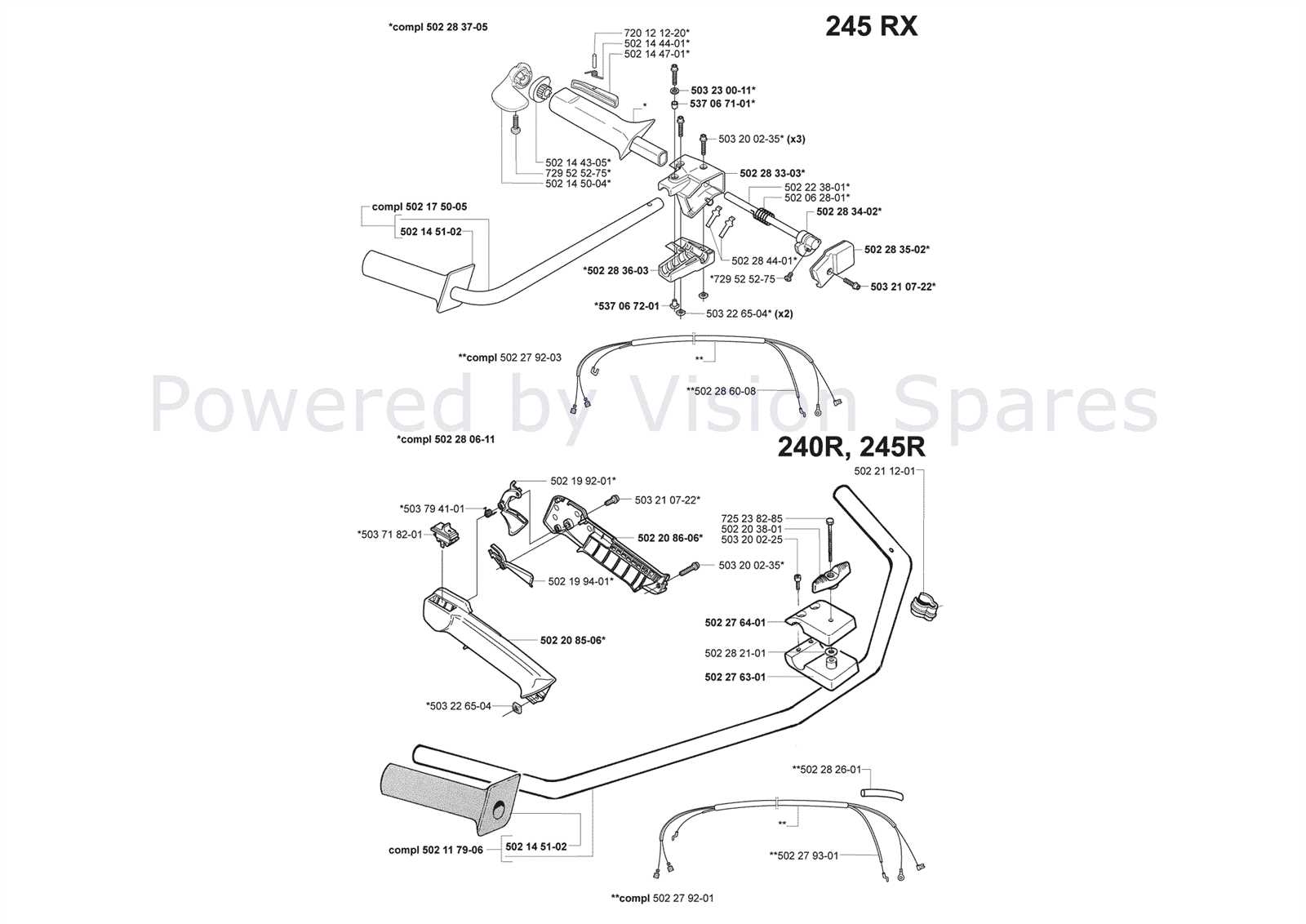

Ultimate Guide to Husqvarna 50 Parts Diagram

When working on small engines, having a clear understanding of the individual elements that comprise these machines is essential. Each component plays a vital role in the overall functionality, and recognizing their interconnections can significantly enhance your maintenance and repair efforts.

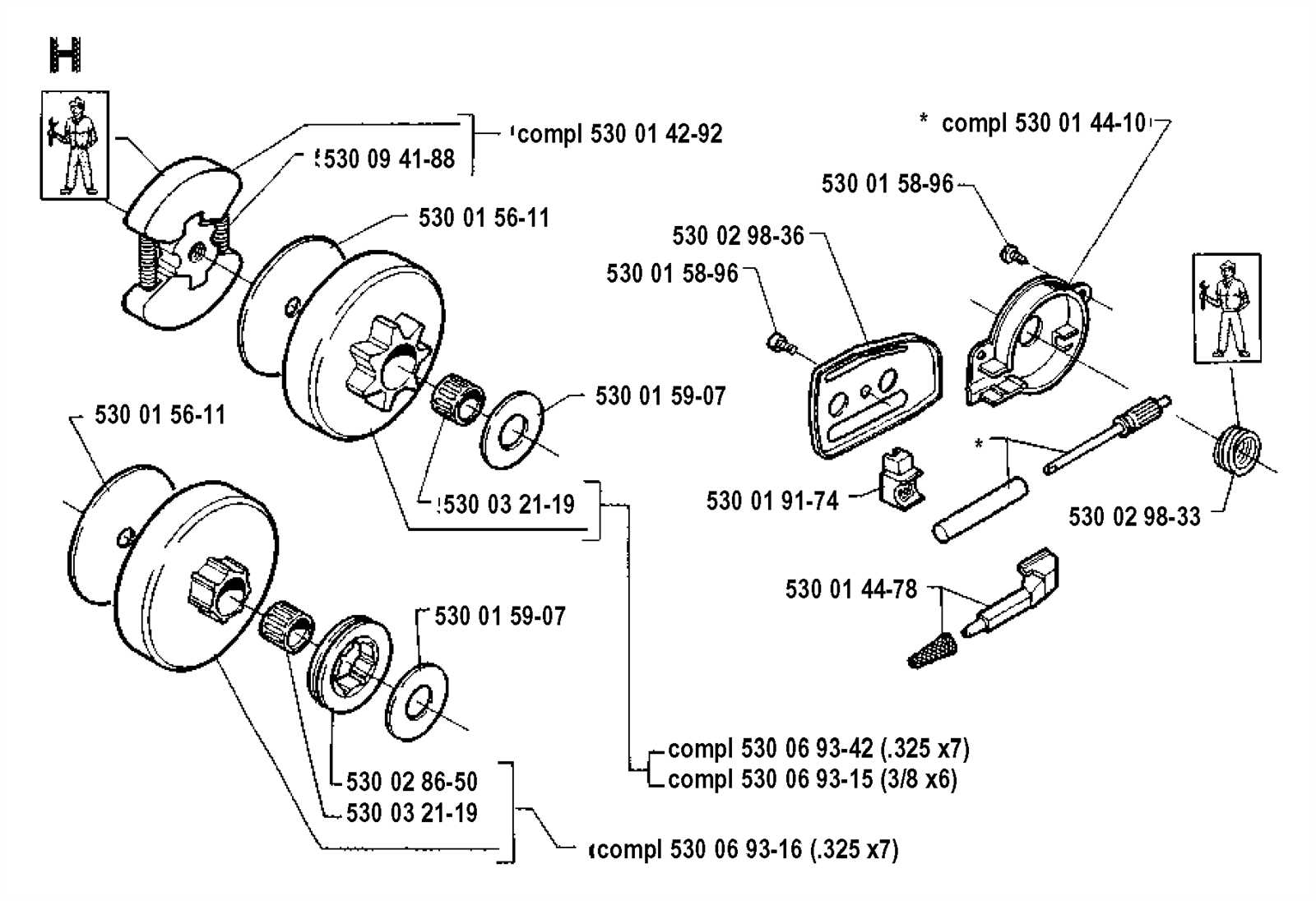

Visual aids can be invaluable for anyone looking to grasp the intricacies of engine assembly. By exploring detailed illustrations, users can identify specific parts and their functions, leading to improved troubleshooting and repair strategies.

Furthermore, a comprehensive overview of these elements not only aids in repairs but also helps in optimizing performance. The ability to delve into the mechanical layout can empower users to make informed decisions about upgrades and replacements, ultimately prolonging the life of their equipment.

Understanding Husqvarna 50 Parts

Gaining insight into the components of outdoor power equipment is essential for effective maintenance and repair. A clear understanding of each element’s role not only enhances performance but also prolongs the lifespan of the machine. By familiarizing oneself with the various elements, users can tackle issues more confidently and efficiently.

Key Components and Their Functions

Each segment of the equipment serves a specific purpose, contributing to the overall functionality. For instance, the engine provides the necessary power, while the ignition system ensures reliable starting. Other crucial elements, such as the fuel delivery mechanism and exhaust system, work together to optimize performance and reduce emissions. Recognizing how these components interact can significantly impact repair efforts.

Common Issues and Solutions

Understanding potential problems associated with each part can lead to quicker resolutions. Issues like fuel leaks or starting failures often stem from specific components. Regular inspection and knowledge of common faults allow users to address concerns proactively, preventing more severe complications down the line. Maintenance practices such as cleaning filters and checking connections can further enhance reliability.

Overview of Husqvarna 50 Model

The subject of this section centers around a specific machine known for its reliability and efficiency in various applications. This model is recognized for its robust construction, making it a favorite among users seeking durability and performance in their tools.

Key Features

This particular machine boasts several noteworthy attributes, including a powerful engine, user-friendly controls, and a lightweight design. These characteristics combine to enhance the overall experience for both novice and experienced users.

Specifications

| Specification | Details |

|---|---|

| Engine Type | Two-Stroke |

| Displacement | 50 cc |

| Weight | 10 lbs |

| Fuel Capacity | 1.1 liters |

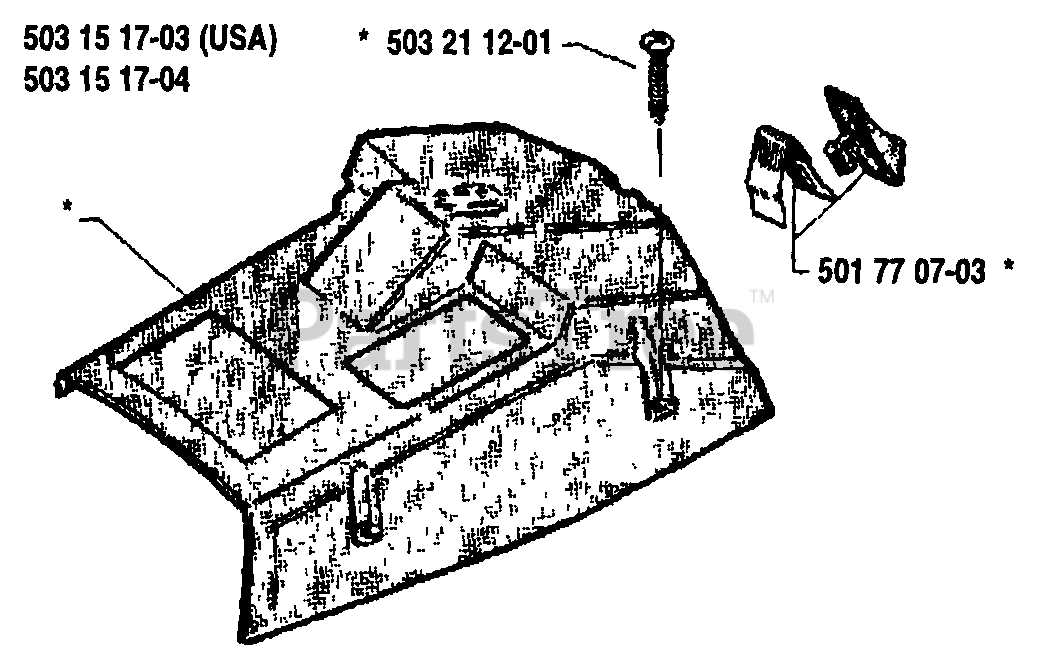

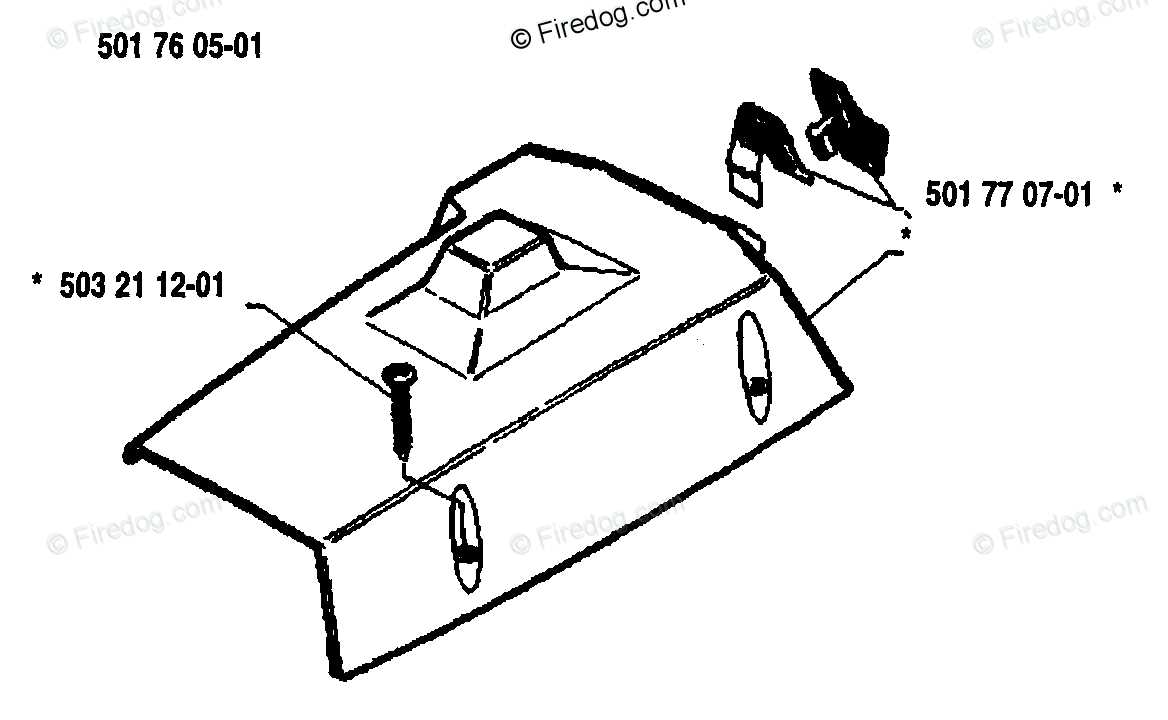

Importance of Parts Diagrams

Understanding the assembly and components of any mechanical device is crucial for effective maintenance and repair. Visual representations play a significant role in simplifying complex structures, allowing users to identify individual elements and their interrelations. This clarity enhances the troubleshooting process and promotes efficient repairs.

Enhanced Understanding

Visual schematics serve as a valuable tool for both novice and experienced technicians. They provide a clear overview of how different components fit together, making it easier to comprehend the functionality of the entire system. With these illustrations, users can quickly locate specific items, ensuring that the right pieces are addressed during servicing.

Streamlined Repairs

Accurate visuals can greatly expedite the repair process. By referring to detailed illustrations, individuals can identify the exact components needed for replacement or adjustment, minimizing the risk of errors. This leads to less downtime and improved performance of the equipment, ultimately resulting in cost savings and enhanced longevity.

Common Components of the Husqvarna 50

Understanding the essential elements of this model is crucial for effective maintenance and repair. Each component plays a significant role in the overall functionality and performance, contributing to the efficiency and durability of the machine.

Key Elements

The following are some of the vital components found in this model, which are essential for its operation:

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the machine, providing necessary torque and speed. |

| Fuel System | Comprises the fuel tank, lines, and carburetor, ensuring optimal fuel delivery. |

| Ignition System | Includes spark plugs and ignition coils, crucial for starting the engine efficiently. |

| Drive Mechanism | Transmits power from the engine to the wheels, affecting speed and handling. |

| Body Frame | The structural foundation that supports all other components and provides stability. |

Maintenance Tips

Regular inspection and maintenance of these components are essential for ensuring longevity and optimal performance. Keeping the engine clean, checking fuel lines for leaks, and ensuring the ignition system functions correctly are simple yet effective practices.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visual representations help users identify components and their relationships within a system. Mastering the ability to interpret these images can enhance your repair experience and efficiency.

Here are some key steps to help you navigate these illustrations:

- Familiarize Yourself with Symbols: Each illustration uses specific icons and notations. Make sure you know what each symbol represents.

- Identify Sections: Diagrams are often divided into sections based on the machine’s components. Recognizing these divisions helps in locating parts more easily.

- Follow Numbering Systems: Components are usually labeled with numbers or letters. Cross-reference these labels with the accompanying list to find detailed descriptions.

- Understand Scale: Pay attention to the scale of the illustration. This will help you visualize the size and placement of parts relative to one another.

- Look for Assembly Instructions: Some images include arrows or lines that indicate how parts fit together. Follow these indicators to grasp the assembly process.

By mastering these techniques, you will enhance your ability to read and understand technical representations, making your repair tasks more straightforward and effective.

Finding Replacement Parts Easily

Locating suitable components for your machinery can be a straightforward process when you know where to look. Understanding the various sources and methods available to you can simplify the task significantly, ensuring you get the right items quickly and efficiently.

Start by consulting official resources that provide detailed information about the specific model you are working with. Manufacturer websites often offer online catalogs, allowing you to search by model number and find compatible items without hassle. Additionally, user manuals can serve as invaluable references, detailing the necessary specifications and item numbers.

Local dealers and authorized retailers can also be reliable sources for high-quality components. Establishing a relationship with a trusted dealer may provide insights into stock availability and special orders, saving you time in the search process. Furthermore, online marketplaces often feature user reviews, enabling you to gauge the reliability of various sellers.

Another effective approach is to connect with online communities and forums dedicated to enthusiasts and professionals in your field. These platforms can provide recommendations and experiences from others who have faced similar challenges, guiding you toward the best options. Crowdsourcing knowledge can reveal alternative solutions you might not have considered.

By utilizing these strategies, you can streamline the search for the right components and ensure your equipment is back in optimal working condition with minimal delay.

Tips for Maintaining Your Equipment

Proper upkeep of your machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency, saving you time and money in the long run. Here are some effective strategies to keep your tools in top shape.

Regular Inspections

Conduct routine checks on all components to identify any wear or damage. Look for signs of rust, leaks, or loose fittings. Addressing these issues promptly can prevent further complications and ensure your equipment operates smoothly.

Cleanliness is Key

Maintaining a clean workspace is crucial. Remove dirt and debris from all surfaces, especially around moving parts. This helps avoid overheating and reduces the risk of mechanical failure. Regular cleaning will also enhance the overall appearance and functionality of your tools.

By incorporating these practices into your maintenance routine, you can significantly extend the lifespan of your equipment and ensure it performs at its best.

Identifying Unique Features of Husqvarna 50

This section explores the distinctive characteristics of a specific model in the realm of outdoor machinery, emphasizing its design and functionality. Recognizing these traits enhances the understanding of its performance and usability in various tasks.

Ergonomic Design

The model boasts an ergonomic design, ensuring user comfort during prolonged usage. The handle is crafted to reduce fatigue, allowing for easier maneuverability, which is crucial for achieving efficiency in operations.

Durable Construction

With a robust build, this equipment is engineered for longevity. The materials used are resistant to wear and tear, ensuring that it can withstand challenging environments, making it a reliable choice for both professionals and enthusiasts.

Sources for Genuine Parts

Finding authentic components is essential for ensuring the longevity and performance of your equipment. Utilizing reliable sources not only guarantees quality but also enhances overall efficiency.

- Authorized Dealers: These establishments provide verified items that meet manufacturer standards.

- Official Websites: Many brands have online stores that offer a wide range of original supplies.

- Specialty Retailers: Look for shops dedicated to outdoor machinery, as they often stock genuine materials.

- Online Marketplaces: Trusted platforms may have sections for verified sellers offering authentic items.

When seeking replacements, always prioritize sources that emphasize quality and reliability to ensure the best results.

Aftermarket vs. OEM Parts

When maintaining or repairing equipment, choices abound regarding component sourcing. Two primary categories often arise: components produced by original manufacturers and those created by third-party companies. Understanding the distinctions between these options is essential for making informed decisions that impact performance, reliability, and cost.

Original manufacturer components typically ensure a perfect fit and compatibility, adhering to specific quality standards. They may come at a higher price, reflecting the brand’s assurance of durability and reliability. In contrast, third-party alternatives often provide cost savings and variety but can vary significantly in quality and performance. Some may offer impressive features, while others might compromise longevity.

Ultimately, evaluating your specific needs, budget, and the intended use of your equipment will guide you in selecting the best components for your situation. Delve into user reviews and expert opinions to make the most informed choice, balancing cost with the desired level of quality.

Common Repairs and Their Diagrams

Understanding the frequent maintenance tasks for outdoor equipment is crucial for ensuring optimal performance and longevity. This section will explore typical repairs, providing illustrative guides to facilitate the process. By familiarizing oneself with these common issues, users can confidently address problems as they arise.

Engine Overhaul: Regularly inspecting the engine is essential. Common issues include worn gaskets and faulty spark plugs. A clear guide can help identify components and steps needed for a successful overhaul.

Fuel System Cleaning: Blockages in the fuel lines can lead to performance drops. Detailed visuals aid in understanding how to clean or replace filters and lines effectively.

Starter Mechanism Repair: A malfunctioning starter can be frustrating. Diagrams showing the assembly and disassembly process help in diagnosing and fixing starter issues with ease.

Chain Maintenance: Ensuring the chain is in good condition is vital for safety and efficiency. A visual representation can guide users through chain tensioning and replacement.

Electrical System Checks: Faulty wiring can disrupt functionality. Clear illustrations of the electrical system can assist in troubleshooting and repairing issues.

Tools Needed for Parts Replacement

When undertaking a repair or maintenance task, having the right instruments at your disposal is essential for efficiency and effectiveness. The proper tools not only facilitate the process but also ensure that each component is handled with care, minimizing the risk of damage. Whether you’re a seasoned technician or a novice, equipping yourself with the necessary gear will greatly enhance your experience.

Basic hand tools, such as screwdrivers and wrenches, form the foundation of any repair toolkit. These essentials allow you to easily access and remove components, ensuring a smooth workflow. Additionally, specialized tools may be required for more intricate tasks, enabling precise adjustments and secure fittings. Investing in quality equipment can make a significant difference in both the ease of use and the longevity of your gear.

Moreover, having safety equipment is paramount. Gloves, goggles, and other protective gear will safeguard you against potential hazards during the process. Proper preparation not only improves your efficiency but also promotes a safer working environment.

Ultimately, ensuring you have the right instruments at hand will lead to a successful and enjoyable maintenance experience. Thoroughly assessing what is needed before starting can save time and frustration, making your project more rewarding.

FAQs About Husqvarna 50 Parts

This section addresses common inquiries regarding components for the 50 model, providing clarity and support for users seeking information about replacements, maintenance, and compatibility.

Common Questions

- What are the most frequently replaced items for this model?

- How can I identify the correct components for my machine?

- Are there aftermarket options available?

- What is the best way to maintain these components?

Replacement and Compatibility

- Where can I find reliable suppliers for these components?

- How do I ensure compatibility with older models?

- What should I do if I receive the wrong item?