Understanding the Husqvarna 336FR Parts Diagram for Efficient Maintenance

Maintaining outdoor machinery requires a deep understanding of its inner workings. By exploring the essential elements that contribute to its functionality, users can ensure optimal performance and longevity. This knowledge not only enhances repair skills but also empowers owners to make informed decisions regarding upgrades and maintenance.

Each component plays a pivotal role in the overall efficiency of the machine. Familiarizing oneself with these individual parts can streamline troubleshooting processes and minimize downtime. Additionally, recognizing how these elements interact with one another allows for a more comprehensive approach to maintenance.

In this guide, we will delve into the intricate details of these crucial components, offering insights into their arrangement and function. Ultimately, understanding this machinery will equip you with the tools necessary to keep your outdoor equipment in peak condition.

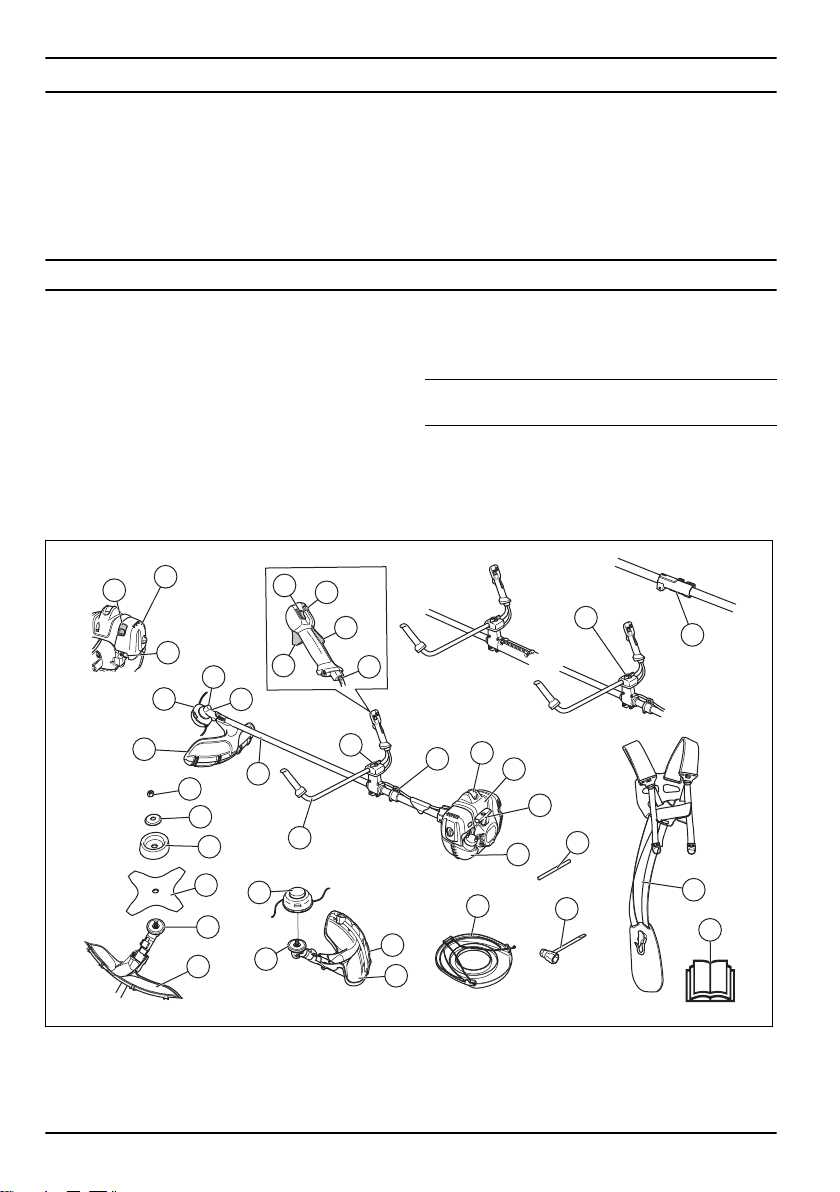

Understanding Husqvarna 336FR Overview

This section aims to provide an insightful examination of a popular outdoor power tool designed for various landscaping tasks. Its robust build and versatile features make it an essential addition to any gardener’s toolkit.

Key characteristics include:

- Powerful engine performance for efficient operation.

- Lightweight design that enhances maneuverability.

- Ergonomic handle for reduced fatigue during extended use.

To fully appreciate this tool, it’s important to consider its components and how they contribute to overall functionality. Below are some vital elements:

- Engine: The heart of the machine, ensuring reliable power delivery.

- Cutting head: Designed for optimal cutting efficiency and ease of maintenance.

- Fuel system: Enables smooth operation and reduces emissions.

Understanding these aspects not only improves the user experience but also aids in troubleshooting and maintenance, ensuring longevity and performance. Overall, this machine exemplifies a blend of power and practicality, making it a favored choice among professionals and enthusiasts alike.

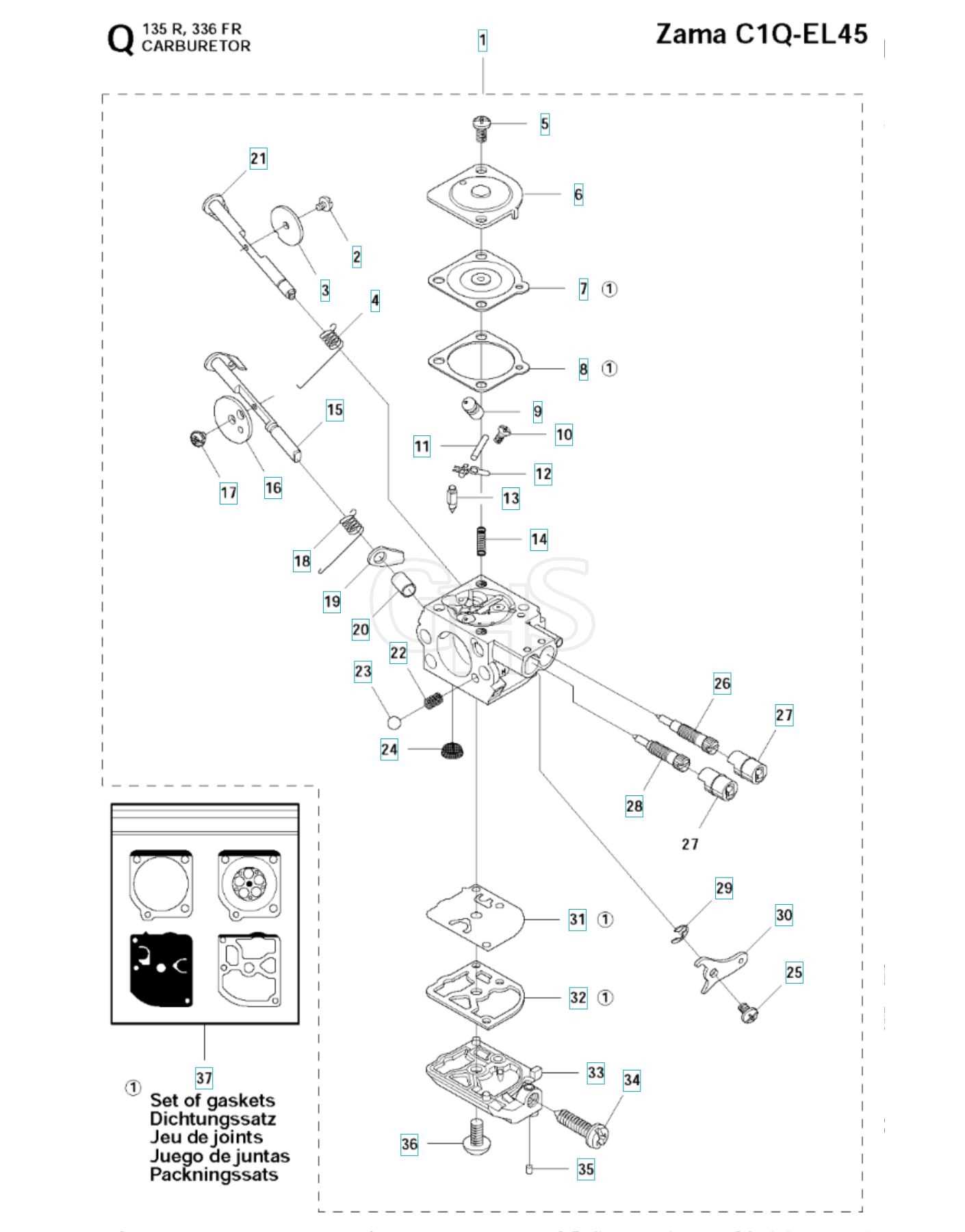

Importance of Parts Diagrams

Understanding the layout of components in machinery is essential for effective maintenance and repair. Visual representations serve as valuable tools, providing clarity and simplifying the identification of individual pieces.

- Enhances troubleshooting by pinpointing specific elements.

- Facilitates the ordering of replacements by showing exact models.

- Improves assembly and disassembly processes, ensuring proper reassembly.

- Increases efficiency during repairs, saving time and reducing errors.

In summary, utilizing these visual guides is crucial for anyone aiming to maintain their equipment properly.

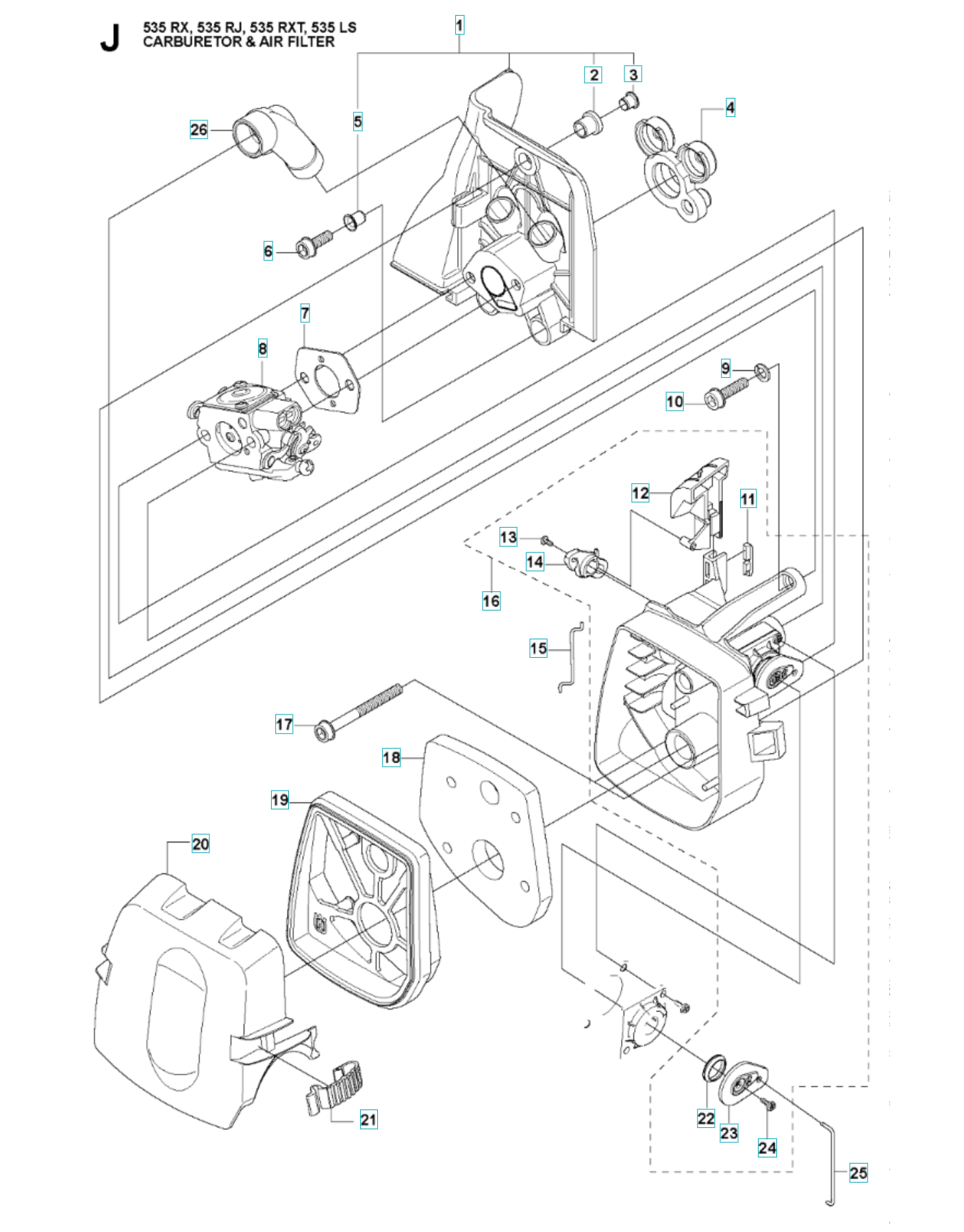

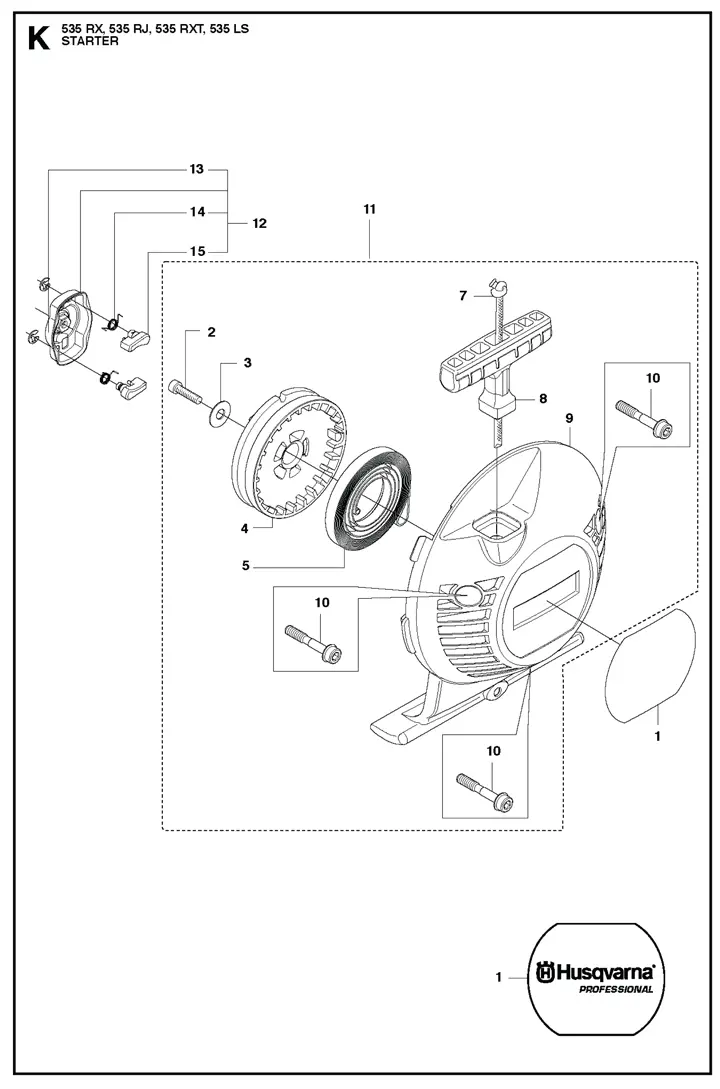

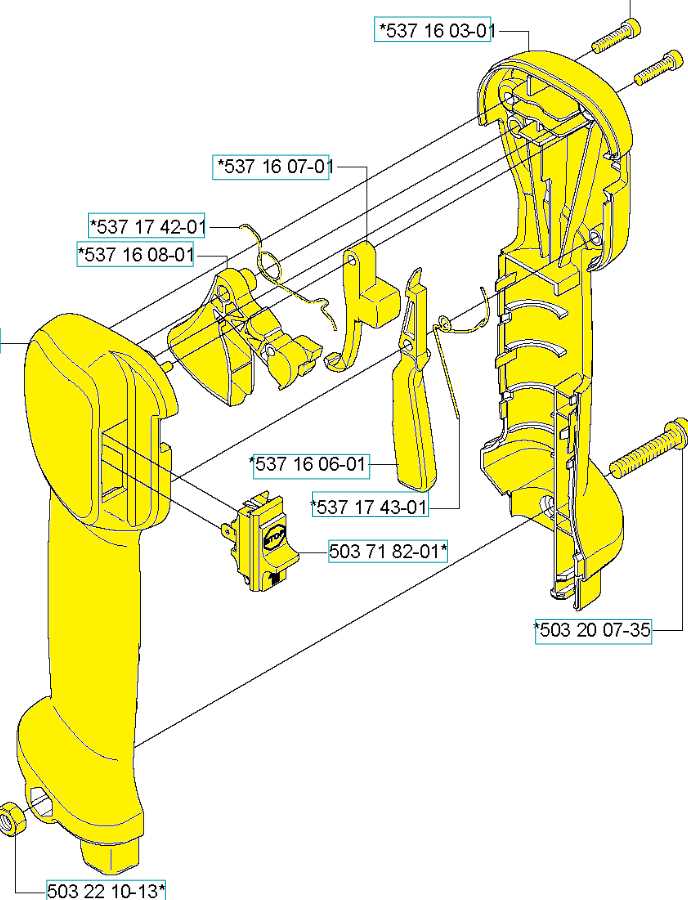

Main Components of the 336FR

This section delves into the essential elements that make up this efficient outdoor power tool. Each part plays a critical role in ensuring optimal performance and durability, contributing to the overall functionality and reliability of the machine.

Key Features

The core components of this tool include the engine, cutting system, and ergonomic handles. Understanding how these parts interact helps in maintaining the device effectively.

Component Overview

| Component | Description |

|---|---|

| Engine | Powers the machine, providing the necessary force for operation. |

| Cutting System | Designed for precision cutting, featuring a robust blade or trimmer head. |

| Handles | Ergonomically designed for comfort and control during use. |

| Fuel Tank | Holds the necessary fuel for the engine, ensuring extended use. |

| Air Filter | Prevents dirt and debris from entering the engine, enhancing longevity. |

How to Interpret the Diagram

Understanding the layout of components in a mechanical illustration can greatly enhance your ability to maintain and repair your equipment. A well-structured visual representation will guide you through the various elements and their relationships, making it easier to identify what you need for any service or replacement tasks.

| Symbol/Label | Description |

|---|---|

| 1 | Main body |

| 2 | Handle assembly |

| 3 | Power unit |

| 4 | Cutting attachment |

| 5 | Safety guard |

Begin by familiarizing yourself with the symbols and labels used in the illustration, as each signifies a specific part or function. Cross-referencing these with your maintenance manual can lead to the ultimate understanding of how to effectively use the equipment.

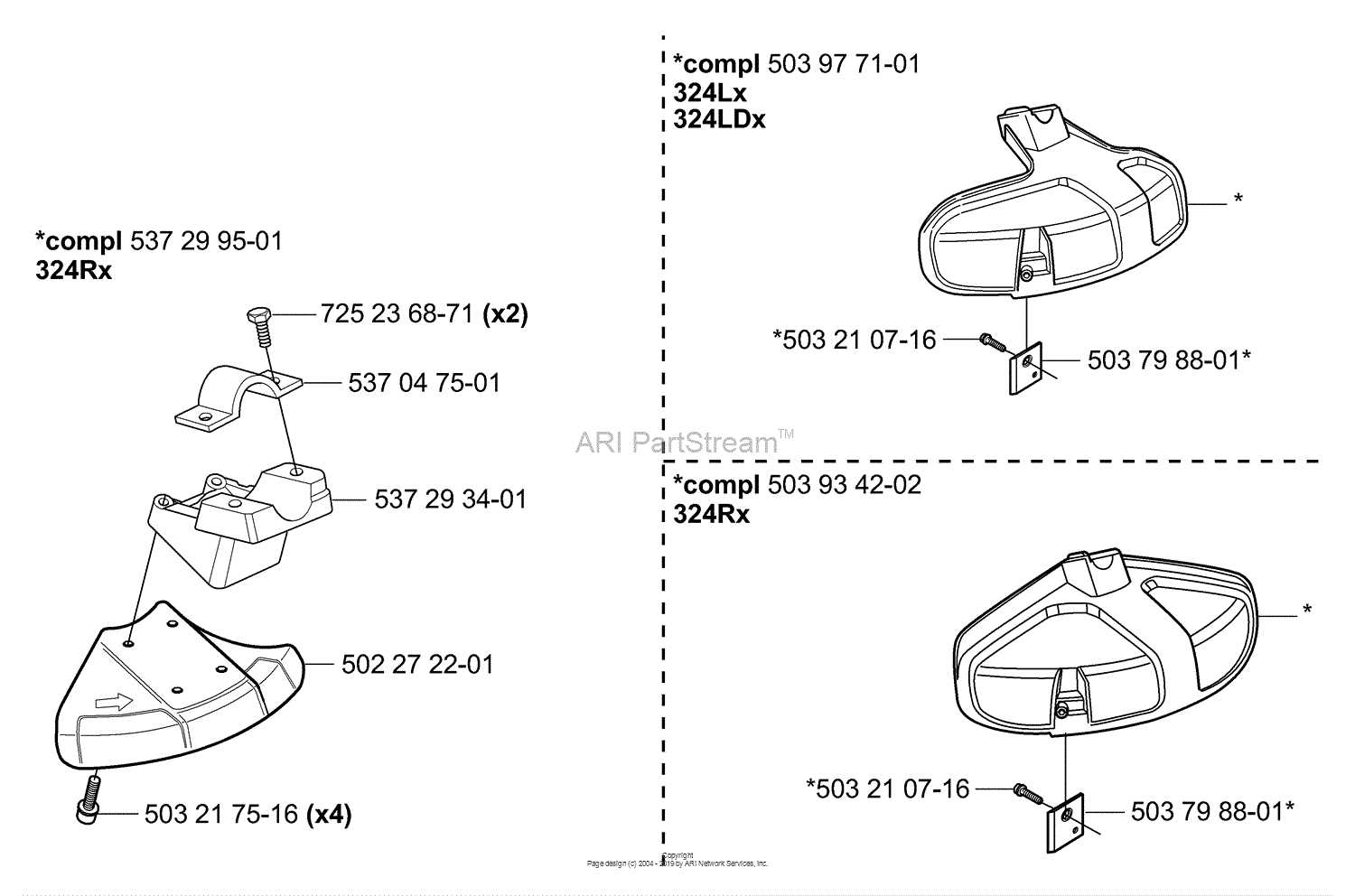

Common Replacement Parts

Maintaining optimal performance in outdoor power equipment often requires the timely replacement of certain components. Understanding which elements frequently wear out can help users keep their machines running smoothly and efficiently.

Here are some of the most commonly replaced components:

- Trimmer Head: Essential for cutting grass and weeds, a worn or damaged head can lead to inefficient performance.

- Cutting Line: The line is subject to significant wear and tear; replacing it regularly ensures effective trimming.

- Air Filter: A clean filter is crucial for proper airflow. Replacing it can improve engine performance and fuel efficiency.

- Spark Plug: A faulty plug can result in starting issues or poor engine performance. Regular replacement is advisable.

- Fuel Filter: Ensuring a clean fuel system helps prevent engine problems. Replacing the filter is an easy maintenance step.

Regularly checking and replacing these items not only enhances the functionality of your equipment but also extends its lifespan, making maintenance an essential part of ownership.

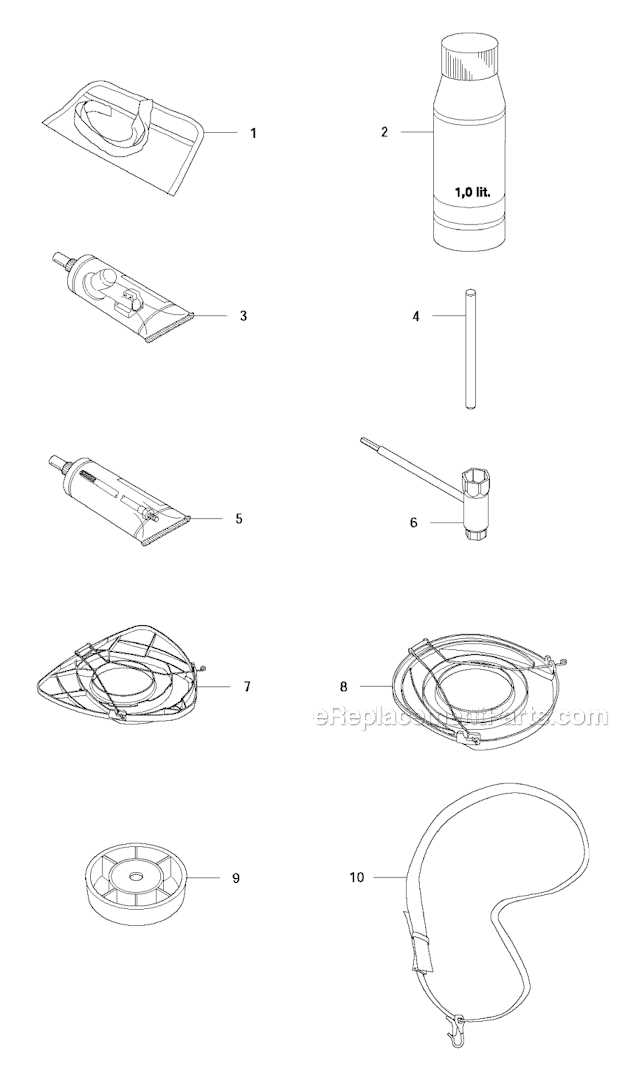

Tools Needed for Repairs

When it comes to performing maintenance and repairs on outdoor equipment, having the right tools is essential for ensuring efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also enhances safety and accuracy in every task.

First and foremost, basic hand tools such as wrenches, screwdrivers, and pliers are indispensable. These instruments allow for easy disassembly and reassembly of components, making troubleshooting straightforward. Additionally, a torque wrench can ensure that fasteners are tightened to the manufacturer’s specifications, preventing potential damage.

In some cases, specialized tools may be required. For instance, specific types of blades or attachments may necessitate unique wrenches or drivers. Having these specialized tools on hand will save time and effort during repairs.

Safety gear is another critical consideration. Protective eyewear and gloves can safeguard against injuries while working with machinery, ensuring a safer repair environment. Keeping these essentials readily available is crucial for a successful maintenance routine.

Lastly, a clean and organized workspace enhances focus and efficiency. Tools should be stored in a designated area, making it easier to locate what you need when tackling repairs. An orderly setup not only saves time but also minimizes the risk of accidents.

Step-by-Step Repair Process

This section outlines a comprehensive approach to effectively repairing your outdoor equipment. Following a structured method ensures that all components are addressed systematically, enhancing the likelihood of successful restoration.

- Preparation:

- Gather necessary tools and replacement items.

- Find a clean, well-lit workspace.

- Disassembly:

- Carefully remove the outer casing.

- Take note of the order and orientation of components.

- Inspection:

- Check for wear or damage on all parts.

- Identify which elements need replacement or repair.

- Replacement:

- Substitute damaged parts with new ones.

- Ensure that each piece fits securely.

- Reassembly:

- Carefully reattach the casing and components.

- Double-check that all screws and fittings are tight.

- Testing:

- Power on the equipment to verify functionality.

- Monitor for any unusual sounds or behaviors.

Following these steps will guide you through the repair process, ensuring your equipment is back in optimal condition.

Safety Precautions When Repairing

When engaging in maintenance or repair tasks, ensuring personal safety and the safety of those around you is paramount. Taking the necessary precautions can help prevent accidents and injuries. Here are some essential guidelines to follow during the repair process.

Personal Protective Equipment

- Always wear safety goggles to protect your eyes from debris.

- Use gloves to avoid cuts and abrasions while handling sharp components.

- Consider wearing a dust mask if working with materials that produce harmful dust.

- Ensure that sturdy footwear is worn to protect your feet from heavy objects.

Work Environment

- Keep the workspace clean and organized to minimize the risk of accidents.

- Ensure proper lighting to clearly see the components you are working on.

- Maintain good ventilation if working with fumes or chemicals.

- Disconnect any power sources before beginning repair work to prevent accidental starts.

By following these safety measures, you can create a secure environment that facilitates effective and efficient repairs.

Where to Find Genuine Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is crucial for optimal performance and longevity. Finding reliable sources for original replacements ensures that your machinery operates efficiently and safely, minimizing the risk of breakdowns.

Authorized Dealers

One of the best avenues for acquiring genuine replacements is through authorized dealers. These outlets are equipped with knowledgeable staff and a comprehensive selection of original components. Purchasing from them guarantees authenticity and often provides support for installation and maintenance.

Official Websites

Another excellent option is to visit the official online platforms dedicated to these machines. Many manufacturers offer direct sales of original components, complete with detailed descriptions and specifications. This method allows you to compare different options and make informed decisions, ensuring you get exactly what you need.

In conclusion, whether through authorized dealers or official online resources, securing original components is vital for maintaining the efficiency and safety of your equipment.

Cost Considerations for Replacements

When it comes to maintaining outdoor equipment, understanding the financial implications of component replacements is essential. Evaluating the costs associated with various parts helps ensure efficient operation and longevity of the machinery.

| Component | Average Cost | Factors Influencing Price |

|---|---|---|

| Engine components | $100 – $300 | Quality, brand, and compatibility |

| Cutting blades | $20 – $60 | Material and size |

| Fuel lines | $10 – $30 | Durability and length |

| Air filters | $5 – $25 | Type and efficiency |

| Spark plugs | $3 – $15 | Brand and performance |

By assessing these costs and factors, users can make informed decisions that ultimately enhance the efficiency and reliability of their equipment.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your outdoor equipment. Regular attention not only enhances performance but also prevents potential issues from escalating. By implementing a consistent maintenance routine, you can ensure that your machine remains reliable and efficient for years to come.

Regular Cleaning

Keep your equipment clean by removing debris, dirt, and grass clippings after each use. This prevents buildup that can cause corrosion or damage over time. Use a soft brush or cloth to gently wipe down surfaces, ensuring that all parts remain in good condition.

Routine Inspections

Conduct regular inspections to identify wear and tear before it becomes a significant problem. Check all components, including blades and filters, for signs of damage or wear. Addressing issues promptly will enhance performance and prevent costly repairs in the future.

FAQs About Husqvarna Parts

This section aims to address common inquiries regarding components and accessories for outdoor equipment. Understanding these elements can enhance the user experience and ensure optimal performance of your machinery.

- What should I consider when replacing a component?

- Compatibility with your specific model.

- Quality and durability of the replacement item.

- Manufacturer recommendations.

- How can I identify the right accessory for my equipment?

- Check the model number and specifications.

- Refer to the user manual.

- Consult with authorized dealers or online resources.

- Are aftermarket options reliable?

- Aftermarket components can vary in quality.

- Research reviews and ratings before purchasing.

- Consider warranties and return policies.

- How often should I replace essential components?

- Follow the maintenance schedule provided in the manual.

- Replace items based on wear and performance issues.

- Regular inspections can help determine the need for replacements.

- Where can I purchase quality replacements?

- Authorized dealers and retailers.

- Reputable online platforms.

- Local repair shops.

Resources for Further Information

When seeking detailed insights and support for your outdoor power equipment, a variety of resources are available to enhance your understanding and troubleshooting skills. Accessing the right materials can significantly improve your maintenance practices and overall performance of your tools.

Online Manuals and Guides

One of the most valuable resources is the collection of manuals and guides available online. These documents often include specifications, maintenance tips, and troubleshooting advice that can help users effectively manage their equipment.

Community Forums and Support Groups

Engaging with fellow enthusiasts through community forums can provide practical advice and shared experiences. These platforms allow users to ask questions, share insights, and access a wealth of knowledge from others who have faced similar challenges.

| Resource Type | Description | Link |

|---|---|---|

| Manuals | Comprehensive user guides and maintenance instructions. | Visit Manuals |

| Forums | Community-driven discussions and support for troubleshooting. | Join Forum |

| Video Tutorials | Step-by-step visual guides for repairs and maintenance. | Watch Tutorials |