Complete Guide to Husqvarna 371K Parts Diagram

When it comes to maintaining the efficiency of a powerful machine, a clear understanding of its internal structure is essential. Every tool comprises numerous elements that work in harmony to deliver peak performance. By exploring the intricate layout of these components, users can ensure optimal functionality and longevity.

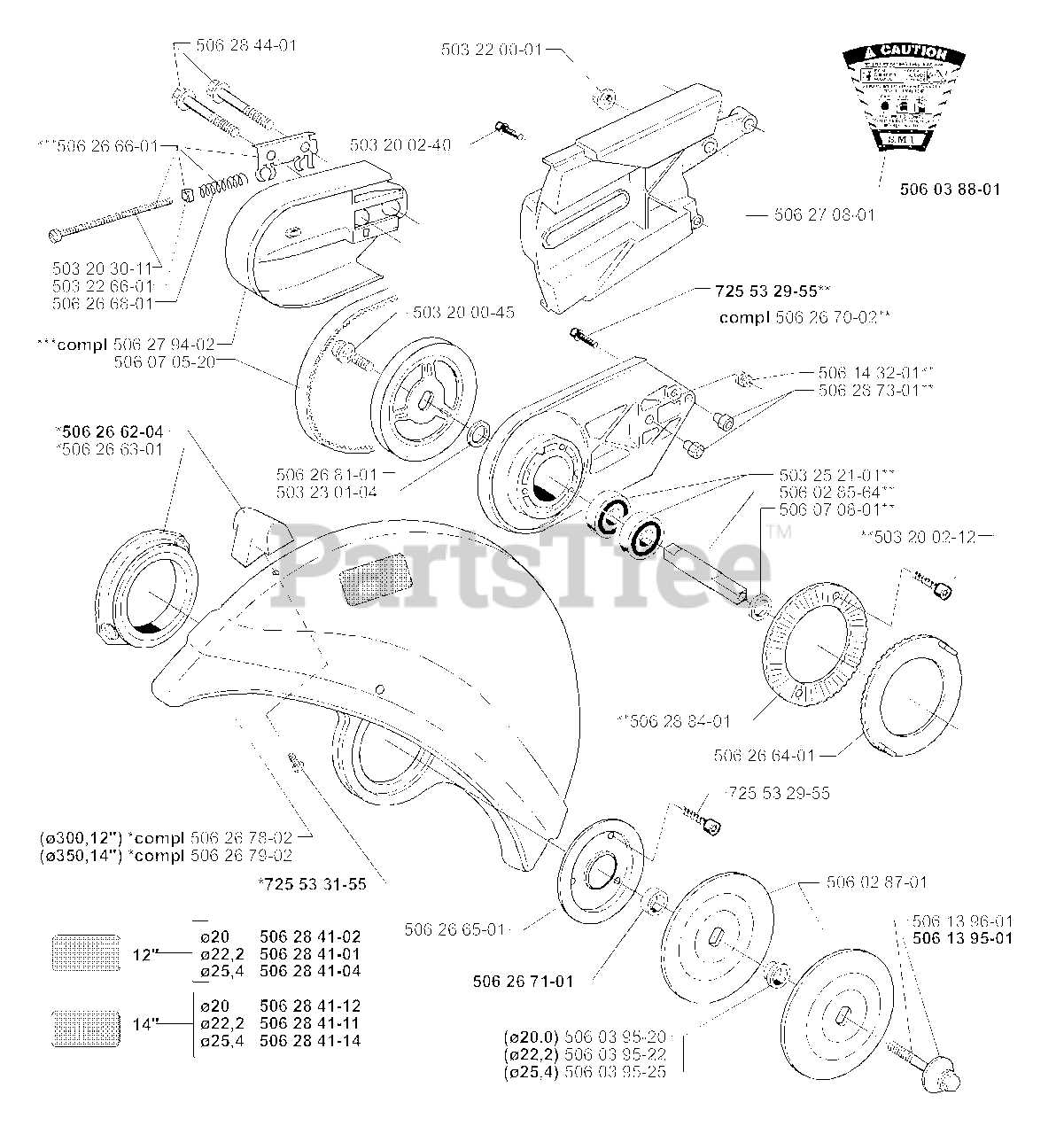

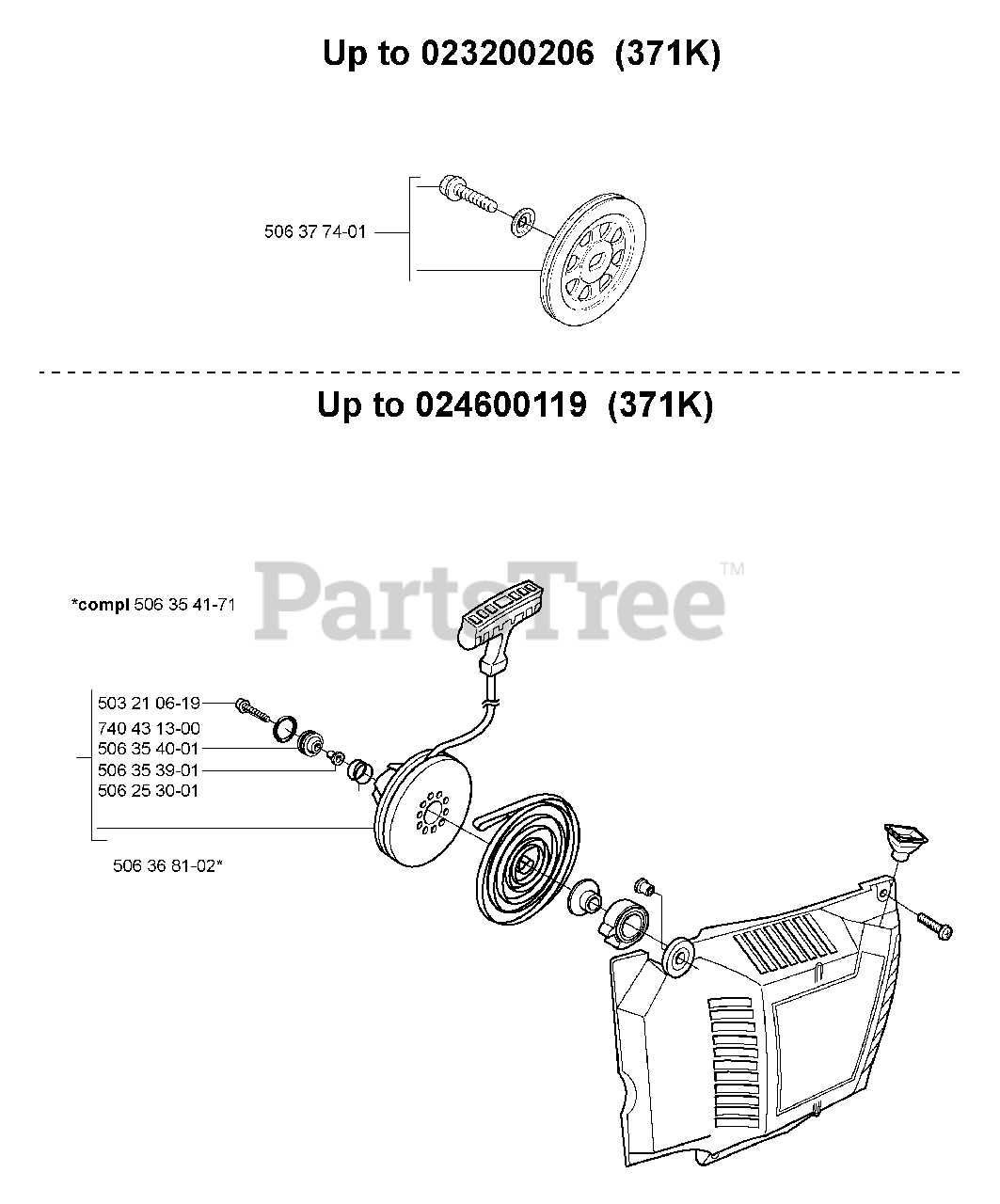

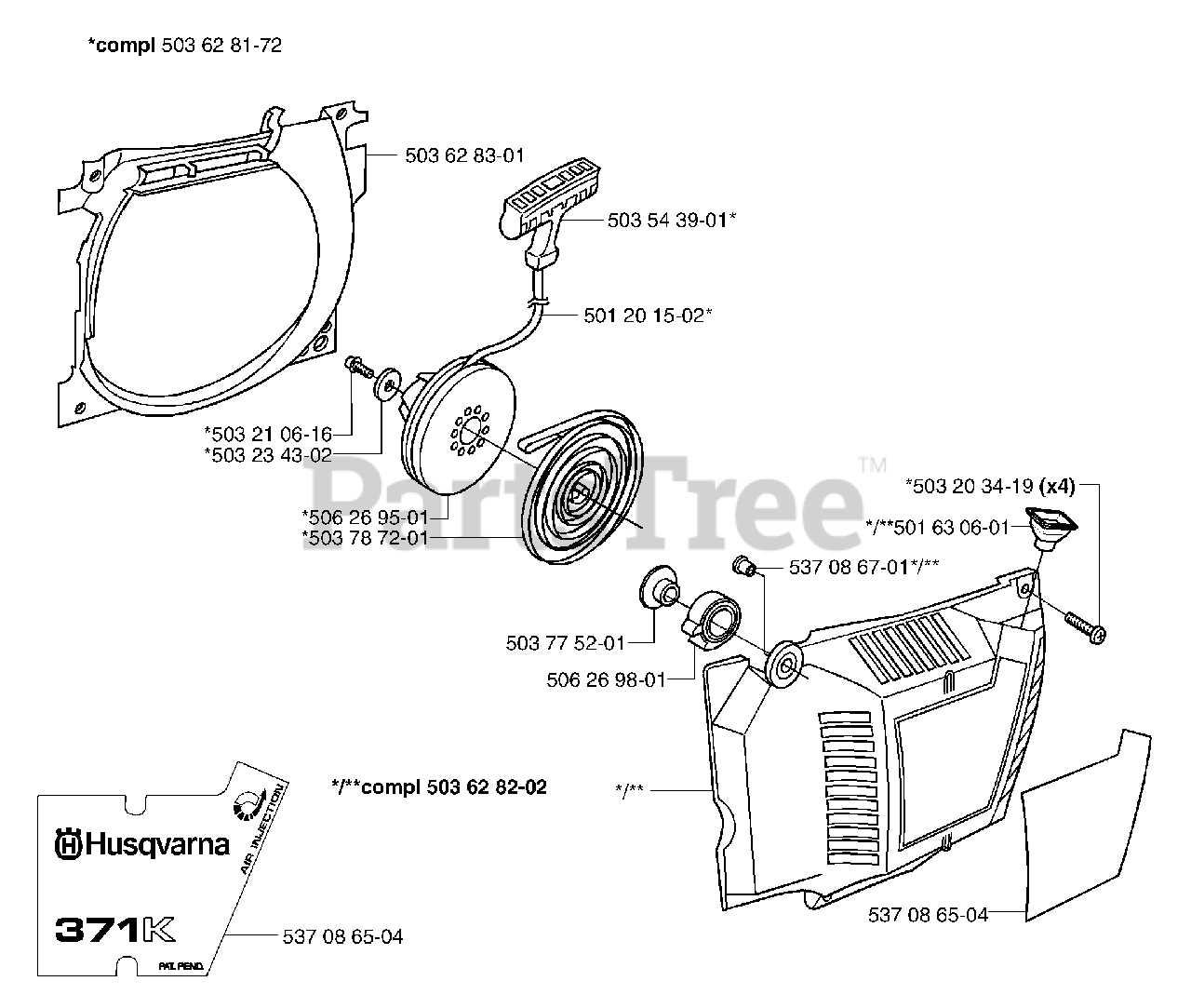

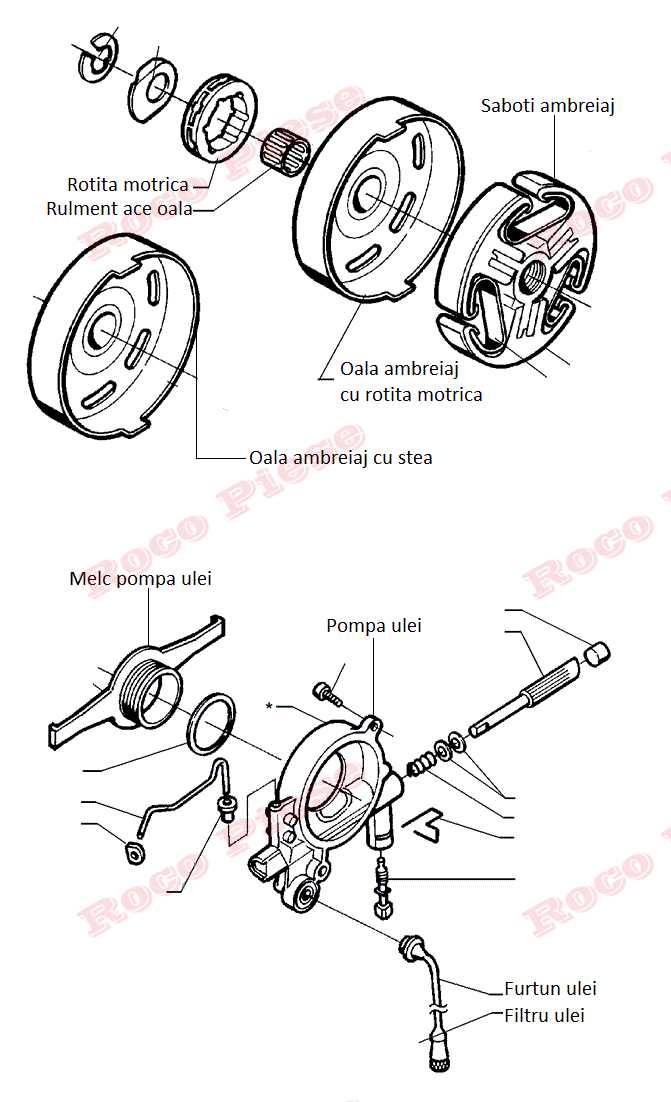

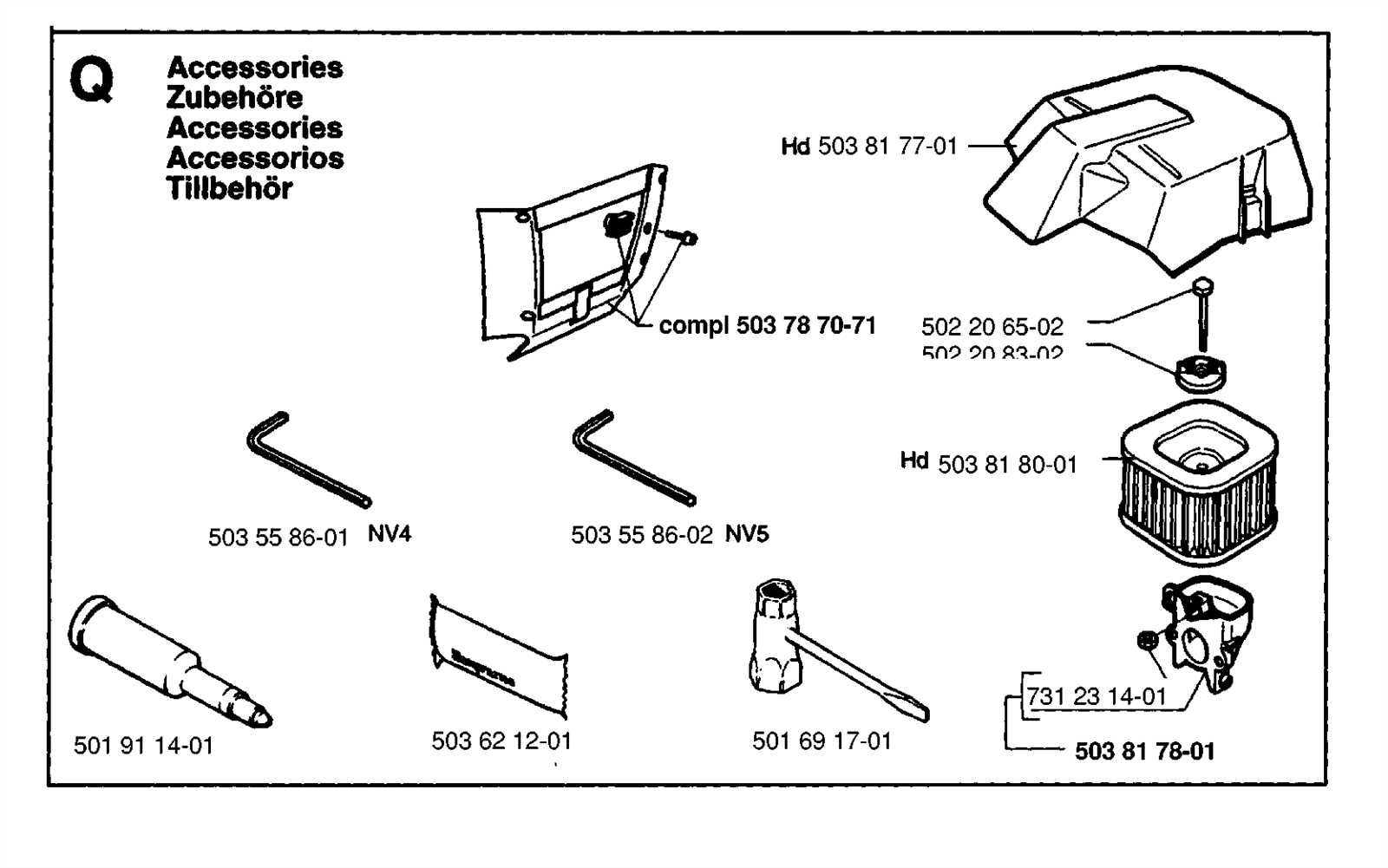

Visual representations of the various segments can significantly enhance comprehension. Such illustrations allow users to pinpoint specific areas, facilitating repairs and replacements with ease. Recognizing each part’s role contributes to a more profound appreciation of the overall mechanism.

In this exploration, we will delve into the essential components, highlighting their interconnections and significance. By grasping the ultimate function of each segment, operators can make informed decisions about maintenance and upgrades, ensuring their equipment remains reliable for years to come.

Understanding Husqvarna 371K Overview

This section provides a comprehensive look at a specific model of outdoor power equipment, focusing on its features, functionality, and overall performance. By examining the components and their roles, users can better appreciate the design and engineering that contribute to its efficiency.

| Feature | Description |

|---|---|

| Engine Type | Two-stroke engine for enhanced power-to-weight ratio. |

| Fuel Capacity | Generous tank size for extended operation without frequent refueling. |

| Weight | Lightweight design for improved maneuverability. |

| Cutting Width | Optimal cutting width for efficient performance in various conditions. |

Importance of Parts Diagrams

Understanding the components of a mechanical device is crucial for effective maintenance and repair. Visual representations of these elements provide clarity and facilitate the identification of each section, ensuring that users can locate and manage the various pieces efficiently.

Effective Communication: These visual aids serve as a universal language for technicians and hobbyists alike. By depicting each component, they eliminate confusion and streamline discussions related to repairs or upgrades.

Improved Accuracy: When attempting to replace or repair parts, having a clear illustration helps ensure that the correct items are identified. This reduces the likelihood of mistakes and enhances the overall efficiency of the repair process.

Streamlined Repairs: A comprehensive visual guide simplifies the process of reassembling a device after maintenance. Users can follow a logical sequence, ensuring that everything is placed correctly, which minimizes the risk of errors.

Enhanced Learning: For those new to machinery, these illustrations serve as educational tools. They provide insights into how components interact, fostering a deeper understanding of the device’s function and encouraging skill development.

Main Components of Husqvarna 371K

Understanding the primary elements of this powerful tool is essential for effective maintenance and operation. Each component plays a crucial role in ensuring optimal performance and durability.

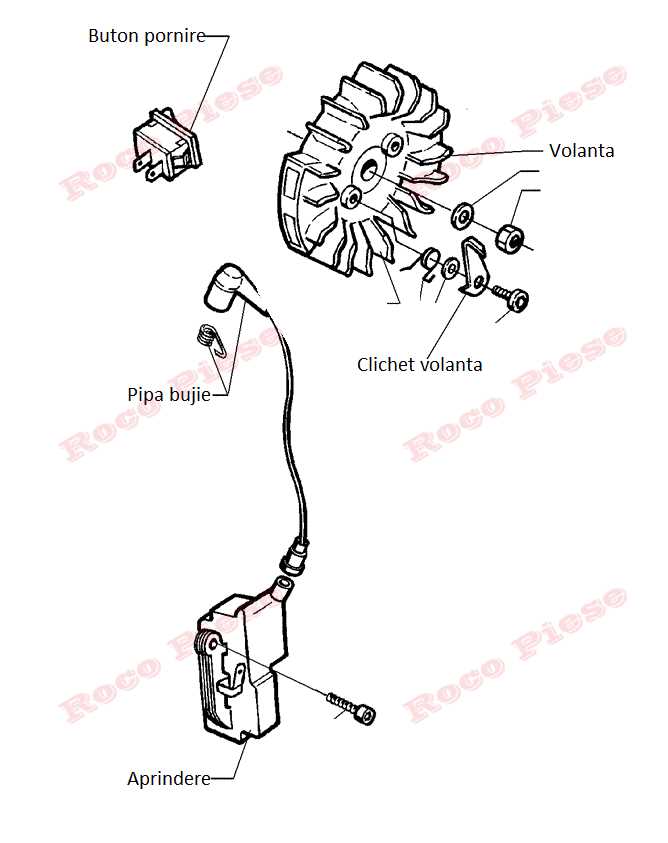

- Engine: The heart of the machine, providing the necessary power for cutting.

- Chain: Designed for efficient cutting, it interacts closely with the bar.

- Guide Bar: Supports the chain and directs its movement during operation.

- Air Filter: Ensures clean air intake, enhancing engine efficiency and longevity.

- Fuel Tank: Holds the mixture needed for operation, crucial for runtime.

Each of these parts contributes significantly to the ultimate functionality of the equipment, allowing users to tackle various tasks effectively.

Identifying Replacement Parts Easily

When maintaining outdoor power equipment, recognizing the correct components is essential for seamless operation. Understanding the various elements that make up your machinery enables efficient troubleshooting and timely replacements, ensuring longevity and performance. A systematic approach to identifying these components can save both time and resources, enhancing your overall maintenance experience.

Utilizing Resources for Accurate Identification

One of the most effective methods for pinpointing the right components is to consult manufacturer manuals or online resources. These documents often provide detailed information, including specifications and compatible options. Utilizing exploded views or reference charts can simplify the process, allowing users to visualize how different elements interact within the system.

Engaging with Community Knowledge

Another valuable strategy is to engage with forums or online communities dedicated to equipment maintenance. Here, experienced users share insights and tips about component identification and compatibility. Networking with fellow enthusiasts can lead to quick solutions and recommendations that may not be readily available through traditional sources.

Common Issues with the 371K

When dealing with outdoor power equipment, users may encounter a range of typical challenges that can affect performance and reliability. Understanding these common problems can help in diagnosing issues and ensuring smooth operation.

- Starting Difficulties: Many operators report issues with ignition, leading to frustrating attempts to start the machine.

- Fuel Leaks: Poor seals or damaged lines can result in fuel escaping, posing safety risks and reducing efficiency.

- Overheating: Insufficient cooling or blocked vents can cause the engine to overheat, potentially leading to serious damage.

- Inconsistent Performance: Fluctuations in power output can occur due to fuel quality or air filter issues.

Addressing these common concerns promptly can enhance the longevity and effectiveness of your equipment. Regular maintenance checks are recommended to mitigate these problems.

Tools Needed for Repairs

When tackling maintenance and repair tasks, having the right tools on hand is essential for a successful outcome. The appropriate equipment not only streamlines the process but also ensures that each component is handled with care and precision. Below is a comprehensive list of essential tools that can aid in performing repairs effectively.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are crucial for loosening and tightening screws.

- Wrenches: Both adjustable and fixed wrenches are necessary for securing nuts and bolts.

- Pliers: Needle-nose and standard pliers can help grip and manipulate small parts.

- Socket Set: A set of sockets will facilitate working with different bolt sizes quickly and efficiently.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Cleaning Supplies: Brushes, cloths, and solvents are important for maintaining cleanliness during repairs.

- Safety Gear: Gloves, goggles, and masks protect against debris and harmful substances.

In addition to these basic tools, having specialized equipment may be beneficial depending on the complexity of the task. Investing in quality tools will not only enhance your repair experience but also extend the life of your equipment.

Step-by-Step Repair Process

This section outlines a detailed guide to assist you in restoring your equipment efficiently and effectively. Following a structured approach will ensure that each component is addressed properly, resulting in a successful repair.

-

Preparation: Gather all necessary tools and replacement components before starting the repair. This includes wrenches, screwdrivers, and any specific parts you may need.

-

Safety Measures: Always wear appropriate safety gear, such as gloves and goggles. Make sure the equipment is powered off and disconnected from any power source.

-

Disassembly: Carefully disassemble the unit by following the recommended sequence. Keep track of screws and small parts to avoid losing them.

- Refer to a visual reference to identify components.

- Label parts if necessary for easy reassembly.

-

Inspection: Examine each part for wear and damage. Identify any components that need replacement or repair.

-

Replacement: Install new parts as needed, ensuring they are compatible with your model. Secure each component firmly to prevent future issues.

-

Reassembly: Follow your initial disassembly steps in reverse order to reassemble the unit. Pay attention to the proper alignment of parts.

-

Testing: Once reassembled, reconnect the power and perform a thorough test to ensure everything functions as expected. Listen for unusual noises and check for leaks.

-

Final Checks: Conduct a final inspection to confirm that all parts are secure and that there are no loose components.

By following these systematic steps, you can effectively troubleshoot and repair your machinery, ensuring it operates optimally for years to come.

Maintenance Tips for Longevity

Proper upkeep of your equipment not only enhances performance but also extends its lifespan. By implementing regular maintenance practices, you can prevent costly repairs and ensure that your machine operates efficiently for years to come.

Regular Cleaning

Keeping your equipment clean is essential for optimal performance. Dust, debris, and residue can hinder functionality. Here are some tips:

- After each use, wipe down surfaces to remove dirt and grime.

- Check air filters regularly and clean or replace them as needed.

- Ensure that all vents and openings are free from blockages.

Routine Inspections

Conducting periodic checks can help identify potential issues before they escalate. Consider the following:

- Inspect belts and hoses for wear and tear.

- Check fluid levels and top off as necessary.

- Look for any loose bolts or connections and tighten them.

By adhering to these maintenance practices, you can significantly enhance the reliability and durability of your equipment, ensuring it serves you well for many years.

Where to Find OEM Parts

When searching for original equipment manufacturer components, it’s essential to identify reliable sources that ensure quality and compatibility. Various outlets specialize in providing authentic replacements for machinery, helping maintain optimal performance and longevity.

Authorized dealers are often the most trustworthy option, as they typically stock a wide range of genuine products. Additionally, official online retailers can offer convenience and often feature detailed catalogs for easy navigation.

Another effective approach is to explore dedicated forums and communities, where enthusiasts share recommendations on reputable suppliers. This can lead to valuable insights and potentially even discounts on purchases.

Aftermarket Parts: Pros and Cons

Exploring alternatives to original components can be a viable option for many consumers. These substitutes often present a mix of advantages and disadvantages, influencing decisions on maintenance and repair. Understanding these factors is essential for making informed choices.

Advantages

Cost-Effectiveness: One of the primary benefits of opting for alternative components is their affordability. Many consumers find these substitutes to be significantly cheaper, making repairs more accessible without compromising functionality.

Variety: The market for alternative components often provides a wider range of options. This variety allows users to select parts that might offer enhanced features or improved performance compared to original components.

Disadvantages

Quality Concerns: While many alternatives are well-made, some may not meet the same quality standards as original components. This disparity can lead to faster wear and tear, ultimately resulting in higher long-term costs.

Warranty Issues: Utilizing substitutes can sometimes void manufacturer warranties. Users should be cautious and check warranty conditions before making substitutions to avoid potential complications.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, adhering to safety measures is paramount. Proper precautions can prevent accidents, injuries, and damage to equipment. Familiarizing oneself with potential hazards and implementing safety protocols is essential for a successful and secure repair process.

Wear Appropriate Protective Gear

Using the right personal protective equipment (PPE) is crucial. This includes gloves, goggles, and sturdy footwear to shield against sharp objects and potential chemical exposure. Ensure that clothing fits snugly to avoid entanglement in moving parts.

Maintain a Clean Workspace

A tidy work area reduces the risk of slips and falls. Keep tools organized and remove any unnecessary items from the vicinity. Proper lighting is also important to enhance visibility and ensure safe handling of components.

Using Diagrams for Efficient Work

Visual representations are invaluable tools for enhancing productivity and understanding complex systems. By providing a clear overview of components and their relationships, these illustrations facilitate quicker decision-making and minimize errors during assembly or maintenance processes. Engaging with visual aids not only improves comprehension but also streamlines workflows, allowing individuals to focus on their tasks more effectively.

Benefits of Visual Aids

Employing visual schematics can lead to several advantages in various fields:

| Benefit | Description |

|---|---|

| Enhanced Clarity | Visual aids simplify complex information, making it easier to grasp. |

| Reduced Errors | Clear representations help minimize mistakes during assembly or repairs. |

| Time Efficiency | Quick reference to visuals speeds up the workflow and decision-making. |

| Improved Training | Newcomers can learn faster through visual aids than through text alone. |

Best Practices for Utilizing Visuals

To maximize the effectiveness of these tools, consider the following strategies:

- Regularly update visuals to reflect any changes in components or systems.

- Ensure clarity and readability by using consistent symbols and notations.

- Integrate visuals into training programs for enhanced learning experiences.

- Encourage team collaboration by sharing visual aids during meetings and discussions.

Community Resources and Support

Engaging with a network of enthusiasts can significantly enhance your experience and knowledge regarding equipment maintenance and repairs. These communities often provide valuable insights, share experiences, and offer assistance for various issues. Joining forums, social media groups, and local clubs can connect you with others who have similar interests and expertise.

Below is a table highlighting some popular community resources:

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Discussion platforms for sharing tips and troubleshooting. | Visit Forum |

| Social Media Groups | Facebook and other social networks dedicated to equipment enthusiasts. | Join Group |

| Local Workshops | Hands-on classes and meetups for practical learning. | Find Workshop |