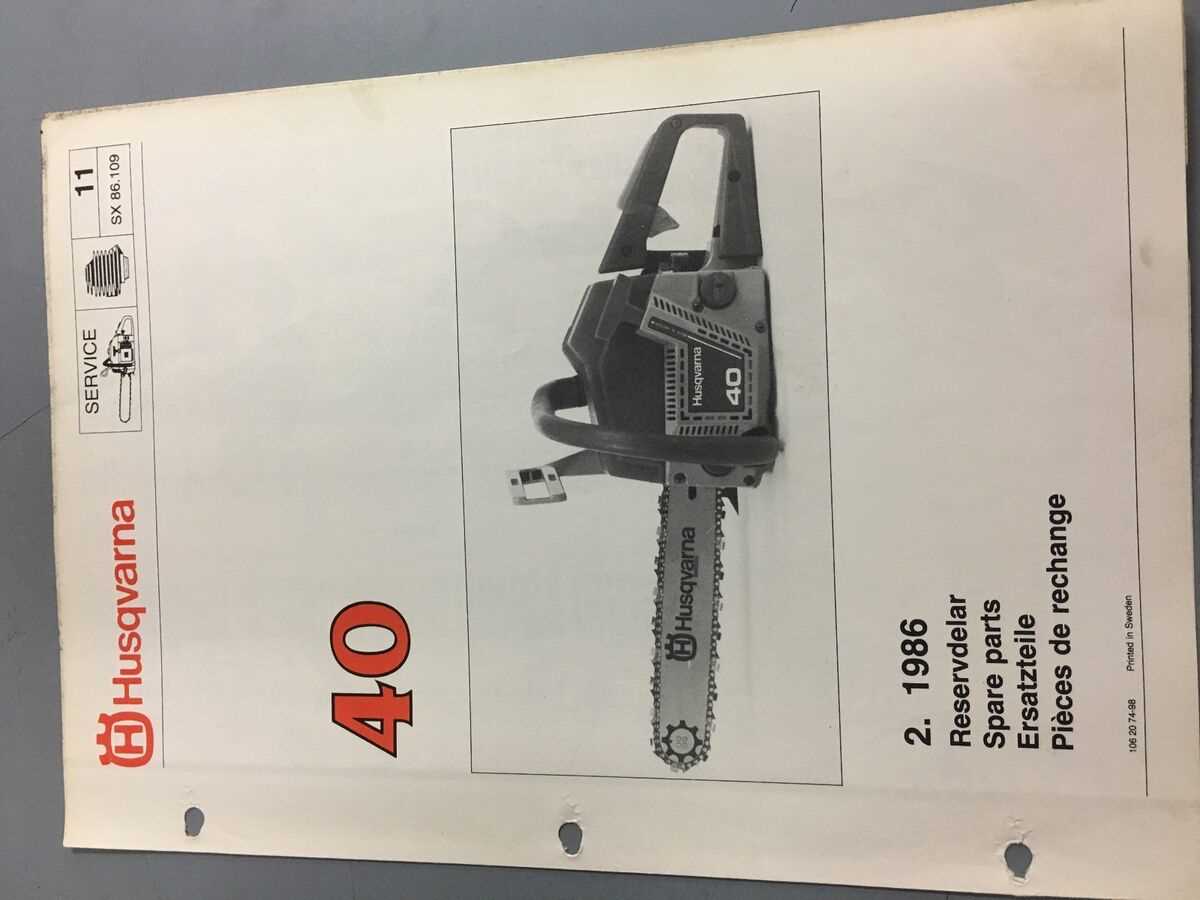

Explore the Comprehensive Husqvarna 40 Parts Diagram

For any outdoor machinery enthusiast, comprehending the intricate layout of various elements is crucial for effective maintenance and repair. A clear visualization of each component can enhance the overall functionality and longevity of your tools.

Exploring the intricate structure not only aids in identifying specific issues but also empowers users to make informed decisions about replacements and upgrades. With the right knowledge, you can ensure your device operates at its ultimate performance.

By delving into detailed representations, you can navigate the complexities of your equipment with ease. This understanding will lead to a more enjoyable and productive experience, whether you are a novice or a seasoned user.

Understanding the Husqvarna 40

The model in question is a well-known tool in its category, offering a blend of durability and performance that appeals to both casual users and professionals. Its design reflects thoughtful engineering, making it an ideal choice for various outdoor tasks. Familiarity with its components can significantly enhance the user experience and ensure efficient operation.

One of the key features of this model is its ease of maintenance. Knowing the function of each element allows users to troubleshoot common issues effectively. This understanding can lead to improved longevity and reliability, minimizing downtime during critical tasks.

Additionally, grasping the overall layout of the device aids in identifying wear and tear. Regular checks on specific components can prevent larger problems and ensure that the tool operates at peak efficiency. With a little knowledge, users can navigate maintenance with confidence, enhancing both safety and productivity.

Essential Components of Husqvarna 40

Understanding the crucial elements of any outdoor power equipment is vital for optimal performance and longevity. Each component plays a specific role, ensuring that the machine operates efficiently and reliably. Familiarity with these essential parts can help users maintain their equipment effectively and troubleshoot any issues that may arise.

Key Elements

- Engine: The heart of the equipment, providing the necessary power for operation.

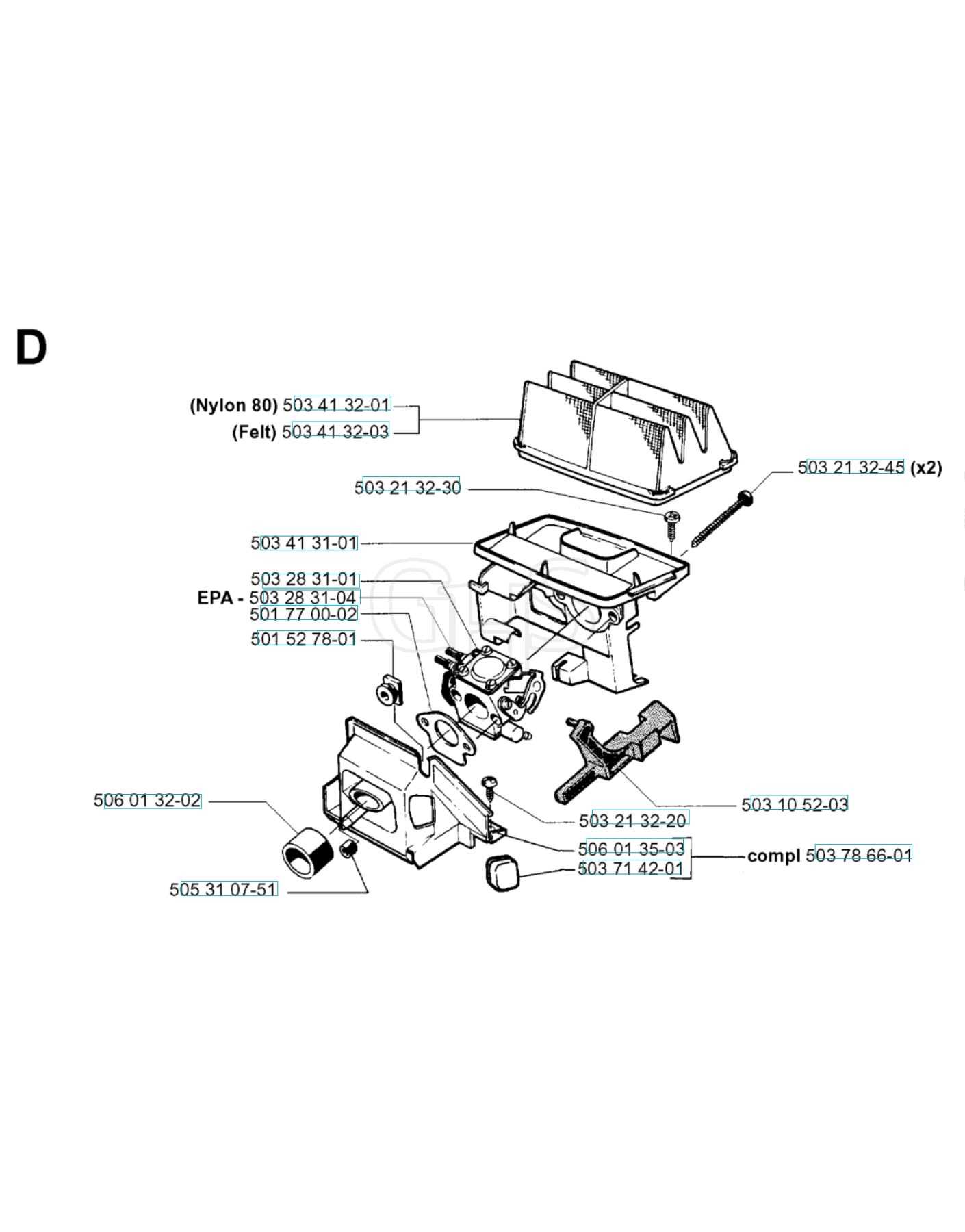

- Fuel System: This includes the tank and carburetor, responsible for fuel delivery and combustion.

- Ignition System: Ensures reliable starting and operation, including the spark plug and ignition coil.

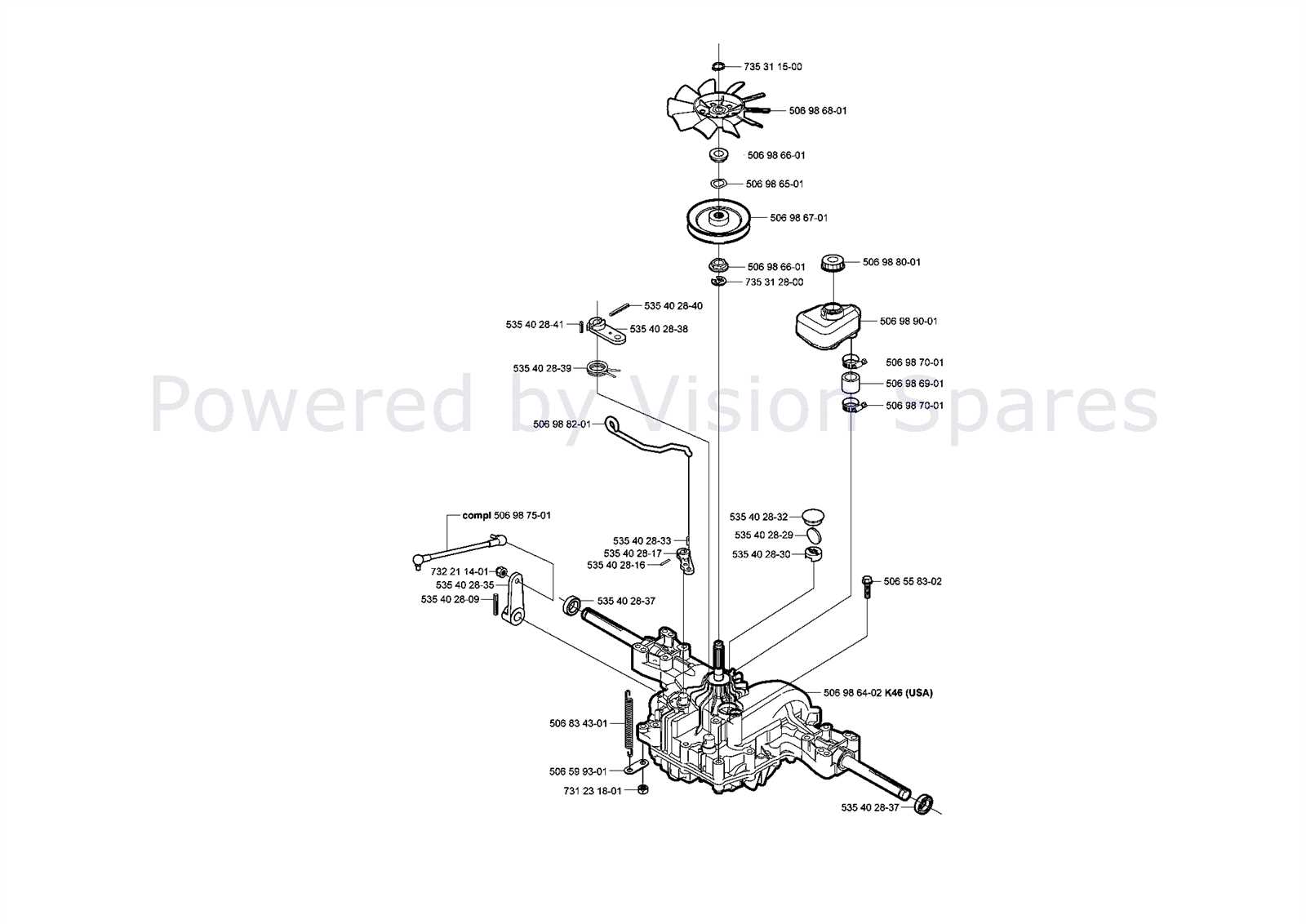

- Cooling System: Maintains optimal engine temperature to prevent overheating during use.

- Drive Mechanism: Transmits power to the cutting or working tool, ensuring effective operation.

Maintenance Considerations

- Regularly check the condition of the spark plug and replace it as needed.

- Inspect the fuel system for leaks or blockages to ensure smooth fuel flow.

- Clean or replace air filters to maintain efficient airflow and performance.

- Examine the cooling fins and ensure they are free from debris.

- Lubricate moving parts to reduce friction and wear over time.

Common Issues and Solutions

In the realm of outdoor equipment, various challenges can arise that may hinder performance and efficiency. Identifying these common problems and understanding effective remedies is essential for maintaining optimal functionality. This section explores prevalent issues encountered with small engine machinery and offers practical solutions to enhance usability.

Starting Difficulties: A frequent concern is trouble starting the engine. This can often be attributed to a clogged air filter or a faulty spark plug. Regularly checking and replacing these components can significantly improve starting performance.

Fuel Issues: Another common problem involves fuel delivery. Stale or contaminated fuel can lead to poor engine performance. It is advisable to use fresh fuel and consider adding a fuel stabilizer for prolonged storage periods.

Overheating: Equipment overheating can stem from inadequate lubrication or blocked cooling fins. Ensuring proper oil levels and clearing debris from cooling areas can mitigate this issue effectively.

Uneven Cutting: For devices equipped with blades, uneven cutting may occur due to dull blades or improper height adjustments. Regular sharpening and correct height settings can resolve this concern and enhance cutting efficiency.

Vibration Problems: Excessive vibration is often indicative of loose or worn components. Inspecting and tightening bolts, as well as replacing damaged parts, can help restore smooth operation.

By addressing these common challenges with the suggested solutions, users can ensure their equipment remains reliable and efficient for all outdoor tasks.

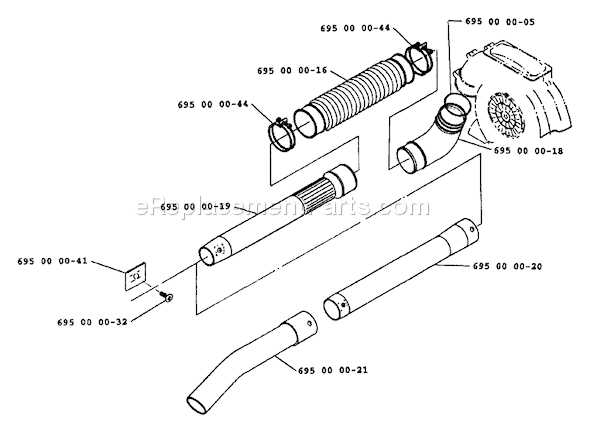

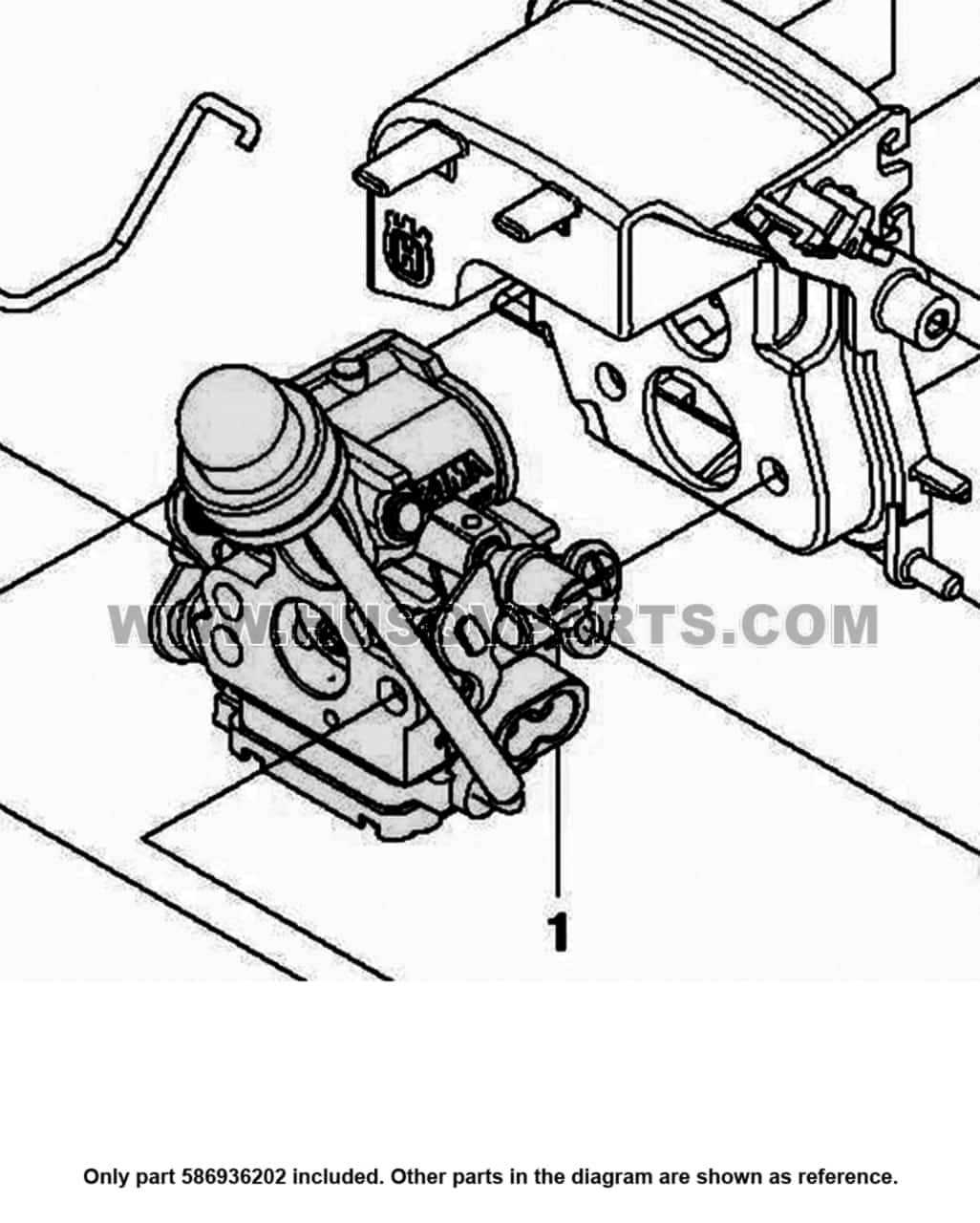

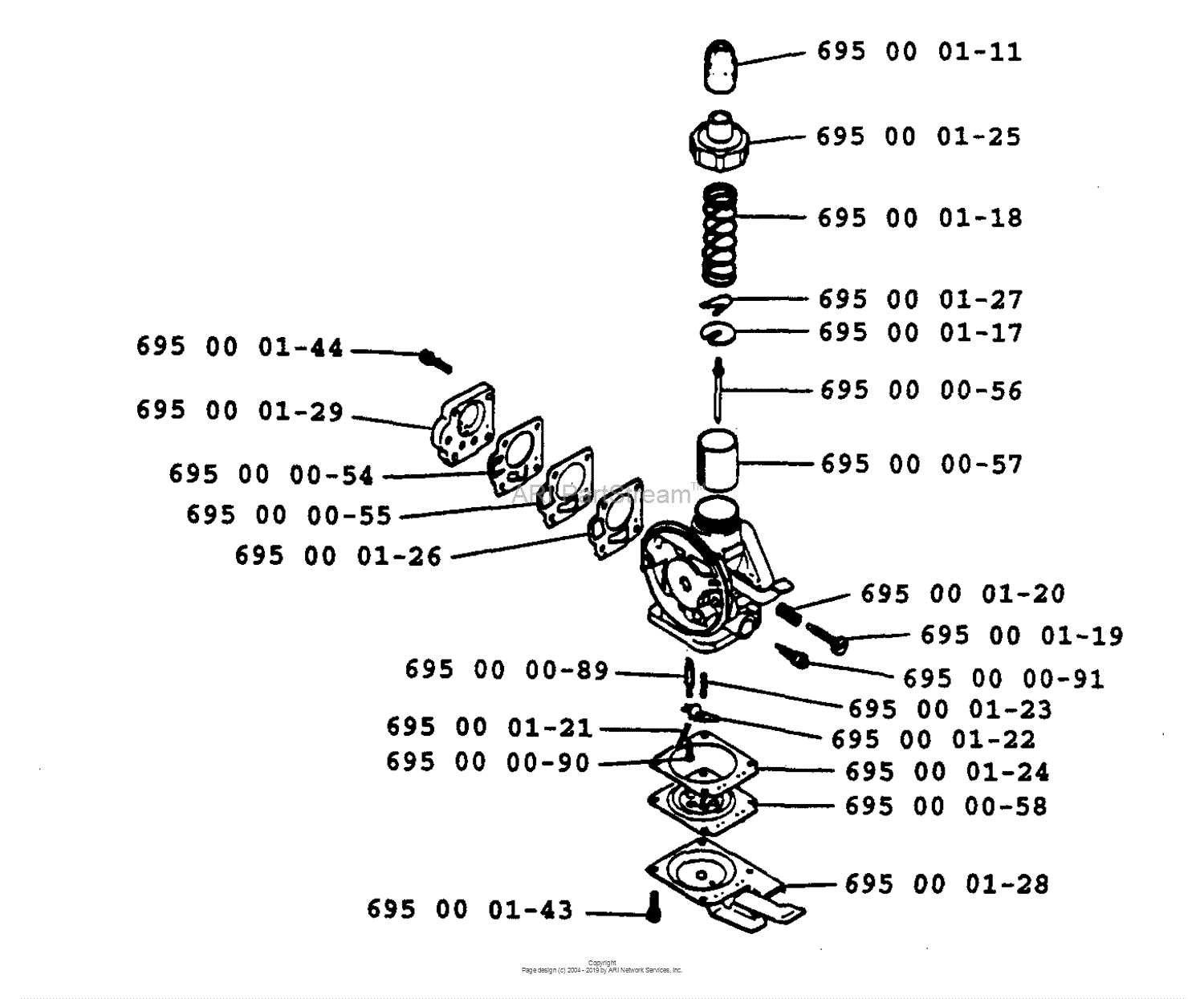

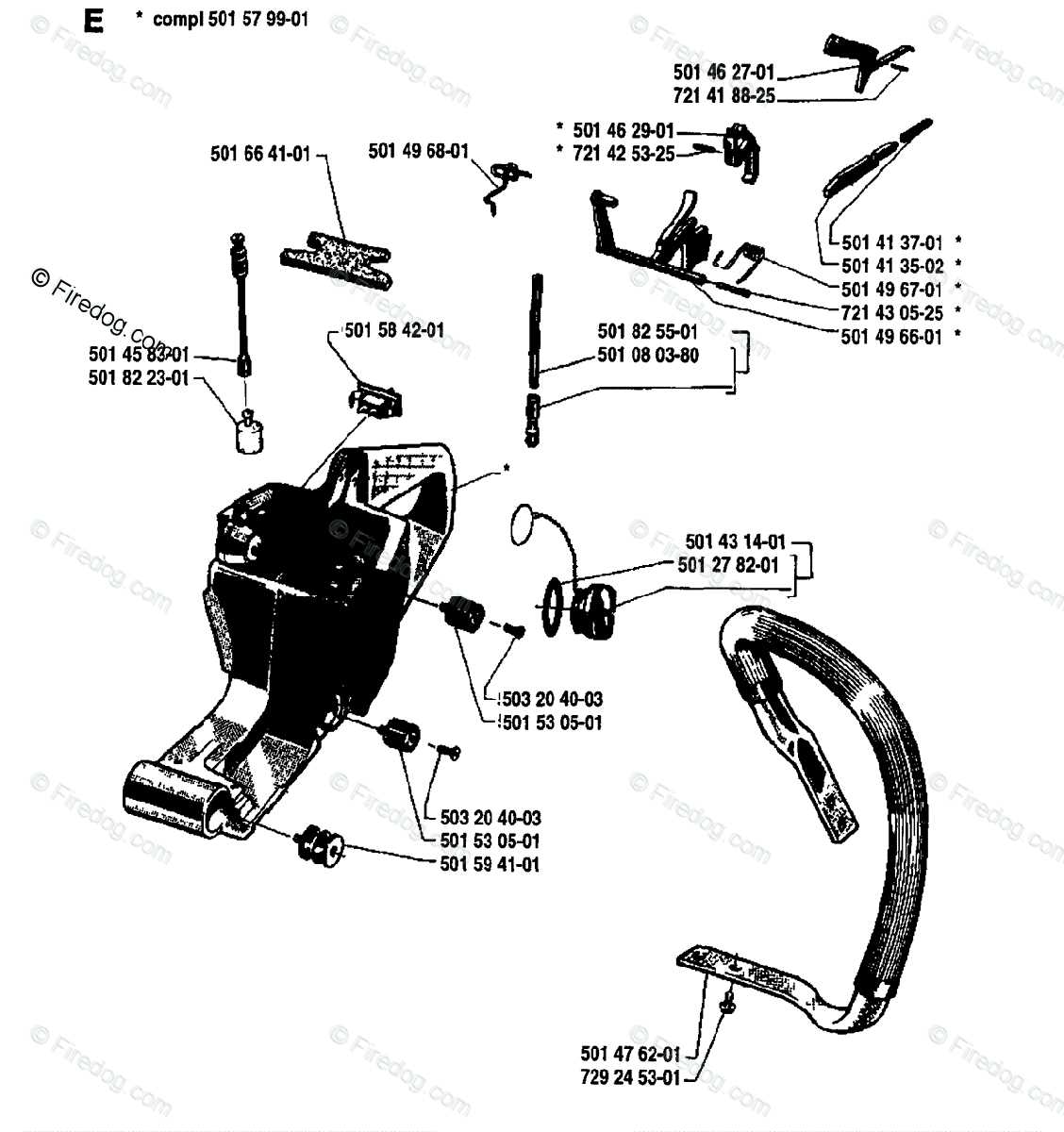

Importance of Accurate Parts Diagram

Having precise visual representations of components is crucial for ensuring effective maintenance and repairs. These illustrations provide a clear understanding of how each element fits together, enabling users to identify specific pieces and their functions efficiently.

When working on machinery, clarity is paramount. Accurate visuals not only simplify the assembly and disassembly processes but also minimize the risk of errors. Inaccuracies in representation can lead to incorrect installations or missing parts, ultimately resulting in costly delays and additional repairs.

Moreover, these resources enhance the overall efficiency of the repair process. By having a reliable reference, technicians can quickly locate the necessary items, reducing downtime and increasing productivity. Investing in comprehensive visual guides fosters a smoother workflow and promotes a deeper understanding of the equipment.

Where to Find Husqvarna Parts

Locating essential components for your outdoor equipment can significantly enhance its performance and longevity. Whether you are looking for original or aftermarket items, several resources can assist you in this endeavor.

Online Retailers: Numerous e-commerce platforms specialize in equipment accessories. Websites like Amazon and eBay offer a vast selection, allowing you to compare prices and read reviews.

Manufacturer’s Website: The official site often has a dedicated section for replacement items, ensuring you get authentic components designed for optimal compatibility.

Local Dealers: Authorized dealerships provide a personal touch, often featuring knowledgeable staff who can help you find the exact item you need.

Forums and Communities: Engaging in online groups dedicated to outdoor equipment can yield valuable insights. Members often share sources and recommendations for acquiring specific components.

Salvage Yards: These locations can be treasure troves for those seeking hard-to-find or discontinued items at a fraction of the cost.

By exploring these avenues, you can successfully procure the necessary elements to keep your outdoor tools running smoothly.

Maintenance Tips for Husqvarna 40

Proper upkeep of your equipment is essential for optimal performance and longevity. Regular attention can prevent common issues and ensure that your machine operates smoothly. Here are some key recommendations to keep in mind.

Regular Cleaning

Keep the exterior and interior components clean. Dirt and debris can affect functionality, so wipe down surfaces and remove any build-up after each use. Pay special attention to the air filter and spark plug area.

Check Lubrication Levels

Ensure all moving parts are adequately lubricated. Regularly check oil levels and refill as necessary to prevent wear and tear. Using high-quality lubricant will enhance performance and extend the life of your equipment.

Replacing Components Safely

When it comes to swapping out essential elements of your equipment, ensuring safety is paramount. Proper preparation and understanding of the process can prevent accidents and prolong the lifespan of your tools. This section highlights key practices that should be followed when replacing any components.

Preparation Steps

Before diving into the replacement process, taking a few preparatory steps can make all the difference. First, gather all necessary tools and materials. Second, ensure that the equipment is turned off and disconnected from any power source. Finally, refer to the manufacturer’s guidelines for specific instructions relevant to your model.

Safety Precautions

Implementing safety measures is crucial during the replacement procedure. Wear appropriate protective gear, such as gloves and safety goggles, to shield against potential hazards. Additionally, work in a well-lit area to maintain visibility. Always double-check that the equipment is stable and secured before making any adjustments.

| Safety Measure | Description |

|---|---|

| Power Off | Ensure the machine is completely powered down to prevent accidental activation. |

| Protective Gear | Wear gloves and goggles to protect yourself from debris and sharp components. |

| Clear Workspace | Maintain a tidy work area to avoid tripping hazards and misplaced tools. |

| Follow Instructions | Adhere to the manufacturer’s instructions for safe disassembly and reassembly. |

Tools Needed for Repairs

When embarking on maintenance tasks, having the right equipment is essential for efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also ensures that repairs are executed safely and correctly.

Essential items include various wrenches and screwdrivers, which allow for precise adjustments and secure fittings. Additionally, pliers and cutting tools are crucial for handling wires and other components. A reliable torque wrench is also beneficial to achieve the ultimate tightness required for specific fittings.

Moreover, consider including a multi-tool for added versatility and a sturdy workbench for stability. Don’t forget safety gear, such as gloves and goggles, to protect yourself during the repair process. By preparing adequately, you can delve into your repair tasks with confidence.

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing and maintaining your equipment. By following these organized steps, you can ensure effective repairs while minimizing the risk of damage. Understanding the various components and their functions will enhance your ability to troubleshoot and restore your device efficiently.

| Step | Description |

|---|---|

| 1 | Gather necessary tools and materials before starting the repair to ensure a smooth process. |

| 2 | Carefully examine the equipment to identify any issues or damaged components that need attention. |

| 3 | Refer to the specific component guide to understand how to disassemble the parts effectively. |

| 4 | Remove the affected parts, taking care to keep track of screws and small pieces for reassembly. |

| 5 | Replace or repair the damaged components as necessary, ensuring proper fit and function. |

| 6 | Reassemble the equipment, following the disassembly steps in reverse order to avoid missing any parts. |

| 7 | Test the repaired device to confirm that it operates correctly and that all issues have been resolved. |

Upgrading Your Husqvarna 40

Enhancing your outdoor power tool can significantly improve its performance and longevity. Whether it’s increasing efficiency or boosting comfort during use, a few strategic upgrades can make a notable difference. This section explores various options for elevating your equipment to meet modern standards.

Performance Enhancements

Consider upgrading the engine components for increased power. Enhanced air filters and spark plugs can optimize combustion, resulting in smoother operation. Additionally, look into specialized blades that provide better cutting efficiency, ensuring your tasks are completed more quickly and effectively.

Comfort and Usability Improvements

Upgrading ergonomic features can transform your experience. Invest in a more comfortable grip and adjustable handle for better control. Accessories like vibration dampeners can reduce fatigue during extended use, allowing you to work longer with less strain.

Identifying Genuine Parts

When maintaining equipment, ensuring the use of authentic components is crucial for optimal performance and longevity. Recognizing original elements can significantly impact functionality and reliability, helping to avoid complications that arise from using imitations. This section provides guidance on distinguishing genuine items from counterfeits, ensuring you make informed choices.

Key Features of Authentic Components

Genuine items often exhibit specific characteristics that set them apart from replicas. Look for high-quality materials, precise measurements, and clear branding. Authentic components typically come with documentation or packaging that confirms their origin, providing additional assurance of their legitimacy. Familiarizing yourself with these traits can aid in making better purchasing decisions.

Where to Purchase

Obtaining authentic components from authorized dealers or reputable retailers is essential. These sources not only guarantee the authenticity of their offerings but also provide customer support and warranty options. Avoid purchasing from unverified online marketplaces, as they often sell substandard replicas that can lead to further issues down the line.

Cost Comparison of Replacement Parts

When it comes to maintaining outdoor equipment, understanding the financial aspects of component replacement is crucial. Different suppliers offer varying prices for similar items, which can significantly impact overall maintenance costs. By comparing these costs, users can make informed decisions that align with their budgets while ensuring the longevity of their machinery.

Quality vs. Price is a vital factor in this comparison. While cheaper options may seem attractive, they often compromise durability and performance. Investing in high-quality replacements can lead to fewer repairs and extended equipment life, ultimately saving money in the long run.

Availability also plays a role in cost assessment. Some components may be readily accessible at local stores, while others might require online orders with potential shipping fees. Evaluating local availability can help minimize additional costs associated with delays and transport.

Additionally, bulk purchasing can offer significant savings. For frequent users, acquiring multiple items at once may provide discounts and reduce overall expenditure. Analyzing these bulk options can lead to considerable savings over time.

In conclusion, conducting a thorough cost analysis of available replacements can not only enhance budget management but also improve equipment reliability. Weighing the pros and cons of price, quality, and availability is essential for making wise investment choices in the long-term care of outdoor machinery.

FAQs About Husqvarna 40 Parts

This section addresses common inquiries regarding components related to the model in question. Understanding these elements is crucial for maintenance and optimal performance, ensuring users can troubleshoot effectively and make informed decisions about replacements or repairs.

What are the most common issues with these components?

Many users report challenges such as wear and tear, fuel efficiency, and starting difficulties. Regular inspections can help identify problems early, allowing for timely interventions.

Where can I find replacement components?

Replacement items can be sourced from authorized dealers, online marketplaces, or local hardware stores. Always ensure that the replacements meet quality standards to maintain performance.