Understanding the Husqvarna 525RX Parts Diagram for Effective Maintenance

In the world of outdoor machinery, familiarity with the individual elements that comprise your device is essential for optimal performance and longevity. Whether you are a casual user or a dedicated professional, having a clear understanding of how each piece fits together enhances maintenance and repair efforts.

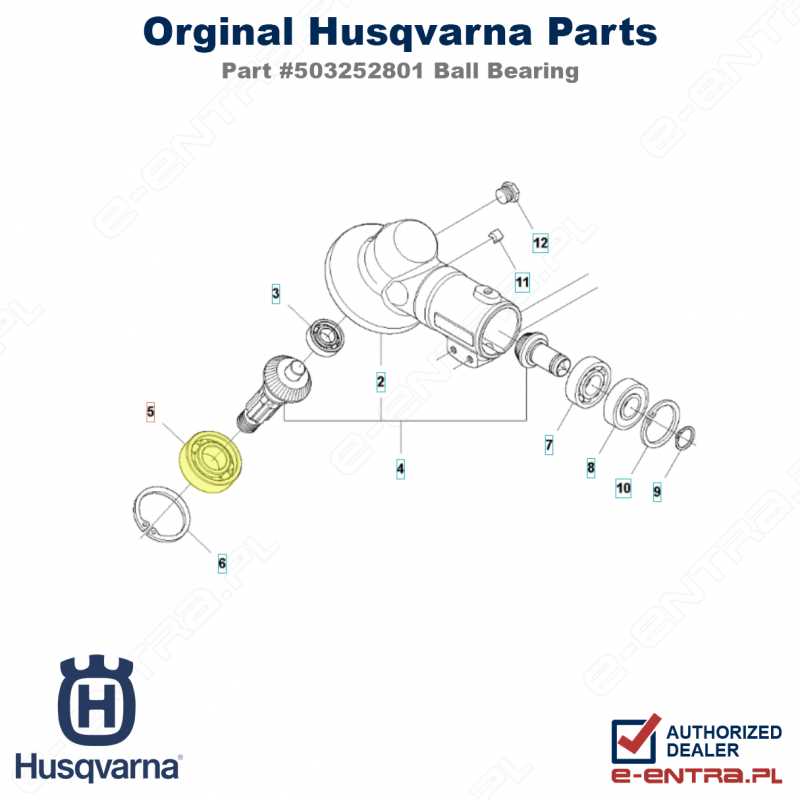

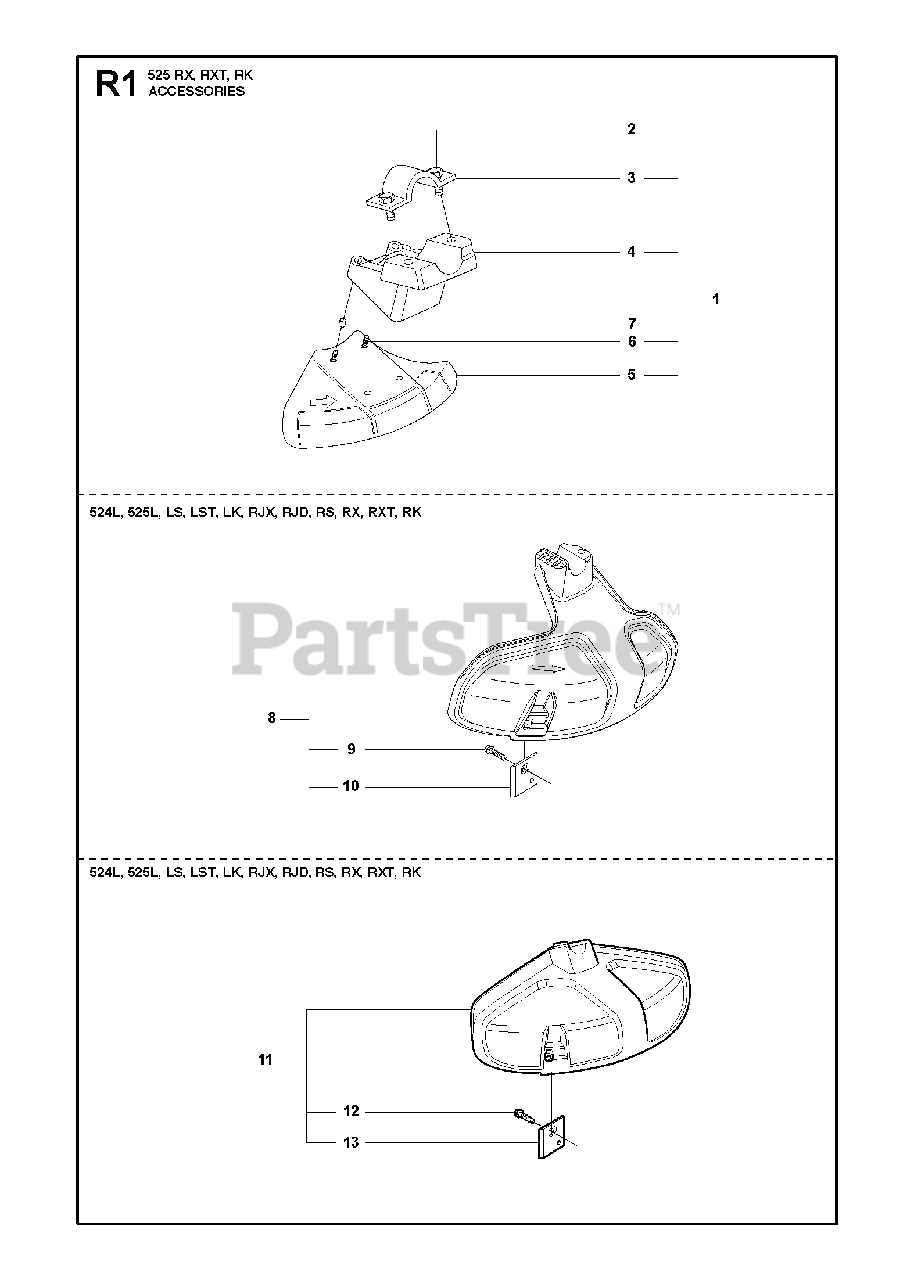

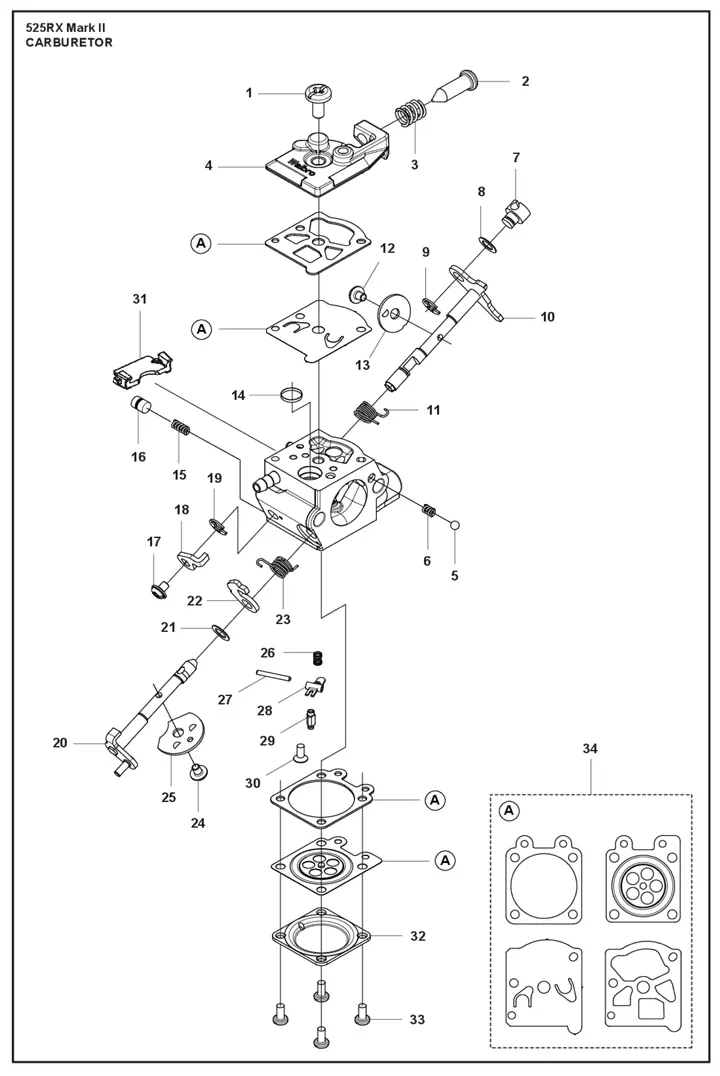

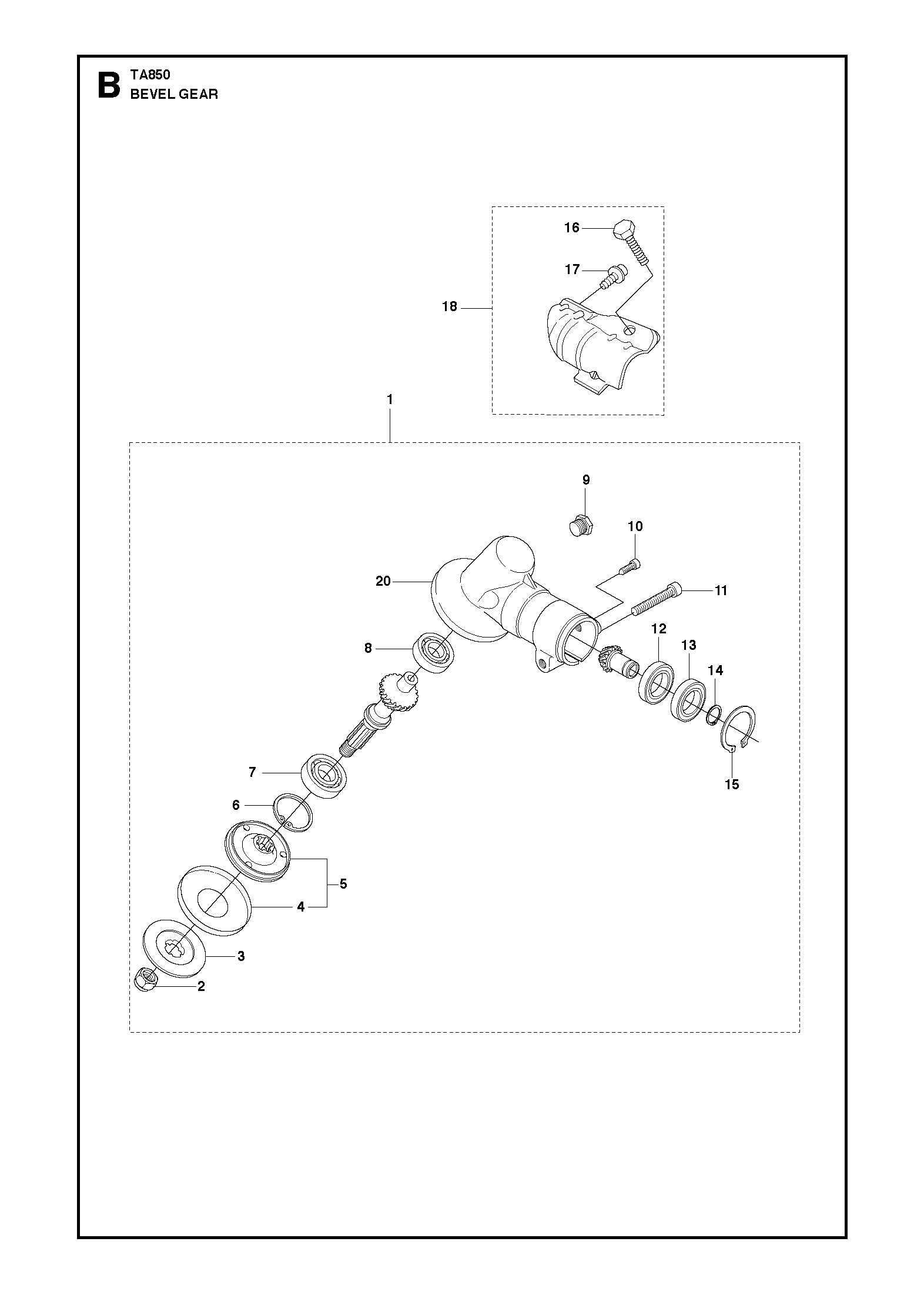

Visual references play a crucial role in identifying and locating specific components. By exploring these illustrations, you can navigate through the intricate assembly, ensuring you can address issues efficiently and effectively. Knowing the layout can save time and reduce frustration when troubleshooting.

Moreover, this knowledge empowers users to make informed decisions when sourcing replacements or upgrades. By delving into the specific arrangements of the various parts, you gain the ultimate advantage in managing your equipment’s needs, fostering a deeper appreciation for its functionality.

Understanding the Husqvarna 525RX

This section provides a comprehensive overview of a versatile outdoor power tool designed for efficiency and durability. Its robust engineering allows users to tackle a variety of landscaping tasks with ease. Whether you’re trimming, clearing, or maintaining your garden, this machine stands out for its performance and reliability.

Key Features

Equipped with a powerful engine, this device ensures smooth operation and optimal results. The lightweight design enhances maneuverability, allowing users to navigate through tight spaces without fatigue. Additionally, the ergonomic handle improves comfort during extended use, making it suitable for both professionals and casual users.

Maintenance and Care

Regular upkeep is essential for sustaining the performance of this equipment. Routine checks and timely replacement of wear components can significantly extend its lifespan. Following the manufacturer’s recommendations for maintenance not only enhances functionality but also ensures safety during operation. Understanding these aspects is crucial for any owner aiming to get the best out of their tool.

Key Components of the 525RX

This section explores the essential elements that contribute to the functionality and efficiency of this outdoor power tool. Understanding these components is crucial for maintenance and optimal performance.

Core Elements

The main features of the device include a robust engine, a durable cutting system, and an ergonomic handle. Each part plays a vital role in delivering power and comfort during operation.

Maintenance Parts

| Component | Description |

|---|---|

| Engine | Provides the necessary power for cutting tasks. |

| Cutting Head | Enables efficient trimming and clearing of vegetation. |

| Handle | Designed for comfort and control during use. |

| Fuel Tank | Stores fuel needed for engine operation. |

Benefits of Proper Parts Diagram

Understanding the layout and components of machinery is essential for effective maintenance and repair. Having a clear visual representation facilitates quicker identification of elements, reducing downtime and enhancing operational efficiency.

Enhanced Troubleshooting

With a well-organized visual guide, users can quickly pinpoint issues and address them directly. This leads to faster resolutions and minimizes the risk of further complications.

Improved Inventory Management

A detailed schematic allows for better tracking of components. This ultimate clarity ensures that replacements are readily available, preventing unnecessary delays in repairs and maintenance tasks.

How to Read the Diagram

Understanding the visual representation of components is essential for effective maintenance and repair tasks. This guide will help you navigate the intricate details often presented in these illustrations, enabling you to identify parts quickly and accurately.

Key Elements to Identify

- Labels: Look for clear markings that indicate each component’s name and function.

- Connections: Observe how different elements are linked, as this shows their relationships and assembly order.

- Legend: Many representations include a legend to clarify symbols or colors used throughout.

Steps to Effectively Analyze

- Start from the outer components and work your way inward to understand the assembly process.

- Cross-reference with a parts list if available to ensure accuracy.

- Take notes on any unique features that might aid in reassembly.

Common Replacement Parts Explained

When it comes to maintaining outdoor power equipment, understanding the essential components that may require substitution is crucial for optimal performance. Regular wear and tear can affect efficiency, making it important to recognize which elements are most commonly replaced to ensure your machinery operates smoothly.

Key Components

Among the frequently substituted items are filters, spark plugs, and fuel lines. Filters are vital for keeping contaminants out of the engine, thereby prolonging its life. Spark plugs play a critical role in ignition; replacing them can significantly improve starting and overall engine performance. Fuel lines, often exposed to wear and environmental factors, may become cracked or clogged, leading to fuel delivery issues.

Maintaining Longevity

To maximize the lifespan of your equipment, it’s essential to regularly check these components. By proactively replacing worn elements, you can prevent more significant issues down the line, ensuring your tools remain reliable and effective. Regular maintenance not only improves functionality but also enhances safety during use.

Tools Needed for Maintenance

Regular upkeep of your equipment ensures optimal performance and longevity. Having the right tools at hand is essential for effective maintenance tasks. Below is a list of necessary instruments that will aid in keeping your machinery in top shape.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For tightening and loosening screws in various components. |

| Wrench Set | Used for adjusting nuts and bolts, providing secure connections. |

| Spark Plug Wrench | Essential for removing and installing spark plugs during checks. |

| Oil Filter Wrench | Helps in replacing the oil filter efficiently. |

| Cleaning Brush | Useful for removing debris and ensuring clean operation. |

Identifying Parts by Model Number

Understanding the components of a machine is crucial for maintenance and repairs. Each model comes with a specific identification number that simplifies the process of finding the right elements for replacement or servicing. This identification system ensures that users can efficiently locate and order the exact items needed for their equipment.

Importance of Model Numbers

Model numbers serve as unique identifiers, making it easier to differentiate between various types and generations of machinery. By using the model number, users can access precise catalogs and resources, ultimately reducing the risk of purchasing incompatible components.

Steps to Identify Components

To locate the correct items, start by finding the model number, usually located on the equipment itself. Once identified, consult the manufacturer’s documentation or online resources that provide detailed listings. This method streamlines the replacement process and enhances overall functionality.

Where to Buy Replacement Parts

Finding high-quality components for your outdoor equipment is essential for maintaining optimal performance and longevity. There are several reliable sources to consider when looking for these necessary items.

- Authorized Dealers: Visiting a certified dealer ensures you receive genuine components that are specifically designed for your equipment.

- Online Retailers: Numerous e-commerce platforms offer a wide selection of components, often with user reviews to guide your choices.

- Local Hardware Stores: Many local shops carry essential parts, allowing you to inspect items in person before making a purchase.

- Manufacturer’s Website: Checking the official website can provide direct access to a complete inventory, often with detailed information and specifications.

- Second-hand Market: Websites and forums dedicated to used goods can be a cost-effective option, but ensure the quality and compatibility of the items.

Regardless of the source, always verify the compatibility of the components with your specific model to ensure optimal performance and reliability.

Comparing Parts with Other Models

This section explores the similarities and differences between components of various models within the same category. Understanding these distinctions can help users make informed decisions when seeking replacements or upgrades.

When comparing components, consider the following factors:

- Compatibility: Assess if the items can be interchangeably used across models.

- Quality: Evaluate the materials and construction methods to determine durability.

- Performance: Analyze how variations affect overall efficiency and functionality.

Here’s a breakdown of common components:

- Engines

- Blades

- Filters

- Handles

By examining these aspects, users can delve deeper into the optimal choice for their needs, ensuring ultimate satisfaction and performance from their equipment.

Importance of Genuine Parts

Utilizing authentic components is crucial for maintaining the longevity and performance of equipment. These original elements ensure that machinery operates as intended, minimizing the risk of malfunction and enhancing efficiency.

Benefits of Using Authentic Components

- Optimal Performance: Genuine items are designed to work seamlessly with your equipment.

- Longevity: High-quality materials lead to increased durability.

- Safety: Original parts meet stringent safety standards, reducing hazards.

Risks of Using Imitation Items

- Frequent Breakdowns: Non-authentic parts may not fit properly, leading to increased wear and tear.

- Warranty Void: Using replicas can nullify manufacturer warranties.

- Increased Costs: Long-term expenses rise due to more frequent replacements.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its long-lasting performance and efficiency. By implementing a few key maintenance practices, you can significantly extend the lifespan of your tools and minimize the need for repairs. Regular care not only enhances functionality but also improves safety during operation.

Regular Cleaning: After each use, make it a habit to clean the exterior and remove any debris or residue. This prevents buildup that can hinder performance and promotes a longer life for moving parts.

Check and Replace Filters: Air and fuel filters play a crucial role in the efficiency of your machinery. Regularly inspect them for dirt and clogs, and replace them as necessary to ensure optimal airflow and fuel delivery.

Inspect the Spark Plug: The spark plug is vital for ignition. Check it periodically for wear and replace it when you notice signs of corrosion or damage. A well-functioning spark plug can lead to better engine performance.

Lubrication: Keeping moving parts lubricated reduces friction and wear. Follow the manufacturer’s guidelines for the type and frequency of lubrication to maintain smooth operation.

Store Properly: When not in use, store your equipment in a dry, clean environment. Protect it from extreme temperatures and moisture, which can lead to rust and deterioration.

By adhering to these maintenance tips, you can ensure your equipment remains reliable and efficient, ultimately saving you time and money in the long run.