Understanding Husqvarna 120 Parts Layout

Understanding the various elements of a mechanical system is essential for maintaining and troubleshooting equipment. By examining detailed illustrations and layouts, users can gain insights into how individual components interact, making it easier to identify specific features and their roles within the system. Such information becomes especially useful when replacement or repairs are necessary, ensuring that each element is correctly identified.

Whether you’re working on a routine maintenance task or addressing a specific issue, having access to visual layouts provides a clear pathway to identifying the correct component. This approach not only simplifies repairs but also helps in sourcing the appropriate replacement items, enhancing the overall efficiency and reliability of the equipment.

Overview of Key Components

The essential elements of this tool are designed to ensure efficient operation and durability. These components work together, providing the necessary support for cutting, safety, and overall functionality. Each part is carefully crafted to optimize performance, making the equipment more reliable and easier to handle during use.

Among the critical mechanisms are those responsible for the drive system, which ensures smooth operation, as well as the safety features that protect the user. These features are integral to maintaining control and stability in a variety of working conditions.

Another vital area is the power delivery system, which plays a central role in achieving the desired level of output. It’s important to understand how these parts contribute to the tool’s ability to handle different tasks efficiently.

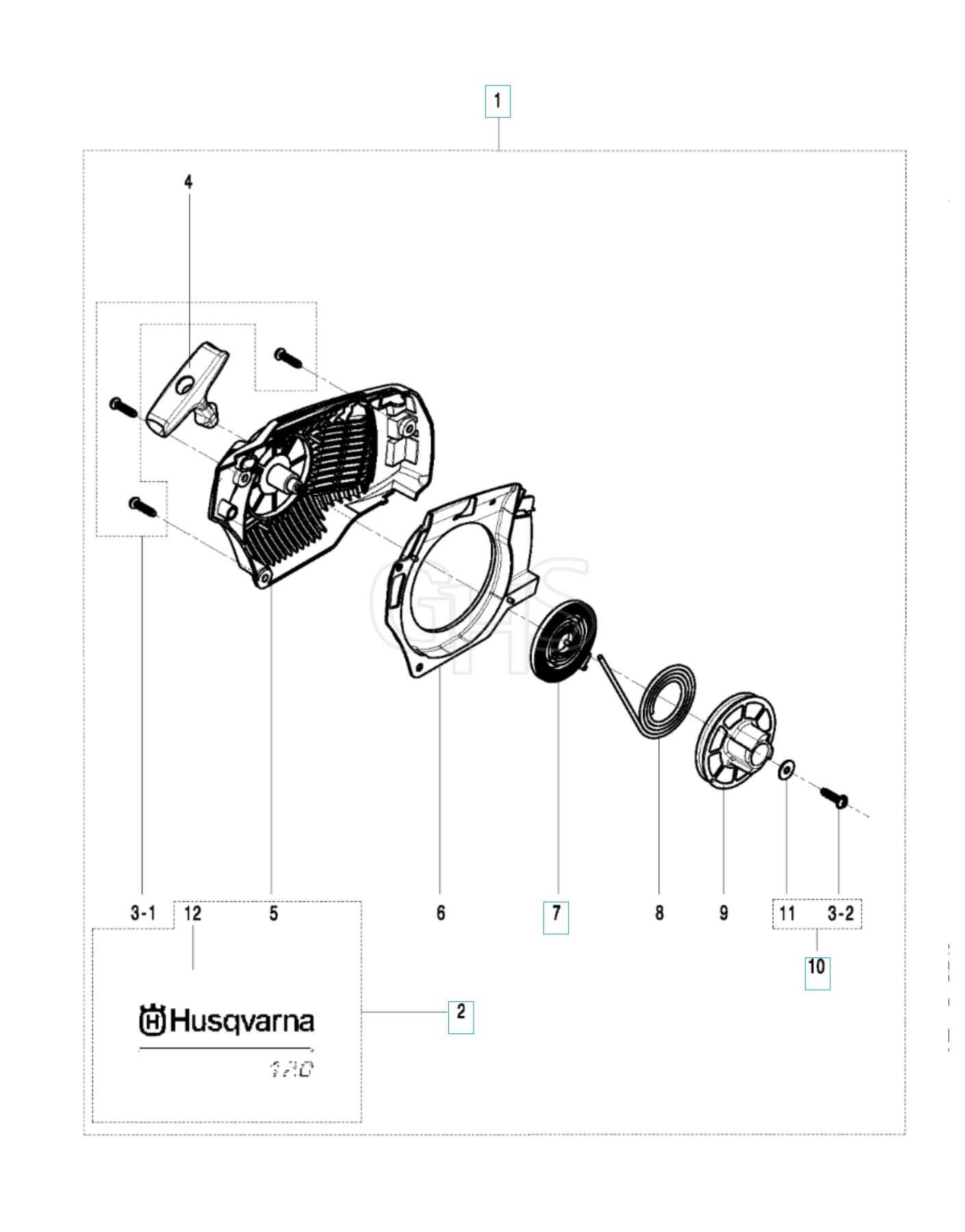

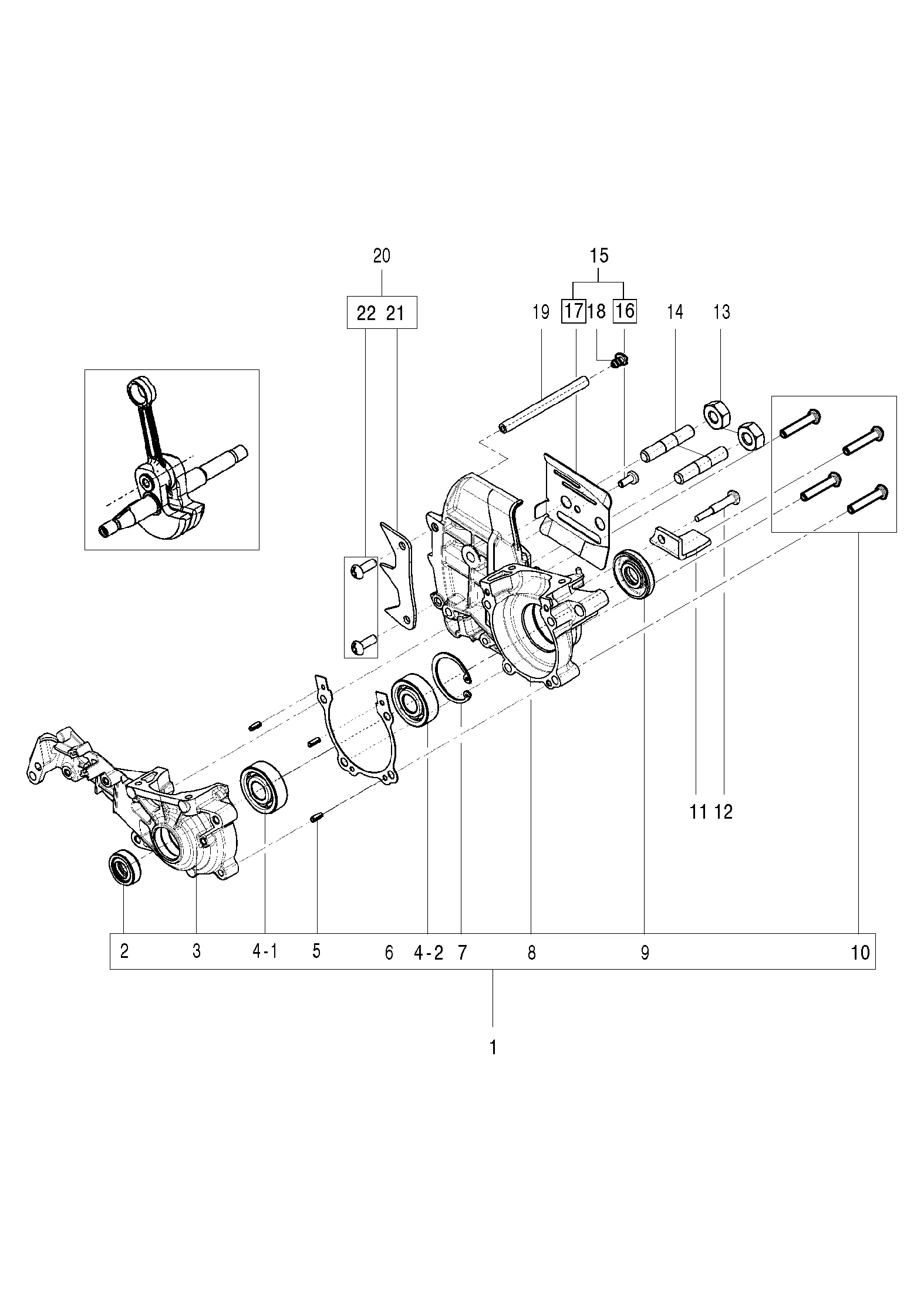

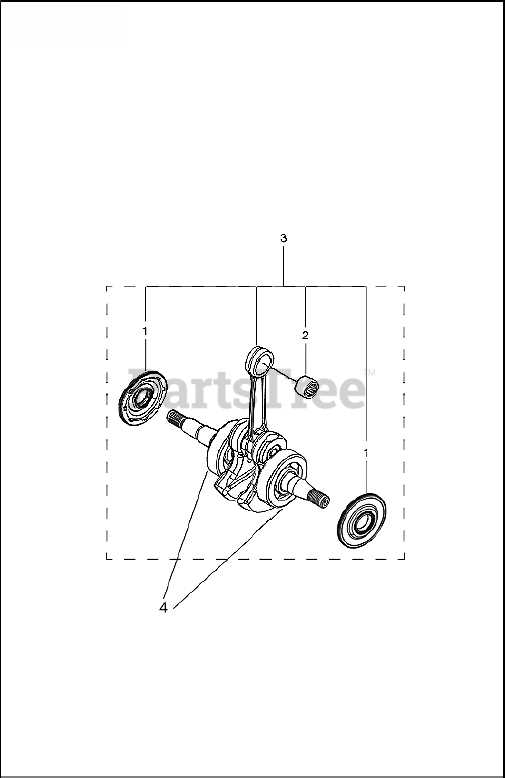

Main Engine Assembly Breakdown

The engine’s core assembly involves numerous components working together to deliver reliable power and performance. Understanding the layout and relationships between these elements is key to maintaining and servicing the engine efficiently.

Key Components Overview

- Cylinder block: The primary structure that houses essential moving parts.

- Piston and crankshaft: These parts convert the energy from combustion into rotational force.

- Cooling system: Ensures the engine operates at optimal temperatures, preventing overheating.

- Fuel intake system: Manages the delivery of fuel into the engine for efficient combustion.

Assembly Process and Connections

The assembly involves a step-by-step process where each part is interconnected. The crankshaft is connected to the piston, and the fuel system is linked to ensure a seamless flow. The cooling system surrounds key areas to maintain balance

Understanding the Chain and Bar System

The chain and bar system plays a crucial role in ensuring efficient cutting performance. It is essential to understand how these components interact to achieve smooth and effective operation. Proper maintenance of both elements helps in extending the lifespan of the tool and guarantees a cleaner cut.

The Role of the Chain

The cutting chain is the primary part responsible for slicing through wood. It moves at high speeds around the bar, driven by the motor. Each link on the chain has sharp edges that bite into the material, allowing the tool to cut with precision. Regular sharpening of the chain ensures optimal performance and prevents excessive wear.

The Bar’s Function

The bar provides a stable guide for the chain, ensuring it moves in a controlled, straight path. It also helps to distribute the tension evenly across the chain. Maintaining the bar’s surface, checking for any damage, and ensuring proper lubrication are key to keeping the system running smoothly.

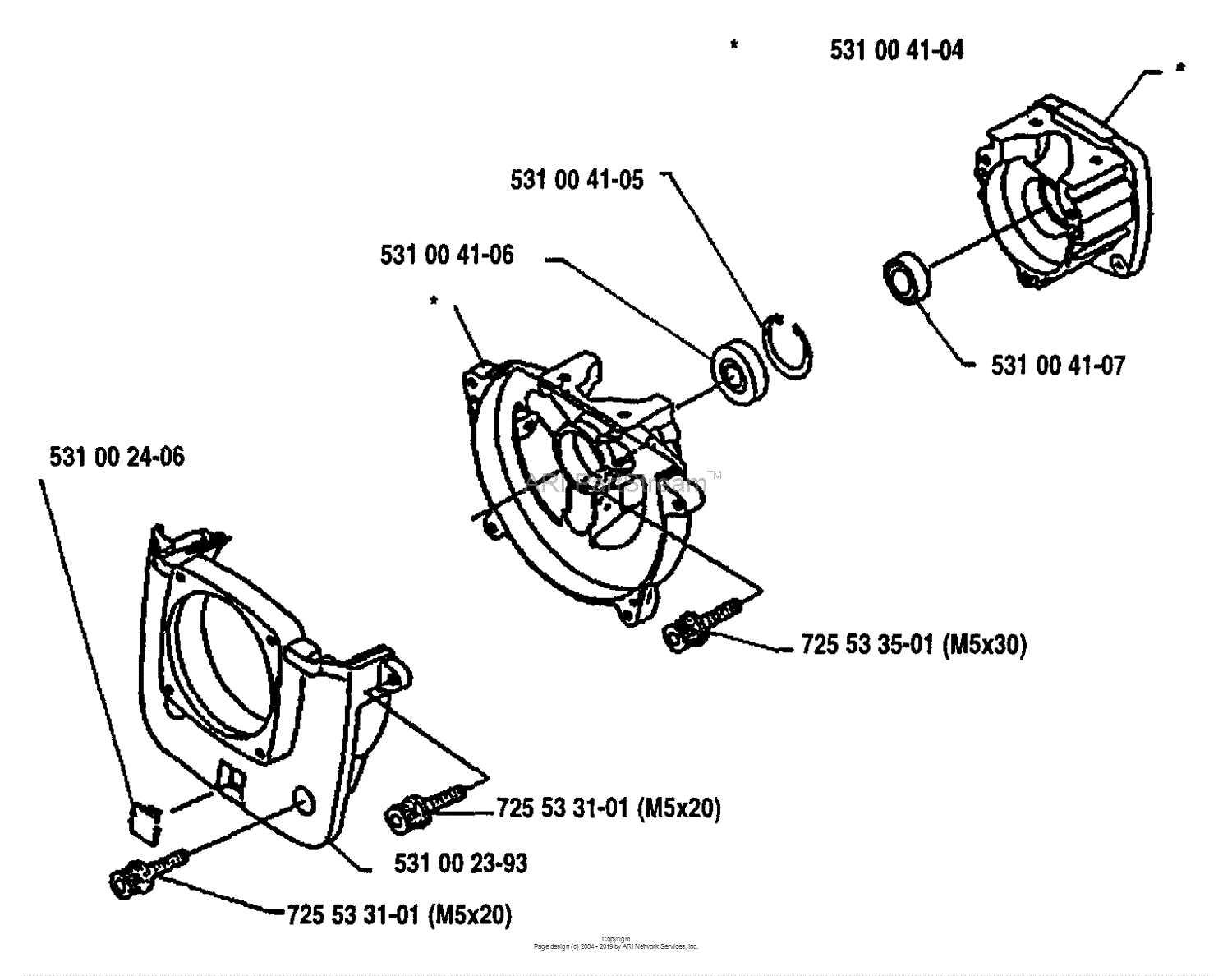

Air Filter Housing and Its Role

The air filter housing is an essential component that ensures the engine receives clean air for optimal functioning. This enclosure shields the filter from external elements, contributing to the overall efficiency and longevity of the machinery. By properly guiding airflow, the housing enhances the engine’s performance while protecting internal components from harmful debris.

Structure and Design

The structure of the housing is designed to accommodate the filter securely while allowing easy access for maintenance. Its layout helps prevent dust, dirt, and other particles from entering sensitive areas, ensuring that air passes through the filter effectively.

Benefits of Proper Housing Maintenance

- Extends engine life by preventing contaminants from reaching critical parts

- Improves fuel efficiency through better airflow

- Reduces wear and tear on internal components

- Regularly inspect for any cracks or damage.

Fuel Tank Structure and Connections

The fuel storage system is a key component ensuring efficient energy delivery. This section covers the layout and connections involved in this system, focusing on how the tank is designed to store fuel securely and deliver it to the necessary areas. Understanding these aspects can help in maintaining the flow of energy and preventing leaks or disruptions.

Tank Design: The tank is constructed to handle different types of liquid fuels. It features a durable outer shell that is resistant to wear and tear, ensuring that the contents are kept safe. Inside, there are partitions or baffles that reduce movement of the liquid, preventing spills or surges when the machine is in use.

Fuel Line Connections: The tank is connected to the rest of the system through secure lines. These tubes are designed to handle high-pressure flow without collapsing or leaking. A proper seal is ensured through clamps and fittings, making sure that the liquid flows smoothly to the engine without any interruptions.

Ventilation and Caps: To maintain proper pressure within the tank, there is a venting system that allows air to circulate, preventing any vacuum formation. The cap plays a crucial role here, providing an airtight seal while allowing c

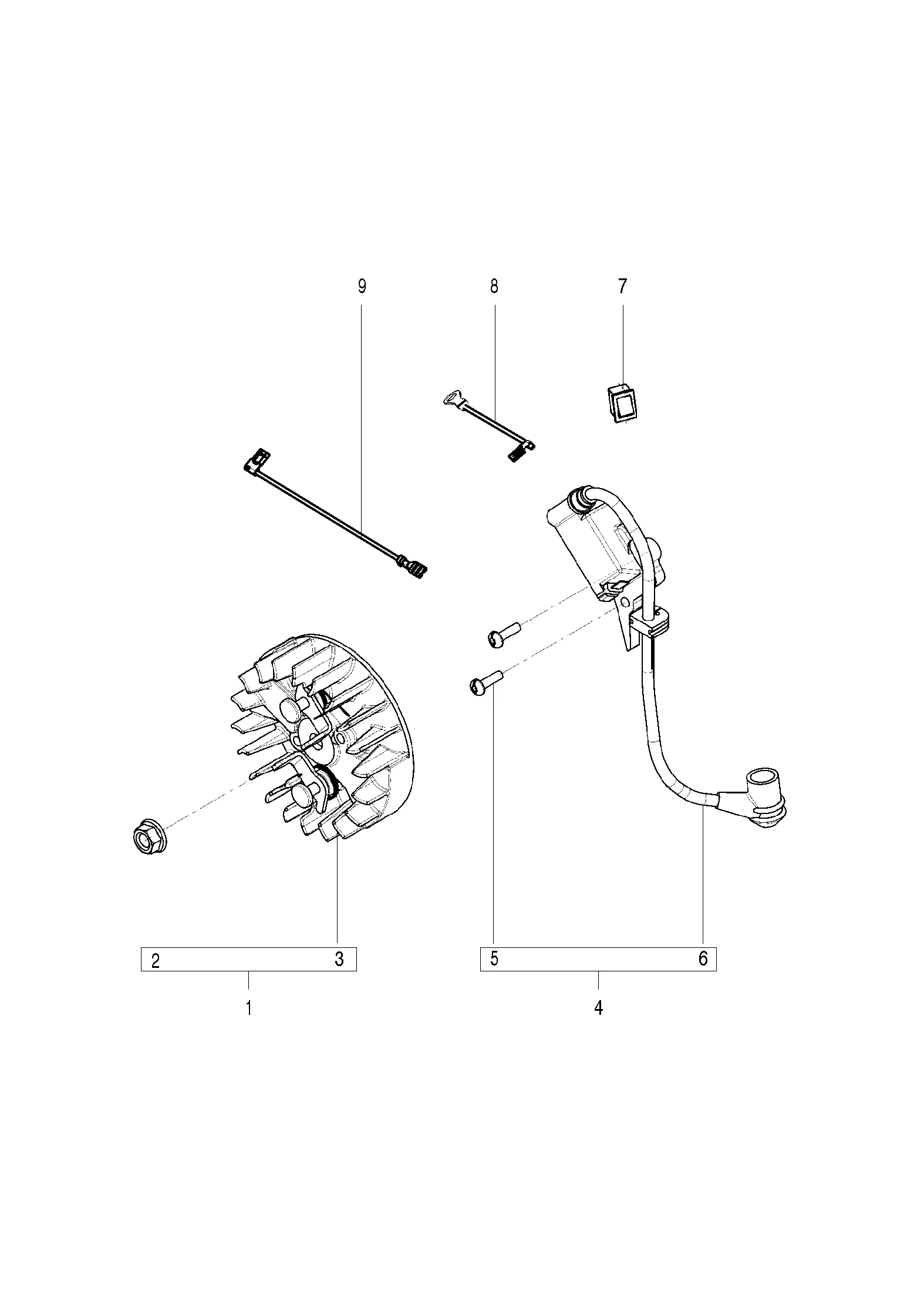

Ignition System Components

The ignition system plays a vital role in the overall functioning of small engines, ensuring proper combustion and optimal performance. Understanding its various elements is essential for effective maintenance and troubleshooting.

Key Elements of the Ignition System

- Spark Plug: This component generates the spark that ignites the air-fuel mixture within the combustion chamber.

- Ignition Coil: It transforms the battery’s low voltage into a high voltage necessary for the spark plug to function effectively.

- Flywheel Magnet: The magnet on the flywheel creates a magnetic field that is crucial for triggering the ignition coil.

- Ignition Module: This electronic component controls the timing and delivery of the spark, ensuring efficient engine operation.

- Wiring Harness: Connects various components of the ignition system, allowing for proper communication and electrical flow.

Maintenance Tips

- Regularly inspect and clean the spark plug to ensure reliable ignition.

- Check the ignition coil for any signs of wear or damage.

- Ensure that the wiring harness is intact and free of corrosion.

- Test the ignition module periodically to confirm proper functioning.

Exhaust System Parts Explained

The exhaust mechanism plays a crucial role in managing engine emissions and enhancing performance. Understanding the components that constitute this system can help users maintain their equipment more effectively. Each element has a specific function that contributes to the overall efficiency and reliability of the engine.

Key Components of the Exhaust System

The exhaust system comprises several essential components, each designed to facilitate the safe expulsion of exhaust gases. Below is a summary of the primary elements:

| Component | Description |

|---|---|

| Exhaust Muffler | This part reduces noise produced by the engine and helps to control the flow of exhaust gases. |

| Exhaust Pipe | It directs exhaust gases away from the engine, ensuring they exit safely from the equipment. |

| Manifold | This component collects exhaust gases from multiple cylinders and channels them into a single pipe. |

| Gaskets | These seals prevent leaks between the manifold and the engine, ensuring a secure connection. |

| Heat Shield | Designed to protect surrounding components from the high temperatures produced by exhaust gases. |

Importance of Maintenance

Regular upkeep of the exhaust system is vital for optimal performance. Inspecting each component for wear and damage can prevent costly repairs and ensure the engine operates smoothly. Understanding these elements enhances the ability to troubleshoot issues and extend the lifespan of the equipment.

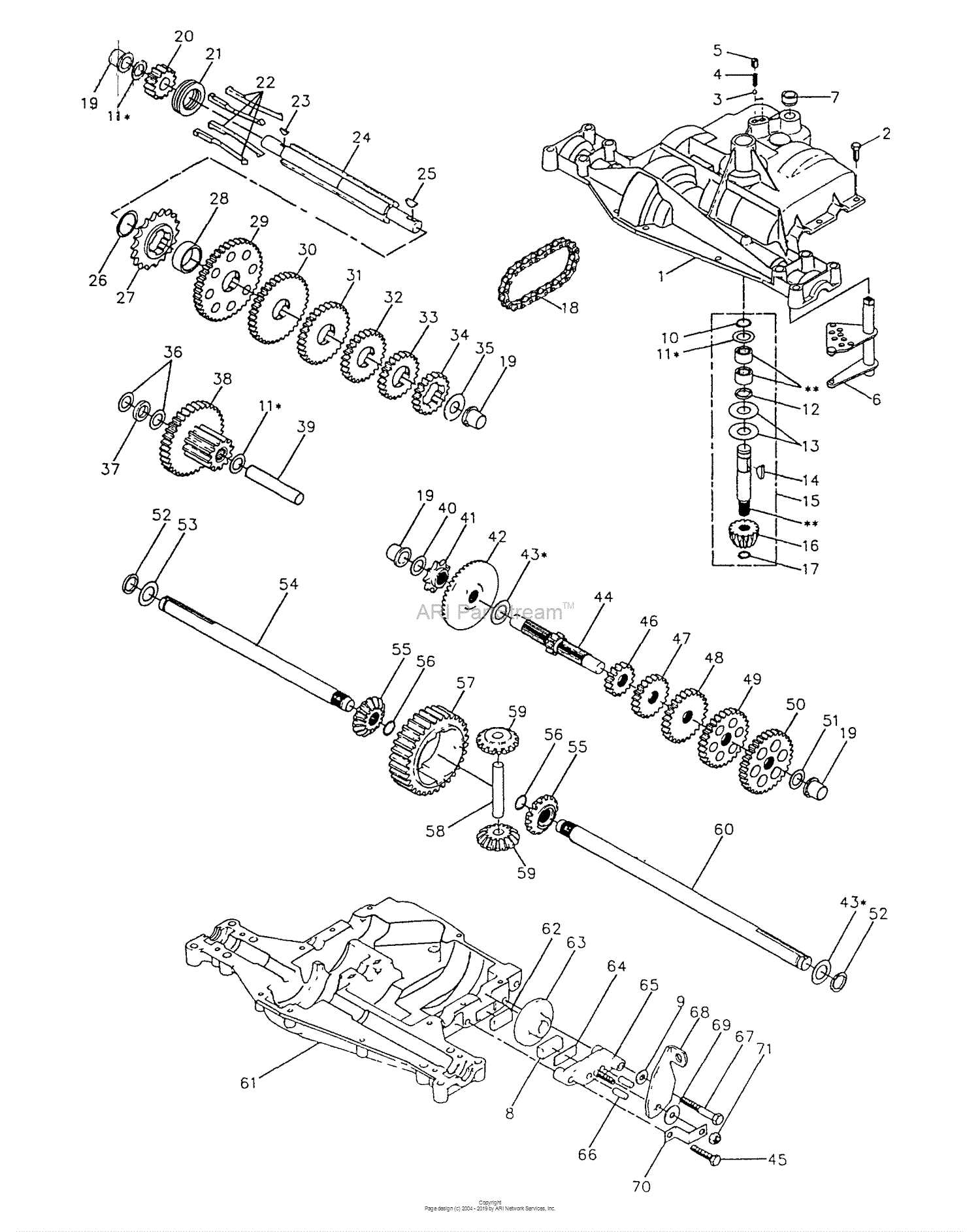

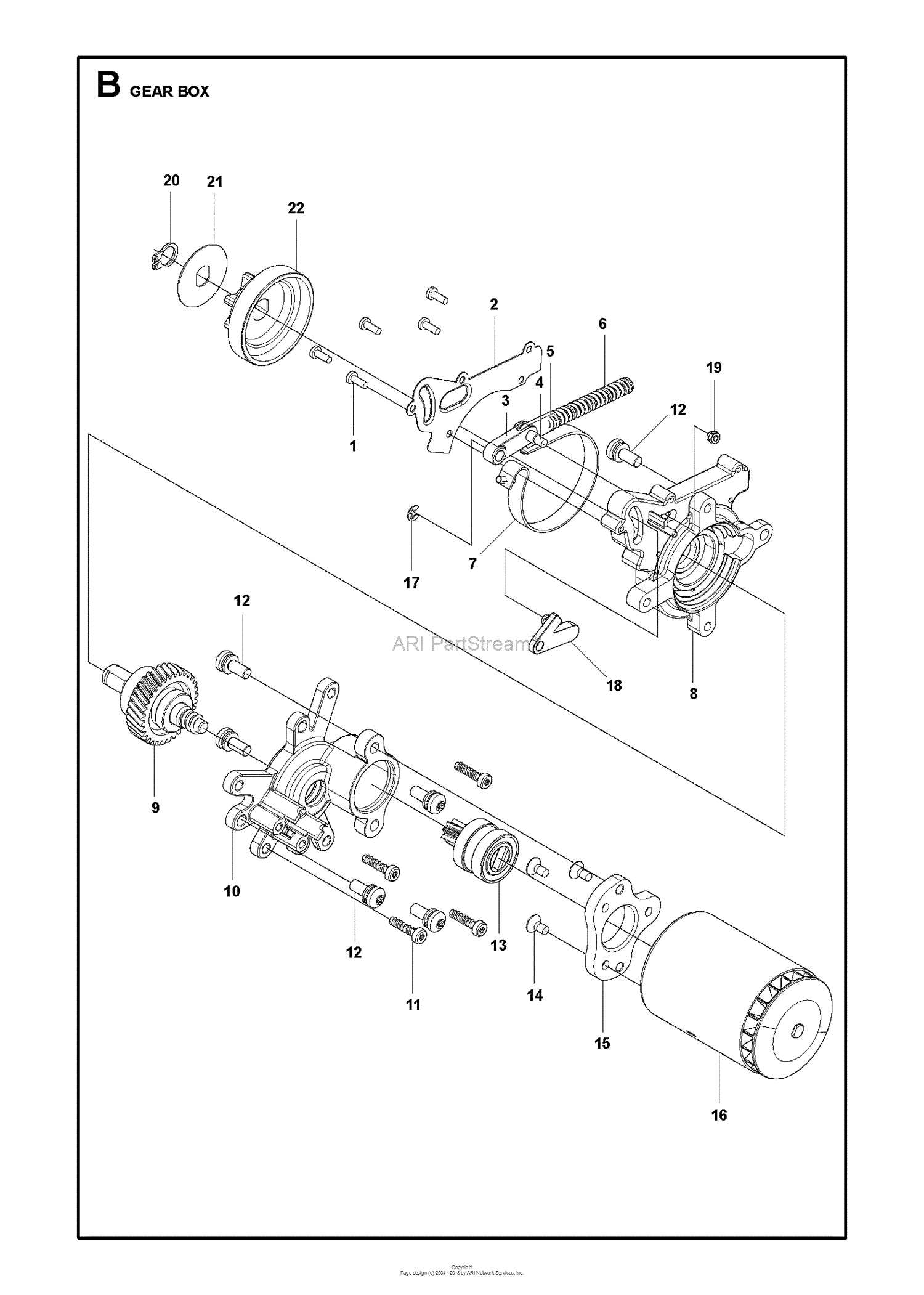

Clutch Mechanism and Its Function

The clutch mechanism serves a vital role in the operation of various machinery, facilitating the engagement and disengagement of power transmission. Its design enables the seamless transfer of energy from the engine to the working components, allowing for controlled operation and improved efficiency.

In essence, this mechanism consists of several key components that work together to manage torque and rotational speed. The primary function is to provide a means of temporarily disconnecting the engine’s power from the drive system, enabling the user to start and stop the machine without stalling the engine. This capability is crucial for effective operation, especially in tasks that require precision and control.

Furthermore, the clutch system is engineered to absorb shocks and vibrations during operation, enhancing the overall durability of the equipment. By allowing for smooth transitions between various speeds and loads, it significantly contributes to the longevity and performance of the machinery, making it an indispensable feature in modern engineering designs.

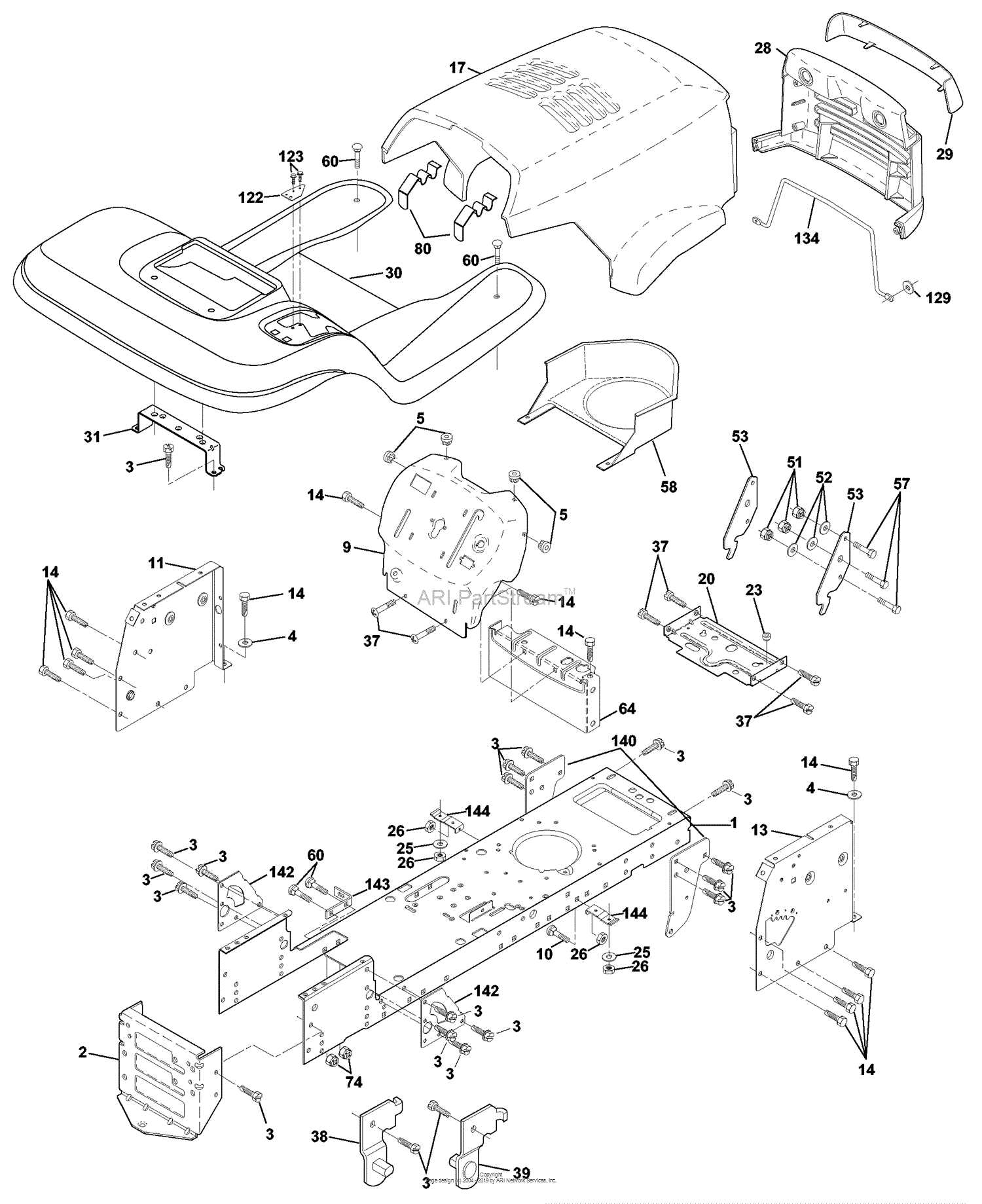

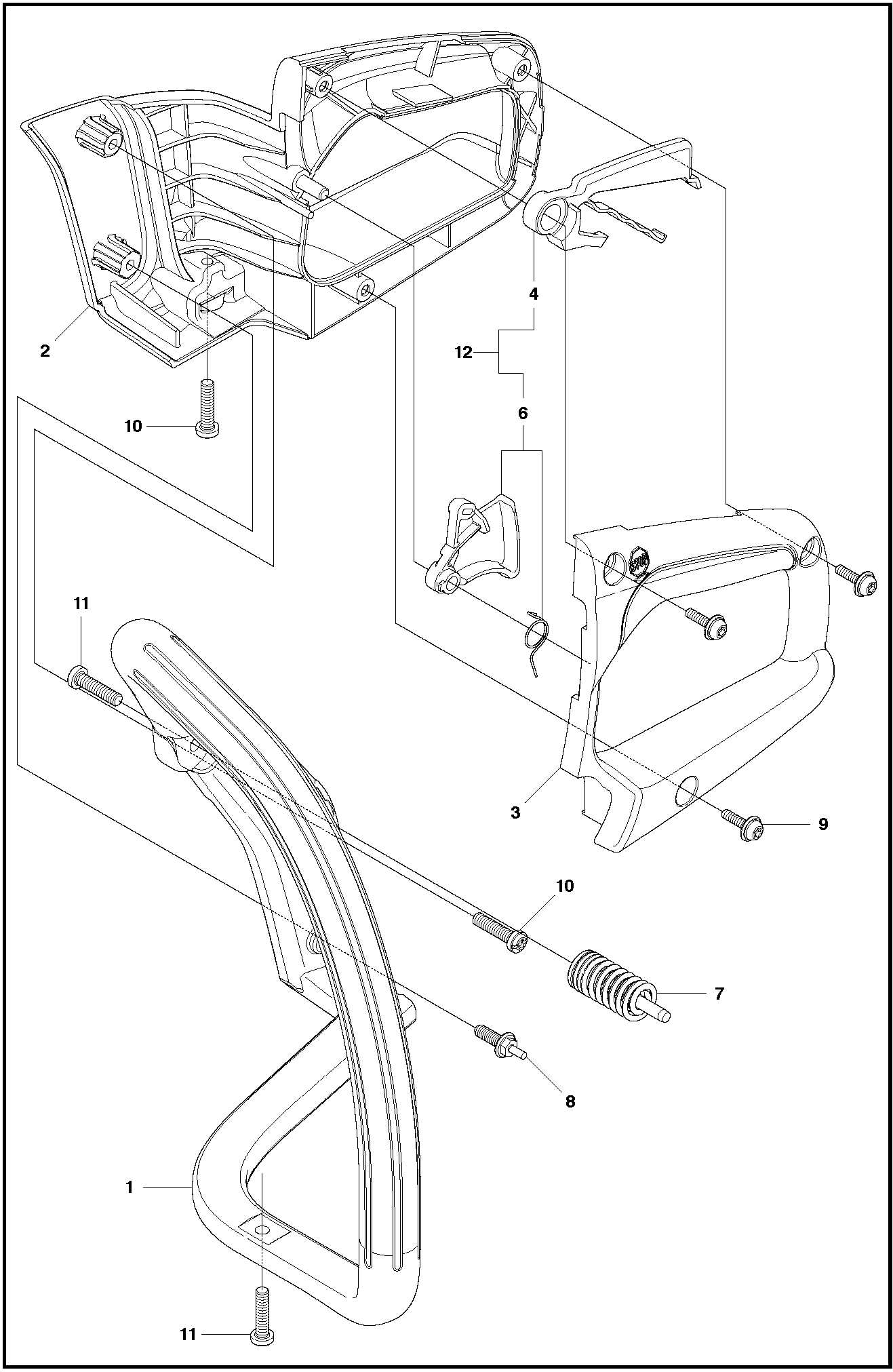

Handlebar and Controls Layout

The configuration of the handlebar and its associated controls plays a crucial role in ensuring optimal maneuverability and comfort during operation. A well-designed layout allows the user to access various functionalities seamlessly, enhancing the overall experience while maintaining safety and efficiency.

Ergonomics and Accessibility

Ergonomics is a key consideration in the arrangement of the handlebar and controls. The positioning of levers and switches should promote a natural grip, reducing strain on the operator’s hands and wrists. This thoughtful design enables quick access to essential functions without compromising control over the device. Adjustability options may also be available, allowing users to customize the setup to suit their individual preferences.

Control Mechanisms

The layout includes various control mechanisms, each designed to perform specific tasks. Throttle controls, brake levers, and other switches are strategically placed to ensure they are intuitive and easy to operate. This not only aids in efficient handling but also enhances safety by minimizing the need for operators to take their hands off the handlebar while adjusting settings or responding to changing conditions.

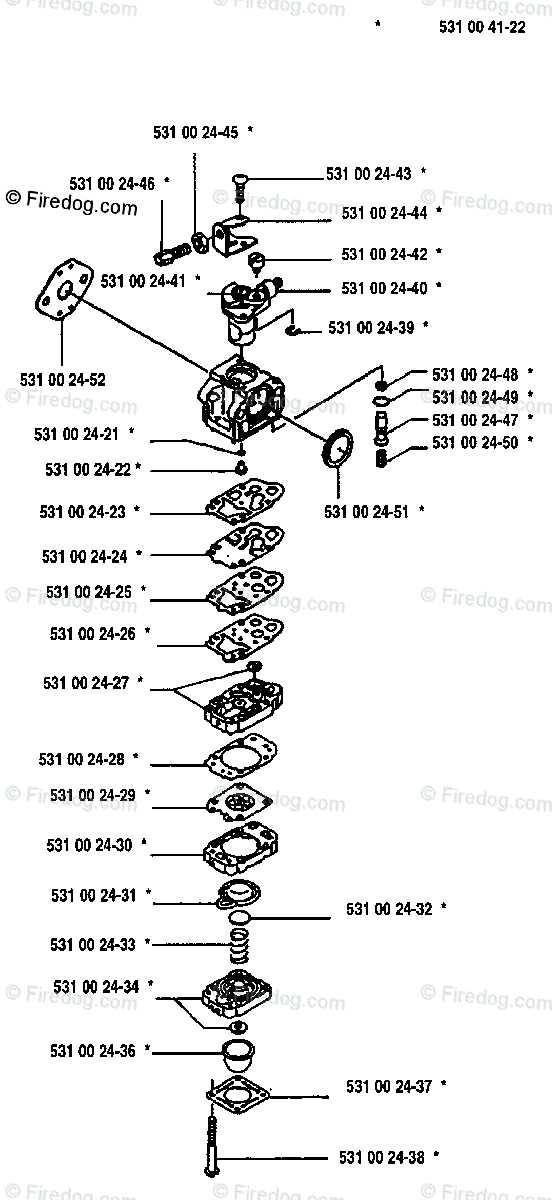

Guide to Carburetor Components

The carburetor is a vital assembly within small engines, responsible for mixing air and fuel in the correct ratio for efficient combustion. Understanding its components can enhance performance and ease troubleshooting during maintenance tasks.

Fuel Inlet: This part serves as the entry point for fuel into the carburetor. It ensures that the right amount of fuel is supplied for the mixing process.

Float Chamber: The float chamber regulates the fuel level within the carburetor, maintaining an optimal supply to prevent overflow or starvation.

Venturi: This section creates a pressure drop as air flows through it, allowing fuel to be drawn into the air stream. The shape and size of the venturi directly impact engine performance.

Throttle Valve: The throttle valve controls the amount of air entering the engine, which in turn affects engine speed and power output. Its position dictates the engine’s responsiveness.

Choke: The choke is utilized during starting to enrich the fuel mixture, facilitating easier ignition in colder conditions. It can be manually or automatically operated.

Mixture Screws: These screws allow for fine-tuning of the fuel-air ratio, enabling adjustments to optimize engine performance based on operating conditions.

Familiarity with these components is essential for effective maintenance and repairs, ensuring your engine runs smoothly and efficiently.

Maintenance Parts and Replacements

Regular upkeep of your equipment is essential for ensuring optimal performance and longevity. This section focuses on the various components that may require periodic attention or replacement to keep the machine running smoothly. By staying informed about essential maintenance items, users can enhance the reliability and efficiency of their tools.

Key elements to consider for maintenance include filters, blades, and spark plugs. Filters are crucial for maintaining clean airflow and preventing contaminants from damaging internal components. Regularly checking and replacing these filters can lead to improved engine performance.

Another vital component is the cutting elements, which directly affect the efficiency and quality of operation. Dull or worn-out blades can reduce effectiveness and may cause unnecessary strain on the engine. It’s advisable to inspect and replace them as needed.

Additionally, ignition components, such as spark plugs, play a critical role in starting and overall functionality. Ensuring that these parts are in good condition helps in achieving reliable ignition and smoother operation.

In conclusion, a proactive approach to monitoring and replacing these crucial elements can significantly enhance the performance and durability of your equipment. Regular maintenance checks and timely replacements are key to achieving the best results and extending the lifespan of your tools.