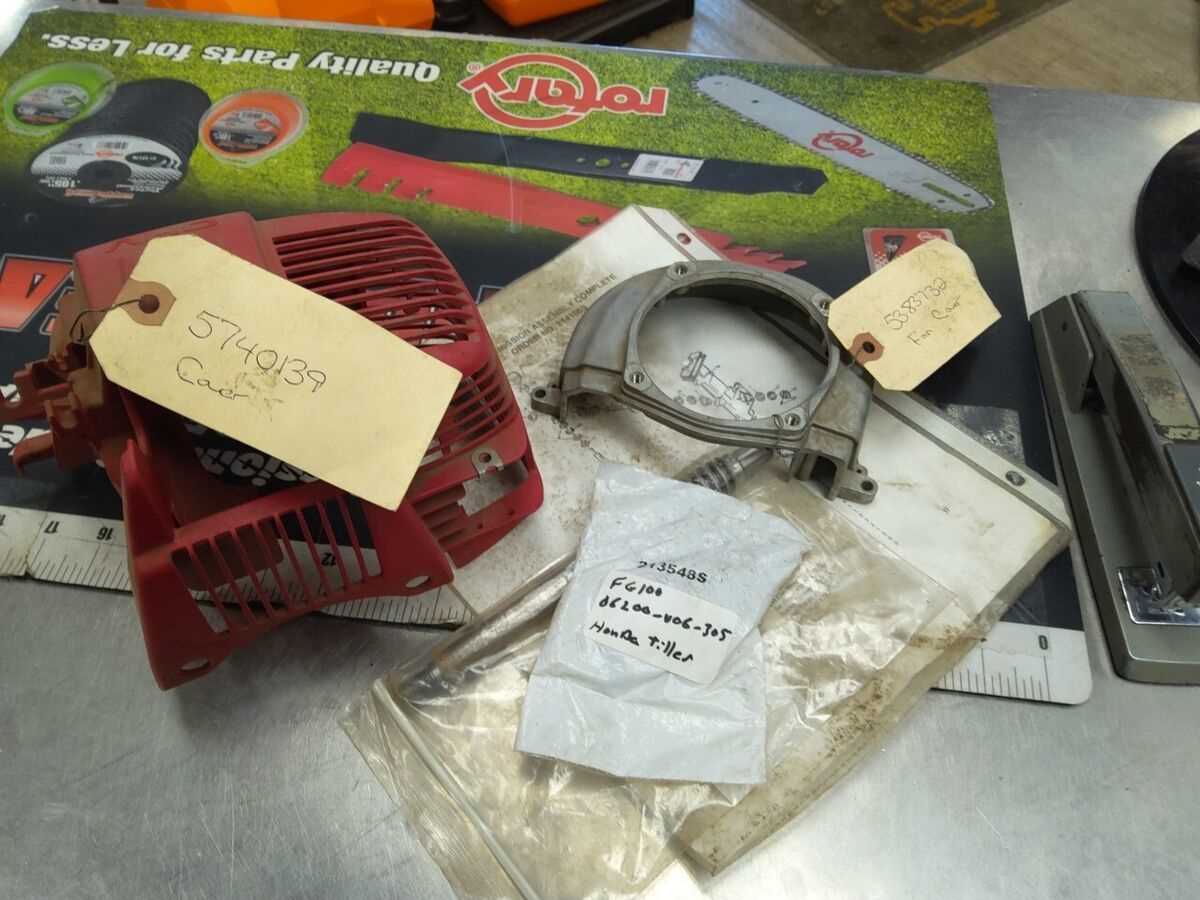

Identifying Specific Replacement Parts

Understanding the nuances of machinery components is essential for effective maintenance and repair. Identifying individual elements can enhance performance and extend the lifespan of your equipment. This section will guide you in recognizing and selecting the right components needed for your machine’s upkeep.

Common Components to Recognize

Familiarize yourself with the key parts that often require replacement. These include items such as blades, drive belts, and gears. Each element plays a crucial role in the overall functionality of the device. Regularly inspecting these components can prevent unexpected breakdowns and ensure optimal operation.

Utilizing Reference Resources

Utilize manuals or digital catalogs that provide detailed illustrations and descriptions. These resources can significantly aid in pinpointing the exact parts you need. When searching, pay close attention to model specifications to avoid discrepancies. Accurate identification is vital for seamless repairs and replacements.

Ordering Genuine Honda Parts Online

Acquiring authentic components for your machinery can significantly enhance performance and longevity. With the convenience of online shopping, it’s easier than ever to find the exact replacements needed to keep your equipment running smoothly. This section will guide you through the process of ordering genuine parts via the internet, ensuring you make informed decisions and receive high-quality items.

Benefits of Ordering Online

Purchasing components online offers numerous advantages. Firstly, it provides access to a wider selection than local retailers can offer. Secondly, online stores often have detailed specifications and user reviews, allowing you to compare products effectively. Lastly, the convenience of home delivery saves time and effort, making it a practical choice for busy individuals.

Tips for Successful Orders

When placing an order online, follow these tips to ensure a smooth experience:

| Tip | Description |

|---|---|

| Verify Authenticity | Ensure the retailer is an authorized dealer to guarantee you receive genuine components. |

| Check Compatibility | Double-check that the item matches your equipment model to avoid issues during installation. |

| Read Reviews | Look for customer feedback to assess the reliability of both the product and the seller. |

| Shipping Policies | Review shipping options and return policies to ensure a hassle-free purchasing process. |

By following these guidelines, you can confidently navigate the online marketplace for your machinery needs, ensuring you receive quality components that support optimal performance.

Tools Needed for Repairs

When undertaking maintenance or repair tasks, having the right equipment is essential for ensuring efficiency and effectiveness. The proper tools not only simplify the process but also enhance safety and precision. This section outlines the fundamental tools necessary for successful repairs.

Essential Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket types.

- Screwdrivers: Both flathead and Phillips, with different sizes for versatility.

- Pliers: Needle-nose and standard types for gripping and twisting.

- Hammers: A lightweight hammer for tapping and a rubber mallet to avoid damage.

- Measuring tape: For accurate measurements of parts and distances.

Power Tools and Accessories

- Drill: A cordless drill for convenience and mobility.

- Impact wrench: To easily remove stubborn bolts and nuts.

- Angle grinder: Useful for cutting and grinding various materials.

- Safety equipment: Goggles, gloves, and ear protection to ensure personal safety.

- Toolbox: A sturdy storage solution to keep everything organized and accessible.

Step-by-Step Repair Process

Repairing outdoor machinery can seem daunting, but following a structured approach simplifies the task significantly. This guide outlines the necessary steps to diagnose issues, gather the required components, and execute repairs effectively. With careful attention to detail and a methodical process, even complex problems can be resolved successfully.

1. Diagnosis and Preparation

Start by identifying the specific malfunction. Listen for unusual sounds and observe any irregular behavior during operation. Once the problem is clear, gather the essential tools and components needed for the repair. Having everything ready before starting saves time and reduces frustration.

2. Disassembly and Replacement

Carefully disassemble the machinery, noting the placement of each component for reassembly. Use diagrams if available, as they provide visual guidance. Replace any faulty parts, ensuring a secure fit. After reassembly, double-check all connections and components to confirm that everything is in its correct position.

Finally, conduct a test run to ensure the repair was successful. If issues persist, revisit the earlier steps to reevaluate and troubleshoot further. With patience and diligence, effective repairs can restore functionality to your equipment.

Tips for Troubleshooting Problems

When encountering issues with gardening equipment, a systematic approach to identifying and resolving problems can save time and effort. By breaking down the situation into manageable parts, users can often pinpoint the source of the malfunction and implement effective solutions.

Common Issues and Solutions

| Issue | Possible Cause | Suggested Solution |

|---|---|---|

| Engine won’t start | Fuel supply issue | Check fuel level and ensure it’s clean and fresh. |

| Unusual vibrations | Loose components | Tighten bolts and inspect for wear. |

| Poor tilling performance | Dull blades | Sharpen or replace blades as necessary. |

| Overheating | Blocked air vents | Clear any debris obstructing airflow. |

General Maintenance Tips

Regular upkeep can prevent many common issues. Ensure to clean the equipment after each use, check fluid levels periodically, and store it in a dry place. Following the manufacturer’s guidelines for maintenance can also extend the lifespan of the machine and improve its performance.

Benefits of Regular Inspections

Conducting routine evaluations of equipment is essential for ensuring optimal performance and longevity. Regular checks help identify potential issues before they escalate, saving time and resources. This proactive approach can enhance efficiency and safety, ultimately leading to improved outcomes in various applications.

One of the key advantages of systematic inspections is the prevention of unexpected breakdowns. By monitoring the condition of machinery, operators can address minor problems promptly, reducing the risk of major failures that may require costly repairs or replacements.

| Benefit | Description |

|---|---|

| Increased Lifespan | Regular assessments help maintain equipment in optimal condition, extending its usable life. |

| Cost Savings | Identifying issues early reduces the likelihood of expensive repairs and downtime. |

| Enhanced Safety | Routine checks help ensure that all components are functioning properly, minimizing the risk of accidents. |

| Improved Efficiency | Well-maintained equipment operates more effectively, leading to better productivity. |

In conclusion, maintaining a regular inspection schedule is a fundamental practice for maximizing the performance and safety of machinery. By embracing this proactive strategy, operators can ensure their equipment remains reliable and efficient over time.

User Reviews and Feedback

This section explores the experiences of users with a specific garden cultivation tool, focusing on its performance, ease of use, and overall satisfaction. Insights gathered from various reviews provide potential buyers with valuable information to make informed decisions.

Many users appreciate the machine’s efficiency and reliability, noting several key features that enhance their gardening tasks:

- Powerful engine performance, enabling smooth operation even in tough soil conditions.

- User-friendly controls that simplify the adjustment of settings and speed.

- Durability of components, ensuring longevity and reduced maintenance needs.

However, some feedback highlights areas for improvement:

- The weight of the unit can make maneuverability challenging in tighter spaces.

- Initial setup may require additional assistance or tools for optimal performance.

- Noise levels during operation could be disruptive in residential areas.

Overall, the consensus among users indicates a strong appreciation for the tool’s capabilities, with many recommending it for both amateur and experienced gardeners alike.