Understanding the Husqvarna L221A Parts Diagram for Efficient Repairs

Maintaining a lawn mower requires a comprehensive understanding of its individual components. Familiarizing oneself with the various elements that make up this essential gardening tool is crucial for effective upkeep and repairs. Knowledge of how these parts work together can greatly enhance the longevity and performance of the machine.

To ensure optimal functionality, it’s important to recognize the intricate design that underlies the operation of your mower. Each section plays a vital role, from the engine to the cutting mechanism. By gaining insight into these components, users can diagnose issues more effectively and implement necessary maintenance tasks with confidence.

In this guide, we will explore the layout of key elements within the mower, providing a clear reference for anyone looking to understand the mechanics behind their equipment. With the right information, you’ll be empowered to tackle repairs and ensure your mower operates smoothly throughout the season.

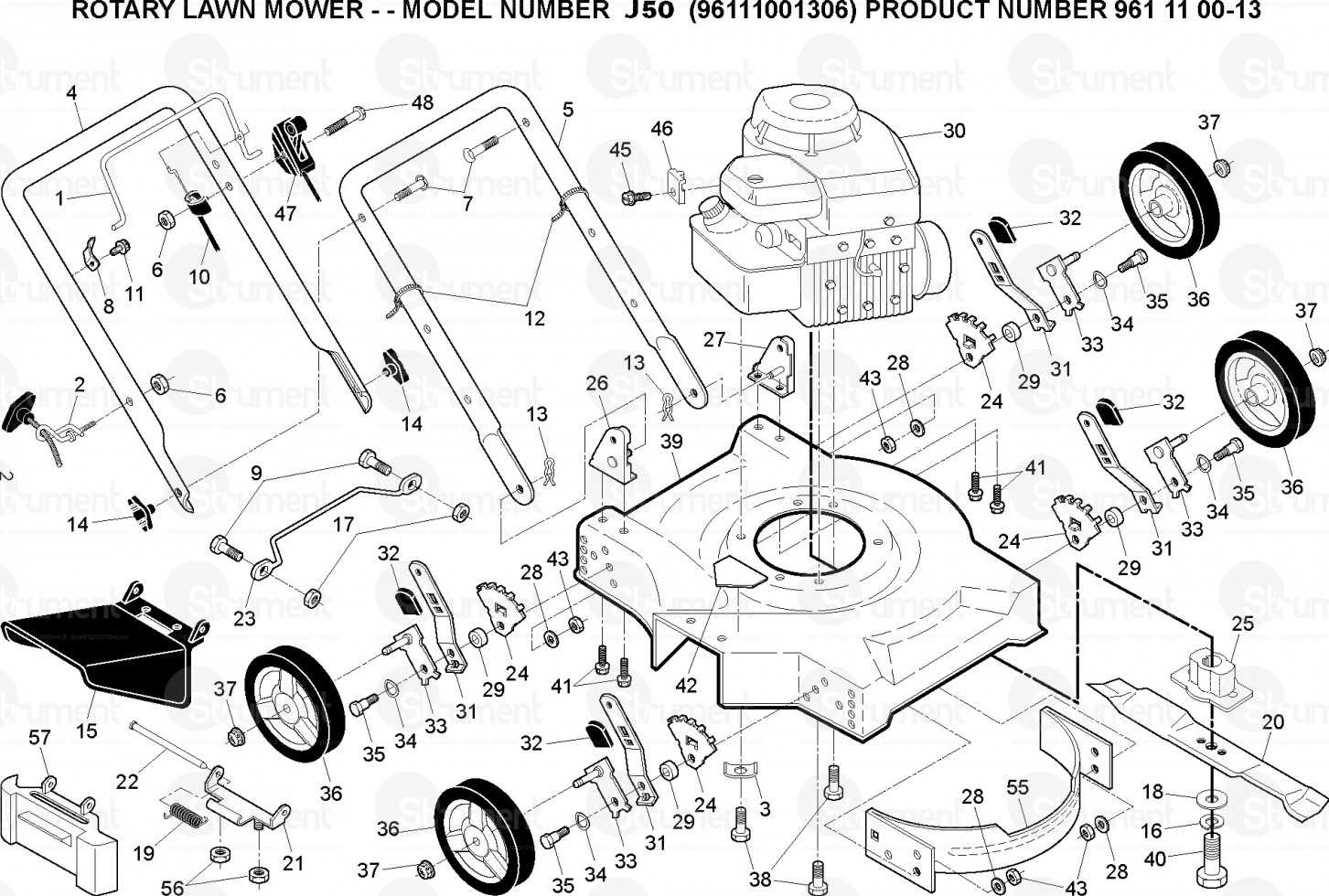

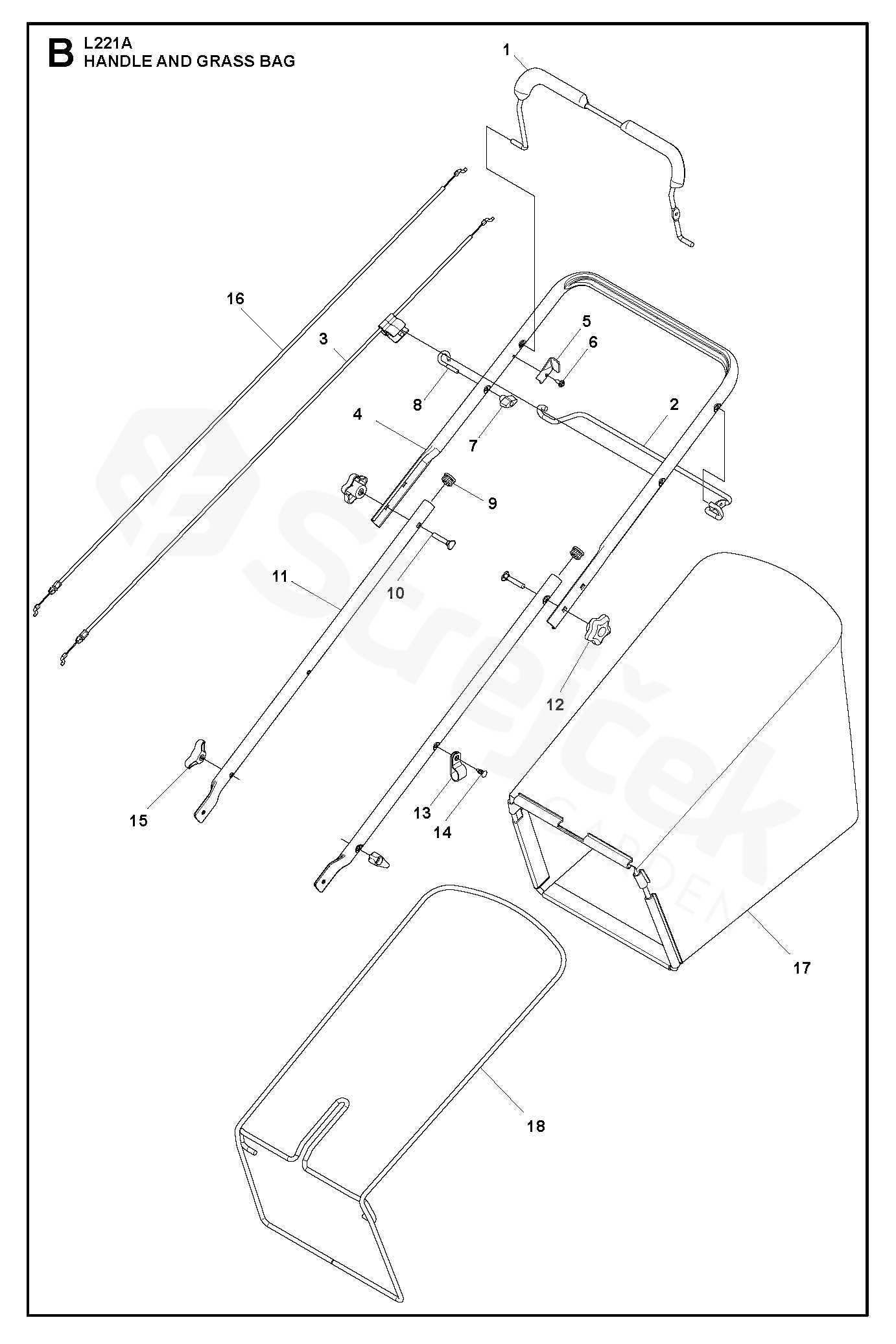

Understanding Husqvarna L221A Components

Exploring the elements of outdoor equipment is essential for effective maintenance and optimal performance. Each component plays a crucial role, contributing to the overall functionality and reliability of the machine. Gaining insight into these individual parts can help users make informed decisions when it comes to repairs and upgrades.

Key Components

- Engine: Powers the device and ensures efficient operation.

- Deck: Houses the cutting mechanism and protects internal parts.

- Handle: Provides control and maneuverability during use.

- Wheels: Facilitate movement across various terrains.

- Blade: Responsible for cutting grass and maintaining a neat appearance.

Maintenance Considerations

- Regularly check the engine for any signs of wear or leaks.

- Inspect the deck for damage that could affect performance.

- Ensure the handle is secure and free from cracks.

- Examine the wheels for proper inflation and alignment.

- Sharpen or replace the blade as needed for efficient cutting.

Understanding these components not only aids in troubleshooting but also enhances the longevity of the equipment, ensuring it operates at its best for years to come.

Importance of Parts Diagrams

Understanding the structure and components of machinery is essential for effective maintenance and repair. Visual representations that outline each element and its relation to others serve as crucial tools for technicians and enthusiasts alike. These illustrations simplify the identification of individual components, making the process of troubleshooting and replacing parts much more manageable.

Enhanced Clarity: A well-structured visual guide provides clarity on the arrangement and function of each component. This clarity helps prevent errors during reassembly and ensures that all necessary elements are addressed.

Time Efficiency: Access to clear visual aids allows users to quickly locate and assess components that require attention. This efficiency not only saves time but also minimizes the risk of overlooking critical parts that may affect overall functionality.

Cost-Effectiveness: By accurately identifying the specific elements needed for repairs, users can avoid unnecessary expenses on incorrect or redundant purchases. This targeted approach fosters more economical maintenance practices.

Learning Tool: For those new to machinery, these visual aids serve as excellent educational resources. They help build foundational knowledge about how different parts work together, enhancing overall understanding and proficiency in repairs.

Key Features of the L221A Model

This particular model stands out in the realm of outdoor power equipment, offering a blend of efficiency and user-friendly design. With a focus on durability and performance, it caters to both casual users and landscaping professionals alike. Here, we explore the main attributes that contribute to its reputation in the market.

Performance and Power

The engine is designed to deliver exceptional power, ensuring that even tough grass and uneven terrains can be managed with ease. This model is equipped with features that enhance cutting efficiency, making lawn maintenance quicker and more effective.

User Comfort and Convenience

One of the most appealing aspects of this machine is its ergonomic design. It provides comfortable handling and easy maneuverability, allowing users to work for extended periods without discomfort. The lightweight structure also contributes to its ease of use.

| Feature | Description |

|---|---|

| Engine Type | Powerful and efficient, suitable for various grass types |

| Cutting Width | Optimal width for quick mowing |

| Weight | Lightweight design for easy transport |

| Handle Design | Ergonomic and adjustable for user comfort |

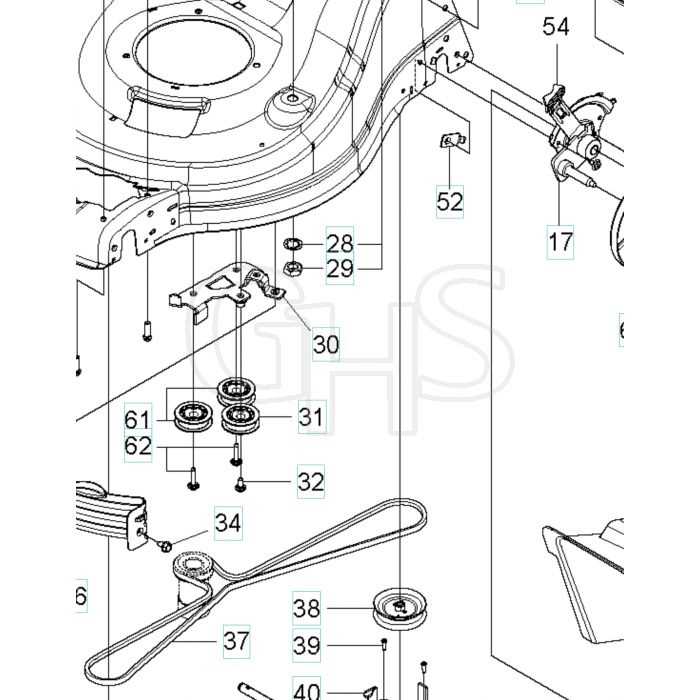

Common Replacement Parts Overview

Maintaining a lawn mower requires awareness of essential components that may need to be replaced over time. Understanding these elements can enhance the longevity and efficiency of your machine, ensuring it operates smoothly season after season.

Key Components to Monitor

Among the crucial items to keep an eye on are the cutting blades, which directly impact the quality of the lawn cut. Over time, blades can become dull or damaged, necessitating timely replacement to maintain optimal performance. Another important element is the air filter, which prevents debris from entering the engine. A clogged filter can hinder airflow, leading to decreased efficiency and potential engine issues.

Additional Vital Parts

Belts are also essential for the proper functioning of various mechanisms, including drive and cutting functions. Wear and tear can lead to slippage or breakage, which may require replacement. Furthermore, spark plugs play a critical role in engine ignition; ensuring they are in good condition is key to reliable startup and operation.

Identifying Parts by Diagram

Understanding the components of your equipment is essential for effective maintenance and repair. Visual representations can significantly simplify this process by providing a clear layout of each individual element. By studying these illustrations, you can easily locate and identify specific parts, ensuring a smoother workflow when addressing issues or performing routine checks.

Utilizing Visual Guides

Visual guides serve as a valuable resource for both novice and experienced users. They break down complex machinery into manageable sections, allowing you to pinpoint where each piece fits into the overall structure. This clarity not only aids in assembly and disassembly but also enhances troubleshooting efforts by highlighting potential areas of concern.

Improving Maintenance Efficiency

Incorporating these visual aids into your maintenance routine can lead to improved efficiency. When you know exactly what you’re looking for, the time spent searching for specific components is minimized. This proactive approach not only saves time but also reduces the likelihood of errors during repairs, ultimately prolonging the life of your equipment.

Maintenance Tips for Your Mower

Regular upkeep is essential for ensuring optimal performance and longevity of your mowing equipment. By following a few simple guidelines, you can keep your machine running smoothly and efficiently throughout the mowing season. Proper care not only enhances cutting efficiency but also minimizes the likelihood of costly repairs.

Cleaning and Inspection

After each use, take a moment to clean the exterior and undercarriage of your mower. Grass clippings and debris can accumulate, affecting performance. Inspect the blades for wear and damage; sharp blades make cleaner cuts and reduce strain on the engine. If you notice any significant wear, consider replacing them to maintain effective operation.

Engine Maintenance

Regularly check the oil level and change it according to the manufacturer’s recommendations. Clean or replace the air filter to ensure proper airflow, which is vital for engine efficiency. Additionally, inspect the spark plug; a clean and properly gapped spark plug ensures smooth starting and optimal performance. Fuel quality is also crucial, so use fresh fuel and consider adding a fuel stabilizer if you store your mower for extended periods.

How to Order Replacement Parts

When it comes to maintaining your outdoor equipment, ensuring you have the correct components is crucial for optimal performance. Ordering new elements may seem daunting, but following a few simple steps can streamline the process, ensuring you get exactly what you need.

Steps to Order Components

- Identify the Component: Before making a purchase, accurately determine which piece needs replacement. Consult the user manual or look for specific identification numbers.

- Research Suppliers: Search for authorized dealers or trusted online retailers that specialize in equipment maintenance.

- Check Compatibility: Ensure that the item you plan to order is compatible with your model. Verify this by cross-referencing with the manufacturer’s specifications.

- Compare Prices: Look at multiple sources to find the best price. Don’t forget to factor in shipping costs.

- Make the Purchase: Once you’ve found the right item at a suitable price, proceed with the order. Keep a record of your transaction for future reference.

Tips for a Smooth Ordering Process

- Have your equipment model number on hand.

- Consider contacting customer service if you have any doubts about compatibility.

- Read customer reviews to gauge the reliability of the seller.

- Keep an eye out for warranties or return policies.

Tools Required for Repairs

When tackling maintenance or restoration tasks on outdoor equipment, having the right tools is essential for achieving efficient and effective results. The correct instruments not only facilitate the process but also enhance safety and precision, allowing for a smoother workflow.

Firstly, a set of wrenches is indispensable. Various sizes are needed to accommodate different fasteners and components. A good-quality socket set can also provide ease in tightening or loosening nuts and bolts.

In addition, a screwdriver set is critical for accessing parts that are secured with screws. Both flathead and Phillips screwdrivers should be included to ensure versatility for various applications.

Safety goggles are another vital item to have on hand. They protect your eyes from debris and other potential hazards while working on machinery. Additionally, wearing gloves can safeguard your hands from sharp edges and provide a better grip.

Lastly, having a multimeter can be beneficial for diagnosing electrical issues. This tool allows you to measure voltage, current, and resistance, helping to troubleshoot any problems efficiently.

Safety Precautions During Repairs

When engaging in maintenance or repair work on equipment, it is essential to prioritize safety to prevent accidents and injuries. Understanding the potential hazards associated with handling mechanical components and tools can help ensure a secure working environment. Following specific guidelines can significantly reduce risks and promote effective repairs.

Essential Safety Measures

Adhering to the following safety measures can make a substantial difference during repair tasks:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety glasses, gloves, and appropriate clothing to shield against sharp edges and debris. |

| Disconnect Power | Ensure the equipment is powered off and disconnected from any electrical source before beginning work. |

| Use Proper Tools | Select the right tools for the job to avoid damaging components and to maintain efficiency. |

| Work in a Well-Lit Area | Maintain good visibility to accurately identify parts and minimize errors during repairs. |

| Follow Manufacturer Guidelines | Consult manuals and guides to understand the specific safety recommendations for the equipment. |

Emergency Preparedness

In the event of an accident, having a plan in place is crucial. Keep a first aid kit accessible, and familiarize yourself with emergency procedures. Being prepared can make a significant difference in handling unforeseen situations effectively.

Frequently Asked Questions About Parts

This section aims to address common inquiries related to components and their functionality. Understanding the intricacies of each element can enhance the overall performance and longevity of your equipment.

What should I consider when purchasing replacements?

When looking for replacements, it’s crucial to check compatibility with your model. Ensure that the specifications match to avoid issues during installation. Additionally, consider the quality of materials; opting for durable options can save you time and money in the long run.

How can I identify a malfunctioning component?

Recognizing a faulty part often involves observing performance changes. Unusual noises, decreased efficiency, or visible wear are strong indicators. Conducting regular maintenance checks can help you spot these issues early, allowing for timely replacements.

Where to Find Authentic Parts

When it comes to maintaining and repairing your outdoor equipment, sourcing genuine components is essential for optimal performance and longevity. Authentic replacements ensure that your machinery operates as intended and reduces the risk of damage that can arise from using substandard alternatives. Here are some reliable avenues to explore for acquiring these vital elements.

Authorized Dealers

One of the most dependable sources for genuine components is through authorized retailers. These dealers are certified to sell original items and often provide warranties that guarantee their quality. Additionally, they typically have knowledgeable staff who can assist you in selecting the correct item for your specific model.

Manufacturer’s Website

Another excellent resource is the official website of the manufacturer. Here, you can often find a dedicated section for replacements, where you can search by model or type of equipment. Purchasing directly from the manufacturer ensures that you receive the correct and authentic items without the risk of counterfeits.

Comparing L221A with Other Models

When evaluating different lawn care machines, it’s essential to understand how various models stack up against one another. Each design comes with its unique features and capabilities, making it crucial for consumers to identify which one best meets their specific needs.

In this comparison, we’ll explore key aspects that set this model apart from others in the same category:

- Engine Performance: The power output and efficiency can vary significantly. Some models might offer a higher horsepower, while others focus on fuel efficiency.

- Cutting Width: This feature determines how much area can be covered in a single pass. Wider blades may reduce mowing time but can be less maneuverable in tight spaces.

- Weight and Maneuverability: Heavier units may provide stability, while lighter alternatives are easier to handle, especially on uneven terrain.

- Durability: Construction materials and design quality play a crucial role in longevity and performance over time.

- Maintenance Needs: Some machines require more frequent upkeep than others, influencing the long-term cost of ownership.

Understanding these differences can help users make informed decisions, ensuring they select the best equipment for their gardening tasks. By considering these factors, one can appreciate the strengths and weaknesses of each option available in the market.