Comprehensive Guide to Husqvarna 55 Parts Diagram

Understanding the intricacies of a robust outdoor equipment model is essential for both enthusiasts and professionals. This section will delve into the various elements that contribute to its performance and longevity. Knowledge of each component allows users to make informed decisions regarding maintenance and repairs.

Identifying the specific functionalities of different sections enhances the overall user experience. By familiarizing yourself with the essential parts, you can ensure optimal operation and prevent potential issues. This resource serves as an ultimate guide for those looking to deepen their understanding of their trusted equipment.

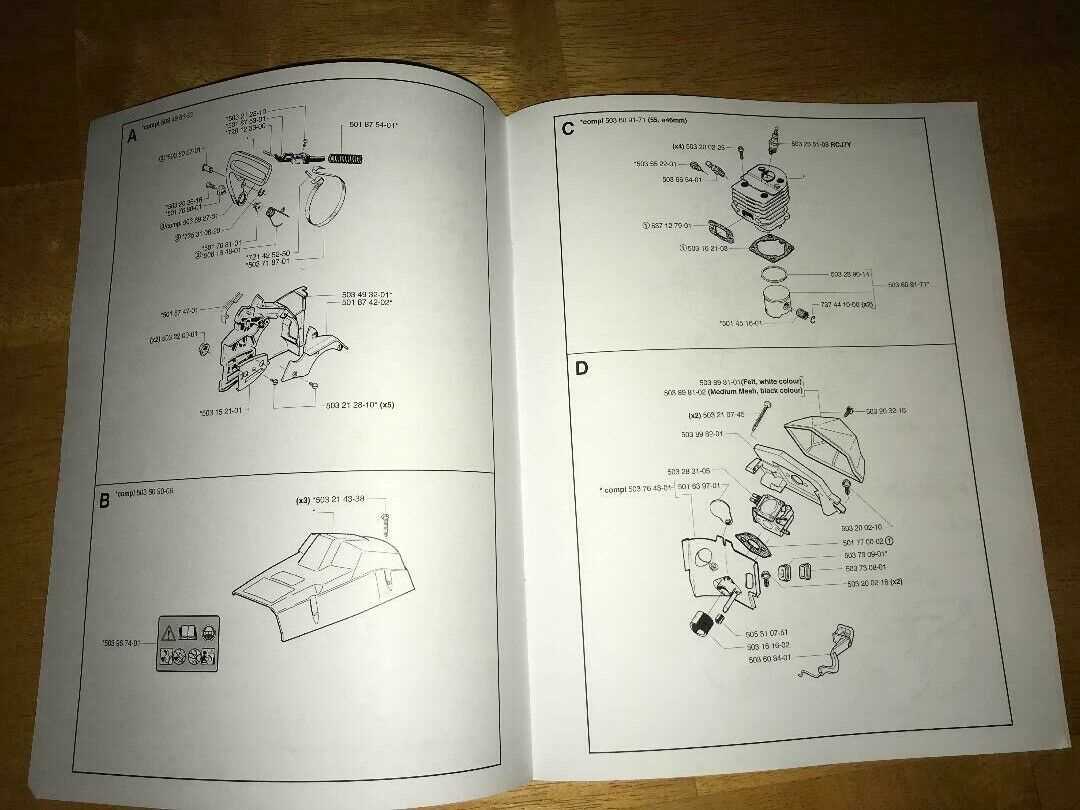

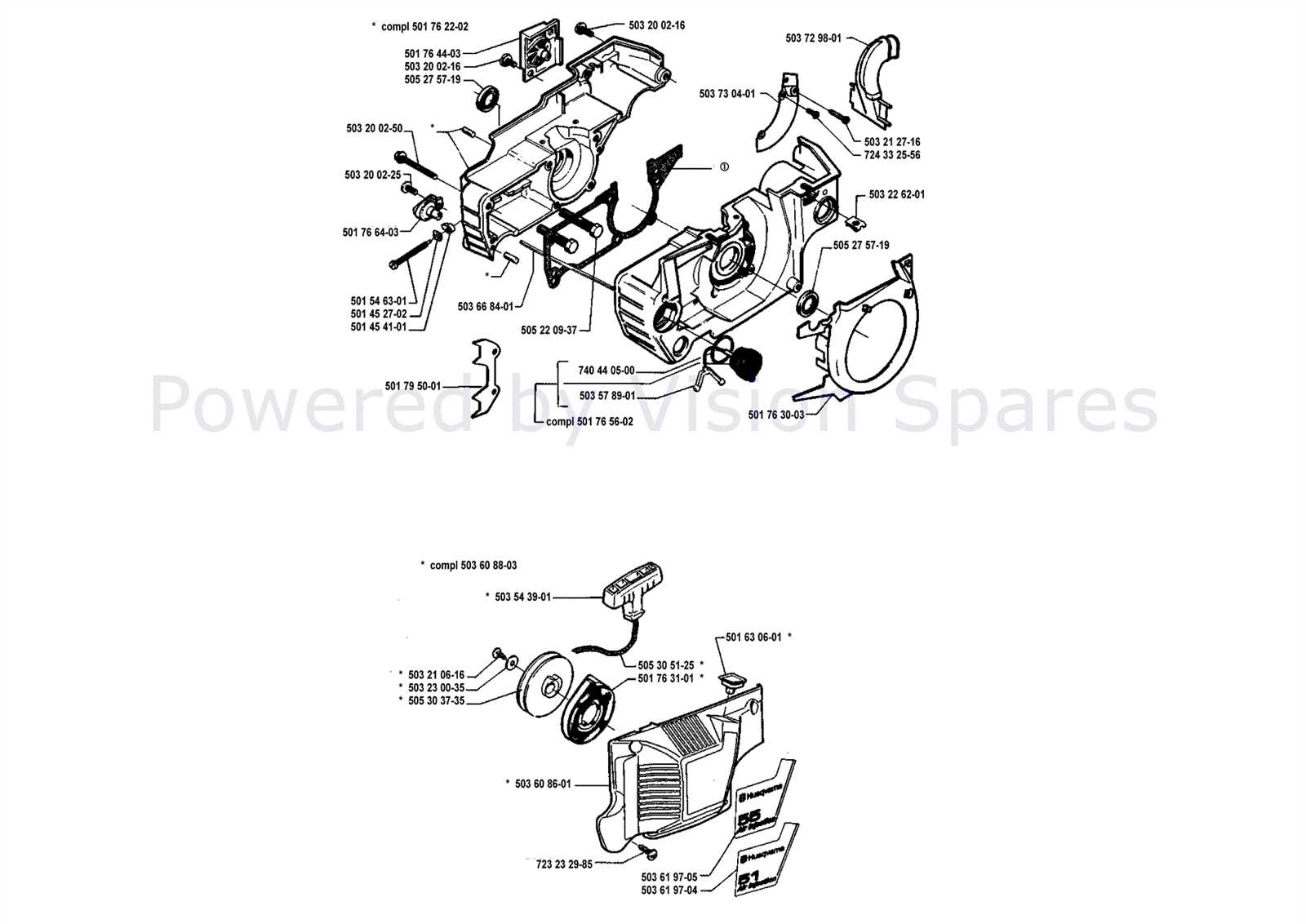

Whether you’re troubleshooting a problem or planning a replacement, having a clear visual representation of the unit’s architecture is invaluable. This comprehensive overview not only simplifies the repair process but also promotes a greater appreciation for the engineering behind these powerful machines.

Understanding Husqvarna 55 Chainsaw

This section delves into the essential aspects of a popular cutting tool known for its reliability and efficiency in various outdoor tasks. By exploring its components and functionality, users can enhance their understanding and maintenance of this equipment.

The chainsaw features a powerful engine that drives the cutting mechanism, making it suitable for a range of applications from pruning to felling trees. Familiarity with its key elements can significantly improve performance and longevity.

- Engine: The heart of the device, providing the necessary power.

- Guide Bar: Supports the chain and directs cutting.

- Chain: The cutting element that interacts with wood.

- Clutch: Engages and disengages the chain for safety and control.

- Air Filter: Keeps the engine clean by filtering out debris.

- Fuel System: Supplies the engine with the necessary mixture for operation.

Understanding each of these components allows for better troubleshooting and maintenance practices. Regular checks and proper care can extend the lifespan of this equipment, ensuring it remains a valuable tool for any outdoor project.

Additionally, users should be aware of safety features that are integrated to protect the operator during use. Familiarity with these can prevent accidents and enhance overall experience.

By gaining insight into this cutting tool, users can ensure efficient operation and proper handling, making outdoor tasks more manageable and enjoyable.

Key Components of Husqvarna 55

This section explores the essential elements of a renowned chainsaw model, highlighting their significance in ensuring optimal performance and durability. Each component plays a critical role, contributing to the overall functionality and user experience.

Engine: The heart of the machine, delivering power and efficiency, enabling smooth operation in various cutting tasks.

Bar and Chain: These elements are crucial for cutting; the bar supports the chain, while the chain itself performs the actual cutting action, showcasing precision and speed.

Fuel System: This system ensures the proper mixture of fuel and oil, essential for maintaining engine performance and longevity.

Air Filter: A vital component that prevents dirt and debris from entering the engine, promoting optimal air flow and engine health.

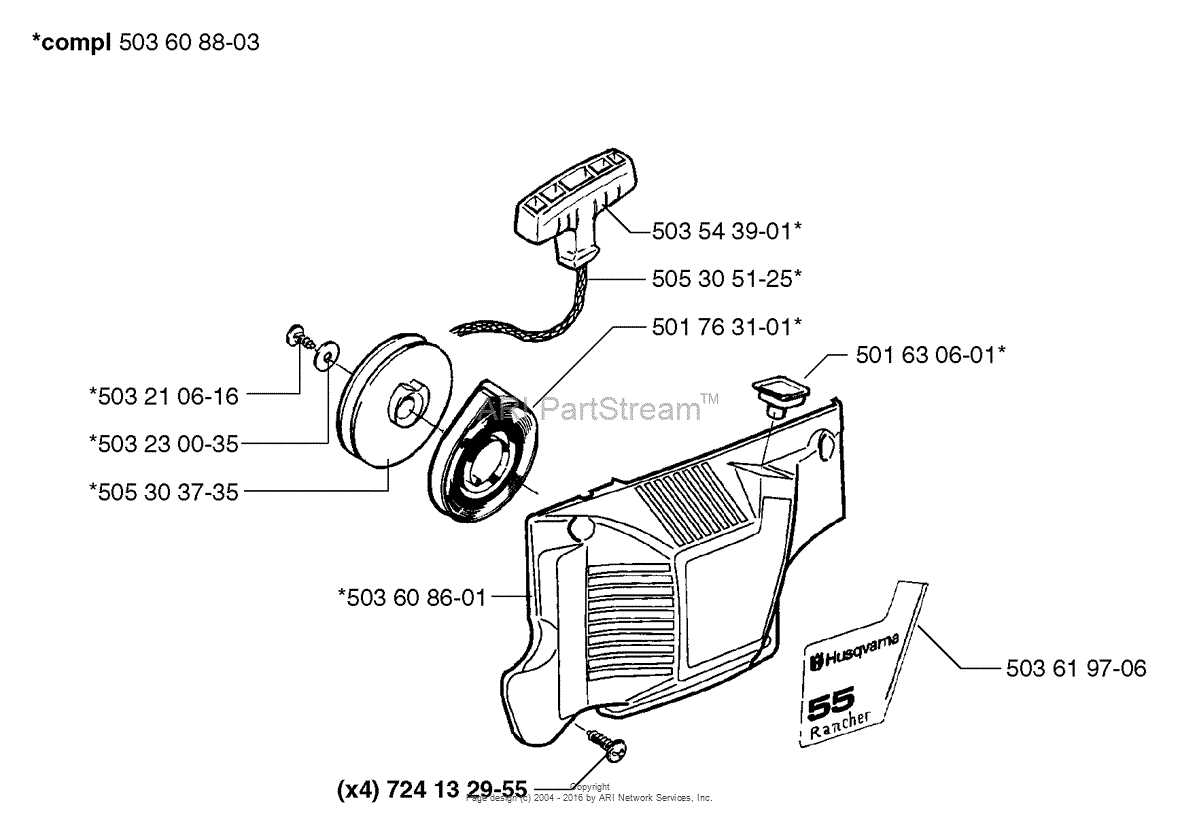

Starter Mechanism: Facilitating easy ignition, this mechanism is designed for user convenience, allowing quick readiness for operation.

Handle and Safety Features: Designed for comfort and control, these features ensure safe handling during use, reducing the risk of accidents.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations of individual elements provide clarity and facilitate a deeper knowledge of how each piece contributes to the overall functionality. This clarity is essential for both novice users and seasoned professionals.

Here are several reasons why these visual guides are valuable:

- Enhanced Understanding: They break down complex systems into manageable sections, making it easier to identify and comprehend each component’s role.

- Efficient Repairs: Quick reference allows technicians to locate necessary items swiftly, minimizing downtime during service.

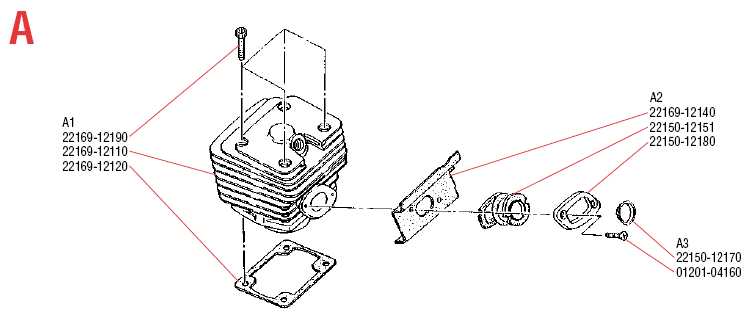

- Accurate Replacements: By clearly showing how parts fit together, these visuals help ensure that replacements are correct and compatible.

- Cost Savings: Knowing exactly what needs to be replaced can prevent unnecessary expenses on incorrect or unnecessary components.

- Educational Resource: They serve as a learning tool for those new to machinery, helping them familiarize themselves with various components and their functions.

In conclusion, visual representations of machinery components are indispensable resources for anyone involved in maintenance and repair, ensuring both efficiency and effectiveness in managing equipment.

Where to Find Diagrams Online

Locating visual guides and technical illustrations can be essential for maintenance and repair tasks. Various resources are available online that cater to this need, offering detailed views of components and their arrangements. These resources can help users identify parts, understand assembly processes, and troubleshoot issues effectively.

One of the best starting points is official manufacturer websites, which often provide comprehensive manuals and exploded views for their products. Additionally, online forums and community groups dedicated to machinery can be valuable. Users frequently share links to relevant documents, enhancing the collective knowledge base.

Furthermore, numerous specialized websites compile technical resources across different brands and models. Search engines can also yield useful results when using specific queries related to the equipment in question. Always ensure that the sources are reliable to obtain accurate and updated information.

Common Issues with Husqvarna 55

When it comes to outdoor power equipment, certain problems frequently arise, affecting performance and reliability. Understanding these common challenges can help users maintain their tools more effectively and enhance their longevity.

- Starting Difficulties:

Many users report trouble with ignition, which can stem from various causes, such as:

- Old fuel or improper fuel mixture.

- Clogged fuel filter.

- Worn spark plug.

- Overheating:

Overheating can lead to severe damage. Key factors include:

- Blocked air vents.

- Insufficient lubrication.

- Extended use without breaks.

- Chain Issues:

Problems with the cutting mechanism are common, often caused by:

- Improper tensioning of the chain.

- Dull or damaged chain links.

- Dirty bar and chain oil.

- Vibration Problems:

Excessive vibration can affect comfort and control. Potential causes include:

- Loose or worn components.

- Unbalanced cutting equipment.

- Improper handling technique.

lessCopy code

By being aware of these common issues and their potential solutions, users can ensure their equipment remains functional and efficient for years to come.

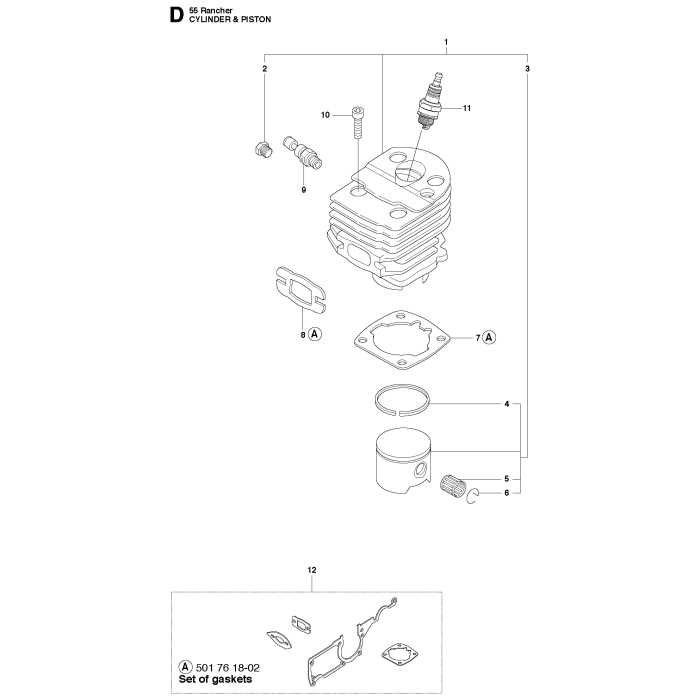

Replacement Parts Overview

Maintaining the efficiency of your outdoor equipment often involves understanding its components. This section provides a comprehensive look at the essential elements that may require replacement over time, ensuring optimal performance and longevity.

Key components typically include:

- Engines: Vital for power generation, these units may need servicing or replacement to maintain functionality.

- Blades: Crucial for cutting efficiency, worn or damaged blades can drastically affect performance.

- Filters: Air and fuel filters are essential for clean operation; replacing them regularly can prevent engine issues.

- Chains: For equipment that utilizes chains, ensuring they are in good condition is necessary for safety and efficiency.

- Spark plugs: These components ignite the fuel mixture; worn plugs can lead to starting difficulties and poor engine performance.

When considering replacements, it’s important to choose high-quality alternatives that match the specifications of your machine. Regular maintenance checks can help identify worn elements before they lead to more significant issues.

In summary, understanding the key components and their maintenance needs is essential for the longevity of your equipment. Regular inspections and timely replacements will ensure your machinery operates smoothly and effectively.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular attention and care. Implementing a few simple practices can significantly enhance performance and reduce the likelihood of breakdowns.

Regular cleaning is essential to prevent debris buildup that can affect functionality. Additionally, checking and replacing worn components proactively can help maintain efficiency. Always refer to your user manual for specific recommendations.

| Tip | Description |

|---|---|

| Clean After Use | Remove dirt and residue to prevent corrosion and damage. |

| Inspect Regularly | Look for signs of wear and replace parts as needed. |

| Store Properly | Keep equipment in a dry, cool place to avoid environmental damage. |

| Use Quality Fuel | Opt for high-quality fuel to enhance performance and longevity. |

Tools Needed for Repairs

Effective maintenance and repair require a specific set of instruments to ensure tasks are completed efficiently and safely. Having the right tools on hand can significantly streamline the process, making it easier to address various issues that may arise during servicing. Familiarity with these essential implements not only aids in performing repairs but also enhances overall understanding of the equipment.

Begin with basic hand tools, such as screwdrivers, pliers, and wrenches. These are crucial for disassembling and reassembling components with precision. Additionally, socket sets can provide the necessary torque for fastening and loosening parts securely. Measuring tools like calipers and rulers may also prove beneficial when ensuring parts fit together correctly.

Specialized tools tailored for specific tasks, such as a chain tool or a torque wrench, can further facilitate the repair process. A good workbench with adequate lighting is vital for a safe and organized workspace. Lastly, having a reliable set of safety gear, including gloves and goggles, ensures protection during any maintenance activity.

Assembly Instructions for Husqvarna 55

Proper assembly is crucial for optimal performance and safety. This section outlines essential steps and considerations for putting together the components of your device, ensuring a smooth and effective process.

Preparation Steps

Before beginning the assembly, gather all necessary tools and components. Ensure your workspace is clean and organized to facilitate a streamlined process. Familiarize yourself with the individual parts and their functions to enhance efficiency during assembly.

Assembly Process

Follow these steps to successfully assemble your unit:

| Step | Description |

|---|---|

| 1 | Start by placing the base component on a flat surface, ensuring stability. |

| 2 | Attach the primary unit, aligning it carefully with the designated slots. |

| 3 | Secure all screws and bolts, following the manufacturer’s torque specifications. |

| 4 | Connect the fuel lines, ensuring there are no kinks or blockages. |

| 5 | Install the safety features, double-checking their functionality. |

Once all components are securely assembled, conduct a final inspection to ensure everything is in place before operation. Following these guidelines will help maintain safety and efficiency during use.

Comparing Original vs. Aftermarket Parts

When it comes to maintaining your equipment, choosing between genuine components and alternatives can significantly impact performance and longevity. Each option has its own advantages and drawbacks that warrant careful consideration.

- Quality: Genuine components are typically manufactured to stricter standards, ensuring reliability and compatibility.

- Cost: Alternatives often come at a lower price point, appealing to budget-conscious users.

- Availability: Aftermarket options may offer a wider range of products, especially for older models.

- Warranty: Genuine components usually come with a manufacturer warranty, providing peace of mind.

Ultimately, the choice between original and alternative options depends on your specific needs, preferences, and the intended use of your equipment.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also ensure that the equipment remains in optimal working condition. By adhering to specific guidelines, you can create a safer working environment.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. Protective gloves shield your hands from sharp edges and hot surfaces, while safety goggles guard your eyes against debris and dust. Sturdy footwear provides stability and reduces the risk of foot injuries from falling objects.

Work Environment Safety

Ensure that your workspace is well-lit and free from clutter. A clean area minimizes the risk of trips and falls. Keep flammable materials away from your repair site, and always have a fire extinguisher nearby. Additionally, ensure that all tools are in good condition and appropriate for the tasks at hand, as using damaged equipment can lead to accidents.

Resources for Husqvarna Owners

For enthusiasts and owners of outdoor power equipment, having access to reliable information and resources is essential. Whether you need maintenance tips, troubleshooting guides, or product enhancements, various platforms can assist you in maximizing the performance of your machinery.

Here are some valuable resources to consider:

- Official Manufacturer Website: The primary source for manuals, safety information, and product updates.

- Online Forums: Communities where users share experiences, tips, and solutions for common issues.

- YouTube Channels: Video tutorials offering step-by-step guidance for repairs and maintenance tasks.

- Local Dealers: Authorized retailers can provide expert advice, service, and genuine accessories.

- Instruction Manuals: Detailed documentation often available for download, covering operation and upkeep.

Utilizing these resources can enhance your understanding and help you effectively care for your equipment, ensuring longevity and optimal performance.