Husqvarna Weed Eater Parts Overview

Garden maintenance often requires specialized equipment designed to keep outdoor spaces neat and well-maintained. To ensure these devices work efficiently, it’s essential to understand their internal setup. Knowing the structure of such tools can greatly aid in maintaining, repairing, and optimizing their performance for long-term use.

Every component plays a crucial role in the functionality of these devices, contributing to smooth operation and durability. Recognizing how each element interacts with others helps users achieve better results during their trimming tasks. This understanding can also lead to easier troubleshooting when issues arise.

Detailed schematics and breakdowns of these devices make it simpler for enthusiasts and professionals alike to comprehend their mechanisms. Such insights can save time and effort, allowing for quick adjustments or replacements when needed, making sure that every outdoor project is completed seamlessly.

Husqvarna Weed Eater Components Overview

The functionality of a versatile garden tool relies on the coordination of several key elements, each contributing to its effective performance in outdoor maintenance. Understanding the main structural and operational components can help users maintain and repair their device, ensuring longer durability and optimal results.

| Component | Description | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor Assembly | This is the power source that drives the device, enabling the rapid rotation needed for trimming. It is crucial for providing the energy required for efficient cutting. | ||||||||||||||||||||||||||

| Cutting Head | The section where the cutting line is attached. It plays a vital role in shaping and trimming, designed to hold the line securely while spinning at high speeds. | ||||||||||||||||||||||||||

| Shaft | The long, tubular part that connects the power source to the cutting end. It provides stability and control during operation, allowing for precision while trimm

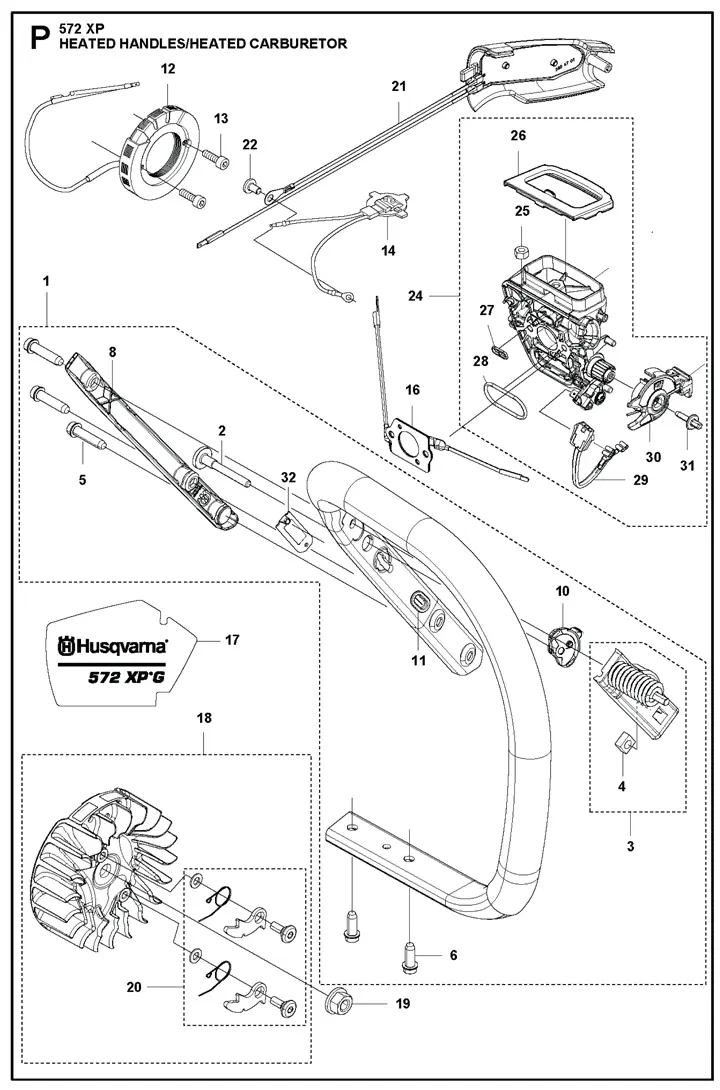

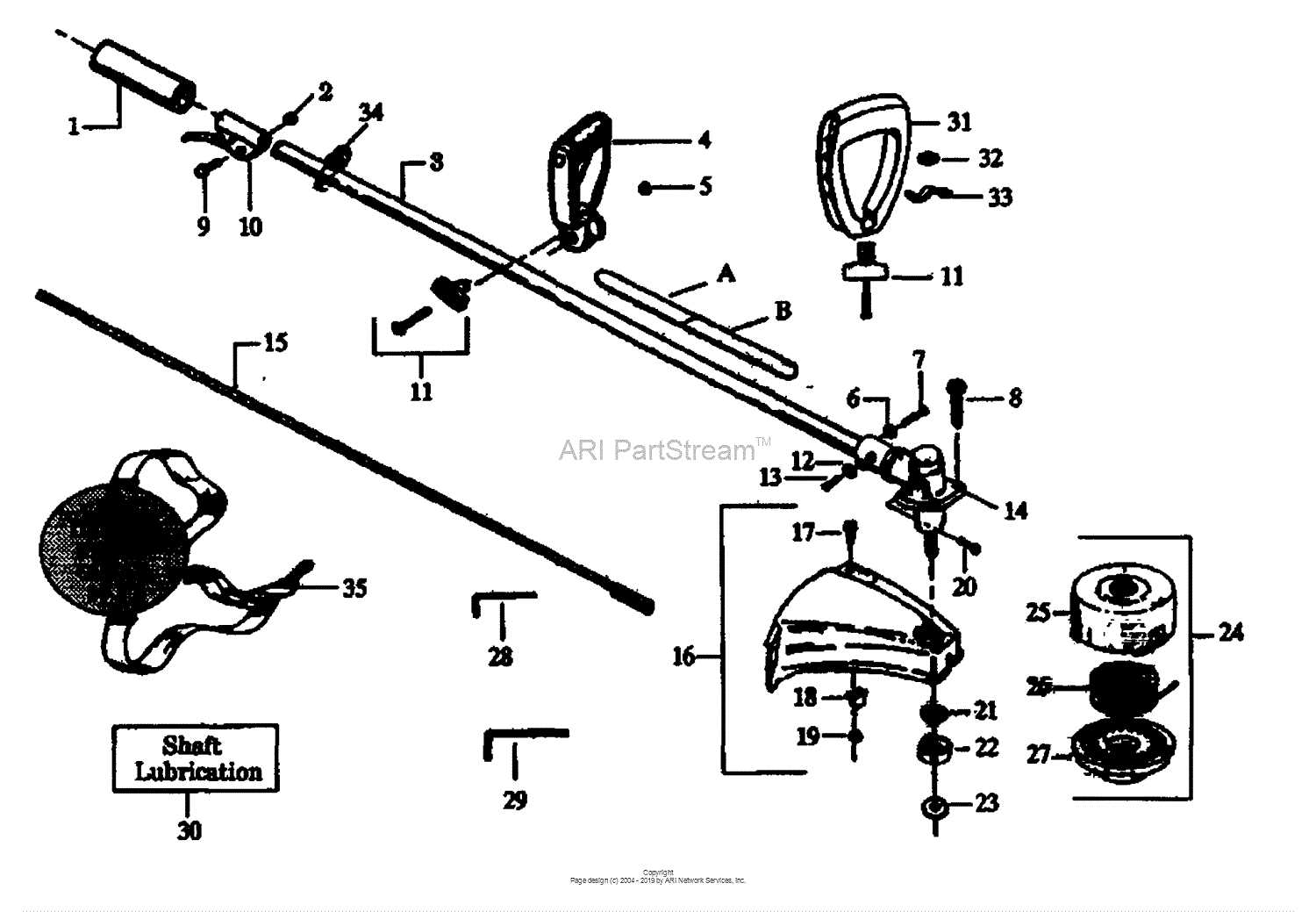

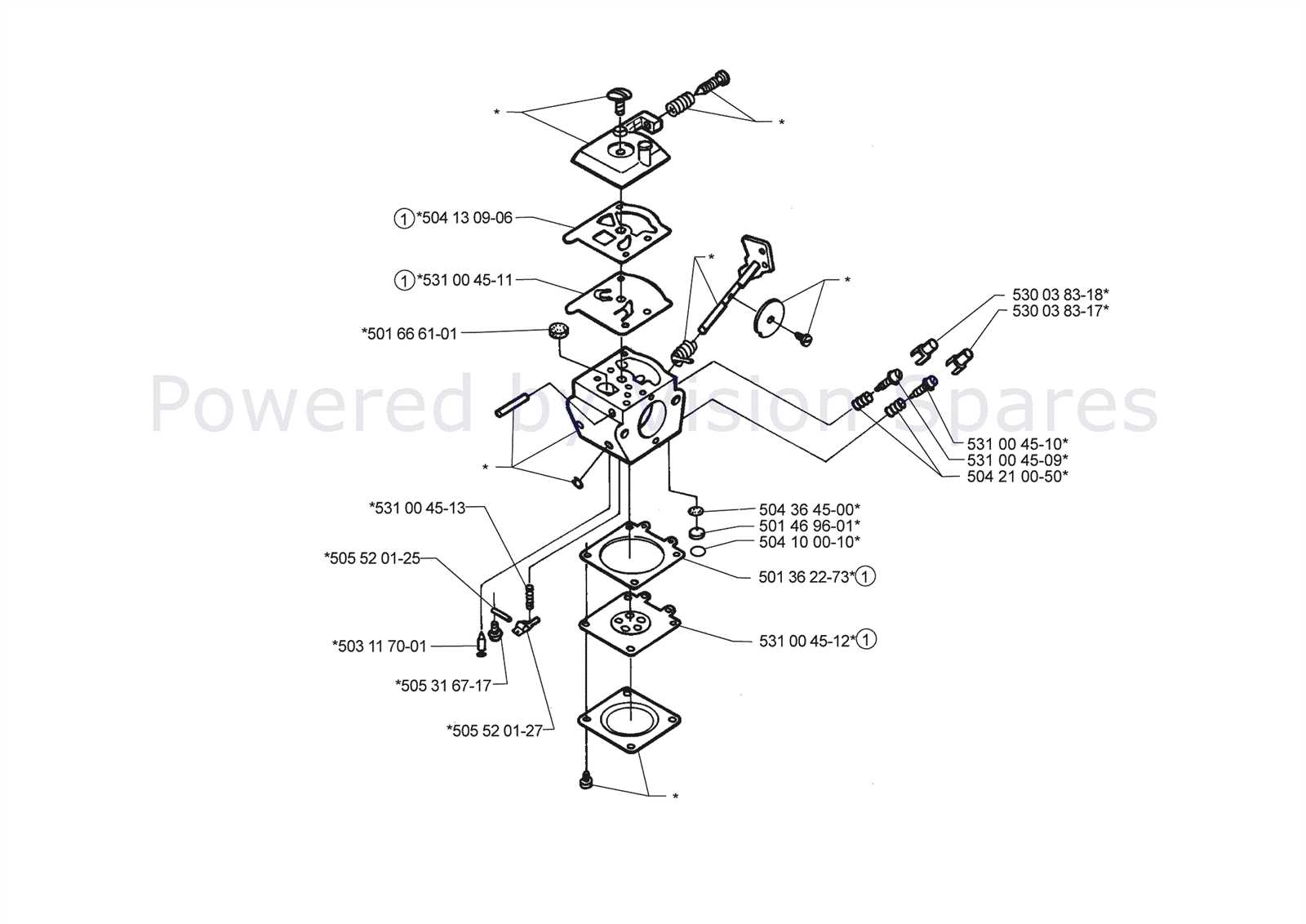

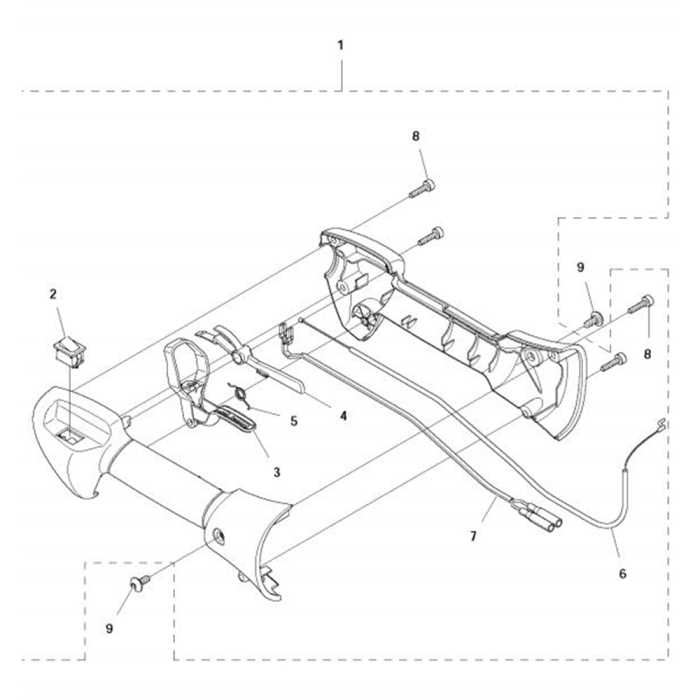

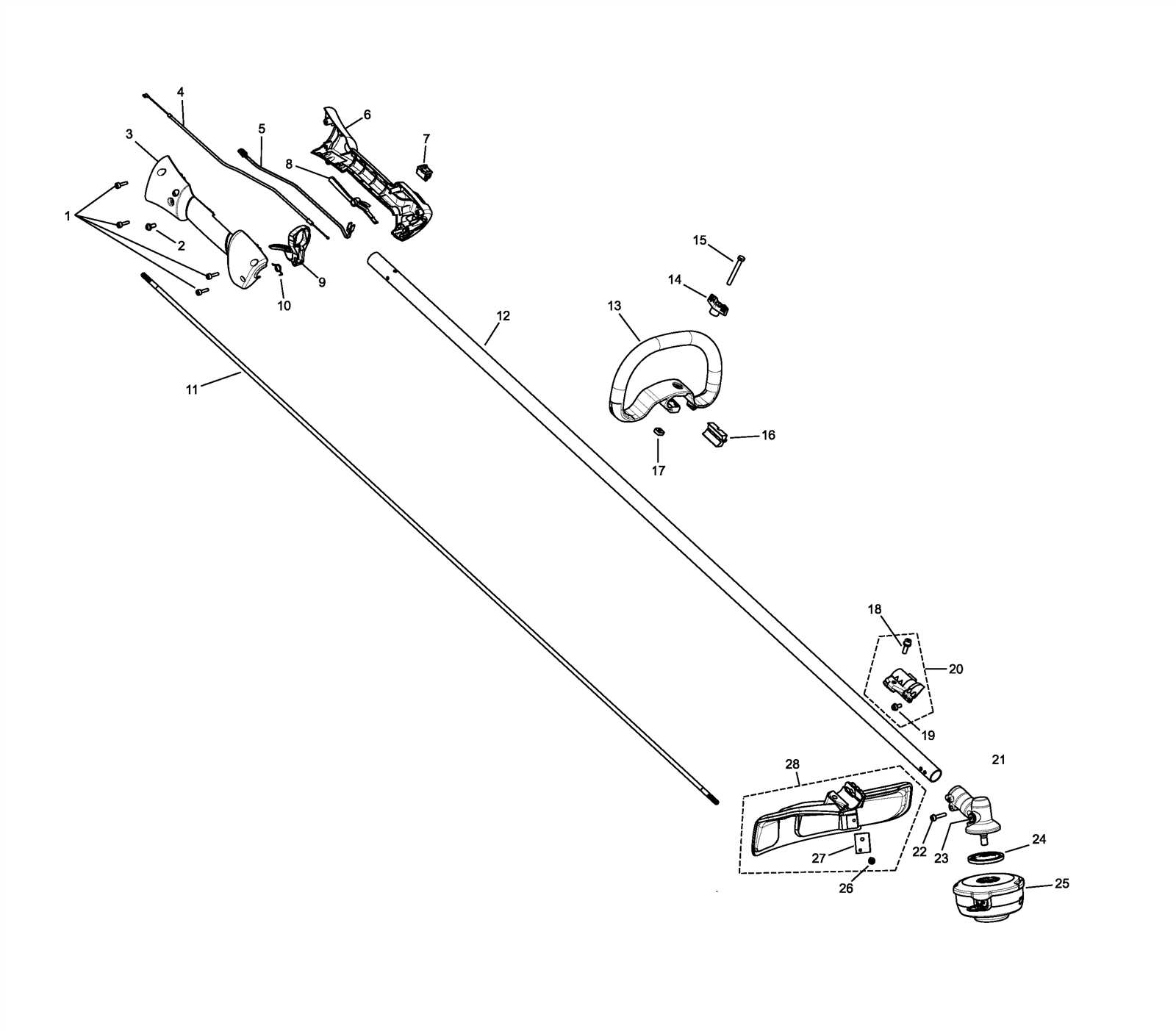

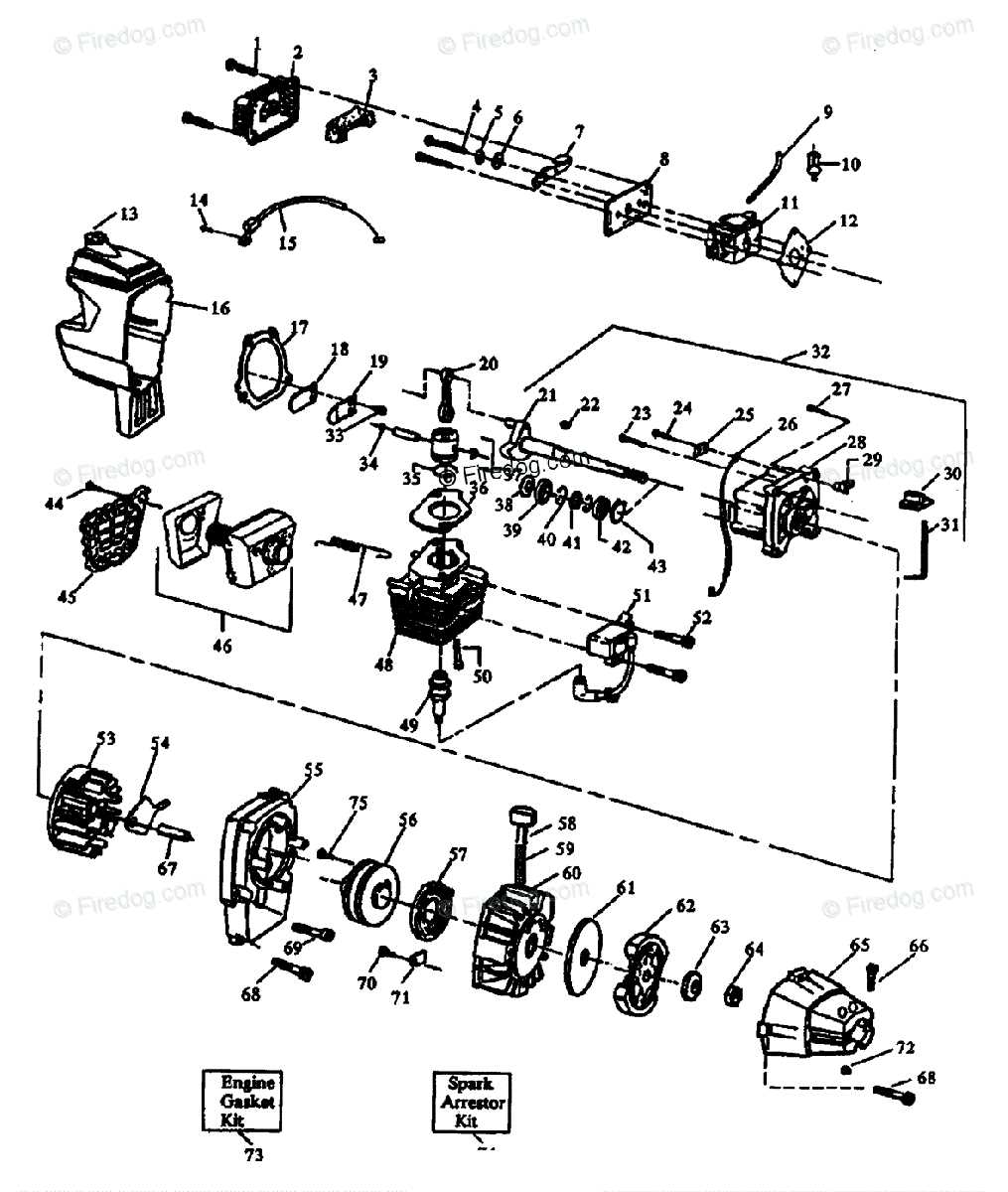

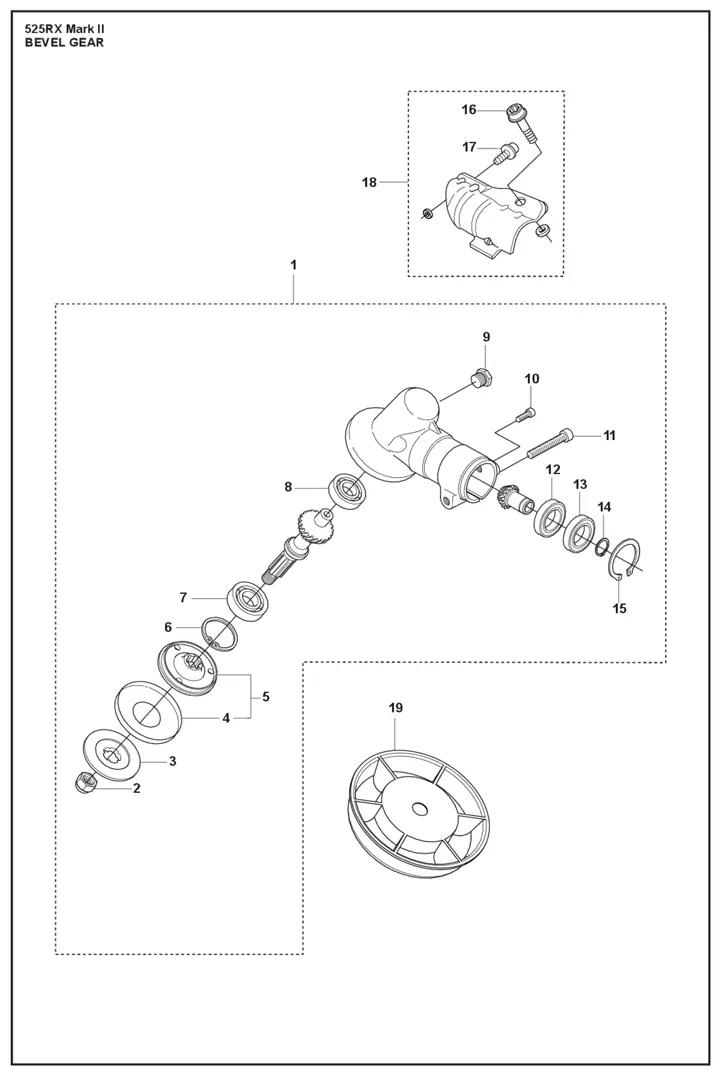

Understanding the Structure of PartsThe design and arrangement of components in a power tool play a crucial role in its functionality and durability. Recognizing how these elements fit and work together helps in maintenance and efficient operation. This section provides a clear view of how each component interacts within the overall mechanism, contributing to the seamless function of the tool. Main AssembliesPower tools are often composed of multiple key assemblies that ensure smooth performance. These assemblies include the engine section, the shaft system, and the cutting mechanism. Each section serves a unique purpose and must be correctly aligned to function efficiently.

Small but Essential ComponentsBeyond the main assemblies, numerous smaller elements ensure the tool Guide to Key Components and Functions

This section provides an overview of the essential elements and their roles in a versatile trimming device. Understanding these components ensures efficient operation and helps in maintaining the tool’s performance over time. Main Structural Elements

Cutting Mechanism

The cutting mechanism is crucial for achieving the desired trimming results. It consists of several key elements that work together to deliver a smooth and effective performance.

Commonly Replaced Parts for Husqvarna Models

Maintenance of outdoor power tools often involves substituting certain components to ensure consistent performance. These items can experience wear and tear over time, necessitating regular attention for efficient operation. Understanding which components tend to require replacement can help users plan ahead and keep their equipment in top condition. Frequent Component ChangesSeveral elements of outdoor power tools often need to be changed due to their high usage and exposure to challenging conditions. This includes items like the rotating mechanisms, tensioning components, and various connectors. Regular inspection of these elements helps prevent unexpected breakdowns. Wearable Elements and Their Importance

Other components, such as protective coverings and filtering systems, are also crucial for optimal function. These parts can accumulate dirt and debris, leading to potential issues if not replaced on time. By keeping these elements in good condition, the overall efficiency and lifespan of the equipment can be greatly improved. How to Identify Essential ComponentsRecognizing the primary elements of a grass trimmer can help ensure its proper functioning and make any maintenance process smoother. Understanding how each piece interacts is crucial for efficient upkeep and troubleshooting. Below are the key aspects to focus on when examining the critical parts of the machine. Main Structural ElementsThe core structure consists of various parts that come together to form the working unit. Pay attention to elements like the powerhead, which drives the mechanism, and the shaft assembly, linking the motor to the cutting head. These components are vital for transferring energy throughout the device. Operational ComponentsFor smooth operation, several smaller parts play a crucial role. The cutting head is where the trimming action occurs, and it’s important to inspect it for wear. Additionally, elements like the throttle trigger and fuel lines Maintenance Tips for Weed Eater PartsProper upkeep of your gardening equipment is essential for ensuring optimal performance and longevity. Regular maintenance can prevent common issues and enhance the efficiency of your tools. Here are some key recommendations to keep your equipment running smoothly.

Following these maintenance tips will help ensure your gardening equipment remains in excellent working condition, allowing you to tackle your landscaping tasks with ease. Replacing and Installing New ComponentsUpgrading or replacing components in your gardening equipment can enhance its performance and extend its lifespan. Whether you’re refreshing old parts or installing new ones, understanding the process is essential for effective maintenance. Preparation Steps

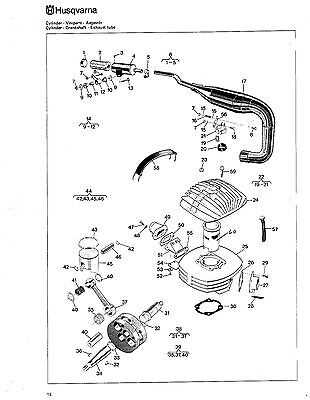

Before starting the replacement, ensure you have the necessary tools and new components ready. Disconnect the equipment from any power source to guarantee safety. Familiarize yourself with the assembly of the machine to identify which components need attention. Installation ProcessCarefully remove the old components by following the manufacturer’s instructions or reference materials. Take note of how each part is positioned to facilitate easy installation of the new items. Once the new components are in place, reassemble the equipment, ensuring all connections are secure. Finally, test the machine to confirm that everything is functioning properly. Diagrams for Efficient Weed Eater RepairsEffective repair strategies often hinge on the availability of clear visual references. These illustrations serve as invaluable tools, allowing users to comprehend the intricate components of their outdoor maintenance equipment. By leveraging detailed graphics, individuals can enhance their understanding of assembly, disassembly, and maintenance tasks, ultimately leading to more successful repair outcomes. Utilizing well-structured visuals enables users to identify each element of the machinery easily. This not only simplifies the process of locating specific parts but also minimizes the risk of misplacement during repairs. Furthermore, these diagrams can provide insights into potential issues and common faults, guiding users in troubleshooting and resolving challenges efficiently. In addition, having access to comprehensive graphics can significantly reduce the time spent on repairs. With a clear visual guide, users can follow step-by-step instructions confidently, ensuring that every component is addressed appropriately. This proactive approach fosters a deeper familiarity with the equipment, empowering users to take charge of their maintenance tasks with assurance. Choosing the Right Parts for Repairs

When it comes to maintaining and restoring outdoor equipment, selecting appropriate components is crucial for ensuring optimal performance. Understanding the various elements involved in the machinery allows for informed decisions, leading to effective repairs and prolonged lifespan. This section will guide you through essential considerations to take into account when sourcing replacements. Here are some key factors to help you make the right choice:

Exploring Different Models and Their Parts

This section delves into the various types of outdoor trimming equipment and their individual components. Understanding the differences in design and functionality among these devices is essential for optimal performance and maintenance. Each model presents unique characteristics that cater to specific gardening needs, making it important to familiarize oneself with their structure. Key Features of Various Models

Different models come equipped with distinct features that enhance usability and efficiency. Below is a table summarizing some common attributes found in various designs:

Understanding Individual ComponentsFamiliarity with the specific elements of each model allows users to make informed decisions regarding maintenance and repairs. Identifying the main components can help in troubleshooting and ensuring efficient operation. Troubleshooting Issues with Weed Eater PartsAddressing complications that arise with trimming equipment is essential for maintaining optimal performance. Identifying the source of malfunctions can help users restore functionality effectively. Below are common issues and their potential solutions to enhance the reliability of your gardening tools. Common Problems and Solutions

Maintenance Tips

Best Practices for Longevity of PartsMaintaining equipment effectively can significantly extend its lifespan and enhance performance. Adopting specific strategies not only ensures optimal functionality but also minimizes the need for frequent replacements. By focusing on proper care and attention, users can enjoy a more durable experience with their tools.

Implementing these practices can significantly contribute to the durability and reliability of your equipment, allowing for a more productive experience. |