Understanding the Parts Diagram for Husqvarna 322L

For anyone looking to maintain or repair their garden equipment, a clear understanding of its components is essential. Knowing how each element interacts not only facilitates smoother operation but also extends the lifespan of the machine. This overview aims to demystify the intricate layout of your tool’s internal and external parts, offering a roadmap for effective upkeep.

Identifying each section plays a crucial role in troubleshooting and enhancements. By breaking down the assembly, you can pinpoint potential issues or areas for improvement. This knowledge empowers you to tackle maintenance tasks with confidence, ensuring your device runs efficiently throughout the gardening season.

Whether you’re a seasoned professional or a casual gardener, familiarizing yourself with the individual components can transform the way you approach repairs and upgrades. Embracing this understanding will not only save you time but also enhance your overall gardening experience.

Understanding Husqvarna 322L Parts

Familiarizing yourself with the components of your outdoor equipment is crucial for maintenance and efficient operation. Each element plays a specific role, contributing to the overall functionality and performance. By grasping how these pieces work together, you can ensure a longer lifespan and optimal performance of your device.

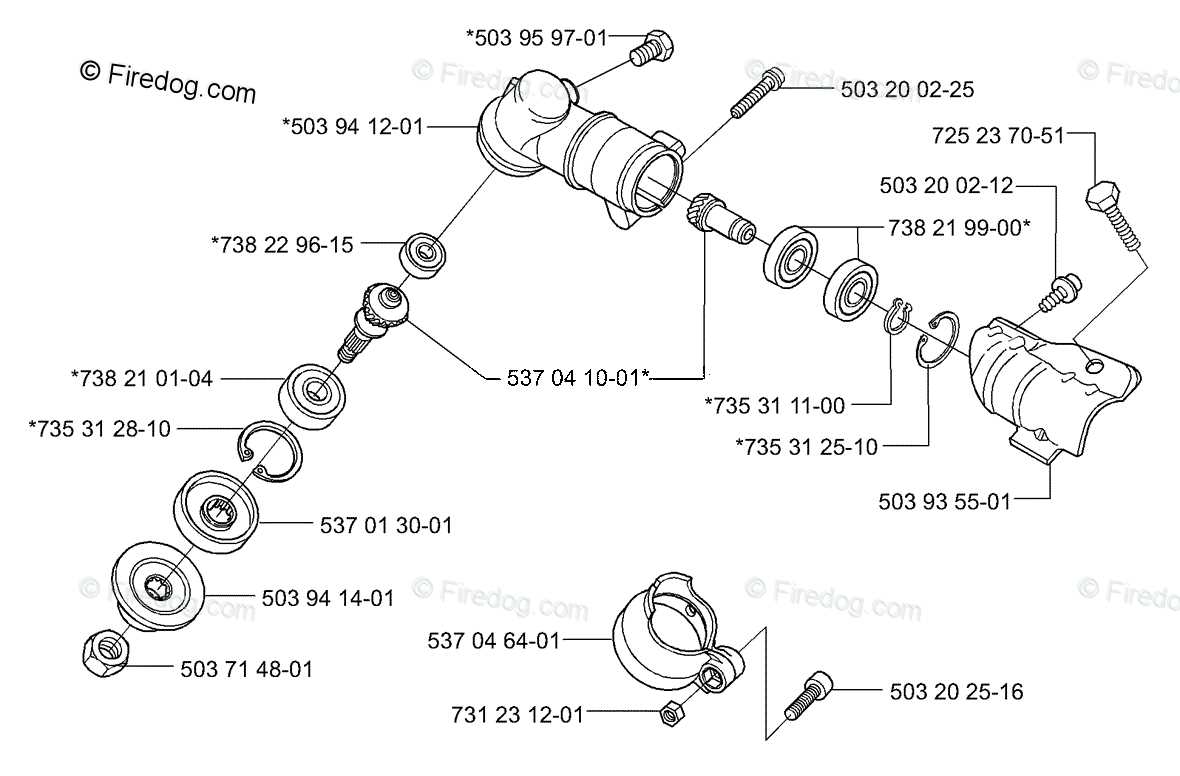

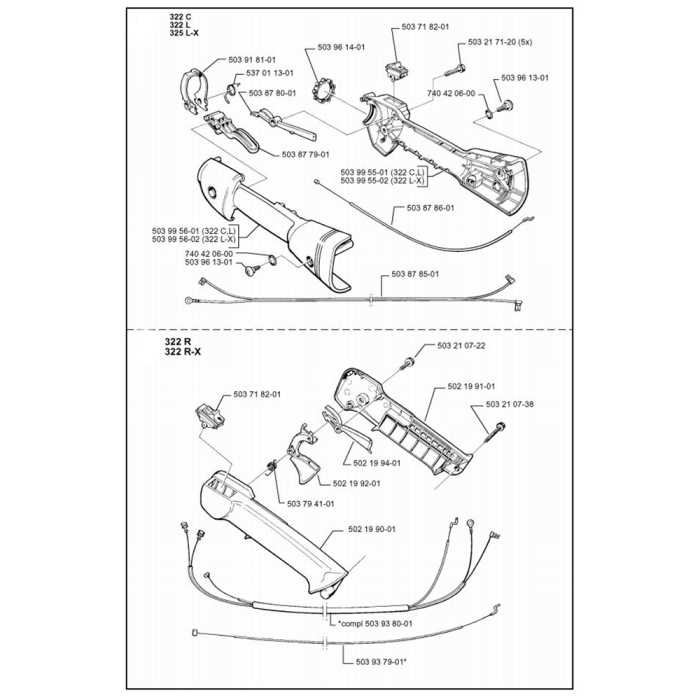

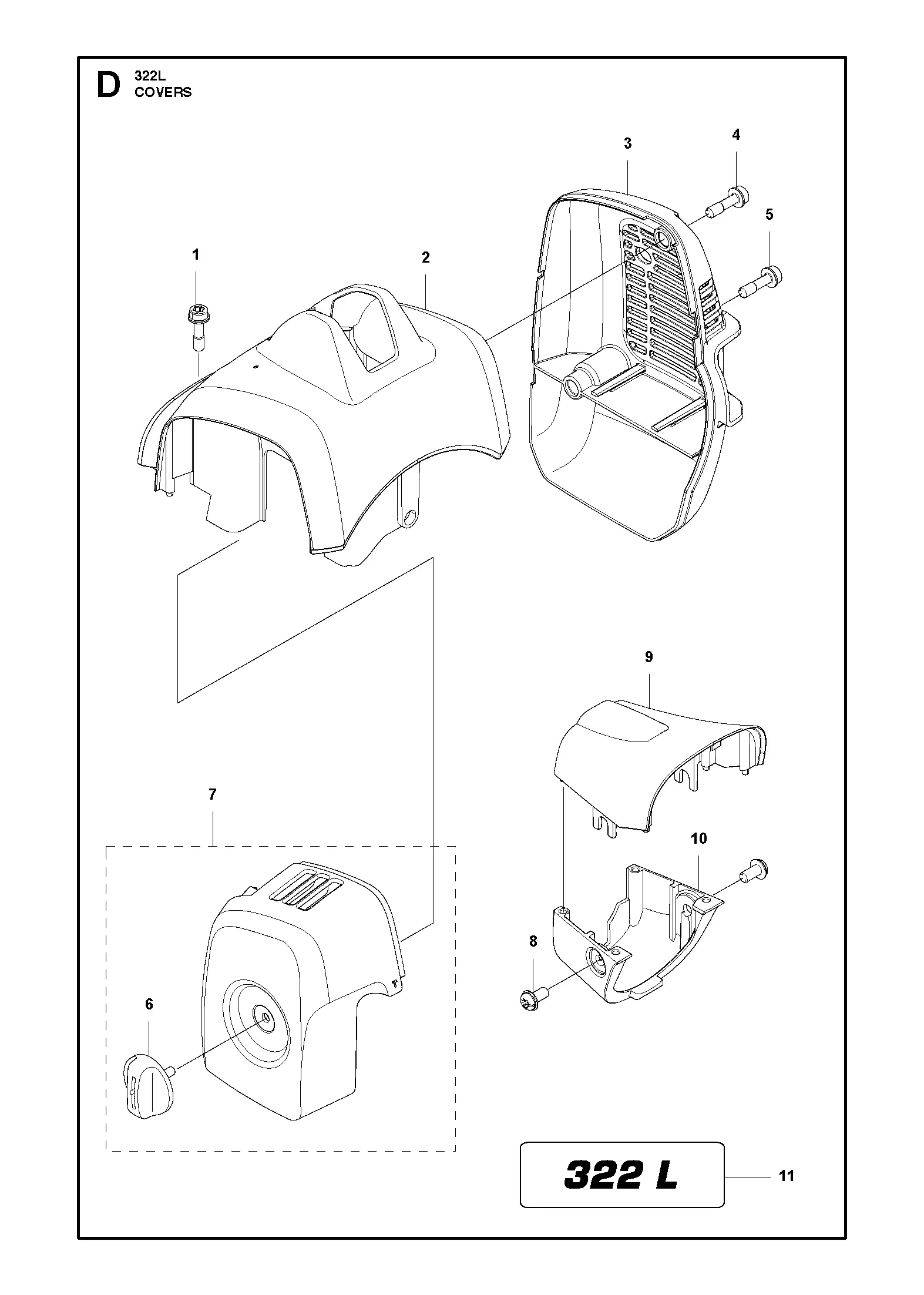

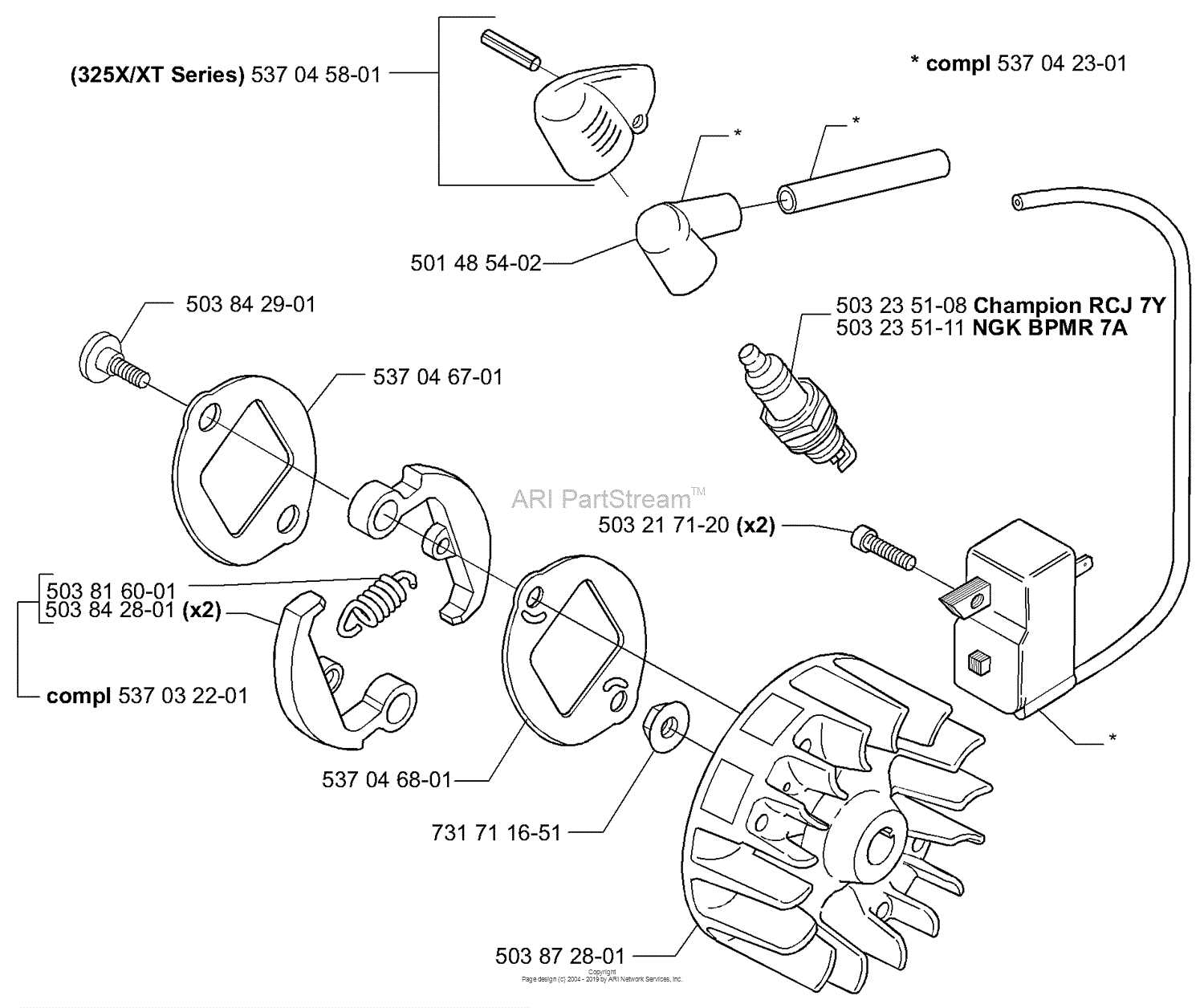

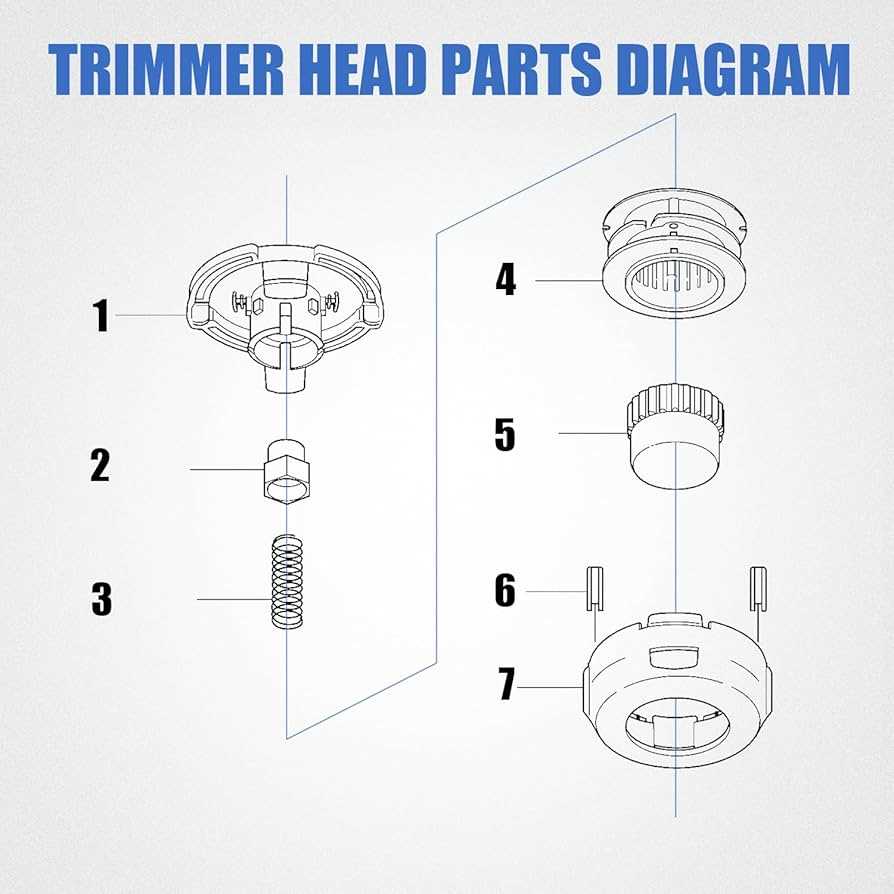

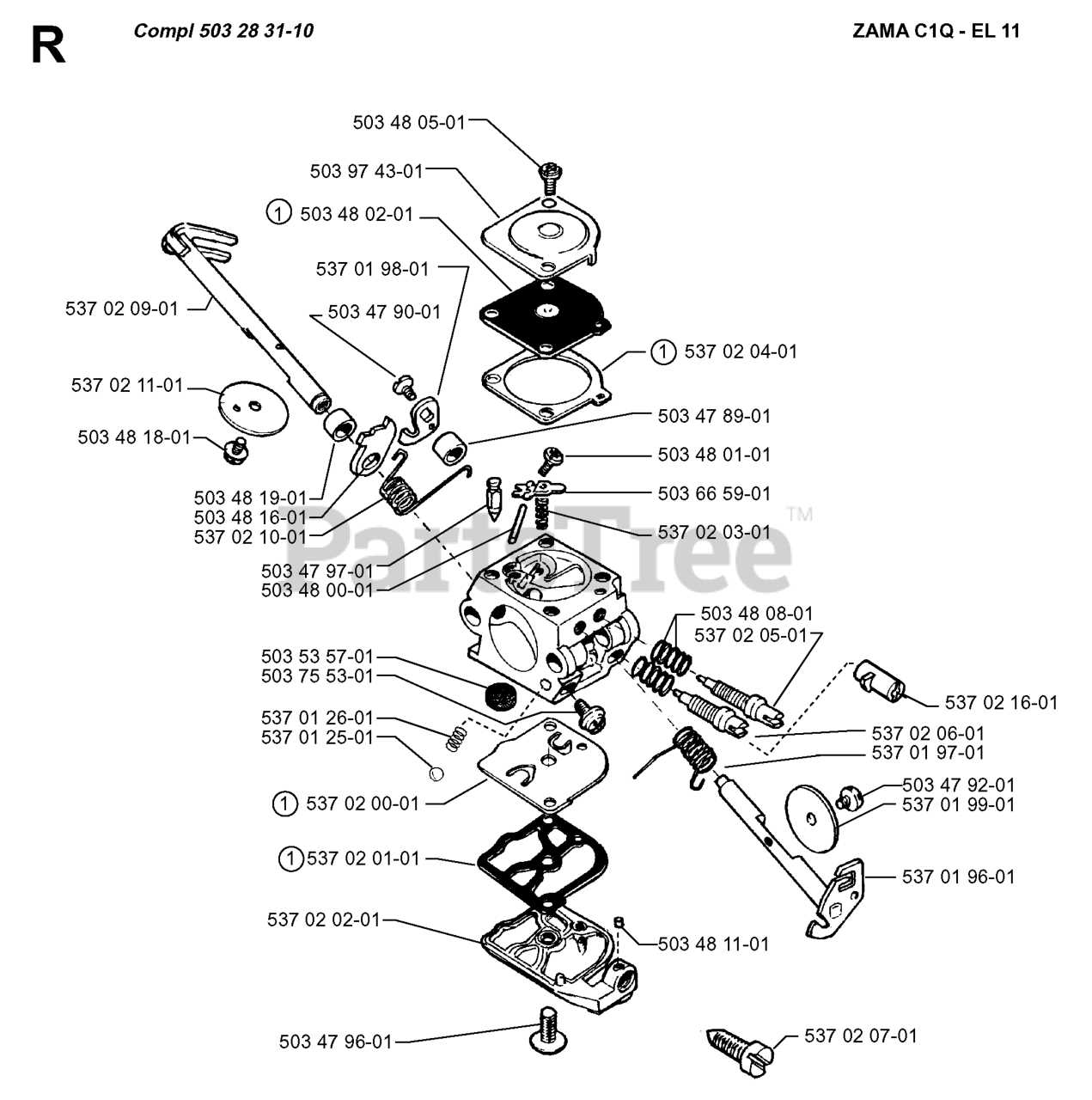

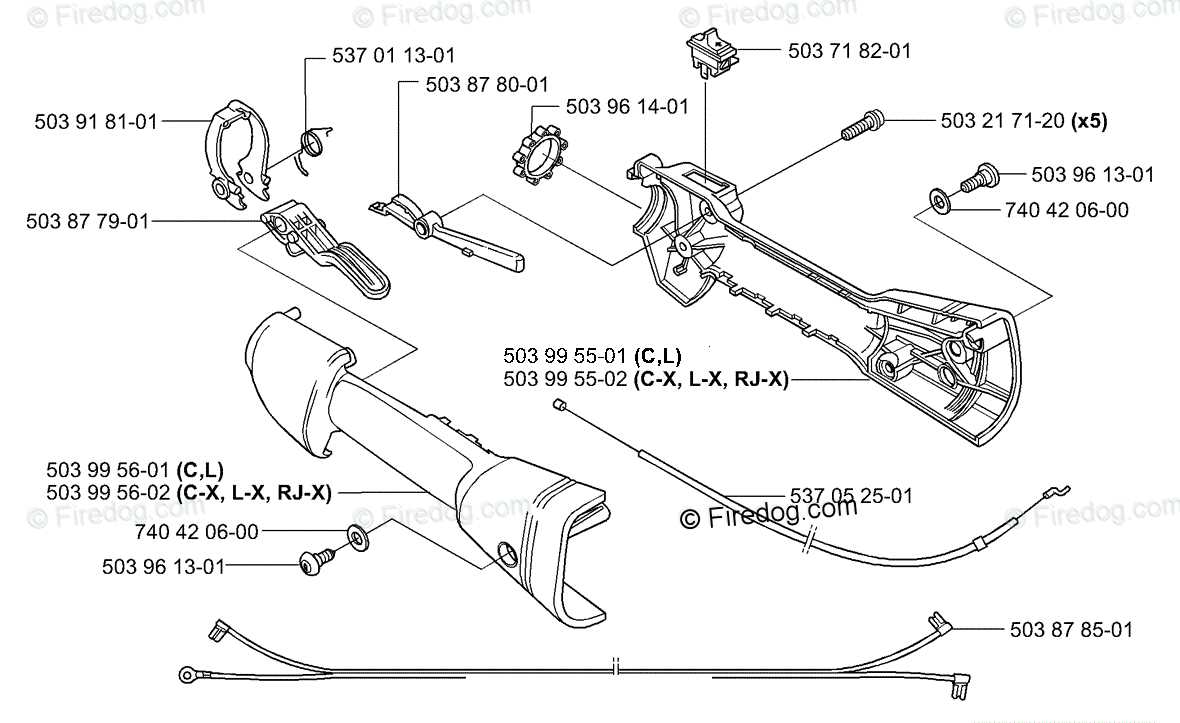

Identification of each component is the first step in effective upkeep. Familiarizing yourself with terms such as the engine assembly, fuel system, and cutting mechanism will enable you to diagnose issues and perform repairs with confidence. Each segment can be replaced or serviced as needed, making understanding their function essential.

Maintenance is significantly influenced by the knowledge of these components. Regular checks and timely replacements can prevent minor issues from escalating into major problems. Knowing what to look for during inspections can save both time and money, ultimately enhancing the longevity of your equipment.

Additionally, having access to a detailed reference can assist you in sourcing replacements when necessary. Reliable suppliers and clear descriptions of each item simplify the process, ensuring you can quickly find what you need. This preparedness allows for smoother operation and less downtime.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for maintenance and repair. Visual representations of individual elements serve as valuable tools, providing clear insights into how each piece fits and functions within the larger system. These illustrations are essential for both novice and experienced users, allowing for easier identification and sourcing of necessary components.

Moreover, such visual aids can significantly enhance troubleshooting efforts. When an issue arises, having a detailed overview facilitates quicker diagnosis and resolution. Technicians can quickly pinpoint the malfunctioning section and determine the appropriate steps for repair or replacement, ultimately saving time and resources.

Additionally, these representations are instrumental in promoting proper assembly and disassembly practices. By following visual guidance, users can avoid common mistakes that might lead to damage or inefficiency. This clarity not only improves the longevity of the equipment but also enhances overall performance.

In summary, visual schematics are indispensable in the realm of machinery maintenance. They provide clarity, enhance troubleshooting capabilities, and promote efficient handling of components, ensuring that equipment remains in optimal working condition.

Overview of the Husqvarna 322L

This model is designed for efficiency and versatility, making it an excellent choice for various outdoor tasks. Whether you need to maintain your garden or handle tougher jobs, this equipment offers the right blend of power and ease of use.

With a lightweight frame, it ensures comfortable handling, allowing users to operate it for extended periods without fatigue. The powerful engine provides ample performance for cutting through thick vegetation, while the innovative features enhance its usability and reliability.

This tool is also equipped with user-friendly mechanisms, making maintenance straightforward. Its durable construction guarantees longevity, allowing you to tackle demanding tasks season after season. Overall, this model represents a solid investment for anyone looking to enhance their outdoor work efficiency.

Common Replacement Parts Explained

Understanding the essential components of a gardening tool can significantly enhance its performance and longevity. Regular maintenance and timely replacements are crucial for optimal functionality. This section delves into frequently needed elements that contribute to the efficiency of your equipment.

- Cutting Head: Vital for trimming and edging, this component requires periodic replacement to ensure clean cuts.

- Air Filter: Prevents debris from entering the engine, making it essential for maintaining airflow and performance.

- Fuel Lines: These tubes transport fuel from the tank to the engine; replacing them can prevent leaks and enhance reliability.

- Starter Rope: A common wear item that may fray or break, necessitating replacement for easy starting.

- Spark Plug: Plays a crucial role in ignition; replacing it regularly ensures smooth engine operation.

Staying informed about these components can lead to a better understanding of your tool’s needs, ultimately ensuring it remains in peak condition.

Where to Find Diagrams Online

Locating detailed schematics for outdoor equipment can significantly enhance maintenance and repair tasks. Various resources are available online that provide these valuable visuals, making it easier to understand assembly and component relationships.

Manufacturer Websites

Official websites often host a wealth of resources, including manuals and comprehensive guides. Visit the support section of the manufacturer’s site to access the latest information directly.

Online Forums and Communities

Engaging with user communities can be beneficial. Platforms like forums and social media groups often share insights and links to helpful resources, allowing enthusiasts to collaborate and share their findings.

Tools Needed for Repairs

When tackling maintenance or fixing tasks, having the right equipment is crucial for a successful outcome. The ultimate selection of tools not only enhances efficiency but also ensures precision in your work.

Basic Hand Tools: A sturdy set of wrenches, screwdrivers, and pliers is essential. These items are fundamental for disassembling and reassembling various components.

Specialized Equipment: Depending on the repair, you may need specific tools like a torque wrench or a multimeter. These help in accurately measuring and applying the right force or voltage.

Safety Gear: Never underestimate the importance of protective equipment. Gloves, goggles, and masks safeguard against potential hazards during repairs.

Maintenance Supplies: Stock up on lubricants, cleaners, and replacement parts to facilitate smooth operation and extend the lifespan of your equipment.

By ensuring you have these tools at your disposal, you can delve deeper into repairs with confidence, leading to optimal results.

Step-by-Step Repair Process

This section outlines a comprehensive approach to troubleshooting and restoring your outdoor equipment. By following a systematic method, you can ensure effective repairs and prolong the lifespan of your device.

- Gather Necessary Tools:

- Screwdrivers

- Wrenches

- Replacement components

- Safety gear

- Inspect the Equipment:

- Look for visible damage

- Check for wear and tear

- Assess functionality

- Consult the Manual:

- Locate the repair instructions

- Identify specific parts needed

- Disassemble Carefully:

- Follow the reverse order of assembly

- Keep track of small parts

- Replace Faulty Components:

- Install new parts as needed

- Ensure proper fit and alignment

- Reassemble the Unit:

- Follow the assembly instructions

- Double-check connections and screws

- Test the Equipment:

- Run the device in a controlled environment

- Observe for any issues or irregularities

By adhering to these steps, you can effectively address common issues and enhance the performance of your machinery.

Identifying Worn Components

Recognizing deteriorated elements in garden equipment is crucial for maintaining optimal performance and safety. Various signs indicate wear, and understanding these can significantly enhance the longevity of your tools.

Visual Inspection: Regularly examine all parts for cracks, fraying, or discoloration. These physical indicators often suggest that components are nearing the end of their functional life.

Performance Issues: If you notice a decline in efficiency or unusual vibrations, this may signal that specific elements require attention or replacement. Pay close attention to how the equipment operates under load.

Wear Patterns: Look for uneven wear on surfaces that interact closely. These patterns can reveal misalignments or the need for replacement to restore proper function.

Timely identification of these issues will ultimately save time and resources, ensuring your equipment remains reliable and effective.

Ordering Genuine Husqvarna Parts

When it comes to maintaining your outdoor equipment, securing authentic components is essential for optimal performance and longevity. Genuine items ensure that your machinery operates smoothly and efficiently, minimizing the risk of malfunctions. This section will guide you through the process of acquiring original components, ensuring your tools remain in top condition.

Start by identifying the specific requirements for your equipment. Each model may have unique specifications, so referencing your owner’s manual is crucial. Once you know what you need, consider using official retailers or authorized dealers to guarantee authenticity. These sources provide a reliable selection and can often assist with inquiries regarding compatibility and installation.

Online platforms have made ordering straightforward. Look for reputable websites that specialize in outdoor equipment. Check for customer reviews and ratings to confirm the reliability of the seller. Additionally, many manufacturers offer direct purchasing options, ensuring you receive the exact components designed for your model.

Finally, keep an eye out for promotions or discounts on genuine items, as many retailers periodically offer deals. Investing in authentic components not only protects your equipment but also enhances your overall experience in using your outdoor tools.

Aftermarket vs. Original Parts

When maintaining outdoor equipment, the choice between replacement components from the manufacturer and alternative options can significantly impact performance and longevity. Understanding the differences between these two categories is essential for making an informed decision that meets both budget and quality requirements.

Original components are specifically designed for a particular model, ensuring optimal compatibility and performance. These parts are often made from high-quality materials, adhering to the manufacturer’s strict standards. Here are some advantages:

- Guaranteed fit and performance

- Potential for longer lifespan

- Manufacturer’s warranty typically included

On the other hand, aftermarket alternatives can offer a cost-effective solution with various options available. While these components may not always match the quality of original ones, they can provide benefits in certain situations:

- Lower prices, which can be appealing for budget-conscious consumers

- Wide range of choices, allowing customization

- Accessibility, as they may be easier to find in local stores

Ultimately, the decision should be based on specific needs, usage patterns, and personal preferences. Evaluating both types of replacements can help in selecting the best option for effective maintenance.

Maintenance Tips for Longevity

To ensure the extended lifespan of your outdoor power equipment, regular upkeep is essential. Proper care not only enhances performance but also reduces the likelihood of unexpected repairs. By following a few simple practices, you can keep your machinery in optimal condition and enjoy its benefits for years to come.

1. Regular Cleaning: After each use, clean the exterior and any visible components. Removing dirt, grass, and debris prevents buildup that can affect functionality.

2. Inspect and Replace Worn Parts: Periodically check for signs of wear and tear. Timely replacement of damaged components can prevent further issues and ensure safe operation.

3. Proper Lubrication: Keep moving parts well-lubricated to reduce friction and wear. Consult your manual for recommended lubricants and application frequency.

4. Fuel Maintenance: Use high-quality fuel and consider using a fuel stabilizer, especially if the equipment will sit unused for extended periods. This helps to prevent fuel degradation.

5. Seasonal Checkups: At the start of each season, conduct a thorough inspection. Look for any necessary adjustments or repairs to prepare your equipment for optimal performance.

6. Store Correctly: When not in use, store your machinery in a clean, dry place. Protect it from extreme temperatures and moisture to avoid rust and corrosion.

By implementing these maintenance tips, you can significantly enhance the durability and reliability of your outdoor tools, ensuring they serve you well for many years.

Frequently Asked Questions

This section aims to address common inquiries related to the maintenance and repair of outdoor power equipment. Understanding key components and their functions can significantly enhance the user experience and prolong the lifespan of your tools.

What should I do if my equipment is not starting?

If your device fails to start, first check the fuel level and ensure that fresh fuel is being used. Inspect the ignition system and air filter for any blockages or damage that may prevent proper operation.

How often should I perform maintenance?

Regular maintenance is essential for optimal performance. It’s recommended to conduct checks and service the machine at least once every season, or more frequently if used in demanding conditions.

Where can I find replacement components?

Replacement parts can typically be sourced from authorized dealers or online retailers specializing in outdoor equipment. Make sure to have the model number on hand for accurate identification.

What tools do I need for basic repairs?

Basic repairs generally require standard hand tools such as screwdrivers, wrenches, and pliers. Additionally, specific tools may be needed depending on the components being serviced.

How can I improve the longevity of my equipment?

To enhance durability, always store your tools in a dry place, clean them after use, and follow the manufacturer’s guidelines for maintenance and operation.

Contacting Customer Support for Help

When facing challenges with your equipment, reaching out to customer assistance can provide the guidance you need. Support teams are equipped to address inquiries and resolve issues effectively, ensuring your tools function optimally.

To initiate contact, locate the official support website, where you can find various communication options. Many companies offer phone support, email, and live chat features, allowing you to choose the most convenient method.

Be prepared with specific details about your device, including model number and a description of the issue. This information helps representatives assist you more efficiently. Additionally, check for any available resources like FAQs or troubleshooting guides on the website that may offer immediate solutions.

Always note the support hours to ensure you reach them during their operational times. Effective communication will enhance your experience and lead to a quicker resolution.