Understanding the Parts Diagram of Husqvarna LC 221

When it comes to maintaining your outdoor equipment, a comprehensive grasp of its construction is essential. This knowledge not only aids in effective repairs but also enhances the overall performance of your machinery. Knowing how various elements interact allows for informed decisions, whether you’re troubleshooting an issue or simply conducting routine maintenance.

Identifying individual components can significantly simplify the process of assembly and disassembly. By visualizing the arrangement and function of each piece, users can develop a clearer picture of how their machines operate. This understanding can lead to improved longevity and efficiency in your lawn care tasks.

In this section, we will delve into the intricate layout of crucial elements that make up your mower. We will explore the significance of each part, their roles in the overall functionality, and how to properly handle them for optimal results. Gaining insight into this structure is a valuable step toward becoming proficient in equipment management.

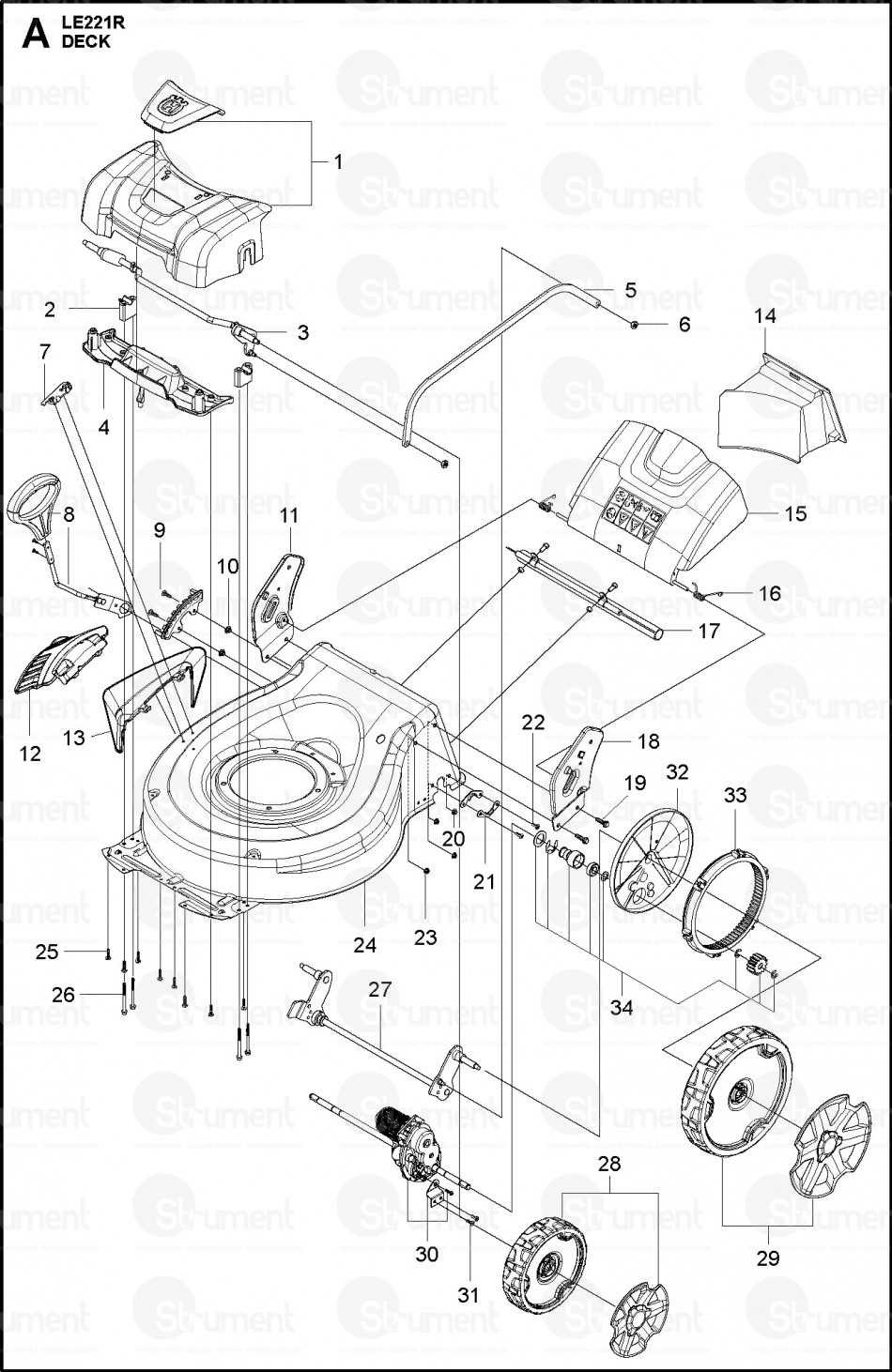

Understanding Husqvarna LC 221 Components

Exploring the intricacies of a lawn care machine involves delving into its essential elements that work harmoniously to deliver optimal performance. Each component plays a crucial role in ensuring efficiency, durability, and user-friendly operation. Gaining insight into these parts not only aids in maintenance but also enhances overall understanding of how the equipment functions.

The assembly of this machine includes a variety of sections, each contributing to the overall operation. Key elements include the power unit, which provides the necessary energy, and the cutting mechanism, designed for precision and effectiveness. Additionally, the chassis offers structural integrity, supporting various components while facilitating maneuverability.

Maintenance is significantly improved with a thorough knowledge of these essential features. Understanding the roles and interconnections of each section allows users to troubleshoot issues effectively, ensuring longevity and peak performance. This knowledge empowers owners to make informed decisions regarding repairs and upgrades, ultimately enhancing their lawn care experience.

Essential Parts of Lawn Mowers

Understanding the fundamental components of lawn maintenance machines is crucial for their effective operation and longevity. Each element plays a specific role in ensuring optimal performance and a healthy lawn.

Main Components

- Engine: Powers the machine and influences its efficiency.

- Deck: Houses the cutting mechanism and protects internal parts.

- Blades: Responsible for cutting grass to the desired height.

- Wheels: Facilitate movement and maneuverability across various terrains.

Supportive Features

- Handles: Provide control and comfort during operation.

- Fuel System: Ensures proper supply of energy to the engine.

- Chassis: Serves as the frame, offering stability and support.

- Air Filter: Maintains engine health by filtering out debris.

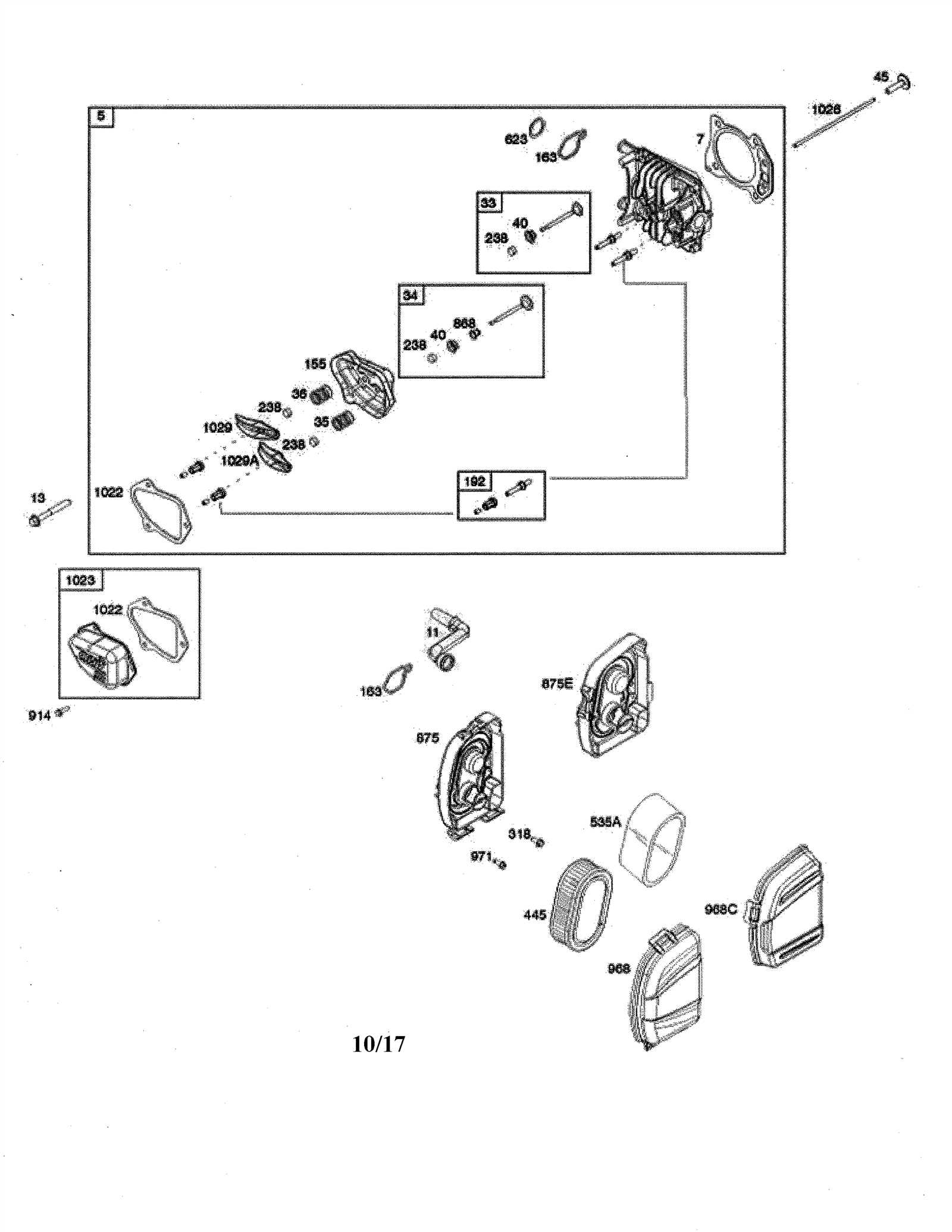

How to Read Parts Diagrams

Understanding technical illustrations can enhance your ability to maintain and repair equipment effectively. Familiarizing yourself with these visual representations is crucial for identifying components and their functions.

Here are key steps to comprehend these illustrations:

- Familiarize with Symbols: Each representation may use specific symbols for different elements. Knowing these helps in quick identification.

- Follow the Numbering System: Components are often numbered sequentially. This organization aids in tracking parts efficiently.

- Reference the Key: Most illustrations include a legend or key that explains each part. Always consult this to clarify any uncertainties.

- Observe Relationships: Pay attention to how parts connect or interact. Understanding their arrangement will help in reassembly.

By practicing these techniques, you’ll ultimately gain confidence in interpreting technical visuals, making repairs more manageable.

Common Issues with LC 221 Parts

When maintaining outdoor power equipment, users often encounter several recurring challenges that can impact performance and longevity. Identifying these frequent problems can lead to more efficient repairs and better care practices.

Wear and Tear: Over time, components may degrade due to regular use. This deterioration can manifest as reduced efficiency or failure to operate properly.

Clogging: Accumulation of debris can obstruct airflow and affect functionality. Regular cleaning is essential to prevent this issue.

Improper Alignment: Misalignment of moving parts can cause strain and lead to premature breakdowns. Ensuring proper setup is crucial for optimal performance.

Material Fatigue: Components made from weaker materials may fail sooner than expected, highlighting the importance of quality in replacements.

Understanding these common issues can significantly enhance the maintenance approach and extend the life of the equipment.

Maintenance Tips for Lawn Mower Parts

Proper upkeep of your lawn care equipment is essential for ensuring optimal performance and longevity. Regular attention to key components can prevent costly repairs and enhance efficiency. Implementing a systematic maintenance routine will ultimately lead to a healthier lawn and a more enjoyable mowing experience.

1. Regular Cleaning: After each use, clear away grass clippings and debris from the underside of the deck. This helps prevent rust and promotes better airflow.

2. Blade Sharpening: Keep the cutting edge sharp. Dull blades tear grass instead of cutting it cleanly, leading to a frayed appearance and potential lawn damage. Aim to sharpen them every season.

3. Oil Changes: Just like a car, your machine requires regular oil changes to function efficiently. Check the oil level frequently and change it as recommended by the manufacturer.

4. Air Filter Maintenance: Clean or replace the air filter regularly to ensure proper airflow and engine performance. A clean filter enhances fuel efficiency.

5. Tire Inspection: Check tire pressure regularly. Properly inflated tires ensure better traction and even cutting.

6. Fuel Care: Use fresh fuel and consider adding a stabilizer if the equipment will sit unused for extended periods. This prevents fuel degradation and starting issues.

7. Seasonal Storage: Prepare your machine for storage by draining the fuel and cleaning it thoroughly. Cover it to protect against dust and moisture.

By following these guidelines, you can ensure your equipment remains in peak condition, enhancing both performance and your mowing experience.

Identifying Wear and Tear

Recognizing signs of degradation in equipment components is crucial for maintaining optimal performance. Early identification can prevent further damage and extend the lifespan of the machinery. This section explores the common indicators that suggest parts may need replacement or repair.

Common Indicators

| Indicator | Description |

|---|---|

| Fraying | Visible wear on edges, often leading to inefficiency. |

| Cracks | Small fissures that can compromise integrity and safety. |

| Discoloration | Color changes that indicate overheating or chemical exposure. |

| Looseness | Parts that do not fit tightly can lead to operational issues. |

Maintenance Tips

Regular inspection and timely replacement of worn components are vital. Keeping a maintenance schedule ensures that all parts function harmoniously, minimizing the risk of unexpected failures.

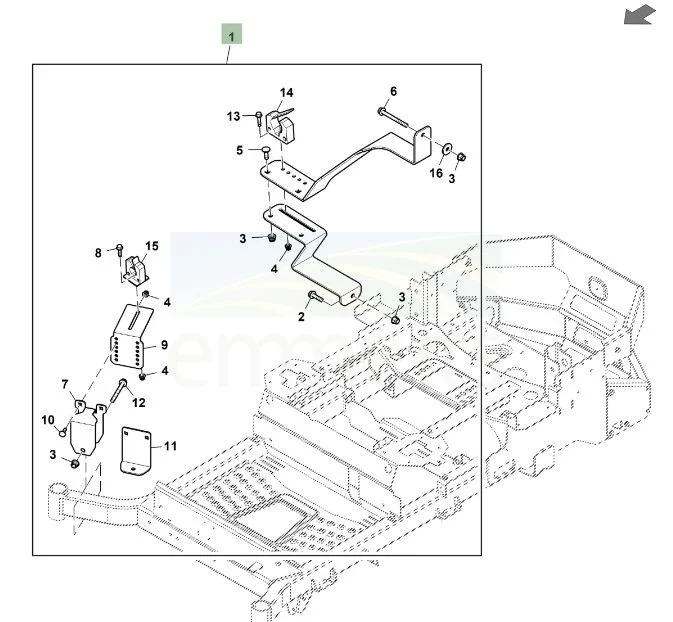

Replacing LC 221 Components Efficiently

Maintaining equipment in optimal condition is crucial for ensuring longevity and performance. Understanding how to replace various elements can significantly enhance operational efficiency. By familiarizing yourself with the process, you can minimize downtime and restore functionality quickly.

Preparation is key. Gather all necessary tools and replacement components before starting. This not only streamlines the process but also prevents interruptions.

When removing old components, ensure you follow a systematic approach. Take notes or photographs of the original setup, as this will help you during reassembly. It’s important to handle all parts carefully to avoid damage.

After installing new components, double-check your work. Ensuring everything is securely in place can prevent future issues. Lastly, conduct a brief test run to confirm that all functions operate smoothly.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for maintaining its performance and longevity. Whether you need a specific piece or an entire assembly, ensuring that you choose original parts can make a significant difference in functionality and reliability. Below are some reliable sources to help you find the genuine items you need.

Authorized Dealers

- Visit local authorized retailers that specialize in outdoor equipment.

- Check their online platforms for availability and ordering options.

- Ask for recommendations from customer service regarding specific components.

Manufacturer’s Website

- Explore the official website of the manufacturer for a dedicated parts section.

- Utilize their search feature to find specific components quickly.

- Consider signing up for newsletters for updates on new arrivals and promotions.

Tools Required for Repairing LC 221

When it comes to maintaining and fixing lawn equipment, having the right tools is essential for a smooth and efficient process. Various implements can assist in ensuring that every aspect of the machinery is addressed, allowing for optimal performance and longevity.

Essential tools include wrenches, screwdrivers, and pliers, which help in accessing and adjusting critical components. Additionally, a socket set can be invaluable for tasks requiring more torque and precision. Keeping a cleaning kit on hand is also crucial for removing debris that can hinder functionality.

For more intricate repairs, a multimeter is recommended to check electrical systems, while a tire gauge ensures proper inflation for smooth operation. By equipping yourself with these essential tools, you can tackle repairs with confidence and efficiency.

Comparative Analysis of Lawn Mower Models

This section explores the essential differences and similarities among various lawn maintenance equipment. By examining features such as engine power, cutting width, and maneuverability, one can make informed decisions when selecting the right model for their specific needs. Each variant brings unique attributes to the table, catering to different preferences and landscaping requirements.

Engine Performance: One of the most critical factors in choosing lawn care equipment is engine performance. While some models prioritize fuel efficiency, others may focus on raw power, allowing for quicker and more efficient grass cutting. Understanding the horsepower and torque can significantly affect the overall performance during heavy-duty tasks.

Cutting Width: The cutting width varies significantly across different models, influencing both efficiency and precision. Wider decks are ideal for large open spaces, reducing the number of passes required. In contrast, narrower widths allow for better navigation in tighter areas, making them suitable for intricate landscapes.

Maneuverability: The ease of handling can greatly enhance the mowing experience. Certain designs offer superior agility, allowing users to navigate around obstacles effortlessly. Features like adjustable heights and lightweight structures further contribute to the user-friendly nature of specific models.

Durability: Long-term investment is another aspect to consider. The materials used in construction can impact the lifespan and reliability of the equipment. Models built with robust components often withstand harsh conditions better than their less durable counterparts, leading to lower maintenance costs over time.

Ultimately, a comprehensive analysis of these features enables users to choose the lawn care solution that best aligns with their landscaping goals and preferences, ensuring efficient and satisfactory results.

Benefits of Regular Maintenance Checks

Routine inspections are essential for the longevity and performance of any machinery. By prioritizing these checks, users can ensure their equipment operates efficiently, reducing the likelihood of unexpected breakdowns and costly repairs. Regular care promotes reliability and enhances the overall user experience.

| Benefit | Description |

|---|---|

| Improved Efficiency | Regular maintenance helps maintain optimal performance, ensuring that machines run smoothly and effectively. |

| Extended Lifespan | Consistent checks and services can significantly prolong the life of equipment, protecting your investment. |

| Cost Savings | Identifying issues early can prevent expensive repairs and reduce operational costs over time. |

| Safety Assurance | Regular maintenance ensures that equipment operates safely, minimizing the risk of accidents or malfunctions. |