Understanding the Parts Diagram of Husqvarna 125BT

When it comes to maintaining outdoor machinery, a clear understanding of its various elements is essential. This knowledge not only aids in effective repairs but also enhances the overall longevity and performance of the equipment. Whether you are a seasoned user or a novice, familiarizing yourself with the internal workings can significantly impact your operational efficiency.

In this section, we will delve into the intricate layout of components for a specific model, breaking down each piece to shed light on its function and importance. By grasping how these elements interconnect, you can better troubleshoot issues and carry out maintenance tasks with confidence.

Utilizing a detailed visual representation of the machinery’s assembly allows for easier identification of individual parts. This can streamline the process of sourcing replacements or upgrades, ensuring that your outdoor tool remains in optimal condition. Knowledge is power, and understanding these components will empower you to keep your equipment running smoothly for years to come.

Understanding Husqvarna 125BT Components

Grasping the various elements of outdoor equipment is essential for effective maintenance and operation. Each part plays a pivotal role in ensuring optimal performance, making it crucial to familiarize oneself with their functions and interconnections.

Core Elements

The essential components include the engine, air filter, and fuel system, which work together to generate power and efficiency. A clean and well-functioning air filter is vital for maintaining air quality and engine longevity, while the fuel system ensures proper delivery of energy sources.

Maintenance and Repair

Regular inspection and replacement of worn-out elements can significantly enhance performance. Understanding how each part fits into the overall machinery allows users to identify issues promptly. Ultimately, a proactive approach to care leads to a more reliable and durable tool.

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for effective maintenance and repair. Visual representations that detail individual components enhance the user’s ability to identify and manage issues efficiently.

Benefits of Visual Guides

- Facilitates quick identification of specific elements.

- Improves accuracy during reassembly processes.

- Helps in locating replacement pieces with ease.

Enhanced Troubleshooting

- Allows users to pinpoint malfunctioning sections.

- Streamlines communication with suppliers or repair professionals.

- Encourages a deeper understanding of the overall system.

Main Parts of Husqvarna 125BT

This section will explore the essential components of a well-known handheld blower, highlighting their functionality and significance in ensuring optimal performance. Understanding these key elements is crucial for maintenance and effective operation.

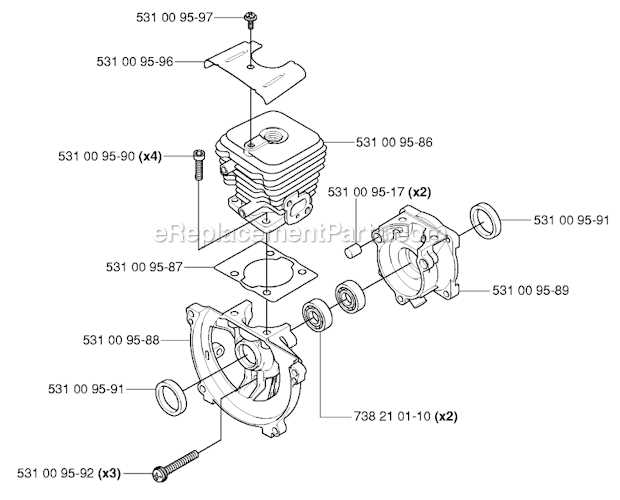

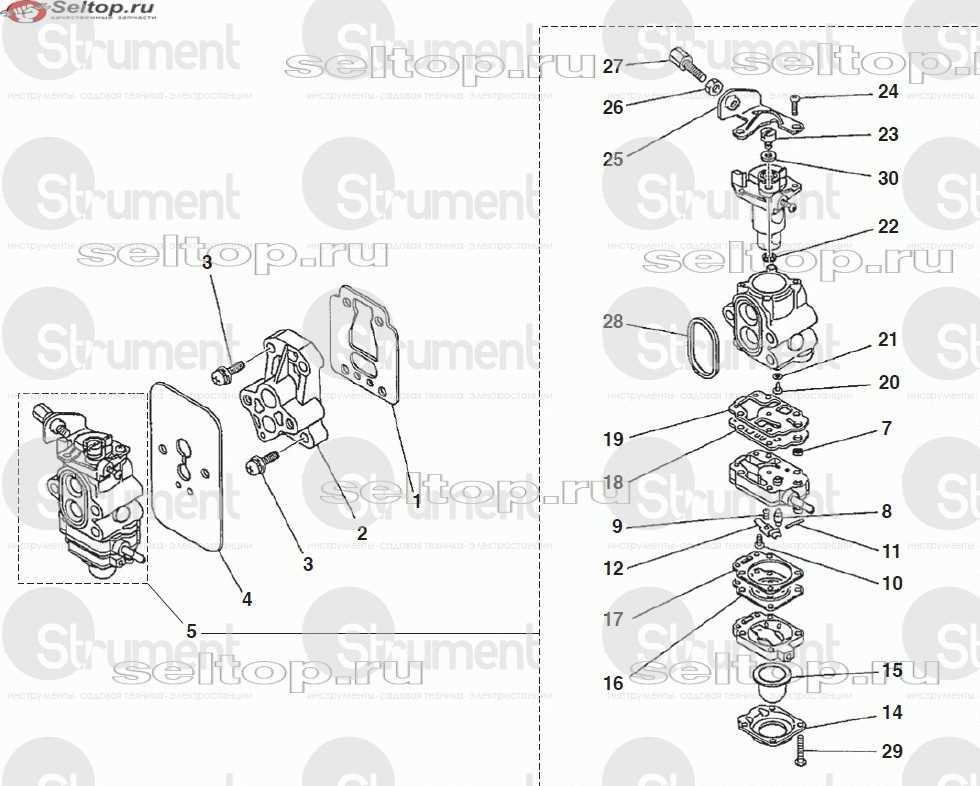

Engine and Fuel System

The heart of the device is its engine, designed for efficient power output. The fuel system, including the tank and carburetor, ensures proper fuel delivery, enhancing overall efficiency and reliability.

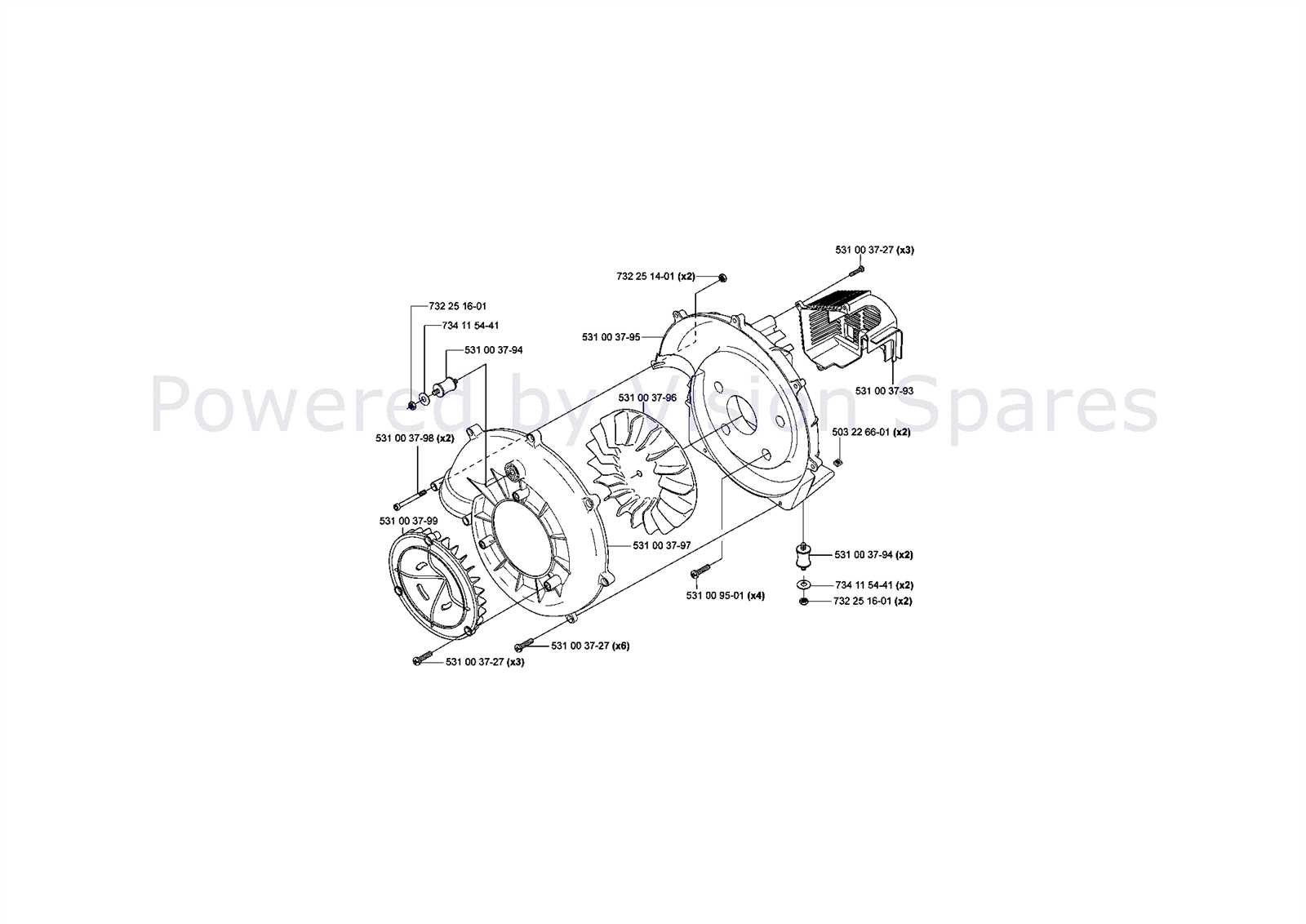

Airflow Components

Critical to the blower’s performance, the airflow components consist of the fan and housing, which work in harmony to create powerful air currents. Maintenance of these parts is vital to achieving the ultimate blowing capacity and effectiveness.

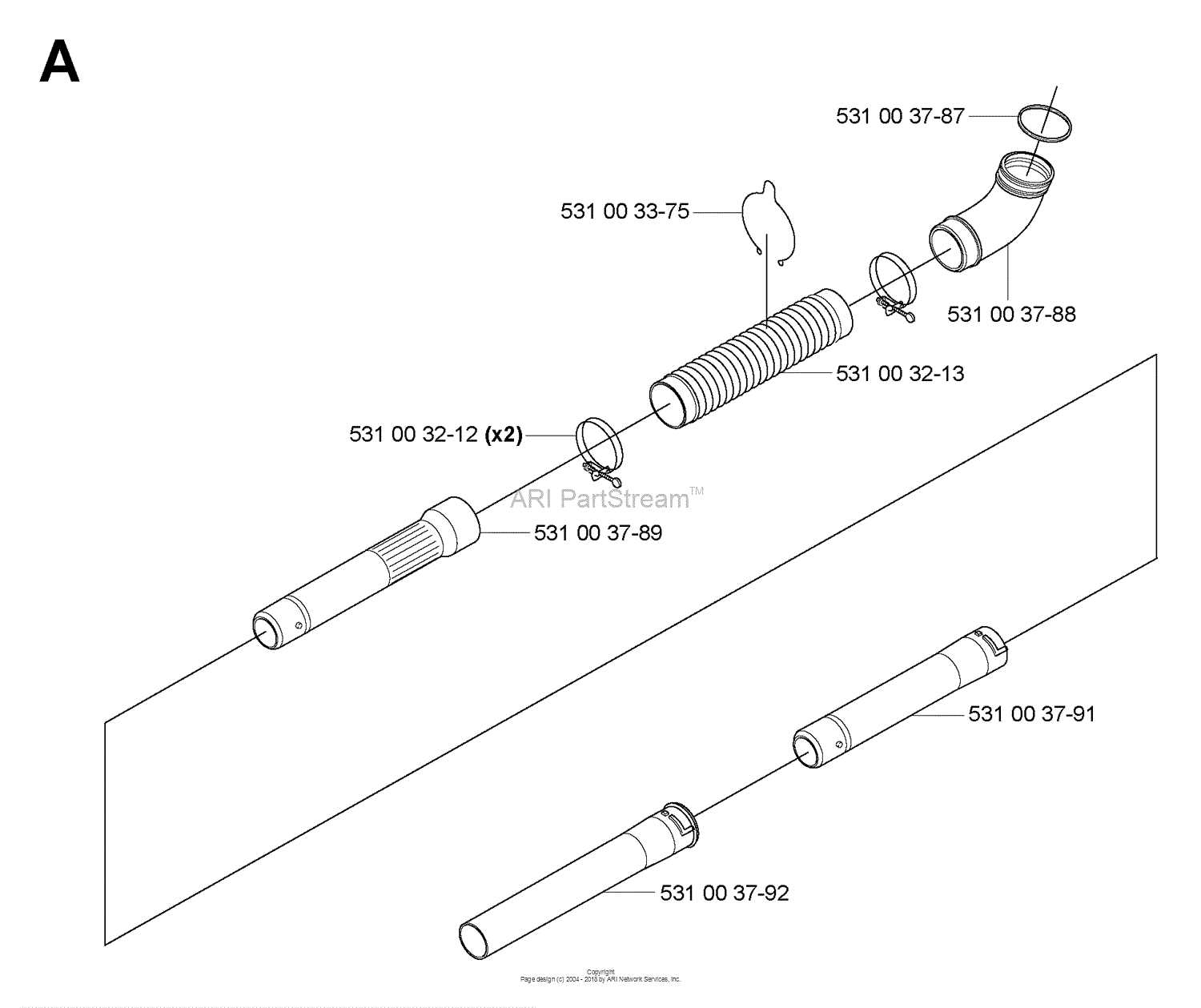

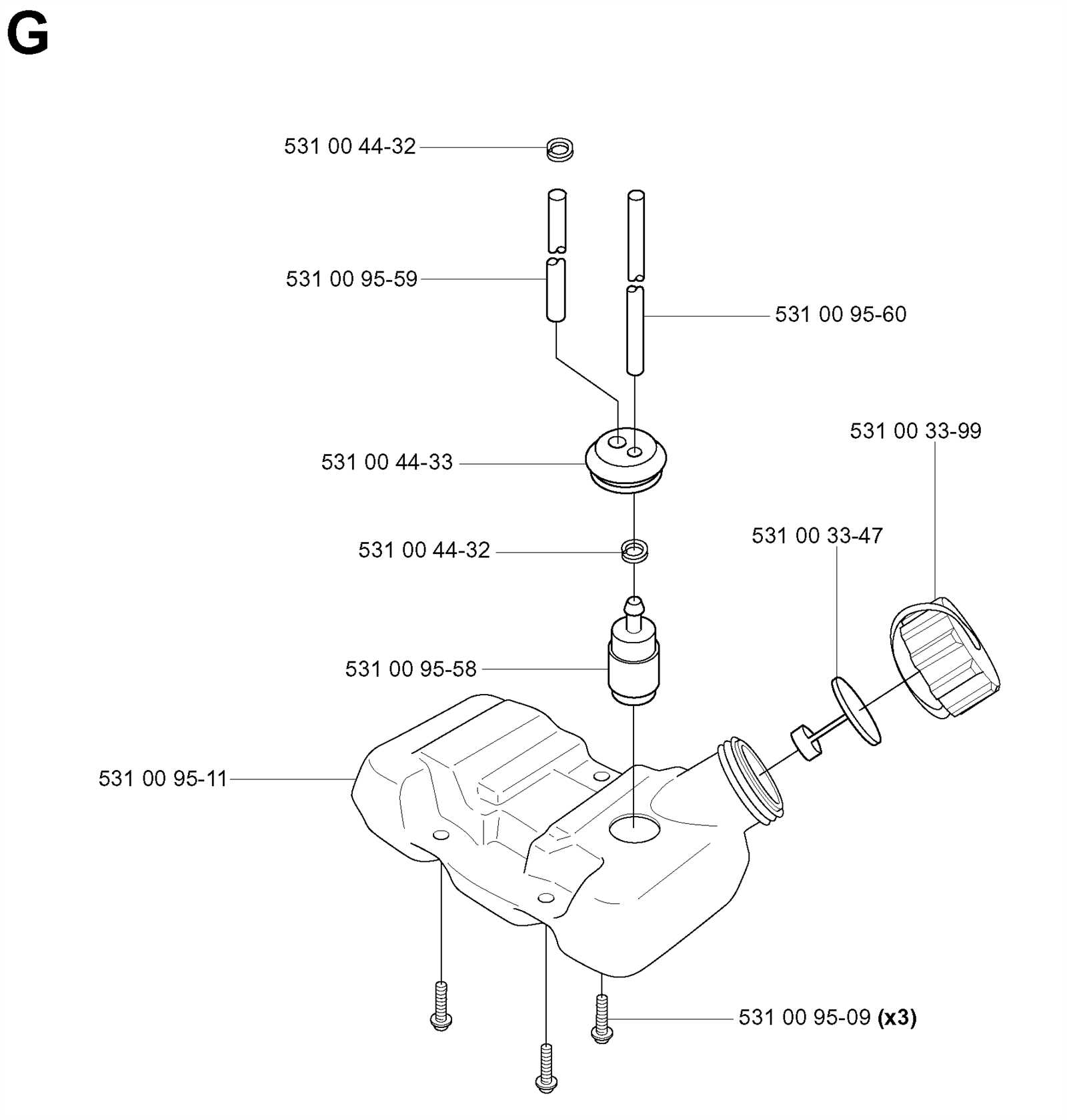

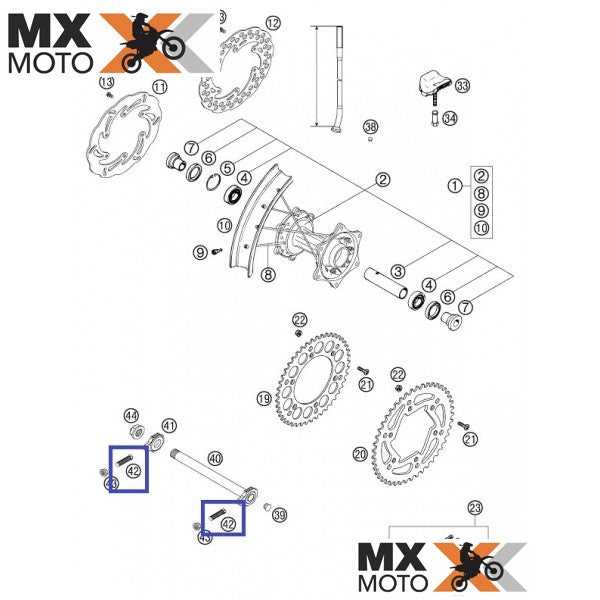

How to Read a Parts Diagram

Understanding a visual representation of components can greatly enhance your ability to identify and source necessary items for maintenance or repair. These illustrations serve as a roadmap, helping you visualize the relationship between different elements within a machine.

Familiarize yourself with the layout: typically, components are grouped logically, which can simplify your search. Numbers or letters often indicate specific parts, while accompanying lists provide detailed descriptions. Recognizing these symbols will facilitate your navigation.

Cross-reference the visual with the list to ensure you grasp each item’s function and compatibility. This process can reveal how components interact and highlight any potential replacements you may need.

By practicing this methodical approach, you can confidently tackle maintenance tasks and ultimately prolong the lifespan of your equipment.

Common Replacement Parts Overview

Understanding the essential components of outdoor power equipment is crucial for maintaining optimal performance. Regular wear and tear necessitates the timely replacement of certain items to ensure efficiency and longevity.

Here’s a look at some frequently replaced components that users should be aware of:

- Air Filter: Ensures clean air intake, vital for engine performance.

- Fuel Filter: Keeps the fuel system clear of impurities, enhancing fuel flow.

- Spark Plug: Critical for ignition, requiring periodic replacement to prevent starting issues.

- Starter Rope: Often wears out with repeated use, affecting the starting mechanism.

- Throttle Cable: Controls engine speed; a frayed cable can hinder operation.

By being aware of these common components, users can better manage their equipment and ensure it operates smoothly for years to come.

Identifying Faulty Components

Recognizing malfunctioning parts in outdoor power equipment is crucial for maintaining optimal performance and extending the lifespan of the machine. A systematic approach can help pinpoint the issues effectively.

To begin diagnosing problems, consider the following indicators:

- Unusual noises during operation

- Decreased efficiency or power output

- Excessive vibrations

- Difficulty starting or maintaining consistent operation

Once you’ve noted any of these symptoms, follow these steps for a more detailed analysis:

- Inspect the air filter for blockages or dirt buildup.

- Check fuel lines for leaks or cracks that may hinder performance.

- Examine the ignition system components for wear or damage.

- Review the condition of the spark plug for signs of fouling or corrosion.

- Look at the fan and housing for debris that could obstruct airflow.

By systematically assessing these areas, you can identify and replace any faulty components, ensuring your equipment operates smoothly and efficiently.

Tools Needed for Maintenance

Regular upkeep of your equipment is essential to ensure optimal performance and longevity. Having the right tools at hand can make the maintenance process more efficient and effective. Below is a list of necessary implements that will assist you in keeping your machine in top condition.

- Screwdrivers: Both flathead and Phillips types are essential for loosening and tightening screws.

- Wrenches: A set of adjustable and fixed wrenches will help you tackle various nuts and bolts.

- Socket Set: Useful for reaching tight spaces and providing better torque on fasteners.

- Pliers: Needle-nose and regular pliers are handy for gripping and twisting wires or small parts.

- Cleaning Brush: A stiff-bristled brush can effectively remove debris and dirt from various components.

- Fuel Container: For safely storing and transferring fuel during maintenance tasks.

- Protective Gloves: To safeguard your hands from chemicals and sharp edges.

Equipping yourself with these tools not only facilitates routine checks but also helps you address any issues promptly, ensuring that your equipment remains reliable for years to come.

Step-by-Step Disassembly Process

Disassembling equipment can be a straightforward task when approached methodically. This guide outlines a clear sequence for dismantling the device, ensuring that each step is easy to follow. Proper preparation and attention to detail are key to a successful breakdown, allowing for efficient cleaning, repairs, or part replacement.

Preparation and Safety

Before starting, ensure you have all necessary tools within reach. Safety gear, such as gloves and goggles, should be worn to protect against debris. Disconnect the power source to prevent accidental activation during the process. Organize a clean workspace to keep track of small components and fasteners.

Disassembly Steps

Begin with the outer casing, removing screws or clips that secure it in place. Gently lift it off to expose internal components. Next, identify and detach any connections, such as hoses or wires, taking care to note their placements. Use a container to store small parts as they are removed to avoid misplacement.

Proceed by taking out major assemblies, following the reverse order of installation where applicable. If necessary, consult a reference guide for the correct sequence to ensure nothing is overlooked. Finally, after all parts are removed, inspect each component for wear or damage, which may need attention during reassembly.

Reassembly Tips for Efficiency

When reassembling equipment, efficiency is key to ensuring smooth operation and longevity. A systematic approach not only streamlines the process but also minimizes the risk of errors and missing components. By following a few strategic tips, you can enhance your reassembly efforts and achieve optimal results.

Organize Your Workspace

A well-organized workspace is crucial for efficient reassembly. Start by gathering all necessary components and tools in one location. Use trays or containers to separate various parts, which can prevent mix-ups and facilitate quick access.

Follow a Step-by-Step Approach

Adopting a methodical, step-by-step approach is essential. Reference guides or manuals to understand the order of assembly, and check off each step as you complete it. This practice not only boosts efficiency but also helps to ensure that nothing is overlooked.

| Tip | Description |

|---|---|

| Label Components | Use labels or markers to identify different parts during disassembly. |

| Group Similar Parts | Keep similar items together to make reassembly quicker. |

| Use Proper Tools | Utilize the correct tools to avoid damage and ensure a proper fit. |

| Take Photos | Document the disassembly process with photos for reference. |

Where to Buy Genuine Parts

When maintaining outdoor equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Quality materials not only enhance the functionality of your tools but also provide peace of mind, knowing that your investments are protected. Here, we explore various avenues to acquire these essential items reliably.

Authorized Dealers

One of the most dependable methods to find authentic components is through authorized dealers. These retailers are officially recognized and often provide a wide range of products specific to your equipment’s requirements. They offer expert advice and often have access to the latest inventory.

Online Marketplaces

In today’s digital age, numerous online platforms specialize in outdoor equipment supplies. These websites often feature a comprehensive selection, allowing for easy comparison of prices and availability. It’s essential to choose reputable sites that guarantee the authenticity of their offerings.

| Source | Pros | Cons |

|---|---|---|

| Authorized Dealers | Expert advice, latest products | Higher prices |

| Online Marketplaces | Convenient, often lower prices | Risk of counterfeit items |

| Local Repair Shops | Personal service, local support | Limited stock |

Online Resources for Parts Diagrams

In today’s digital age, finding specific components for your outdoor equipment has never been easier. A variety of online platforms provide access to detailed visuals and breakdowns of various tools, enabling users to locate and order the necessary items efficiently. These resources not only enhance understanding but also assist in troubleshooting and maintenance tasks.

Manufacturer Websites often serve as the most reliable source for accurate visuals. They typically feature official representations of their products, complete with labels and part numbers, ensuring you can identify exactly what you need.

Online Retailers also play a crucial role. Many e-commerce platforms offer extensive catalogs that include images and descriptions of components, making it simple to compare options and find the best prices. User reviews can further guide your choices, providing insights into the quality and compatibility of various parts.

Forums and Community Groups are valuable for sharing experiences and tips. Enthusiasts often post links to helpful resources or even their own breakdowns, which can be incredibly useful for finding rare or discontinued items.

Finally, video tutorials can provide a visual walkthrough of assembly or disassembly, allowing you to see the parts in action and better understand how they fit together. These resources can empower you to tackle repairs with confidence and ensure your equipment remains in optimal condition.

Customer Reviews on Replacement Parts

Understanding the experiences of users regarding aftermarket components can significantly enhance decision-making for potential buyers. Feedback from fellow consumers provides valuable insights into quality, durability, and overall performance, which can help in selecting the right items for maintenance or repair. This section summarizes various reviews from customers who have purchased replacement components.

Quality and Durability

Many users emphasize the importance of quality in replacement items, noting that high-quality components tend to last longer and perform better. Several reviews highlight the following points:

| Review Summary | Rating |

|---|---|

| Excellent fit and finish; has held up well over months of use. | 5/5 |

| Good quality, but wear and tear started earlier than expected. | 3/5 |

| Perfect replacement; improved performance compared to the original. | 4/5 |

| Not as durable as I hoped; broke after a few uses. | 2/5 |

Value for Money

Cost is a significant factor when considering alternative components. Many customers share their perspectives on whether the investment was justified. Here are some key insights:

| Review Summary | Rating |

|---|---|

| Great value for the price; would purchase again without hesitation. | 5/5 |

| Affordable, but you get what you pay for; performance is mediocre. | 3/5 |

| High cost, but the quality is exceptional; worth every penny. | 4/5 |

| Cheap but very poor quality; not recommended. | 1/5 |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of outdoor equipment. Regular attention not only enhances performance but also extends the lifespan of your tools. Following a few key practices can significantly reduce wear and tear, allowing your machinery to operate optimally for years to come.

Regular Cleaning: Keeping your equipment clean is crucial. After each use, remove dirt, debris, and grass clippings. Use a soft brush or compressed air to reach intricate areas, ensuring no buildup affects functionality.

Routine Inspections: Conduct regular checks for any signs of wear, such as frayed cords or loose components. Early detection of issues can prevent more significant problems and costly repairs down the line.

Lubrication: Apply the appropriate lubricant to moving parts to reduce friction and prevent corrosion. Follow manufacturer recommendations for the best products and intervals for application.

Fuel Maintenance: Use fresh fuel and consider adding stabilizers if your equipment will sit unused for extended periods. This practice helps prevent gumming and ensures easy starts.

Storage Practices: Store your tools in a dry, sheltered location. If possible, keep them off the ground and covered to protect against moisture and pests. Additionally, remove any batteries if applicable.

By incorporating these simple maintenance habits, you can significantly enhance the performance and longevity of your outdoor tools, ensuring they remain reliable companions for your gardening and landscaping tasks.