Understanding the Parts Diagram of Husqvarna 325 LX

When it comes to maintaining outdoor machinery, having a clear view of its individual elements is essential for ensuring optimal performance. A thorough exploration of the assembly and its functionalities can significantly enhance user experience and longevity.

This section aims to provide a comprehensive overview of various elements that make up this particular model. By familiarizing yourself with these components, you can troubleshoot issues more effectively and undertake necessary repairs or upgrades.

Furthermore, an organized visual representation can serve as a valuable reference. Understanding how everything fits together not only aids in maintenance but also enriches your overall knowledge about the machinery you rely on.

Understanding Husqvarna 325 LX Components

Exploring the intricacies of a high-performance tool can enhance your appreciation of its engineering and functionality. Each element plays a crucial role in achieving optimal performance and efficiency.

Key Elements of the Tool

- Engine: Powers the entire mechanism, providing necessary energy for operation.

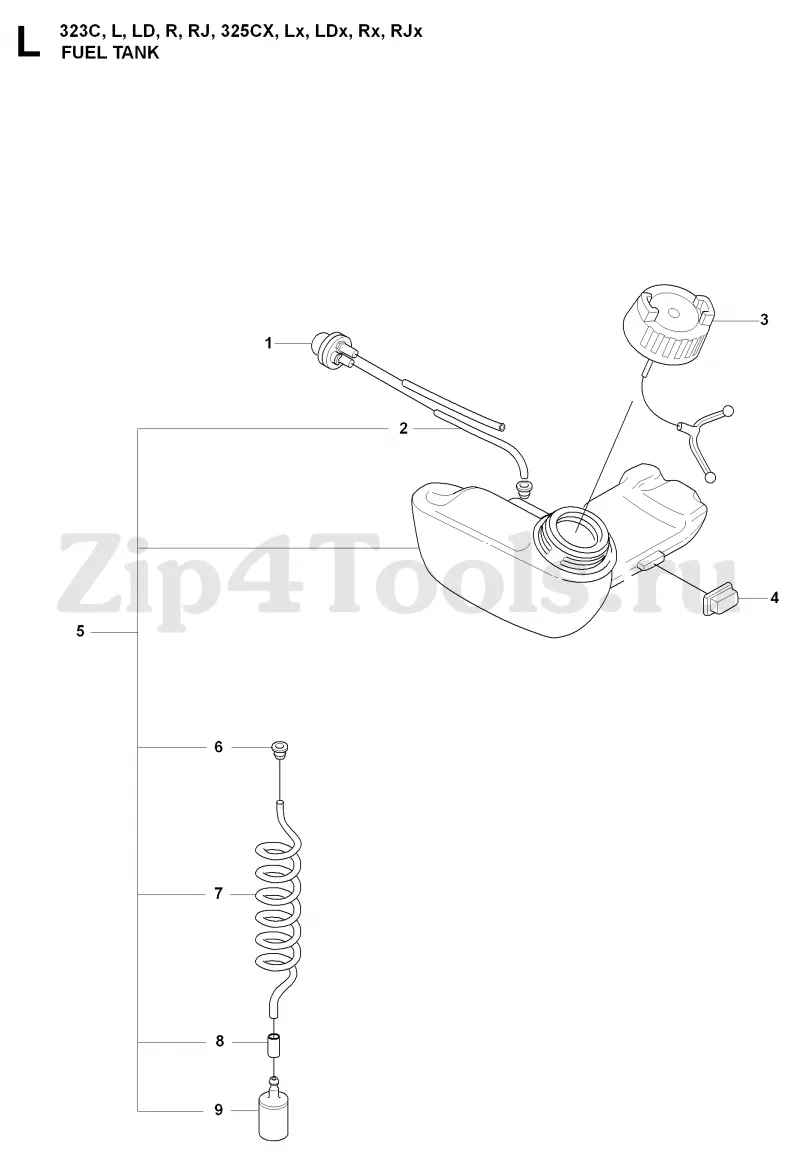

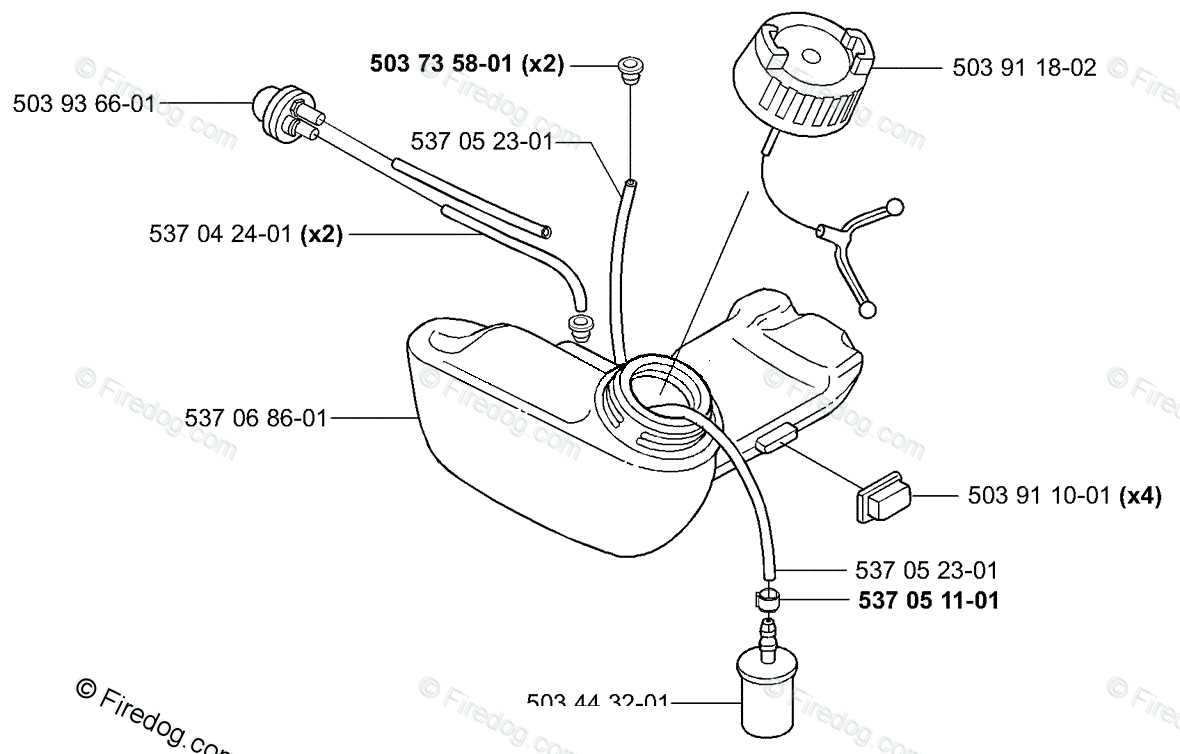

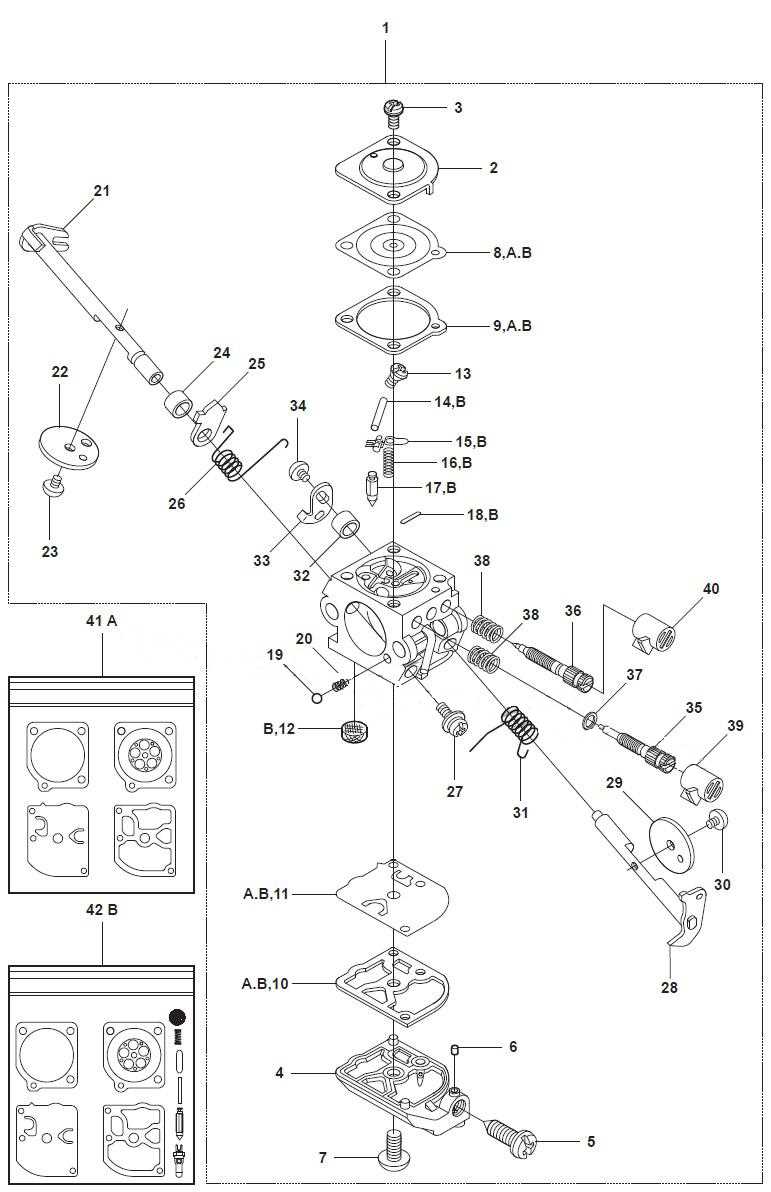

- Fuel System: Ensures the right mixture for combustion, affecting performance.

- Cutting Head: The main component responsible for executing tasks effectively.

- Handle: Provides grip and control, influencing maneuverability.

Maintenance Considerations

- Regular Inspection: Check for wear and tear to maintain functionality.

- Cleaning: Keep components free of debris for efficient operation.

- Replacement: Timely updates of worn parts enhance longevity.

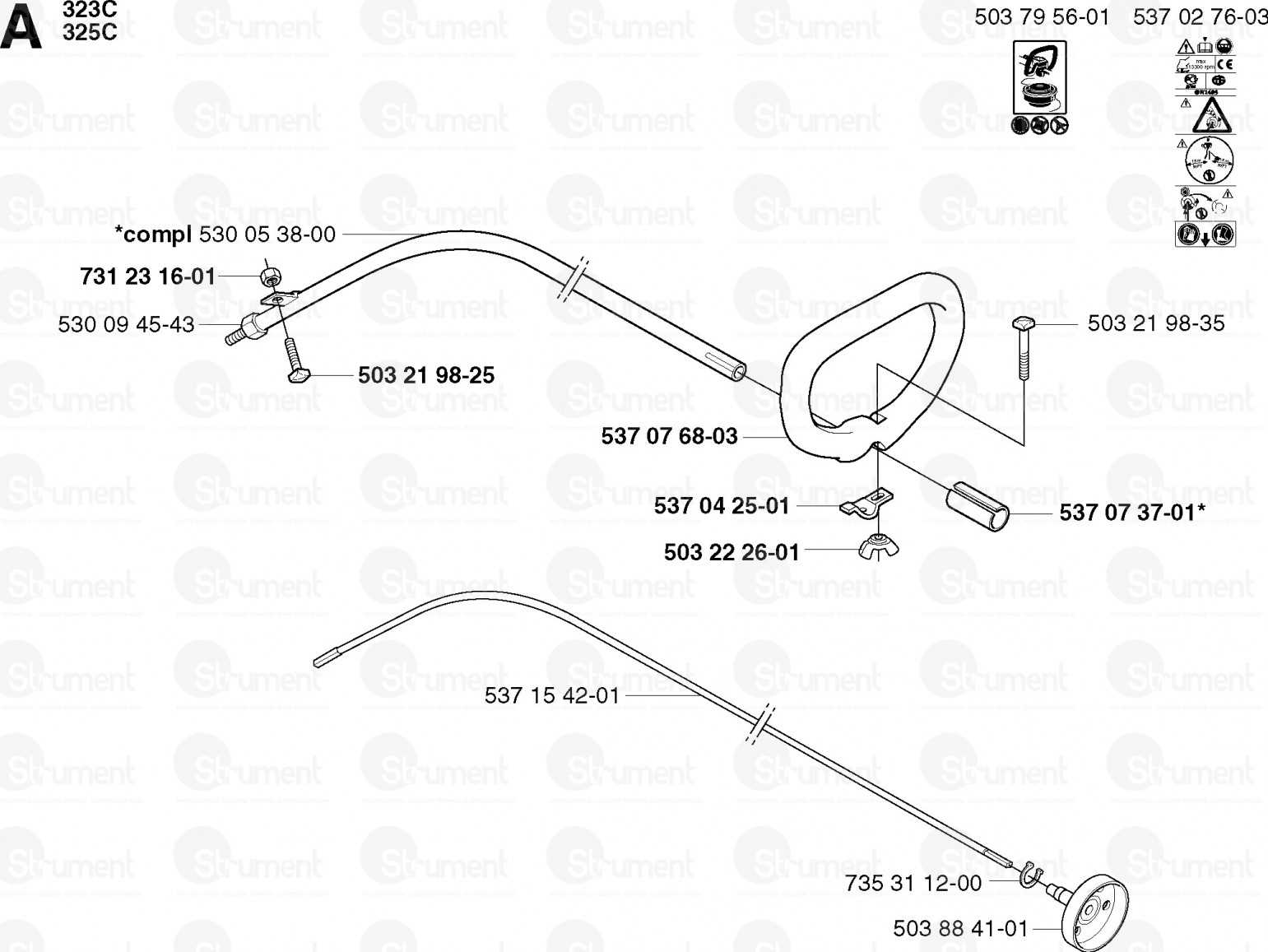

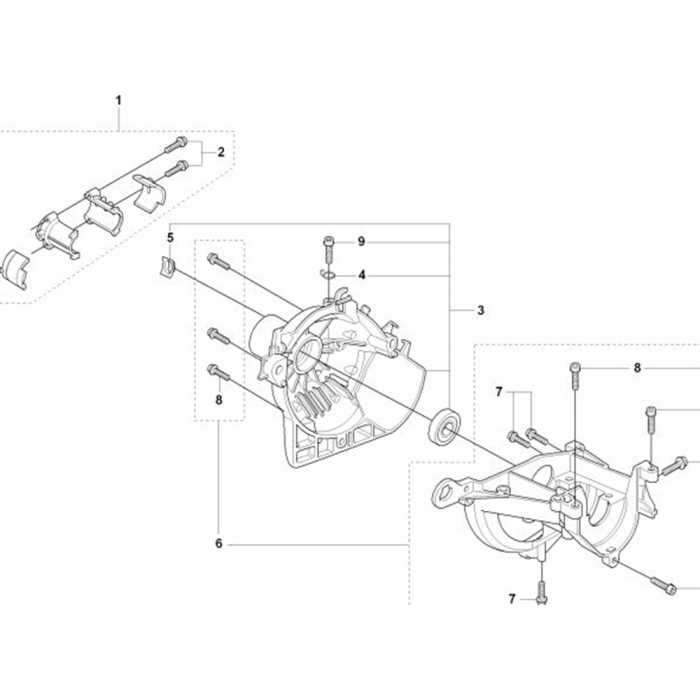

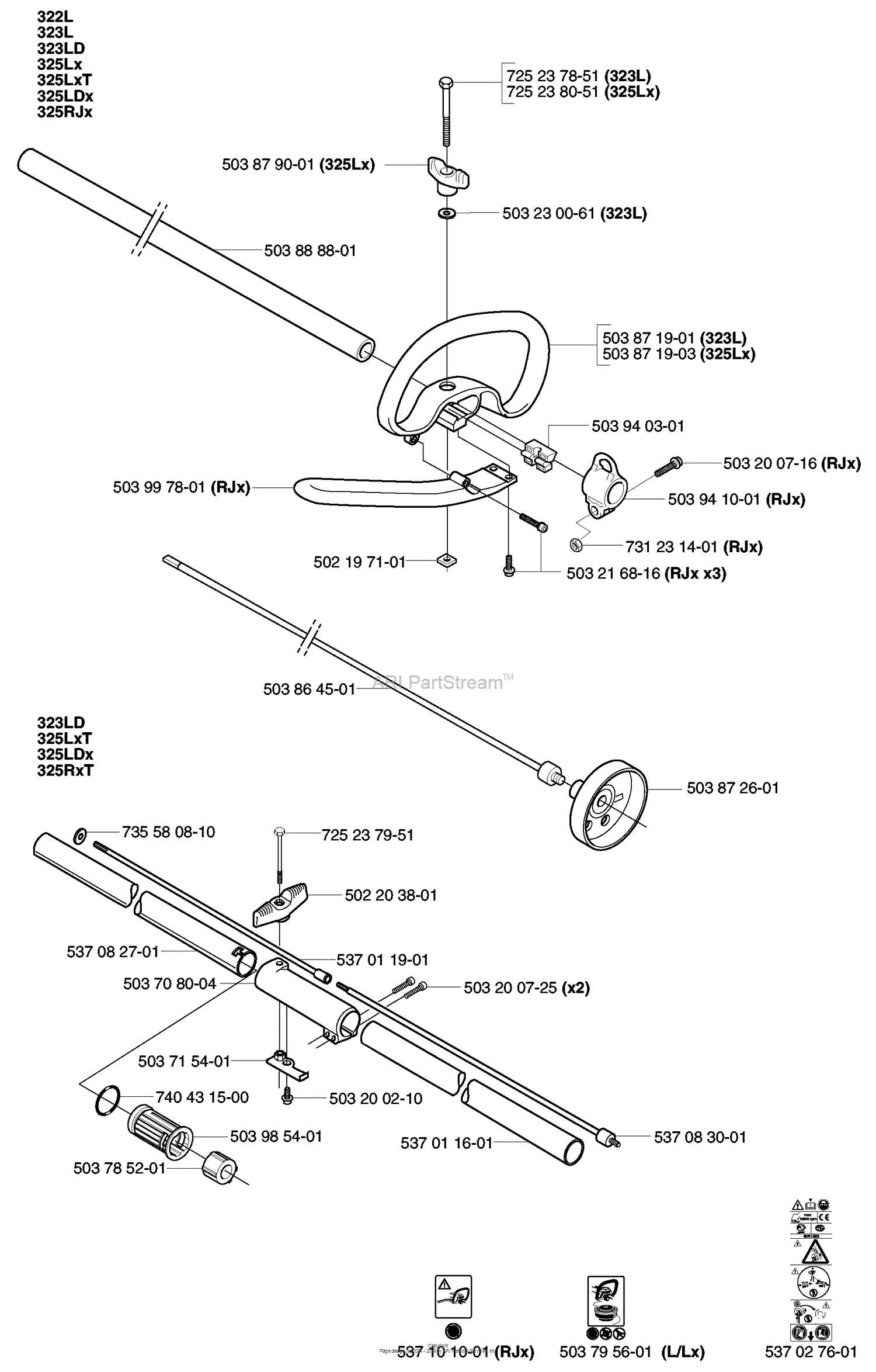

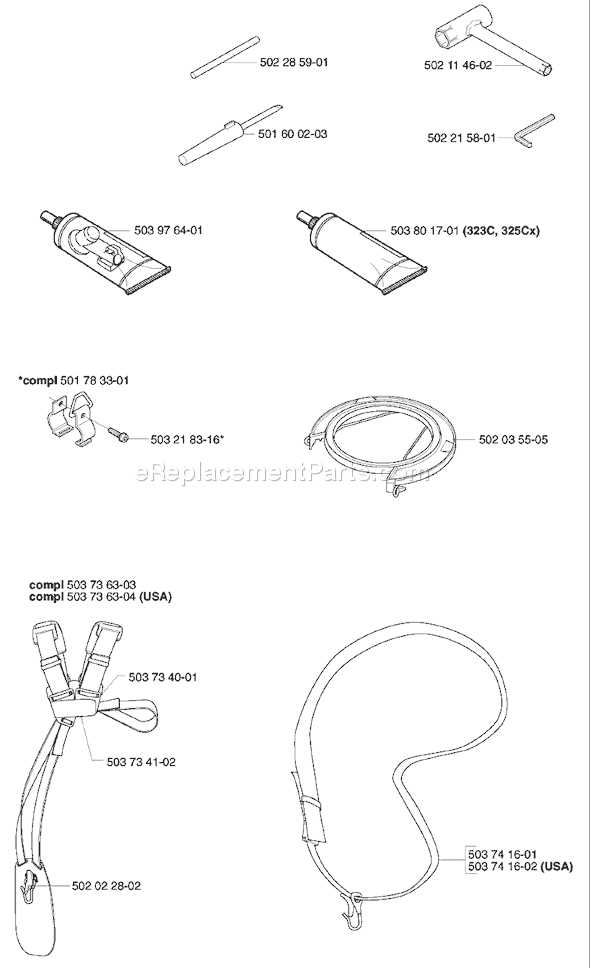

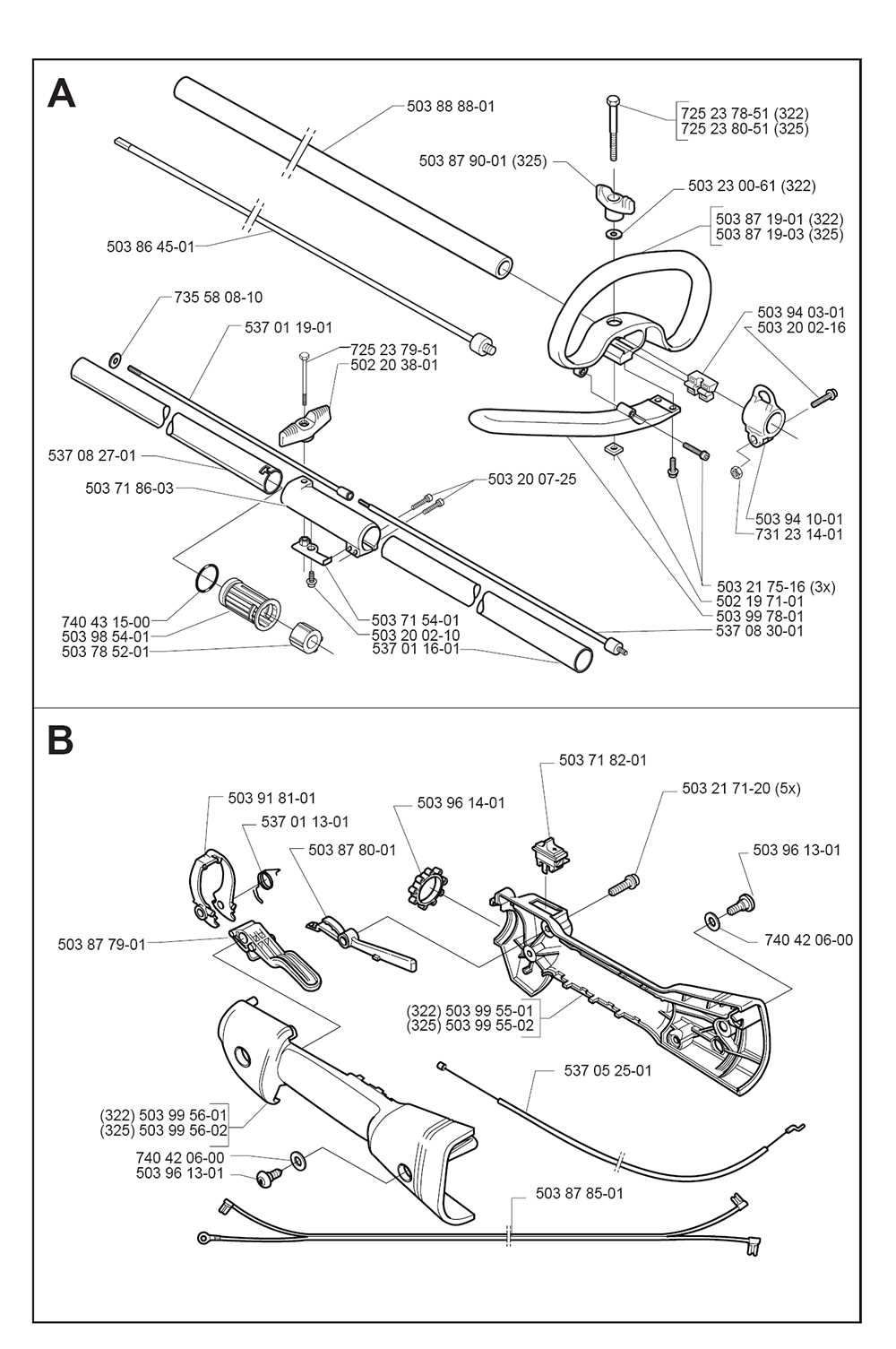

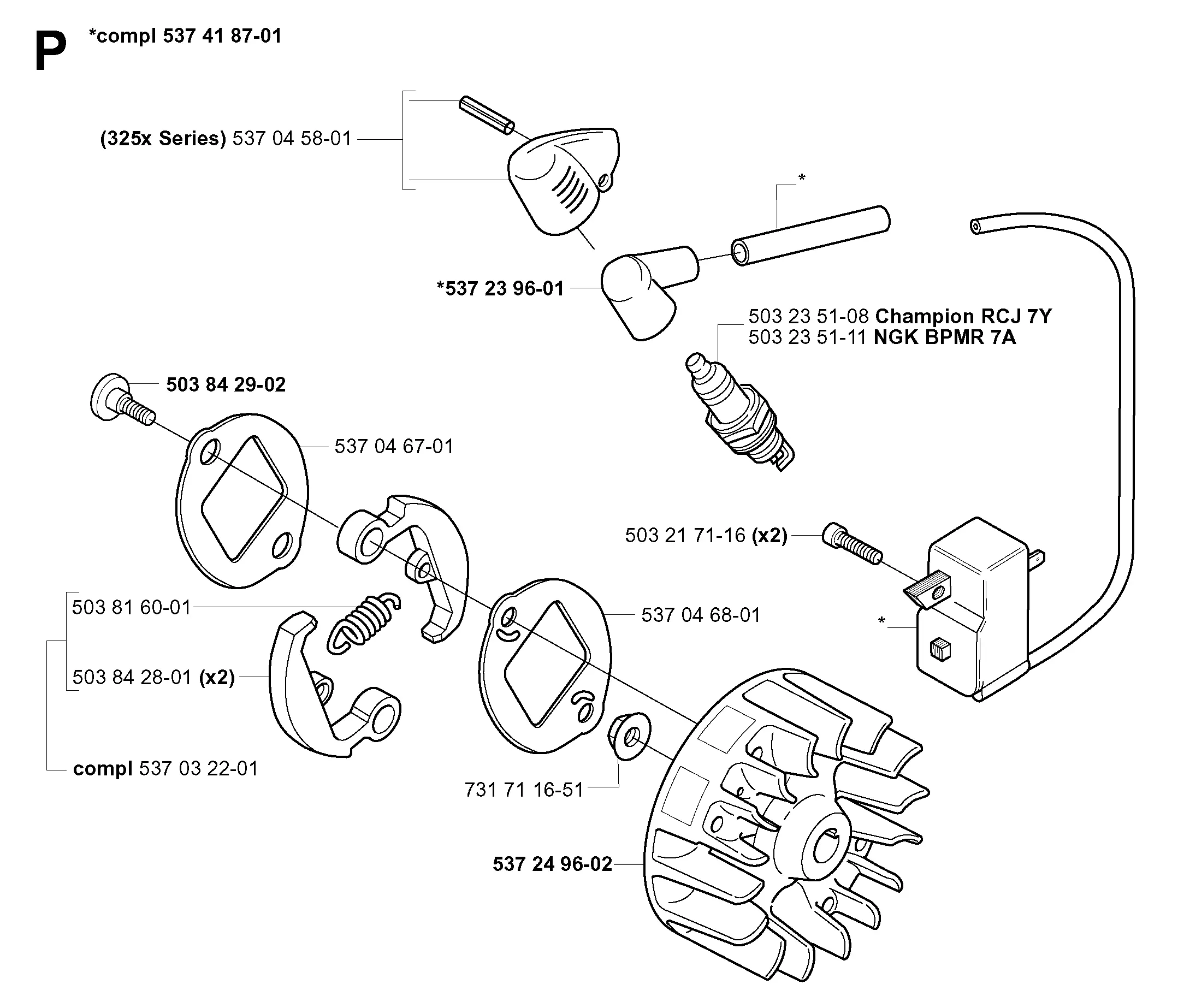

Importance of Parts Diagrams

Visual representations of components are essential tools for anyone involved in maintenance and repair tasks. They provide a clear layout of each element, enabling users to understand the assembly and disassembly processes more effectively. These illustrations serve as valuable references, ensuring that every piece is accounted for and correctly installed.

Utilizing these visual aids can significantly enhance the efficiency of repairs. By offering a comprehensive view of the various segments, they help identify specific parts that may require replacement or attention. This clarity reduces the chances of errors during maintenance, ultimately leading to better performance and longevity of the equipment.

Moreover, these representations facilitate communication between users and suppliers. When discussing replacements or specific issues, referring to a visual guide eliminates ambiguity, making it easier to convey precise needs. This can streamline the procurement process, ensuring that the right components are sourced promptly.

In summary, these visual aids are invaluable in the realm of equipment maintenance. They not only enhance understanding and efficiency but also foster effective communication, ultimately contributing to the overall success of repair and upkeep efforts.

Key Features of Husqvarna 325 LX

This model offers a range of outstanding attributes that enhance performance and user experience. With its robust design and advanced technology, it stands out in the market, catering to both casual users and professionals alike.

- Powerful Engine: Equipped with a high-performance engine, it delivers impressive power for efficient operation.

- Lightweight Construction: The ergonomic design minimizes fatigue, allowing for extended use without discomfort.

- Versatile Accessories: Compatible with various attachments, it adapts easily to different tasks, enhancing functionality.

- Easy Start System: The simplified starting mechanism ensures quick ignition, saving time and effort.

- Durable Build: Constructed with high-quality materials, it withstands wear and tear for long-lasting performance.

Overall, these features make this model an ultimate choice for those seeking reliability and efficiency in their outdoor tasks.

Common Issues and Solutions

Every outdoor power tool may encounter certain challenges over time. Understanding these common problems and their solutions can help ensure smooth operation and extend the lifespan of the equipment.

- Engine Not Starting:

- Check the fuel level and quality.

- Inspect the spark plug for wear or damage.

- Ensure the air filter is clean and unobstructed.

- Poor Performance:

- Examine the fuel mixture ratio.

- Look for clogs in the exhaust system.

- Ensure the cutting head is properly attached.

- Vibration Issues:

- Check for loose components or fasteners.

- Inspect the cutting attachments for damage.

- Ensure that the unit is balanced during operation.

- Overheating:

- Ensure proper ventilation during use.

- Check the cooling fins for debris.

- Monitor the runtime and take breaks as needed.

Identifying Replacement Parts Easily

When maintaining outdoor equipment, knowing how to locate specific components can save time and effort. Recognizing the essential elements of your machinery ensures smooth operation and prolongs its lifespan. By understanding the structure and function of each part, you can effectively identify what needs replacement when issues arise.

Utilizing Resourceful Guides

Accessing comprehensive manuals or online resources can be immensely helpful. These guides often include visual aids and detailed descriptions, allowing you to pinpoint the required items with ease. Always have the model number on hand to streamline your search and enhance accuracy.

Connecting with Support Communities

Engaging with user forums or communities can provide invaluable insights. Experienced users often share their knowledge, including tips on identifying specific components. Asking questions in these spaces can lead to quick and helpful responses, ensuring you make informed decisions about your equipment.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan and efficiency of your equipment. Regular maintenance not only prevents potential breakdowns but also ensures optimal performance during usage. Implementing a few simple practices can significantly extend the life of your machinery.

Regular Cleaning

Keeping your equipment clean is vital for its longevity. Dirt and debris can accumulate, affecting functionality and causing wear. After each use, take time to remove any build-up.

Routine Inspections

Conducting periodic checks on key components helps identify issues before they escalate. Look for signs of wear and tear, and replace any damaged parts promptly to maintain performance.

| Maintenance Task | Frequency |

|---|---|

| Clean equipment | After each use |

| Inspect components | Weekly |

| Oil moving parts | Monthly |

| Replace filters | Every season |

Where to Find Authentic Parts

Finding genuine components for your outdoor equipment is essential for ensuring optimal performance and longevity. With the right approach, you can locate reliable sources that offer quality replacements, maintaining the integrity of your machine.

One of the best places to start is through authorized dealers, who typically carry a comprehensive selection of original items. These retailers are knowledgeable and can provide guidance on the correct specifications for your model, ensuring you get exactly what you need.

Online marketplaces are another viable option. Reputable websites often feature original components, but it’s crucial to verify the seller’s credibility. Look for customer reviews and ratings to ensure you’re purchasing from a trustworthy source.

Additionally, manufacturer websites often have dedicated sections for replacements, allowing you to browse and order directly. This not only guarantees authenticity but also provides access to the latest innovations and updates in available products.

Lastly, local repair shops may also have access to genuine stock or can assist you in sourcing the right items. Building a relationship with these professionals can lead to valuable insights and recommendations for maintaining your equipment effectively.

Cost Comparison of Components

When considering maintenance and repairs, evaluating the expenses associated with various components is crucial. Understanding the pricing dynamics can help users make informed decisions regarding replacements and upgrades. This section aims to provide a comprehensive analysis of the cost differences among essential parts, ensuring that you can effectively budget for your equipment needs.

Essential Components Pricing

The prices of key components can vary significantly based on brand, quality, and availability. Typically, engine parts tend to be among the most expensive, reflecting their critical role in overall performance. In contrast, accessories such as handles or protective covers usually come at a lower cost, making them more accessible for regular maintenance.

Aftermarket vs. Original Equipment

One of the primary considerations in component pricing is whether to choose aftermarket or original equipment options. Aftermarket parts often present a more budget-friendly alternative, but they may differ in quality and durability. Original equipment manufacturer (OEM) parts, while generally more expensive, ensure compatibility and reliability, which can be vital for long-term performance. Balancing cost and quality is essential in making the right choice for your needs.

Installation Guide for Major Parts

This section provides a comprehensive overview of the installation process for essential components of your machine, ensuring optimal performance and longevity. Following these guidelines will help you achieve the best results.

- Preparation:

- Gather necessary tools and replacement components.

- Read the user manual for specific instructions.

- Step-by-step Installation:

- Start by disconnecting the power source to ensure safety.

- Carefully remove the old component, taking note of how it is fitted.

- Align the new part with the designated slots.

- Secure the component using the appropriate fasteners.

- Final Checks:

- Ensure all connections are tight and secure.

- Reconnect the power and test the installation.

By following these steps, you can effectively install major components and enhance the efficiency of your equipment.

Safety Considerations During Repair

When undertaking maintenance or repair tasks, prioritizing safety is essential to prevent accidents and injuries. Understanding potential hazards and following best practices can create a safer working environment. This section outlines key safety measures to consider during any repair process.

Personal Protective Equipment (PPE)

Using the right personal protective gear is crucial. Consider the following items:

- Gloves: Protect hands from sharp edges and chemical exposure.

- Safety goggles: Shield eyes from debris and hazardous materials.

- Hearing protection: Reduce noise exposure when using loud tools.

- Dust masks: Prevent inhalation of harmful particles.

Tool Safety

Ensure safe use of tools to minimize risks:

- Inspect tools for damage before use.

- Use the appropriate tool for each task.

- Keep work areas well-lit and organized to avoid tripping hazards.

- Disconnect power sources when servicing electric equipment.

By adhering to these safety guidelines, you can help ensure a safe and effective repair process.