Understanding the Components of Husqvarna Pole Saw

When maintaining or repairing a specific type of garden equipment designed for trimming, having a clear understanding of its individual components is essential. This overview provides insights into the various elements that make up such a device, emphasizing their functions and importance in ensuring optimal performance. By exploring these components, users can gain a deeper appreciation for the machinery’s design and efficiency.

Moreover, this examination serves as a guide for those looking to troubleshoot or replace parts, offering clarity on how each segment contributes to the overall operation. Knowing the structure allows for informed decisions regarding maintenance, enhancing the longevity of the equipment. Ultimately, a comprehensive grasp of these essential elements aids in fostering a more effective approach to garden care.

Understanding Husqvarna Pole Saw Components

The effective operation of a specific cutting tool relies on a harmonious interplay of its individual elements. Familiarity with these components enhances both the functionality and maintenance of the tool. By recognizing how each segment contributes to overall performance, users can achieve optimal results in their tasks.

Key Elements include the motor, which powers the device, and the cutting mechanism, responsible for the actual trimming process. Additional components such as the handle and guard ensure user safety and control during operation. Understanding how these elements work together can improve efficiency and prolong the lifespan of the equipment.

Regular maintenance of each component is essential for sustained performance. Users should familiarize themselves with potential wear and tear signs, enabling timely replacements and repairs. This proactive approach not only enhances productivity but also ensures safe and reliable operation over time.

Key Features of Pole Saw Models

This section highlights the essential characteristics of various cutting equipment designed for high-reaching tasks. Understanding these features can assist users in making informed decisions and enhance their overall experience.

Ergonomic Design

Comfort and usability are crucial in selecting equipment for prolonged use. Notable attributes include:

- Lightweight construction for easy maneuverability.

- Adjustable handles for personalized comfort.

- Anti-vibration technology to reduce fatigue.

Power and Performance

The effectiveness of the equipment greatly relies on its power source and operational efficiency. Key aspects to consider are:

- Robust engines or motors that provide ample cutting force.

- High torque for efficient operation, especially in dense materials.

- Energy-efficient designs that minimize fuel consumption.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the prolonged functionality and efficiency of any equipment. By dedicating time and effort to maintaining tools, users can significantly enhance their performance and extend their lifespan. This not only saves money on replacements but also ensures consistent operation for various tasks.

Benefits of Routine Care

Performing routine care involves checking components, cleaning debris, and lubricating moving parts. These actions help to prevent wear and tear, leading to smoother operation. Moreover, identifying issues early can prevent minor problems from escalating into costly repairs, thus safeguarding the investment made in quality tools.

Impact on Performance

Well-maintained equipment operates more efficiently, reducing the risk of breakdowns during critical tasks. When all parts are in optimal condition, users experience enhanced productivity and better results. Furthermore, taking care of tools fosters a safer working environment by minimizing the chances of malfunctions.

In summary, the importance of maintenance cannot be overstated. Regular attention not only extends the life of equipment but also ensures optimal performance, making every task easier and more efficient.

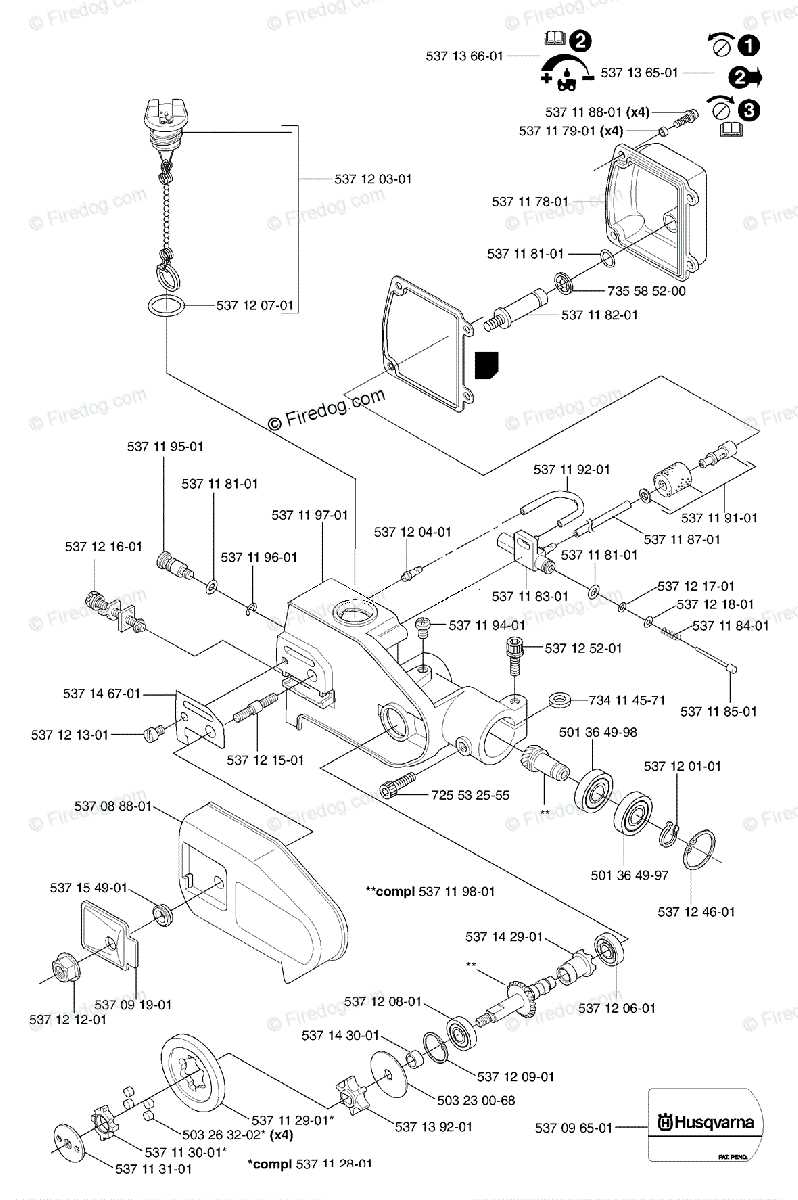

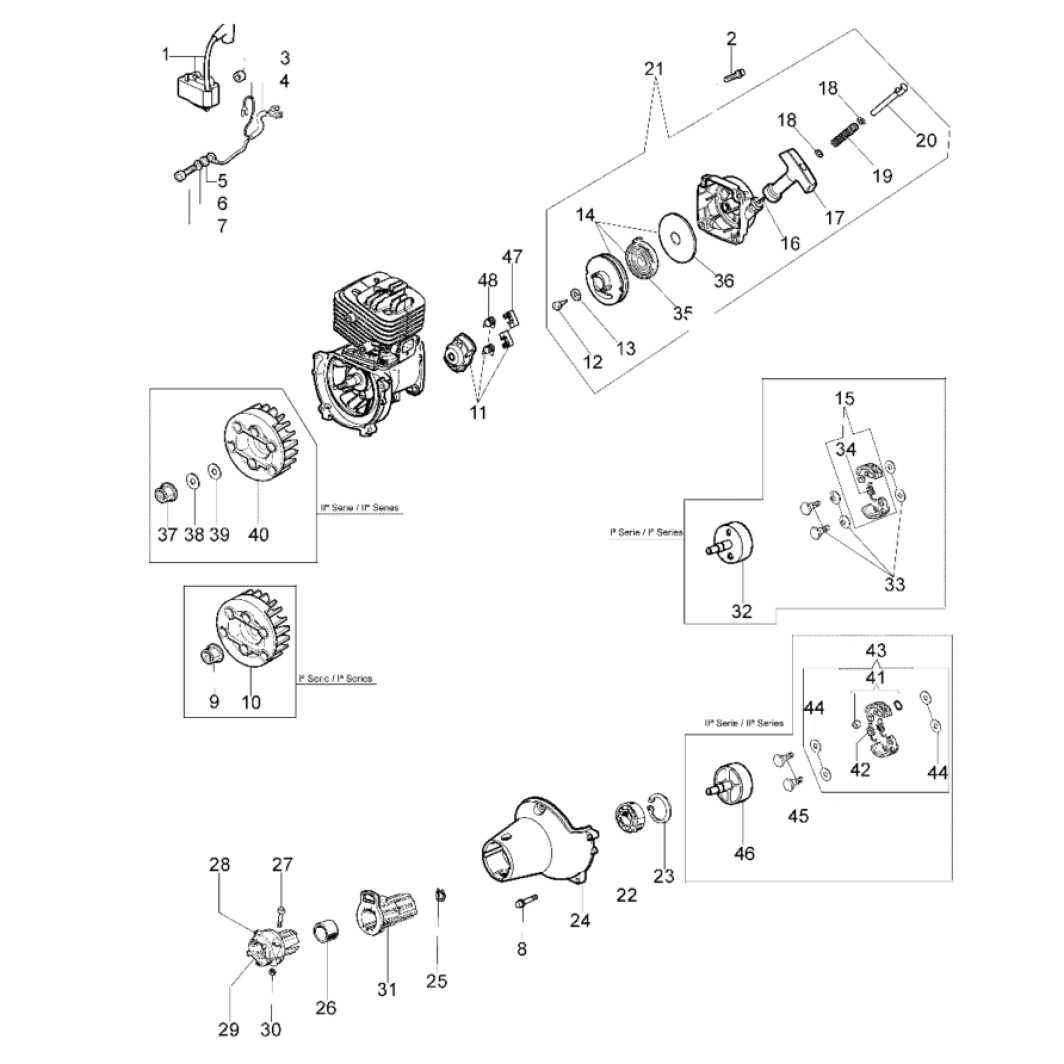

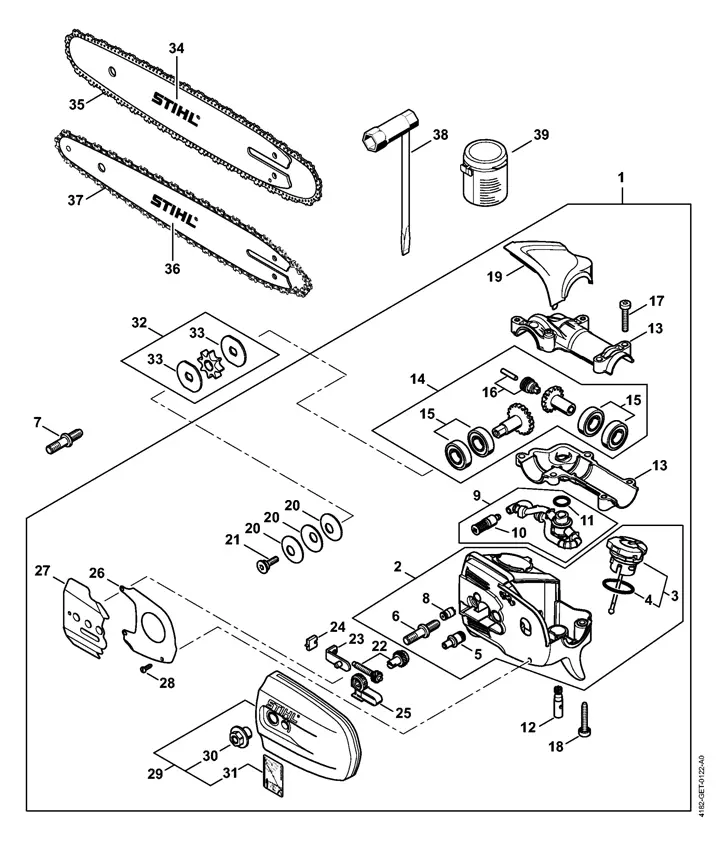

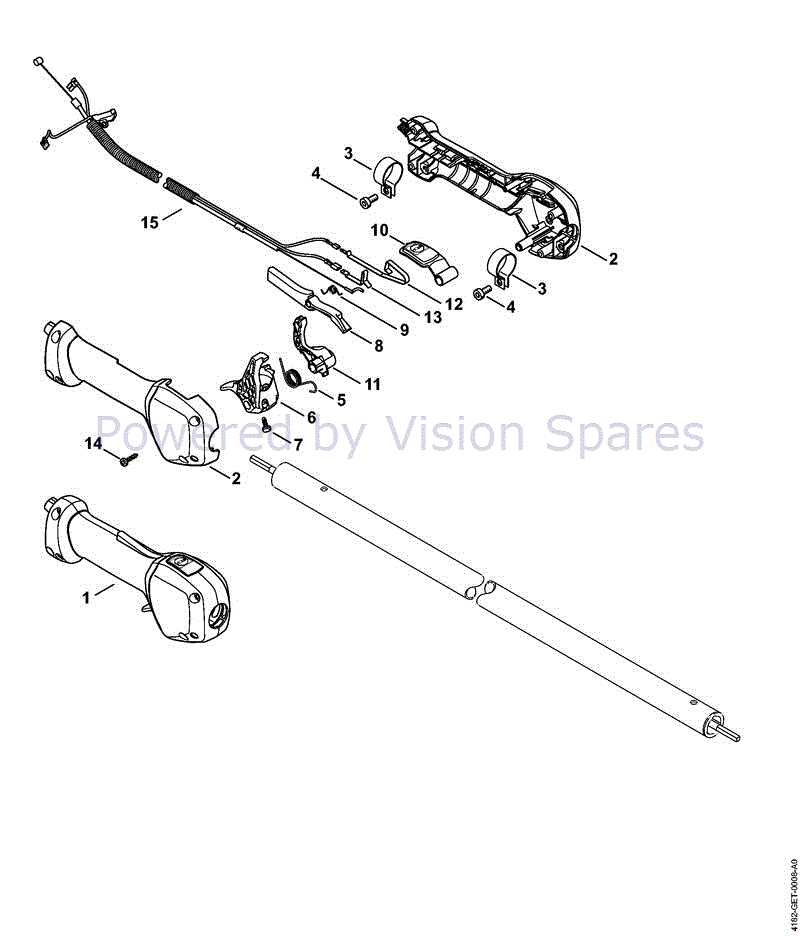

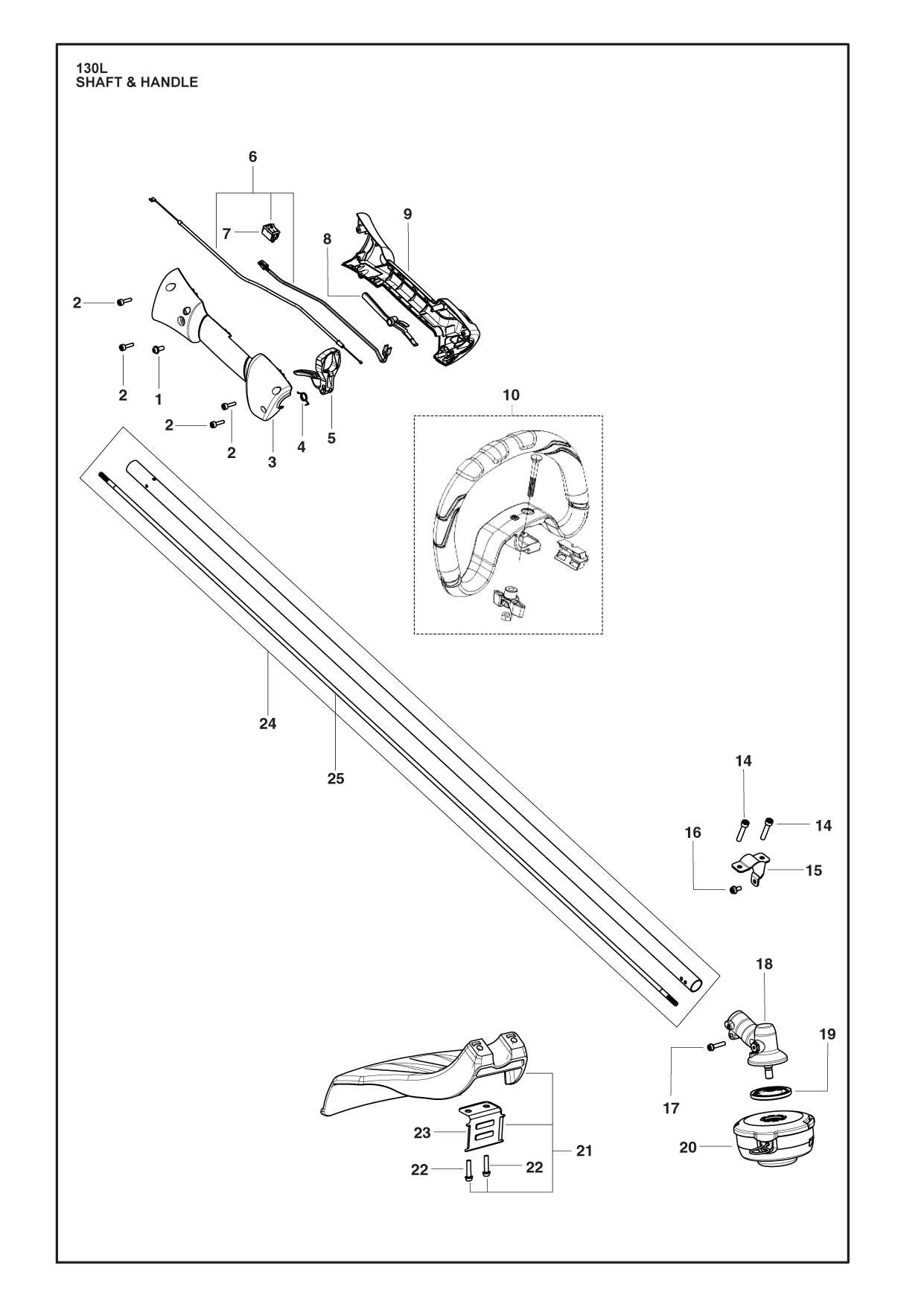

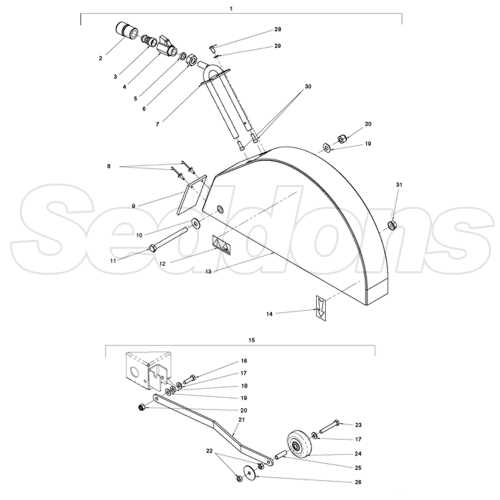

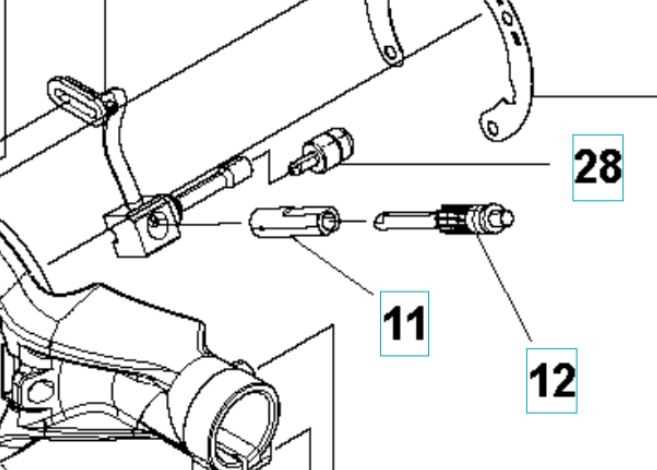

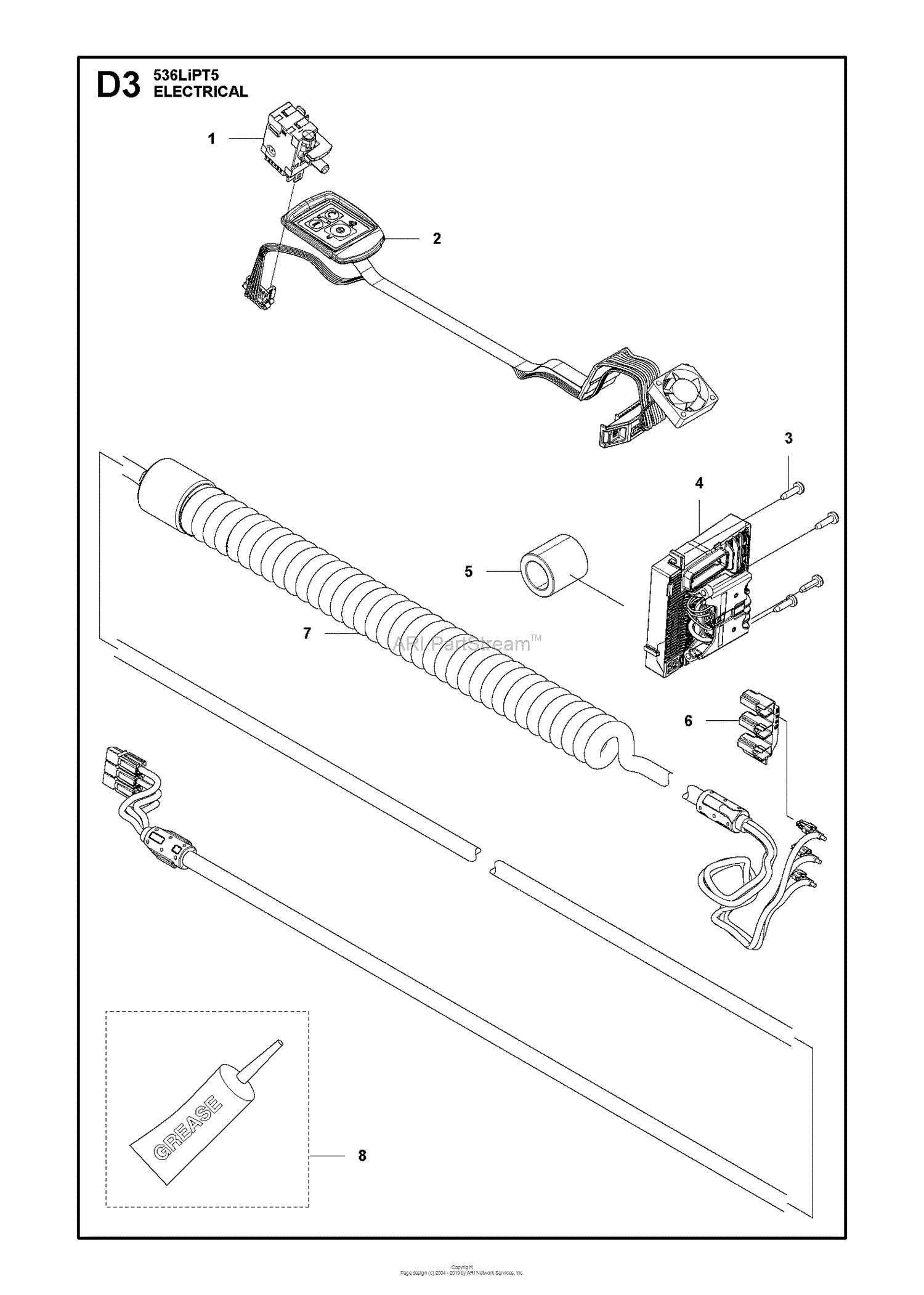

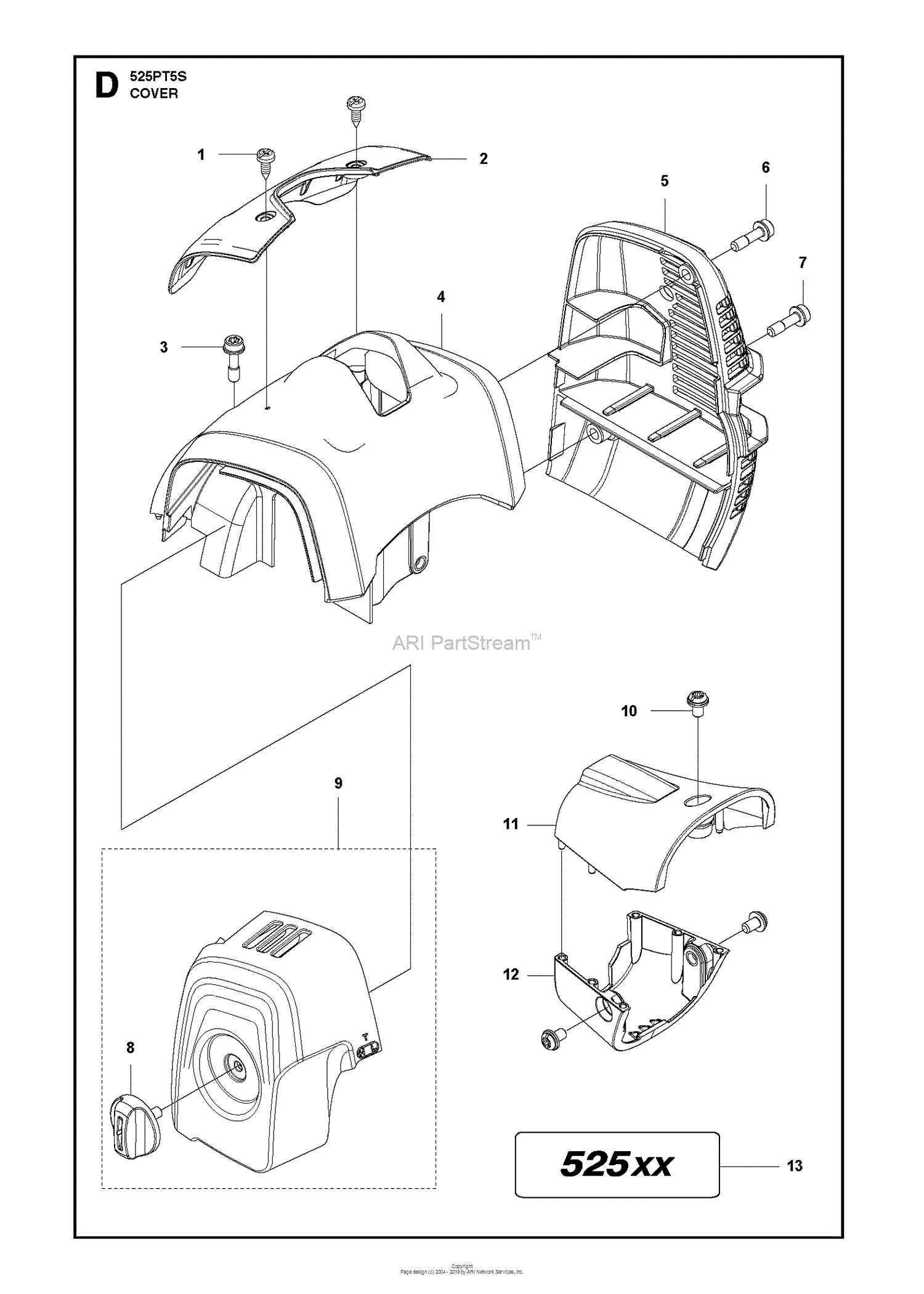

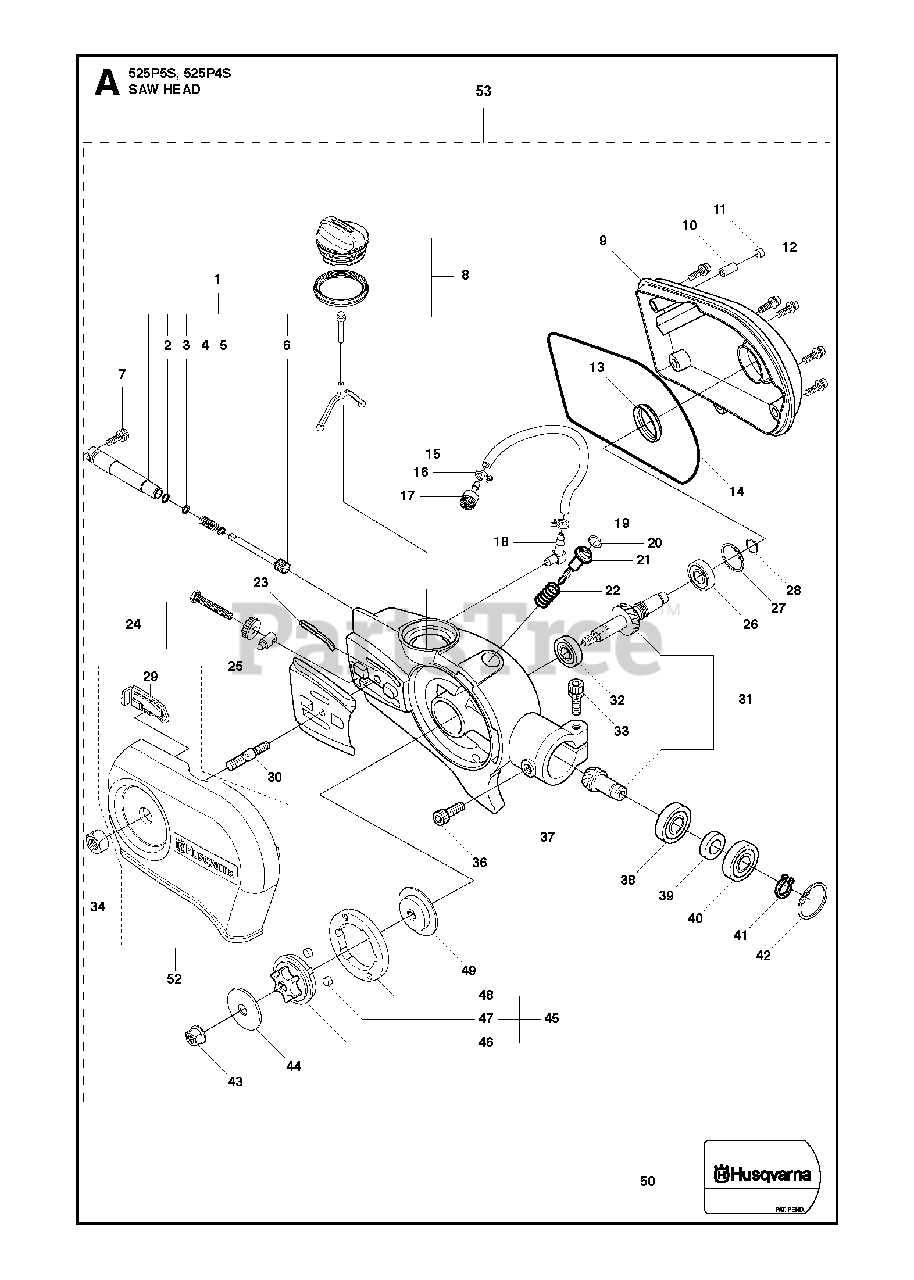

Identifying Parts in User Manual

The user manual serves as a crucial resource for understanding the components of your equipment. By referring to this document, users can effectively recognize and comprehend the various elements, ensuring proper maintenance and operation. Each section is designed to provide clear insights into the specific features and functions, making it easier for users to familiarize themselves with the tool.

Understanding the Layout

The structure of the manual typically includes labeled illustrations that highlight different components. These visuals, accompanied by descriptive text, allow users to correlate the visual elements with their corresponding functions. This organized approach simplifies the learning process and enhances the user experience.

Utilizing Reference Numbers

Most manuals incorporate reference numbers next to each component illustration. These numbers correspond to detailed descriptions and specifications listed elsewhere in the document. By using these references, users can quickly locate information about specific elements, such as maintenance tips and troubleshooting guidance, facilitating a more efficient workflow.

Common Issues and Solutions

In any mechanical equipment, certain problems may arise that can hinder optimal performance. Understanding these common challenges and their respective solutions can enhance the longevity and efficiency of the device. Below are some frequent issues encountered and effective strategies to address them.

1. Difficulty Starting: One prevalent issue is the struggle to initiate the device. This can be caused by various factors, such as insufficient fuel, a clogged air filter, or a malfunctioning spark plug. To resolve this, ensure the fuel is fresh and properly mixed, clean or replace the air filter, and check the spark plug for wear.

2. Excessive Vibration: Unusual vibrations during operation can indicate a problem. This may be due to an imbalanced cutting mechanism or loose components. Inspect the assembly for any signs of damage and tighten any loose screws or bolts to restore stability.

3. Poor Cutting Performance: If the cutting efficiency diminishes, it may result from a dull cutting edge or incorrect tension settings. Sharpen the edge as necessary and adjust the tension to ensure optimal contact with the material being cut.

4. Overheating: Frequent overheating can lead to performance degradation. This issue might arise from inadequate lubrication or blocked cooling vents. Regularly check the lubrication levels and clean any debris obstructing airflow to maintain proper operating temperatures.

By recognizing these common challenges and implementing the suggested solutions, users can maintain their equipment effectively, ensuring it operates smoothly and reliably over time.

Replacement Parts Availability and Sources

When maintaining outdoor equipment, understanding the accessibility of components is crucial for ensuring optimal performance. Users often seek reliable sources for acquiring necessary replacements, which can significantly impact the longevity and functionality of their tools. This section explores various avenues for obtaining essential components and highlights key considerations for consumers.

There are multiple avenues for sourcing replacements. Many retailers specialize in outdoor machinery, offering a wide range of components suitable for various models. Additionally, online platforms provide an extensive selection, allowing users to compare prices and availability from different suppliers.

| Source Type | Examples | Advantages |

|---|---|---|

| Local Retailers | Home improvement stores, specialty shops | Immediate access, expert advice |

| Online Retailers | eCommerce websites, manufacturer sites | Convenient shopping, broader selection |

| Second-Hand Markets | Classified ads, auction sites | Cost-effective options, unique finds |

| Authorized Dealers | Manufacturer-approved shops | Quality assurance, warranty support |

Before making a purchase, consider verifying the compatibility of the components with your specific equipment model. This ensures a seamless fit and functionality, allowing for efficient operation.

Tools Needed for Component Replacement

Replacing components in any machinery requires the right tools to ensure efficiency and effectiveness. Proper equipment not only simplifies the process but also minimizes the risk of damage to the device. Below is a list of essential tools that are commonly needed for component replacement tasks.

- Wrenches: Adjustable or socket wrenches are crucial for loosening and tightening bolts.

- Screwdrivers: A set of Phillips and flathead screwdrivers will help in accessing screws of various types.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating small parts.

- Safety Gear: Always wear safety goggles and gloves to protect yourself during the replacement process.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing over-tightening.

- Cleaning Supplies: Having cloths, brushes, and lubricants on hand can help maintain the cleanliness and functionality of components.

Using the appropriate tools not only facilitates a smoother replacement process but also contributes to the longevity and performance of the machinery.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues with outdoor cutting equipment. By following a systematic method, you can effectively identify problems, replace faulty components, and ensure optimal functionality. Each step is designed to guide you through the necessary actions to restore your device to peak performance.

Begin by gathering essential tools and replacement elements required for the repair. Familiarize yourself with the user manual to understand the specific requirements for disassembly. Carefully detach the components, taking note of their arrangement for easier reassembly later.

Inspect each part for signs of wear or damage, paying close attention to critical areas that affect performance. Replace any compromised components with high-quality alternatives to ensure longevity. After replacing the necessary elements, reassemble the device methodically, confirming that all parts are securely in place.

Once the assembly is complete, conduct thorough testing to confirm that the equipment operates smoothly. If any issues persist, revisit your previous steps to ensure all connections are intact and functioning as intended. Regular maintenance will enhance the lifespan and efficiency of your outdoor equipment.

Safety Precautions When Repairing

When undertaking maintenance on outdoor equipment, it is essential to prioritize safety. Proper precautions not only protect the individual performing the repair but also ensure the longevity and efficiency of the equipment. By adhering to specific guidelines, one can minimize the risk of accidents and injuries during the repair process.

Before beginning any repair work, always make sure to wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and sturdy footwear to safeguard against potential hazards. Additionally, ensuring a clean and organized workspace can significantly reduce the chances of accidents.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use gloves, goggles, and closed-toe shoes to protect against injury. |

| Work in a Well-Lit Area | Ensure adequate lighting to see clearly and avoid mistakes. |

| Disconnect Power Source | Always unplug or disconnect the power supply before starting repairs. |

| Use the Right Tools | Employ appropriate tools for each task to avoid damage and injury. |

| Follow Manufacturer Guidelines | Refer to instructions for specific safety measures related to the equipment. |

By following these safety precautions, individuals can effectively reduce the likelihood of accidents while performing repairs. Being mindful of one’s surroundings and the equipment involved fosters a safer working environment.

Enhancing Performance with Upgrades

Improving the efficiency and effectiveness of your outdoor tools is crucial for achieving optimal results. By implementing various enhancements, users can experience increased functionality and longevity, allowing for more productive work sessions.

Here are several upgrades to consider:

- Power Enhancements: Upgrading the engine or motor can lead to significant boosts in power output, making tasks easier and quicker.

- Cutting Attachments: Utilizing high-quality cutting heads can improve precision and reduce the effort needed for each cut.

- Ergonomic Handles: Investing in better grip and ergonomic designs helps reduce fatigue, enabling longer usage without discomfort.

- Improved Fuel Systems: Enhancing fuel efficiency through upgraded systems can save money and minimize downtime for refueling.

- Maintenance Tools: Using specialized maintenance accessories ensures that your equipment remains in top condition, leading to consistent performance.

Upgrading these components not only maximizes performance but also enhances overall user satisfaction. Careful consideration of enhancements can yield remarkable improvements in efficiency and effectiveness during outdoor projects.

FAQs About Husqvarna Pole Saws

This section addresses common inquiries regarding specialized cutting equipment designed for trimming and pruning tasks. Users often seek clarification on various aspects of these tools to enhance their understanding and usage experience.

Common Questions and Answers

Below are frequently asked questions and their corresponding answers to assist users in navigating the features and functionalities of these tools.

| Question | Answer |

|---|---|

| What maintenance is required? | Regular cleaning, sharpening of the cutting edge, and checking for wear are essential for optimal performance. |

| How do I choose the right model? | Consider factors such as reach, power source, and intended use to find the best fit for your needs. |

| Can these tools be used for commercial purposes? | Yes, many users employ these tools in professional settings, thanks to their efficiency and reliability. |

| Are replacement components readily available? | Yes, various suppliers offer a wide selection of replacement components to ensure continuous operation. |

| What safety measures should be taken? | Always wear appropriate protective gear, and follow the manufacturer’s guidelines to ensure safe usage. |

Additional Resources

For more information, users can refer to the manufacturer’s website or consult product manuals that provide detailed insights and guidelines for effective operation.