Husqvarna 346xp Parts Overview and Component Breakdown

Understanding the intricate setup of mechanical systems is crucial for those looking to ensure their equipment functions at its best. This guide provides a detailed look into the arrangement of various elements that make up a high-performance machine, allowing for smoother operations and easier maintenance. Whether you’re a professional or a do-it-yourself enthusiast, knowing how the components interact is essential for proper upkeep.

The structure and organization of individual elements play a significant role in the overall performance of machinery. Identifying the positioning and connection points helps troubleshoot potential issues and ensures efficient assembly. This section will provide a clear and concise explanation, enabling users to make informed decisions about the care and repair of their tools.

Proper maintenance and periodic review of these elements are key to extending the life of any equipment. By familiarizing yourself with the layout of each piece, you can improve the durability and reliability of the machinery, ensuring it operates at optimal levels for years to come.

Husqvarna 346XP Parts Overview

Exploring the components of this high-performance model offers valuable insight into its design and functionality. Understanding the layout of its individual sections helps ensure optimal maintenance and replacement strategies.

The mechanical structure is composed of various elements designed for efficiency, power, and durability. These essential pieces include the motor, handles, cutting equipment, and protective covers. Each section plays a crucial role in the machine’s overall operation, contributing to its reliability and performance.

Familiarity with these components allows for easier troubleshooting and part replacement when necessary. Knowing how these segments fit together also enhances the user’s ability to perform routine servicing and adjustments.

Essential Components of Husqvarna 346XP Chainsaw

The reliable operation of this chainsaw relies on several key elements working together. These components ensure the tool functions efficiently, delivering the performance needed for various cutting tasks. Understanding the primary parts of the machine can help in proper maintenance and repairs, extending its longevity and enhancing its power output.

Engine and Ignition System

The heart of the saw is its engine, which powers the entire operation. Alongside the engine, the ignition system is responsible for starting and keeping the motor running smoothly. A well-maintained engine and ignition setup are critical for optimum functionality and fuel efficiency.

Chain and Bar

The chain and the guiding bar are the business end of the equipment. They are responsible for cutting through wood with precision and power. Regular sharpening and tension adjustments of the chain are necessary to keep the cutting process smooth and effective. The bar, which holds the chain, must also be kept in good condition to avoid wear and damage.

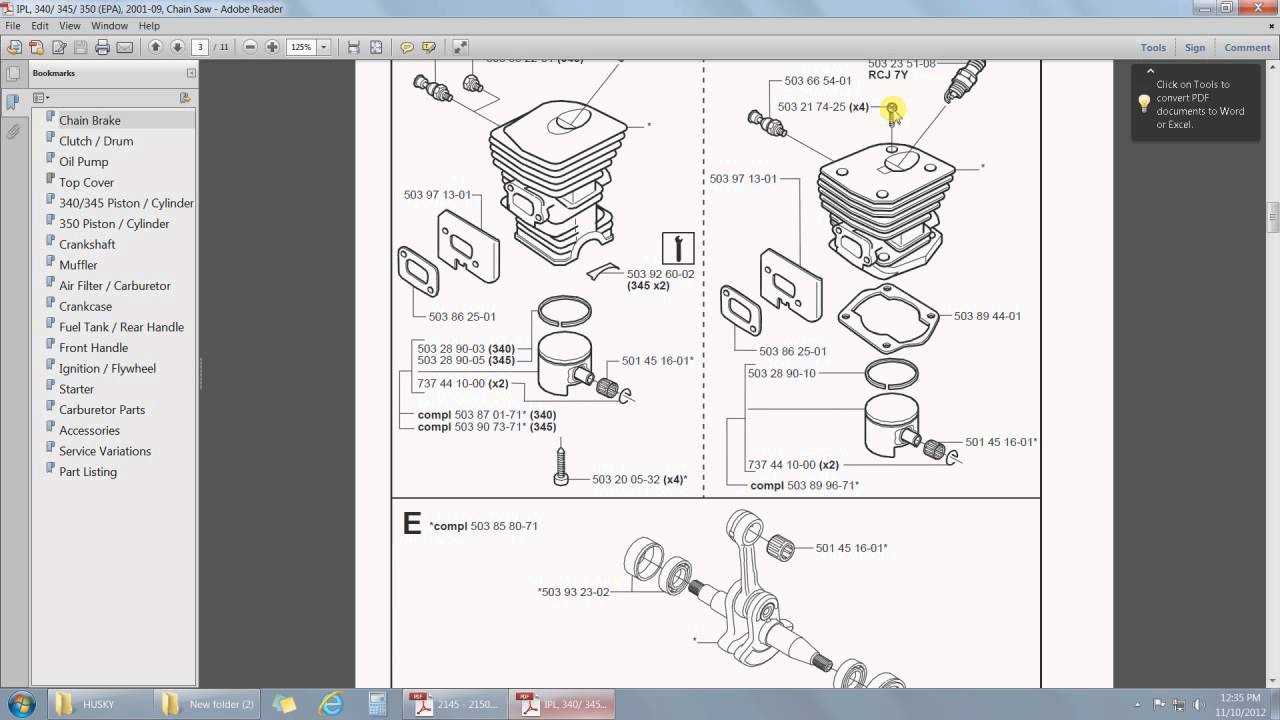

Guide to Husqvarna 346XP Engine Parts

Understanding the essential components of the engine ensures optimal performance and longevity. These elements work together to deliver power and efficiency, making it important to know their functions and how they interact within the system.

Core Engine Components

The heart of this machinery lies in several key mechanisms that generate energy and drive the tool’s operation. These include the cylinder, piston, and crankshaft, which together convert fuel into mechanical energy. Each of these plays a specific role in ensuring smooth operation, providing the necessary force to keep everything running efficiently.

Maintenance and Replacement

Regular upkeep of these core mechanisms is vital for sustained functionality. Parts like the piston rings or bearings may wear out over time, requiring replacement to maintain performance. Checking these components frequently can prevent major breakdowns and prolong the life of the entire system.

Understanding the Internal Mechanisms of the Chainsaw

Chainsaws are complex tools, composed of multiple interconnected components working together to deliver power and precision during operation. To fully grasp how these machines function, it’s important to examine the key elements inside the engine, the system that manages fuel, and the mechanisms responsible for cutting. This understanding helps users maintain efficiency and ensure longevity of the machine.

The core of the machine is its engine, which generates the necessary force to drive the chain around the bar. Fuel is mixed with air and ignited in the combustion chamber, producing power. This energy is transferred through various parts to keep the cutting chain in motion.

The chain mechanism itself is designed to rotate at high speeds, slicing through wood with precision. Tension adjustments and proper lubrication are crucial to the chain’s smooth operation, preventing unnecessary wear and ensuring safety during use.

In addition, the fuel system regulates the flow of gasoline to the engine, ensuring the right mixture for optimal performance. Filters and valves in the system help maintain cleanliness and control, which in turn prolongs the life of the tool.

Finally, understanding the importance of regular maintenance on these internal mechanisms ensures that the chainsaw operates at peak performance, allowing for efficient and safe cutting experiences over time.

Chainsaw Bar and Chain Maintenance

Proper upkeep of your chainsaw’s cutting components is crucial for efficient operation and long-term durability. Routine checks and care can help prevent premature wear, ensuring safe and optimal performance.

Follow these key steps to maintain the bar and chain:

- Inspect the bar: Regularly examine the bar for signs of wear or damage, particularly around the edges. A worn bar can reduce cutting efficiency and increase the risk of accidents.

- Clean the bar groove: Dirt and debris tend to accumulate in the bar groove, causing friction and impeding the chain’s movement. Use a tool to clean it thoroughly.

- Check the chain tension: Ensure the chain is neither too loose nor too tight. A correctly adjusted chain prevents slippage and enhances cutting accuracy.

- Sharpen the chain: Over time, the chain teeth dull, making cutting more difficult. Regular sharpening will keep the chain working smoothly and reduce stress on the motor.

- Lubricate regularly: Keeping the bar and chain well-oiled minimizes friction and prolongs the life of both parts. Always use appropriate lubrication designed for chainsaws.

By integrating these practices into your maintenance routine, you’ll enhance the longevity of your cutting equipment and ensure safer operation during tasks.

Ensuring Longevity of Cutting Elements

Maintaining the effectiveness and durability of cutting tools is essential for optimal performance and prolonged usage. Proper care not only enhances the functionality of these components but also extends their service life, ultimately leading to improved efficiency and reduced costs associated with replacements. This section outlines key practices to ensure that cutting elements remain in excellent condition throughout their lifespan.

Regular Maintenance Practices

Implementing a routine maintenance schedule is crucial. Regularly inspecting the cutting tools for wear and tear allows users to identify potential issues before they escalate. Cleaning the blades after each use helps remove debris and resin build-up, which can affect performance. Additionally, sharpening the edges as needed will enhance cutting efficiency and prevent unnecessary strain on the equipment.

Proper Storage Techniques

Storing cutting elements appropriately plays a significant role in their longevity. Keep them in a dry, cool place, away from direct sunlight to prevent corrosion and degradation of materials. Utilizing protective cases or sheaths can further shield the components from accidental damage. By adopting these strategies, users can ensure that their cutting tools remain effective and reliable for years to come.

Replacing Husqvarna 346XP Air Filter

Maintaining optimal performance in your outdoor power equipment is crucial, and one of the key components that require regular attention is the air filter. This part ensures that the engine receives clean air, enhancing efficiency and prolonging its lifespan. In this section, we will discuss the procedure for replacing the air filter, ensuring that your device operates smoothly and effectively.

Tools and Materials Needed

- New air filter

- Screwdriver

- Clean cloth

- Protective gloves

Steps for Replacement

- Power Off the Equipment: Ensure that the device is turned off and cooled down to prevent any accidents.

- Locate the Air Filter Cover: Identify the location of the air filter cover, usually found on the side of the engine.

- Remove the Cover: Using a screwdriver, carefully unscrew the cover to access the air filter.

- Take Out the Old Filter: Gently remove the old filter from its compartment, taking care not to let any debris fall into the engine.

- Clean the Area: Use a clean cloth to wipe away any dirt or dust from the filter housing.

- Install the New Filter: Place the new air filter into the compartment, ensuring it fits snugly.

- Reattach the Cover: Screw the air filter cover back into place, making sure it is secure.

- Check for Proper Fit: Ensure that the cover is properly sealed to prevent any air leaks.

Following these steps will help maintain the performance of your equipment, allowing it to function efficiently. Regular checks and replacements of the air filter are recommended to ensure longevity and reliability.

Steps for Improving Chainsaw Performance

Enhancing the efficiency of a power saw involves several key practices that can significantly boost its functionality. By focusing on proper maintenance, adjusting settings, and utilizing the right accessories, users can ensure their cutting tool operates at its peak. Below are essential steps to consider for optimizing performance.

| Step | Description |

|---|---|

| Regular Maintenance | Consistent cleaning and inspection of components can prevent buildup and wear, ensuring smooth operation. |

| Sharpen the Chain | Maintaining a sharp cutting chain is crucial for effective cutting. Regularly sharpen the teeth to enhance performance. |

| Check Fuel Quality | Using high-quality fuel can improve combustion efficiency and reduce engine knocking. |

| Adjust Carburetor Settings | Fine-tuning the air-fuel mixture in the carburetor can optimize power output and fuel efficiency. |

| Inspect the Bar | Ensure the guide bar is not excessively worn and is properly lubricated to avoid overheating during use. |

Clutch System Components in 346XP

The clutch system is a crucial aspect of any power tool, serving to connect and disconnect the engine’s power from the working components. In the context of this specific model, the clutch mechanism plays a significant role in ensuring efficient operation and performance. Understanding the various components that make up this system is essential for maintenance and troubleshooting.

Primary Components

The primary elements of the clutch system include the clutch drum, drive shoes, and springs. The clutch drum is responsible for housing the drive mechanism and facilitating the engagement and disengagement of power. Drive shoes are spring-loaded components that expand outward when the engine reaches a certain RPM, thereby connecting the drum to the engine’s power. The springs help to retract the drive shoes when the engine slows down, ensuring a smooth disengagement.

Maintenance Considerations

Regular maintenance of the clutch system is vital for optimal performance. Inspecting the drive shoes for wear and ensuring the springs maintain their tension are essential practices. Lubrication of moving parts can also enhance the efficiency and longevity of the system. Understanding these components and their functions can significantly impact the overall performance of the tool.

Analyzing the Importance of the Clutch

The clutch plays a crucial role in the functionality of a mechanical device, serving as a vital component that ensures efficient power transmission. Its primary function is to engage and disengage the engine from the drive system, allowing for smoother operation and better control. Understanding the significance of this element can enhance performance and longevity, making it essential for optimal operation.

A properly functioning clutch not only aids in seamless power delivery but also protects the entire system from potential damage caused by sudden changes in speed or load. This component is designed to absorb shocks and prevent wear on other critical parts, thus maintaining the overall integrity of the machinery.

| Clutch Type | Functionality | Impact on Performance |

|---|---|---|

| Friction Clutch | Engages/disengages power transmission | Improves control during operation |

| Automatic Clutch | Automatically adjusts to load conditions | Enhances ease of use and efficiency |

| Spring-loaded Clutch | Provides consistent engagement force | Reduces wear and extends lifespan |

In conclusion, recognizing the importance of the clutch within a mechanical system is vital for ensuring effective performance. Regular maintenance and timely replacement of this component can lead to improved reliability and efficiency, ultimately enhancing the overall experience of using the machinery.

Fuel System of Husqvarna 346XP

The fuel system of this model is crucial for efficient operation, ensuring that the engine receives the right mixture of fuel and air. A well-functioning fuel delivery system not only enhances performance but also contributes to the longevity of the machine. Understanding the components involved in this system is essential for maintenance and troubleshooting.

Key Components

Several key elements work together to facilitate the fuel flow in this equipment. These components include the fuel tank, fuel filter, fuel pump, and carburetor. Each part plays a vital role in delivering a precise fuel mixture to the engine, allowing for optimal combustion and power generation.

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel needed for operation. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine. |

| Fuel Pump | Delivers fuel from the tank to the carburetor. |

| Carburetor | Mixes fuel with air for combustion. |

Maintenance Tips

Regular maintenance of the fuel system is necessary to ensure reliable performance. This includes checking and replacing the fuel filter as needed, inspecting the fuel lines for leaks, and ensuring that the carburetor is clean and functioning properly. Proper care of these components can prevent issues related to fuel delivery and enhance overall efficiency.

Maintaining Optimal Fuel Flow for Efficient Operation

Ensuring a consistent and effective fuel supply is essential for the seamless functioning of any outdoor power equipment. Proper management of the fuel system enhances performance, increases longevity, and minimizes the risk of breakdowns. This section will explore vital practices and components that contribute to maintaining an optimal fuel flow, thereby supporting the efficient operation of your machinery.

Regular Inspection of Fuel Lines is crucial for preventing clogs and leaks. Inspecting the fuel lines for cracks or wear ensures that fuel can flow freely to the engine. Any signs of damage should be addressed promptly to avoid further complications.

Quality of Fuel also plays a significant role in the overall performance of the equipment. Using clean, high-quality fuel prevents the buildup of deposits that can obstruct fuel flow and affect engine efficiency. It is advisable to avoid using old or contaminated fuel, as this can lead to poor combustion and reduced power output.

Filter Maintenance is another important aspect of fuel system upkeep. Regularly replacing or cleaning the fuel filter can prevent dirt and debris from entering the engine, ensuring a smooth and reliable flow of fuel. A clean filter contributes to better engine performance and reduces wear on internal components.

In summary, implementing these practices will significantly enhance the efficiency of your equipment. By focusing on the integrity of the fuel system, operators can ensure optimal performance and prolong the life of their machines.

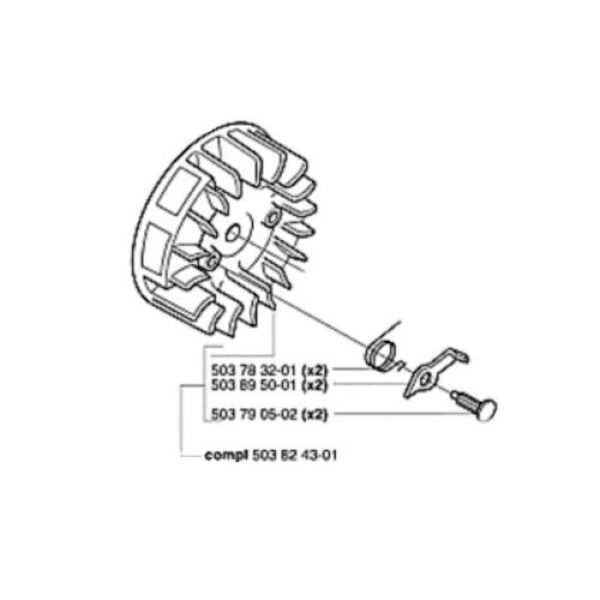

Electrical Components of the Chainsaw

The electrical components of a chainsaw play a crucial role in ensuring efficient operation and safety. These parts work together to facilitate ignition, control, and various functions that enhance performance. Understanding their roles helps in maintaining the tool and troubleshooting any issues that may arise.

Key electrical components include the ignition system, starter assembly, and wiring harness. Each element contributes to the overall functionality and reliability of the chainsaw.

| Component | Description |

|---|---|

| Ignition Module | Generates the spark needed to ignite the fuel-air mixture in the combustion chamber. |

| Starter Motor | Provides the initial torque required to start the engine, often activated by a pull cord. |

| Wiring Harness | Connects various electrical parts, ensuring proper communication and power distribution throughout the tool. |

| Switch | Controls the flow of electricity, allowing the operator to start or stop the engine as needed. |

| Fuel Pump | Delivers fuel to the engine, often relying on electrical components to function efficiently. |