Understanding the Husqvarna 555 Parts Diagram

In the world of outdoor machinery, the intricate relationships between various components play a crucial role in their functionality and efficiency. A detailed exploration of these elements can provide valuable insights into maintenance and repair, ultimately enhancing performance and longevity.

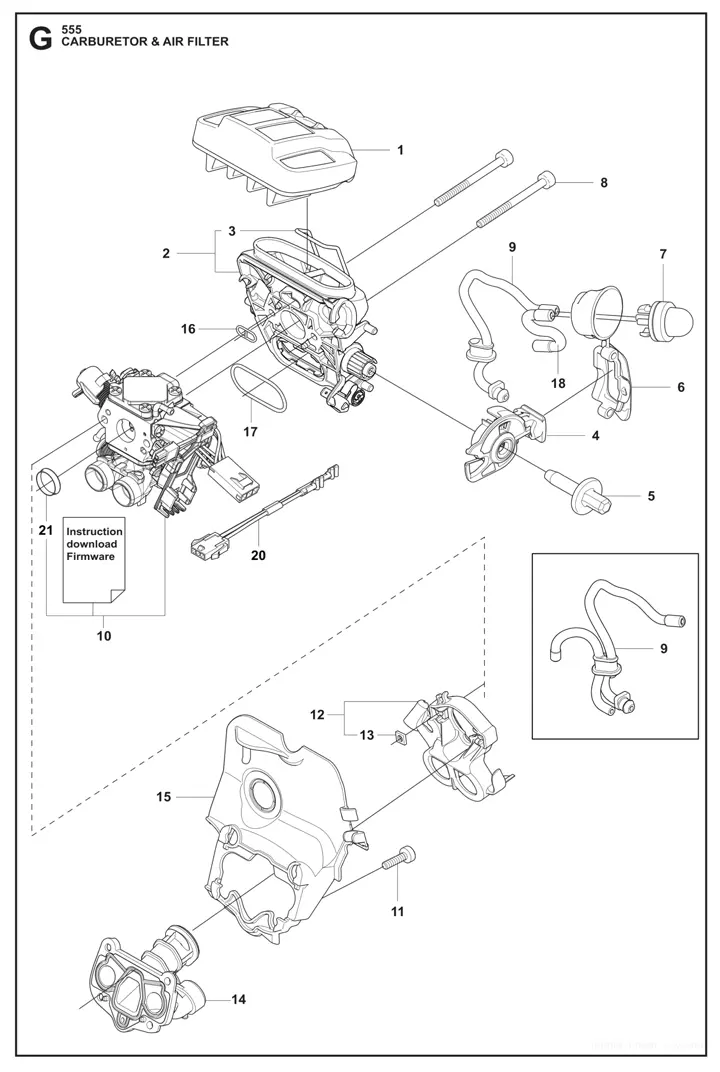

Visual representations of these relationships serve as essential tools for both novices and experienced users alike. They facilitate a deeper understanding of how each piece contributes to the overall operation, allowing for more informed decision-making during service.

By examining these layouts closely, one can delve into the ultimate intricacies of machinery design, paving the way for effective troubleshooting and optimal upkeep. This knowledge empowers users to tackle repairs with confidence, ensuring their equipment remains in peak condition.

Understanding Husqvarna 555 Parts

When it comes to maintenance and repair of outdoor equipment, a solid grasp of its components is essential. Knowing how each element functions and interacts with others not only aids in troubleshooting but also ensures longevity and optimal performance.

Every machine consists of various elements, from the engine to the cutting mechanism, all working together to achieve the ultimate goal of efficiency. Familiarity with these components can help users identify issues early and prevent costly repairs.

Moreover, being informed about replacement options and upgrades can enhance the overall experience, allowing users to make informed decisions when seeking improvements or fixes. Understanding the intricacies of these elements is key to mastering equipment management.

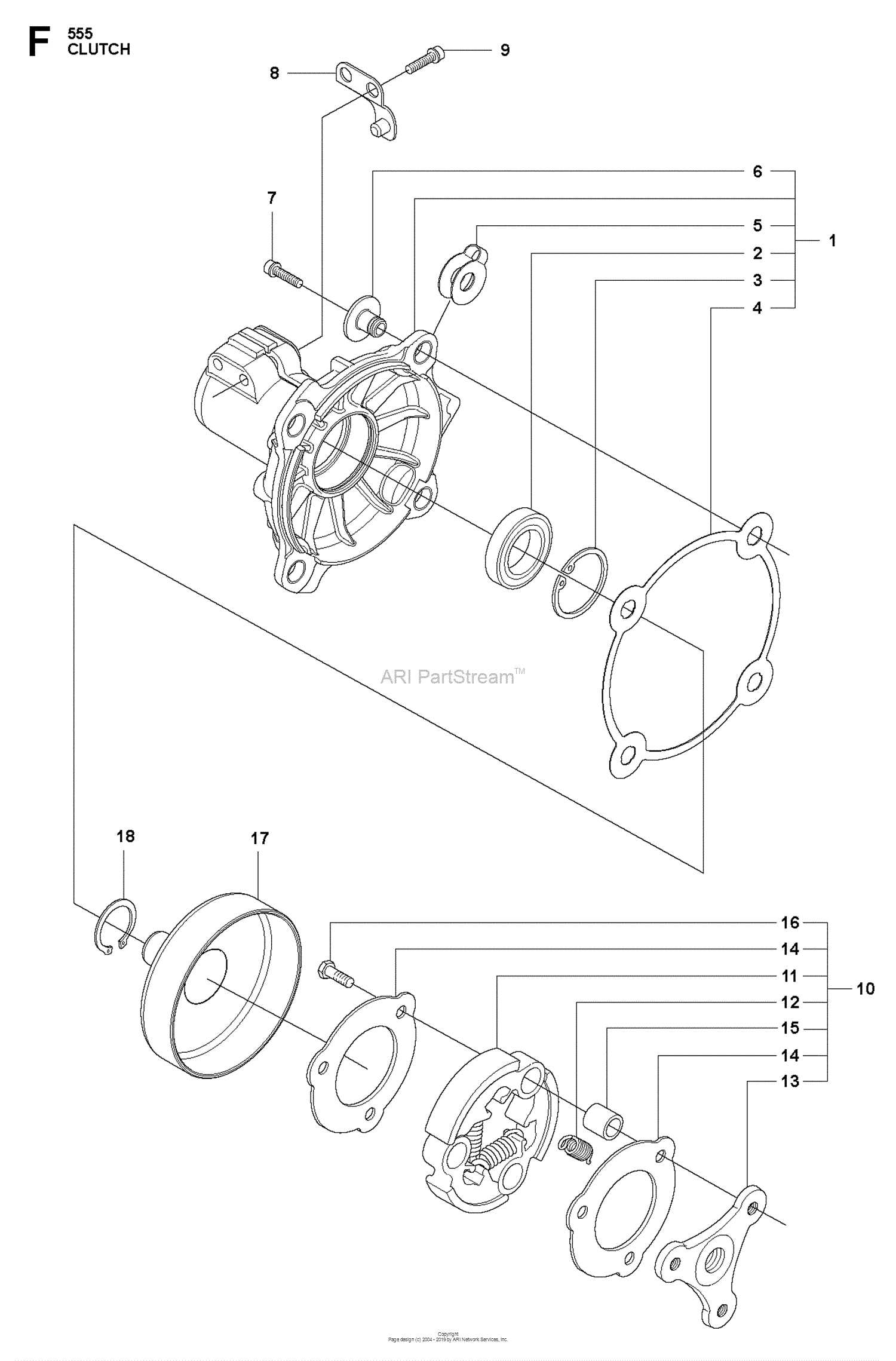

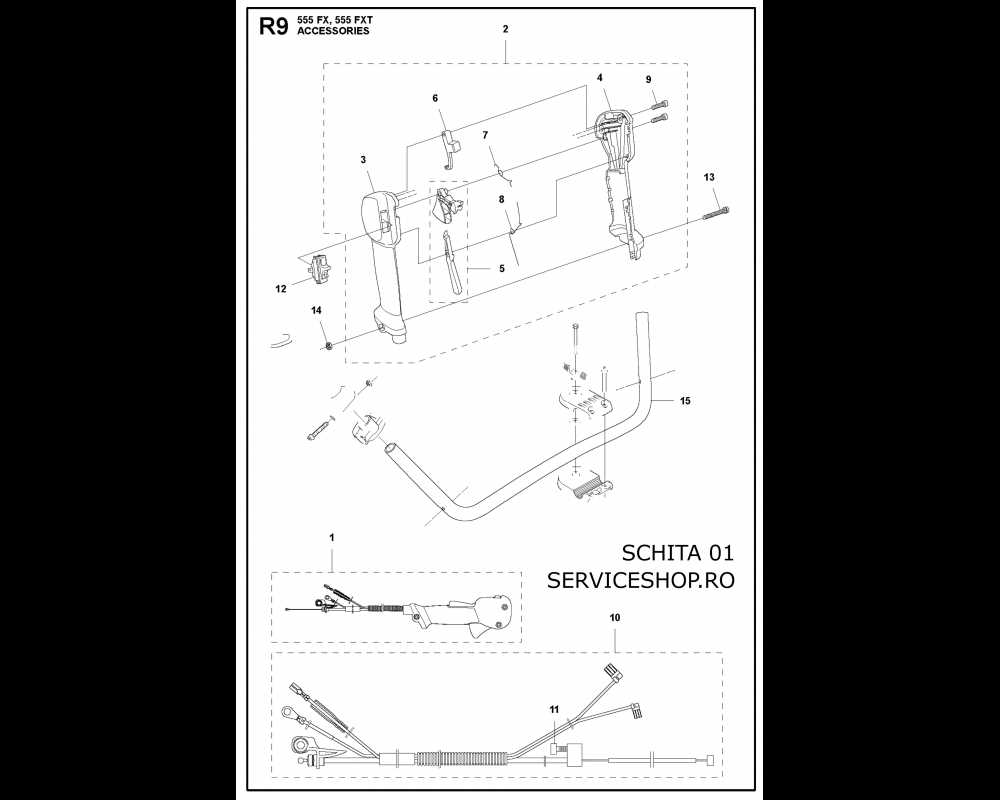

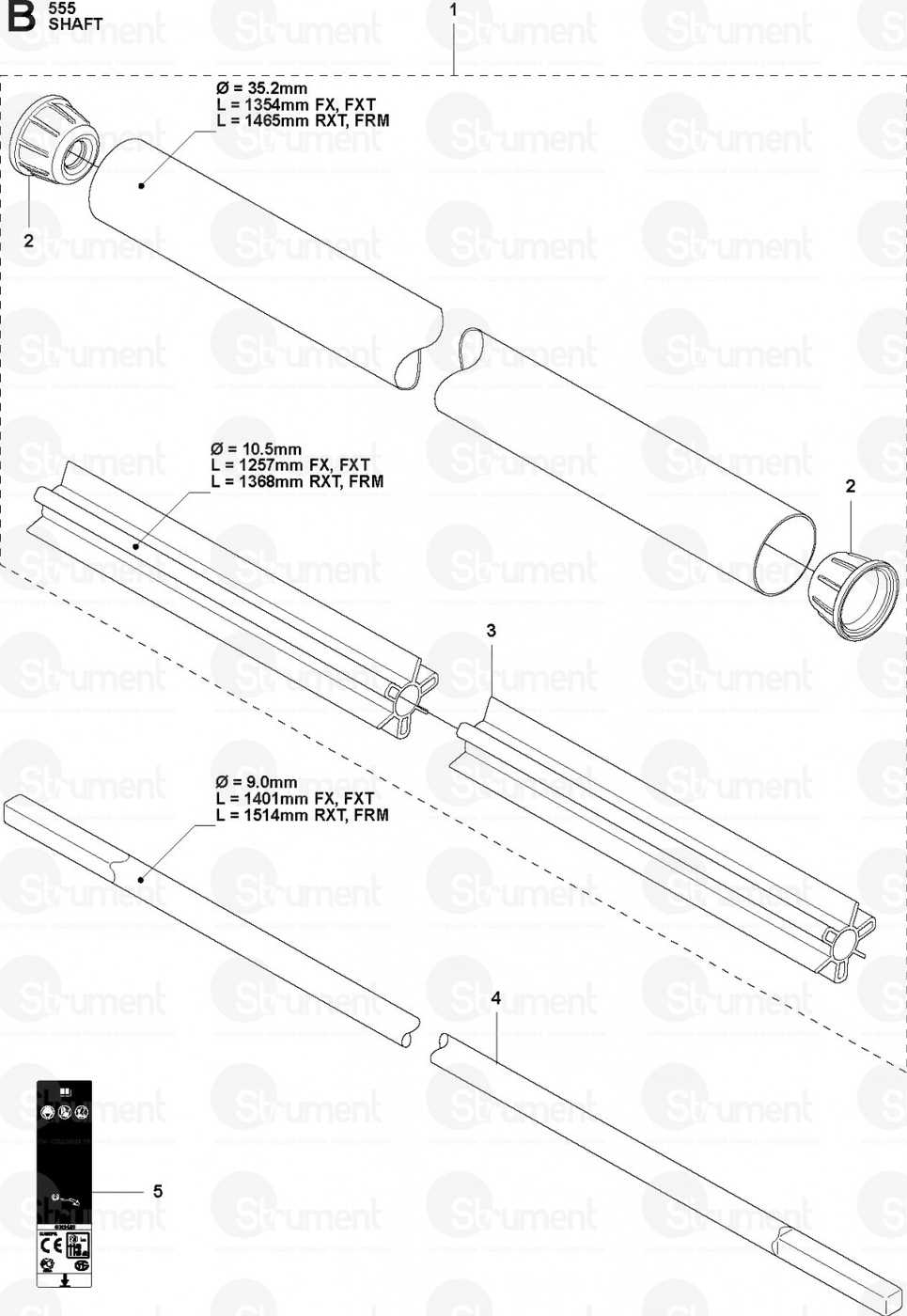

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. They serve as essential guides for users and technicians, enabling efficient maintenance and repair tasks. By offering a clear view of individual elements and their interconnections, these illustrations enhance troubleshooting and part identification.

Moreover, having access to such visuals can significantly reduce downtime and improve operational efficiency. Whether for amateur enthusiasts or professional mechanics, these references streamline the process of sourcing replacements and ensuring proper installation.

| Benefit | Description |

|---|---|

| Clarity | Provides a clear visual guide for understanding complex assemblies. |

| Efficiency | Reduces the time spent on repairs and maintenance. |

| Accuracy | Helps ensure the correct parts are sourced and installed. |

| Accessibility | Facilitates easier communication between users and service providers. |

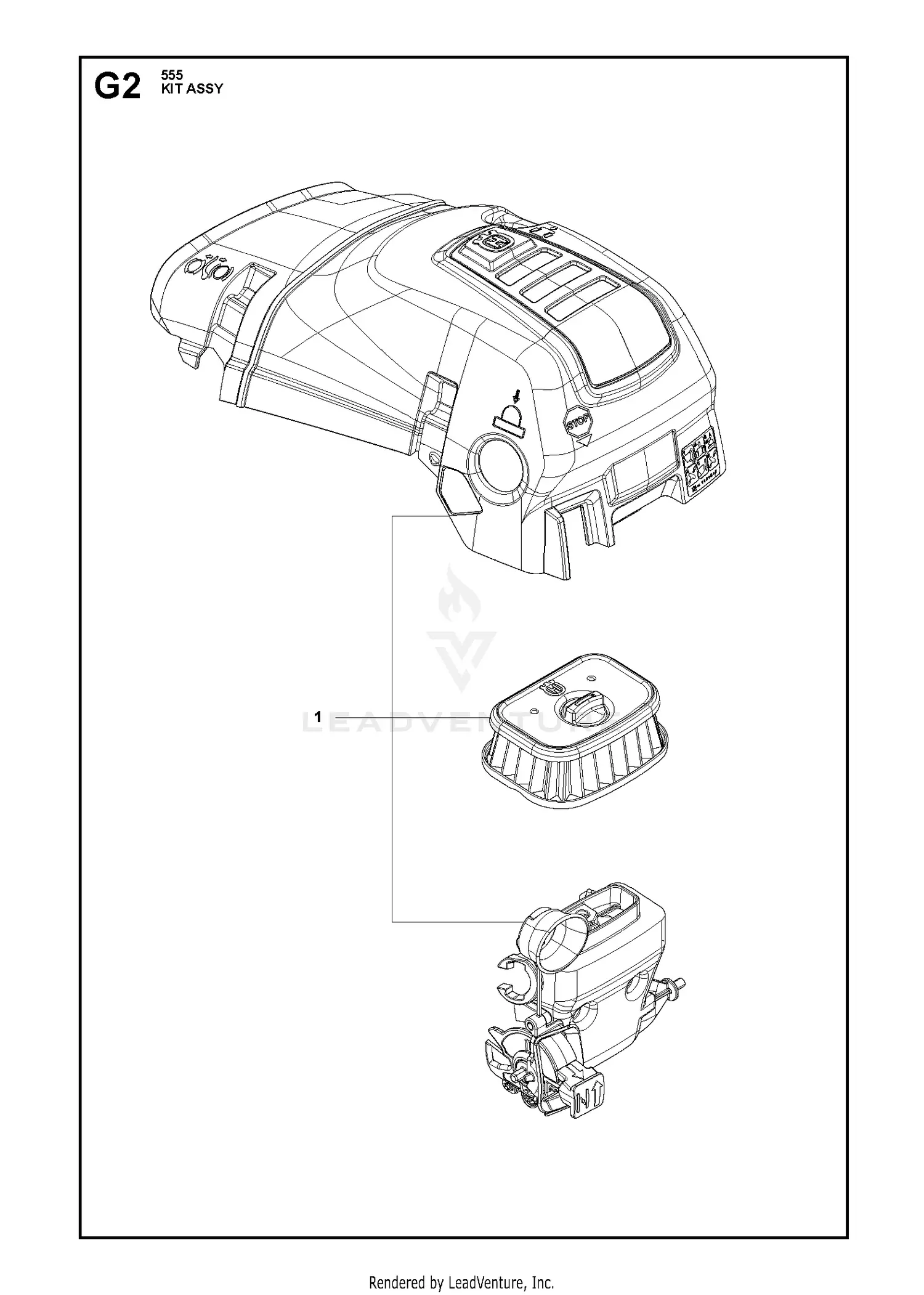

Overview of Husqvarna 555 Model

This section provides a comprehensive look at a highly regarded chainsaw known for its performance and reliability. Designed for both professional and occasional users, this machine excels in various cutting tasks, offering a perfect blend of power and efficiency.

With a robust engine, this tool ensures high torque and exceptional cutting speed, making it suitable for felling trees, limbing, and other heavy-duty applications. Its ergonomic design contributes to user comfort, allowing for extended operation without fatigue.

The innovative technology integrated into this model enhances fuel efficiency while reducing emissions, aligning with modern environmental standards. Features such as easy-start mechanisms and automatic oiling systems further improve usability and maintenance.

Durability is a key aspect, with high-quality materials used throughout its construction. This ensures that the machine withstands demanding conditions, providing longevity and consistent performance over time.

Overall, this chainsaw represents a reliable choice for those seeking a powerful and efficient tool to tackle various forestry and landscaping challenges.

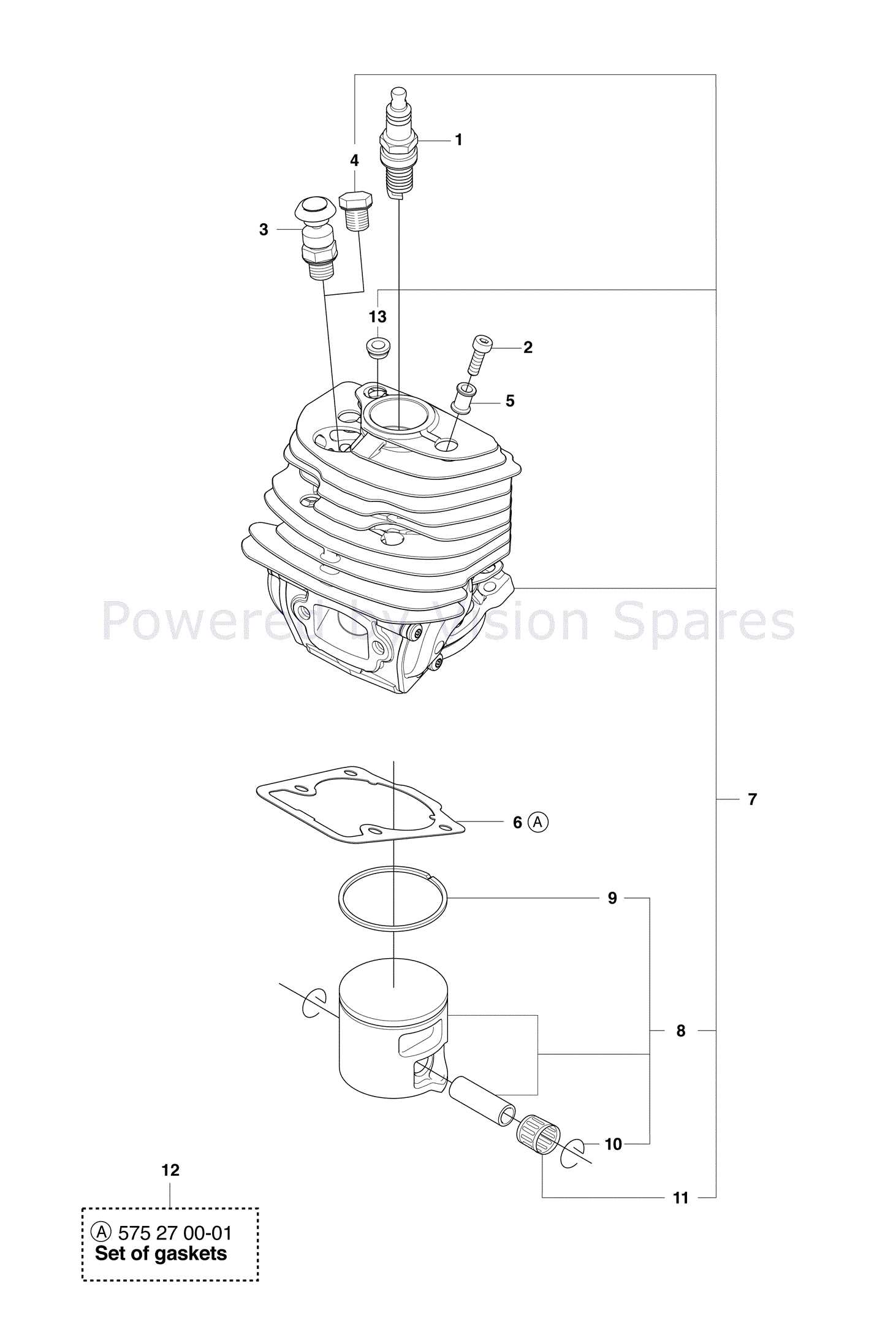

Key Components of the Chainsaw

Understanding the essential elements of a chainsaw is crucial for both maintenance and effective operation. Each component plays a significant role in ensuring the tool functions smoothly and efficiently. From the engine to the cutting bar, each part contributes to the overall performance and durability of the equipment.

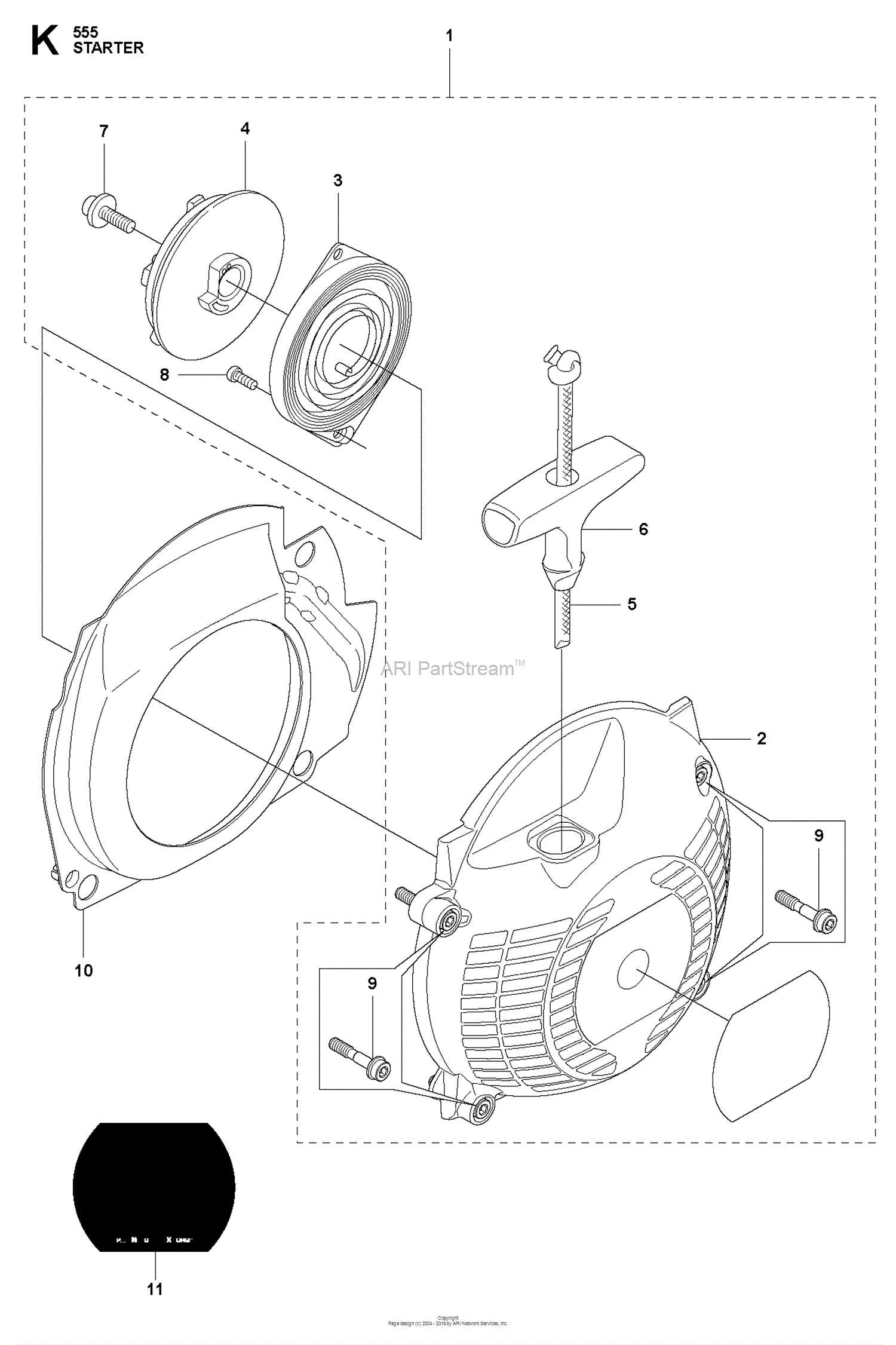

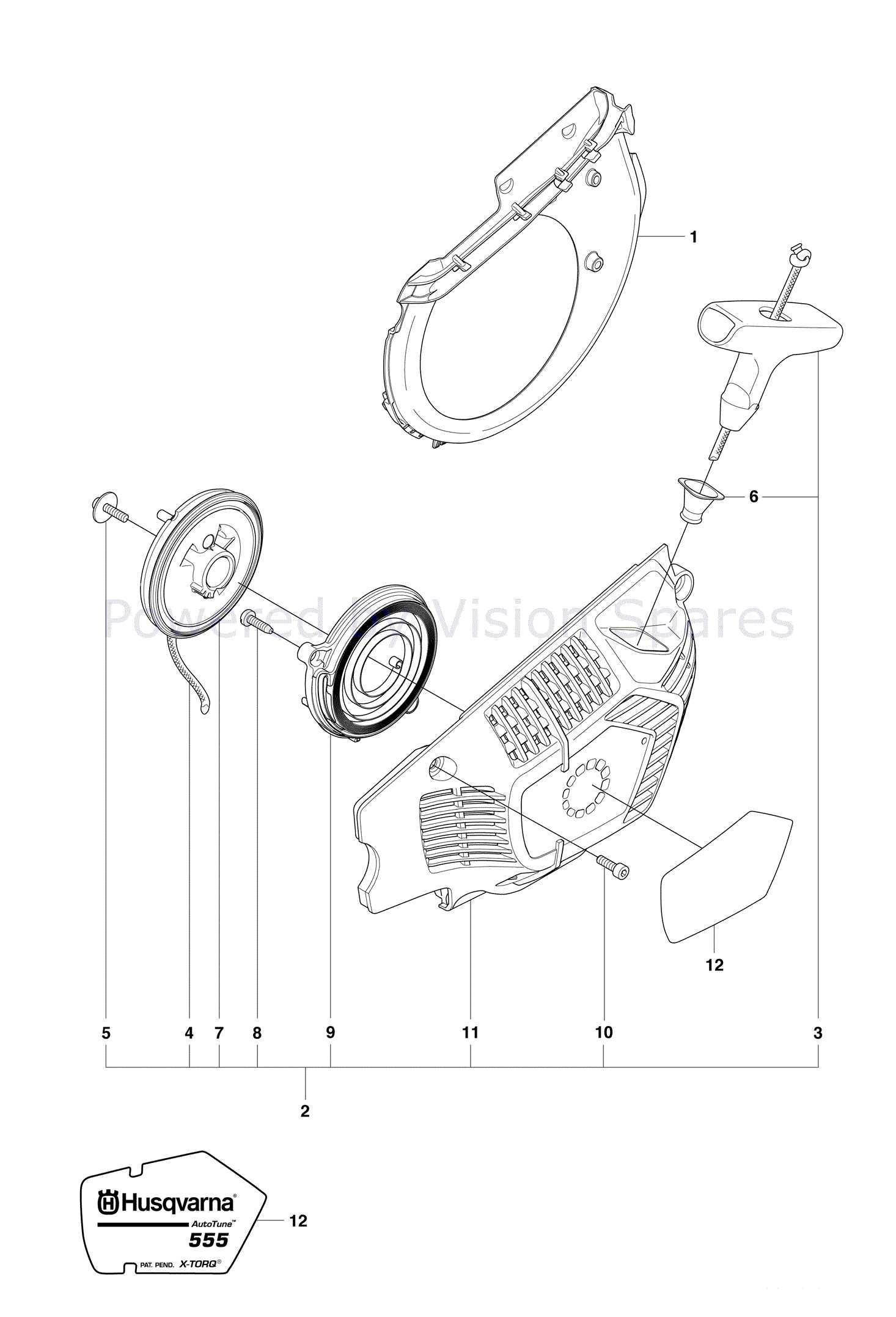

The power unit serves as the heart of the machine, generating the necessary energy for operation. Attached to this is the fuel system, which stores and delivers the energy source, ensuring consistent performance. The ignition system ignites the fuel-air mixture, while the starter mechanism allows for easy activation of the chainsaw.

Another vital aspect is the cutting assembly, which includes the chain and the guide bar. The chain, designed for optimal cutting efficiency, moves rapidly around the bar, enabling precise and swift cuts through various materials. Proper tensioning and lubrication of this assembly are essential for effective operation.

Safety features are also integral to the design, with mechanisms that prevent accidental starts and protect the operator from potential hazards. The handle and body of the device are engineered for comfortable grip and control, ensuring that the user can maneuver it safely and effectively during use.

Lastly, maintenance components like air filters and spark plugs are necessary for prolonging the lifespan of the chainsaw. Regular checks and replacements of these elements help maintain optimal performance and reliability. Understanding these key components allows users to make informed decisions regarding maintenance and usage, enhancing their overall experience with the equipment.

How to Read the Diagram

Understanding a technical illustration can seem daunting at first, but it becomes manageable with a few key strategies. These visual representations serve as invaluable guides, allowing users to identify components and their functions efficiently. By familiarizing yourself with the layout and symbols used, you can navigate the information with confidence.

First, start by examining the overall structure. Most illustrations are organized into sections, with each area representing different assemblies or functionalities. Take your time to observe how the elements are grouped together, which can provide insights into their relationships.

Next, focus on the legend or key if available. This part often contains symbols and notations that explain the various elements depicted. Understanding these will clarify any ambiguities you encounter while analyzing the visual.

Finally, cross-reference the illustration with any accompanying manuals or documents. These resources often contain detailed explanations and part numbers that can enhance your comprehension of the visual. By applying these techniques, you can effectively interpret the technical representation and utilize it for your needs.

Identifying Replacement Parts

Understanding how to pinpoint the necessary components for maintenance or repair is crucial for ensuring optimal performance of your equipment. Accurately identifying the right elements can save time, reduce costs, and extend the lifespan of your machine.

To effectively determine the required items, consider the following steps:

- Consult the Manual: Always refer to the user guide. It provides valuable insights into the specifications and common issues related to your model.

- Visual Inspection: Examine the machine thoroughly. Look for signs of wear or damage, noting any components that may need replacement.

- Identify Component Numbers: Many elements have specific identification numbers. Use these to search for exact matches.

- Seek Online Resources: Various online platforms offer comprehensive databases. Use them to find compatible components based on your findings.

- Contact Professionals: If in doubt, consult with experts or authorized dealers. They can provide guidance tailored to your situation.

By following these steps, you can ensure that you acquire the correct components for your machinery, facilitating efficient repairs and maintenance.

Common Issues with Husqvarna 555

This section explores frequent challenges faced by users of a specific chainsaw model, highlighting mechanical and operational concerns that may arise over time.

Mechanical Problems

- Worn-out components leading to decreased performance.

- Fuel leaks that can affect safety and functionality.

- Issues with the ignition system causing starting difficulties.

Operational Concerns

- Vibration during use, which can lead to user fatigue.

- Inconsistent cutting performance, often due to dull blades.

- Difficulty in adjusting tension, impacting chain operation.

Maintenance Tips for Longevity

Regular upkeep is essential for maximizing the lifespan and performance of your equipment. By following specific practices, you can ensure that your machinery remains efficient and reliable over time.

| Tip | Description |

|---|---|

| Clean Regularly | Remove debris and dirt after each use to prevent build-up that can cause wear and tear. |

| Check Oil Levels | Consistently monitor and change the lubricant to maintain optimal engine function. |

| Inspect Components | Frequent examination of parts helps identify potential issues before they escalate. |

| Sharpen Blades | Keeping cutting edges sharp enhances performance and reduces strain on the motor. |

| Store Properly | Ensure that the unit is kept in a dry, protected environment to avoid rust and damage. |

Where to Purchase Genuine Parts

Finding authentic components for your equipment is essential to ensure optimal performance and longevity. Quality replacements are crucial for maintaining efficiency and safety, and knowing where to source them can make all the difference. This section provides guidance on the best places to obtain original items that meet the required standards.

Authorized Dealers

One of the most reliable options is to visit authorized retailers. These vendors are officially recognized and provide a selection of certified merchandise. By choosing this route, you can be confident in the authenticity of the items you purchase. Furthermore, many authorized dealers offer expert advice and support to help you select the right components for your needs.

Online Marketplaces

Another convenient method to acquire original replacements is through reputable online platforms. Many e-commerce sites specialize in equipment components and often have extensive catalogs available for browsing. Look for sellers with positive reviews and clear return policies to ensure a secure transaction. Always verify that the items listed are genuine to avoid counterfeit products.

Using Aftermarket vs. Original Parts

The choice between generic components and those from the original manufacturer is a significant consideration for many users. Each option offers distinct advantages and potential drawbacks that can influence performance, longevity, and cost-effectiveness. Understanding these differences is crucial for making informed decisions that align with individual needs and preferences.

Advantages of Original Components

Original components are designed specifically for a particular model, ensuring compatibility and reliability. These parts often come with warranties and are subjected to rigorous quality control standards. Users can expect optimal performance and longevity, as these components are manufactured to the exact specifications set by the producer.

Benefits of Aftermarket Components

On the other hand, aftermarket options frequently present a more budget-friendly alternative. They can vary widely in quality, with some being superior to their original counterparts. Additionally, the availability of diverse brands and models allows for greater flexibility in selection. However, potential users should conduct thorough research to avoid subpar quality that could lead to premature wear or failures.

| Criteria | Original Components | Aftermarket Components |

|---|---|---|

| Compatibility | Perfect fit | Variable fit |

| Cost | Higher price | Generally lower |

| Quality | Consistent | Varies |

| Warranty | Often included | Varies by manufacturer |

| Performance | Optimized | Can be variable |

Step-by-Step Repair Guide

This guide aims to provide a systematic approach for repairing outdoor equipment, ensuring that each step is clear and actionable. By following these instructions, you can effectively troubleshoot and fix common issues, enhancing the longevity and performance of your machine.

Step 1: Begin by gathering the necessary tools and materials. Having everything on hand will streamline the process and minimize interruptions.

Step 2: Disconnect the power source to ensure safety while you work. This is crucial to prevent accidents during the repair.

Step 3: Carefully inspect the unit for visible signs of damage or wear. Identifying problematic areas will help you focus your efforts effectively.

Step 4: Refer to the service manual for specific instructions related to your model. This will provide you with vital information regarding assembly and disassembly.

Step 5: Remove any necessary components with precision. Keep track of all screws and parts to avoid losing them during the repair.

Step 6: Clean any debris or dirt from the internal parts. A clean workspace contributes to better functionality post-repair.

Step 7: Replace any damaged components with high-quality replacements. Ensure compatibility to guarantee optimal performance.

Step 8: Reassemble the unit carefully, reversing the disassembly steps. Take your time to avoid mistakes that could lead to further issues.

Step 9: Once reassembled, reconnect the power source and perform a thorough test to ensure everything is functioning correctly.

Step 10: Finally, document any repairs made for future reference. Keeping a record can be invaluable for subsequent maintenance.

Tools Needed for Repairs

Effective maintenance and repair of equipment require a specific set of tools to ensure accuracy and efficiency. Utilizing the right instruments not only simplifies the process but also enhances the overall performance of the machinery.

- Screwdrivers: Essential for loosening or tightening screws.

- Wrenches: Necessary for adjusting nuts and bolts.

- Pliers: Useful for gripping and manipulating components.

- Socket set: Provides a range of sizes for various fittings.

- Torque wrench: Ensures correct tension on fasteners.

- Utility knife: Helpful for cutting materials or stripping wires.

Having these tools readily available can significantly improve the repair process and help maintain the longevity of the equipment.

FAQs About Husqvarna 555 Parts

This section addresses common inquiries regarding components for the well-known forestry tool. Understanding these elements can enhance maintenance and repair efforts, ensuring optimal performance and longevity.

What are the most common issues with these components? Users frequently report wear and tear, particularly on high-contact areas. Regular inspections can help identify potential failures before they escalate.

How can I identify the right components for my tool? Always refer to the manufacturer’s guidelines or user manual. These resources provide crucial information on specifications and compatibility.

Where can I find quality replacements? Authorized dealers and trusted online retailers typically offer authentic replacements. It’s essential to verify the source to avoid counterfeit items.

Are there maintenance tips to extend component life? Regular cleaning, proper storage, and timely replacements can significantly enhance the lifespan of the various elements. Following best practices is key.

Can I perform repairs myself? While some users possess the skills for DIY repairs, it’s advisable to consult a professional for complex issues to avoid further damage.