Exploring the Husqvarna 323L Parts Diagram for Ultimate Understanding

In the realm of gardening and landscaping, the efficient functioning of a cutting device heavily relies on the intricate assembly of its individual elements. A comprehensive understanding of these components can significantly enhance both maintenance and operational efficacy. By familiarizing oneself with the structure, users can easily identify parts that require attention or replacement, ensuring optimal performance over time.

Each element plays a pivotal role in the overall functionality of the tool, contributing to its reliability and ease of use. From the motor to the cutting head, knowing the specific functions and interrelations of these sections empowers operators to troubleshoot issues effectively. This knowledge not only aids in prolonging the lifespan of the equipment but also maximizes productivity in tasks that demand precision and power.

For enthusiasts and professionals alike, accessing a visual reference that illustrates the configuration of these components can be invaluable. Such resources enable users to gain insights into their equipment’s design and assist in the seamless execution of repairs and upgrades. Embracing this information leads to a deeper appreciation of the engineering behind these essential devices.

Understanding Husqvarna 323L Components

Exploring the intricacies of outdoor power tools involves a closer look at their various elements. Each component plays a crucial role in the machine’s functionality, contributing to its overall performance and efficiency. By familiarizing oneself with these parts, users can enhance their maintenance skills and optimize the tool’s lifespan.

| Component | Description |

|---|---|

| Engine | The powerhouse responsible for driving the equipment. |

| Fuel Tank | Stores the necessary fuel for operation. |

| Cutting Head | Facilitates the trimming and cutting tasks. |

| Handle | Provides control and maneuverability during use. |

| Guard | Ensures safety by shielding the user from debris. |

Essential Parts of the 323L Model

The efficient operation of this tool relies on a variety of crucial components that work in harmony. Understanding these elements is key for maintaining optimal performance and ensuring longevity. Each section plays a specific role, contributing to the overall functionality and user experience.

Key Components Overview

Below is a breakdown of the primary sections that are essential for effective operation:

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire machine, providing the necessary energy for operation. |

| Cutting Head | Responsible for executing the cutting action, designed for precision and efficiency. |

| Handle | Ensures user comfort and control during operation, allowing for maneuverability. |

| Fuel Tank | Stores the necessary fuel for powering the engine, designed for easy access and refueling. |

| Throttle Trigger | Regulates engine speed, enabling the operator to adjust power according to needs. |

Maintenance Considerations

Regular inspection and maintenance of these vital sections can significantly enhance the durability and effectiveness of the tool. Ensuring that each component is functioning correctly will help in avoiding unnecessary breakdowns and prolonging the life of the equipment.

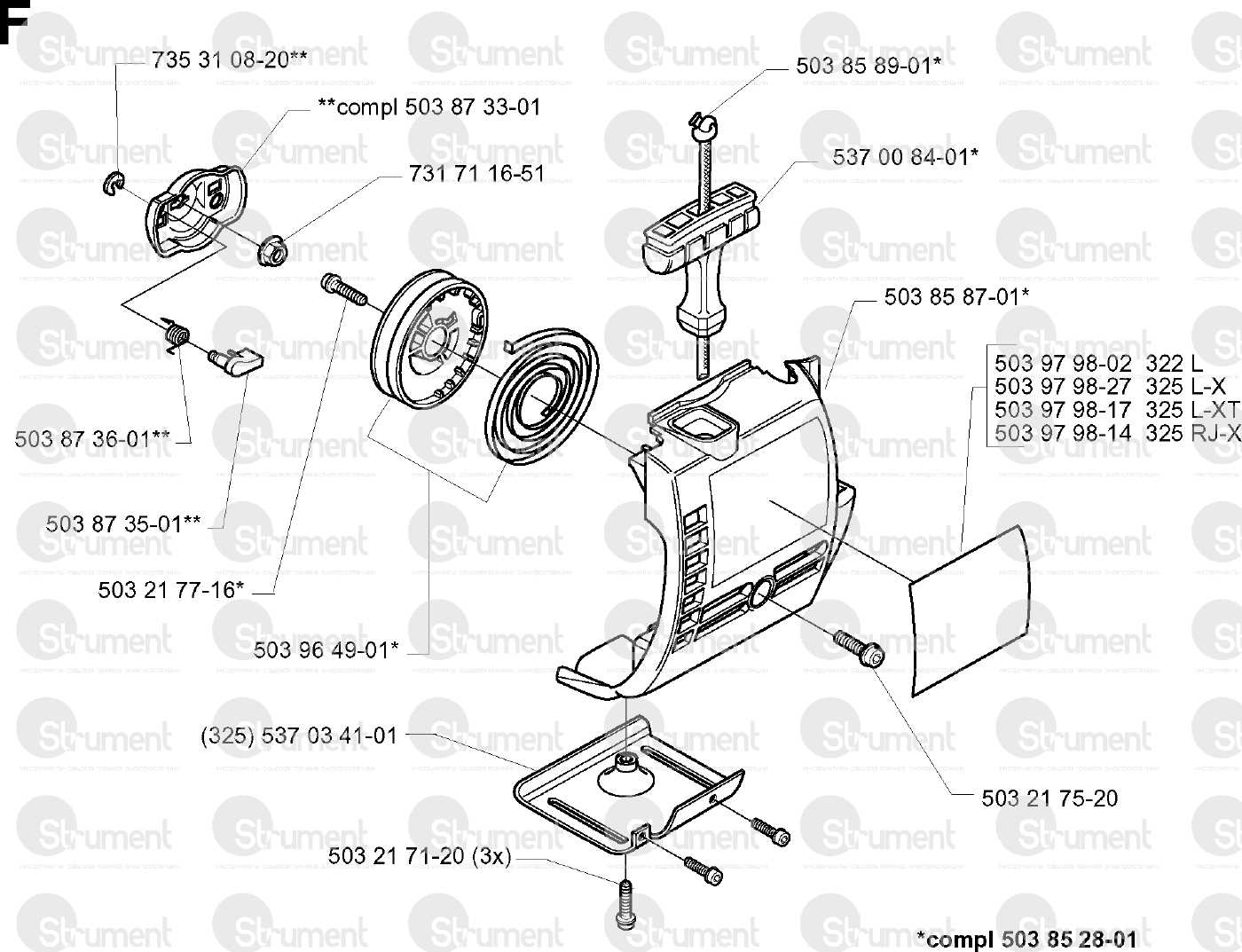

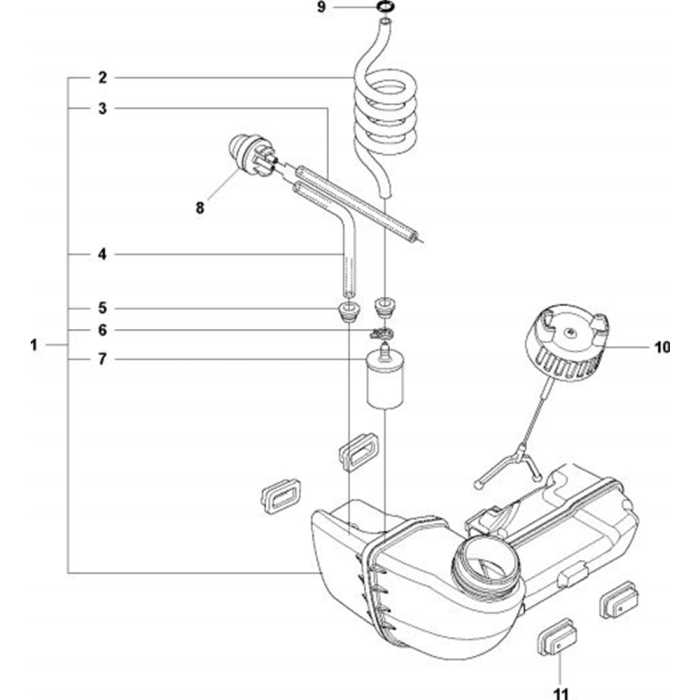

How to Interpret Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visual aids provide a detailed representation of components, helping users identify and source the necessary elements for their equipment. By familiarizing yourself with the symbols, labels, and layout, you can navigate these resources with confidence and accuracy.

Key Elements to Look For

When examining a visual representation, pay attention to the legends and numbering system used. Each part is typically labeled with a specific code or number that corresponds to a list, allowing for easy identification. Additionally, observe the arrangement of components, as it often reflects the assembly sequence and the relationship between different elements.

Decoding the Information

To fully grasp the content, cross-reference the illustration with the accompanying documentation. This may include descriptions of each component’s function and specifications. Familiarizing yourself with common symbols, such as arrows indicating movement or connection points, can further enhance your understanding and ensure you can effectively troubleshoot and replace parts as needed.

Common Repairs for Husqvarna 323L

Regular maintenance and timely repairs are essential for ensuring the longevity and efficiency of your outdoor equipment. Common issues often arise due to wear and tear, making it important to identify and address these problems swiftly. Understanding typical repairs can help users maintain optimal performance.

Fuel System Issues

One frequent problem involves the fuel system. Clogged filters or damaged fuel lines can hinder performance. Regularly checking these components is crucial. If issues persist, consider cleaning or replacing the affected parts to restore functionality.

Cutting Head Maintenance

The cutting head is another area that may require attention. Worn-out lines or blades can lead to ineffective cutting. Ensure you inspect the cutting components frequently and replace them when necessary to achieve the best results.

Where to Find Replacement Parts

Finding suitable components for your equipment can be crucial to maintaining its performance and longevity. There are various sources available for acquiring spare items, including both online retailers and physical stores. Exploring these options can help ensure you get quality materials for repairs or upgrades.

Online platforms often provide a wide selection of choices, allowing for quick comparisons between different sellers and products. Many websites also offer reviews from previous buyers, which can be helpful in making an informed decision. Additionally, local dealerships and specialized shops may carry a range of necessary items, offering expert advice and the ability to inspect products firsthand before purchasing.

When looking for replacements, it’s important to verify that the items are compatible with your specific model. Manufacturer websites and authorized distributors are good places to check for compatibility information and to ensure that you’re purchasing genuine, high-quality products.

Maintenance Tips for Optimal Performance

Ensuring that your equipment runs smoothly over time requires regular attention to its upkeep. Consistent care helps prevent wear and tear, enhancing longevity and efficiency. By following a few simple maintenance practices, you can avoid costly repairs and downtime, keeping your tool in top condition for extended use.

Start by routinely cleaning the machine after each use. Dirt, debris, and other particles can accumulate in critical areas, potentially affecting performance. Use a soft brush or cloth to wipe down the surfaces and clear any build-up.

Another key step is to inspect moving components regularly. Lubricating these parts can reduce friction, ensuring they operate seamlessly. Pay attention to any unusual noises or resistance, as these could signal that parts need lubrication or replacement.

Additionally, make it a habit to check fluid levels, such as fuel and oil. Low levels can cause inefficiencies or even damage. Refilling these fluids according to the manufacturer’s recommendations will keep the equipment functioning at its best.

Lastly, regular sharpening or replacement of certain components can significantly improve performance. Dull or worn-out parts hinder the machine’s efficiency, so keeping these in good condition is crucial for optimal operation.

Comparing 323L with Other Models

When selecting a tool from this line, it’s essential to understand how it stacks up against alternative models. Each one offers specific features that cater to different needs, from power output to handling comfort. By examining the differences and similarities, users can make informed decisions based on their specific tasks.

Power and Performance

One key area to compare is engine power. While some models are designed for lighter duties, others provide greater strength for more intensive tasks. This variation allows users to choose a tool that best matches the demands of their work, whether it’s regular maintenance or more challenging projects.

Ergonomics and Usability

Another significant factor is comfort during prolonged use. Different models may feature advanced ergonomics, including lighter weight and vibration-reduction technologies. These enhancements ensure that the equipment can be operated efficiently without causing undue strain on the user.

Assembly Instructions for Easy Repairs

For smooth and efficient maintenance, it’s essential to follow clear instructions that simplify the assembly process. By adhering to these steps, you can ensure that all components fit seamlessly, preventing future issues. This guide outlines the basic procedures needed to perform straightforward fixes without requiring expert knowledge.

Step-by-Step Overview

Begin by organizing the necessary tools and laying out the individual elements. Make sure that all pieces are cleaned and free of any debris before starting. Following these steps will help in reassembling the equipment smoothly and effectively:

| Step | Description |

|---|---|

| 1 | Align the base structure and ensure all connections are secure. |

| 2 | Insert the fastening pins, carefully matching the designated slots. |

| 3 | Tighten any bolts or screws, ensuring everything is firm but not overly tightened. |

| 4 | Check all moving parts for proper alignment and make adjustments as needed. |