Understanding the International 284 Parts Diagram for Efficient Repairs

In the realm of modern farming, the intricate design and functionality of machinery play a pivotal role in enhancing productivity and efficiency. A thorough comprehension of these machines’ intricate elements is essential for effective maintenance and repair. This knowledge empowers operators to troubleshoot issues and ensures that equipment runs smoothly, maximizing its lifespan and performance.

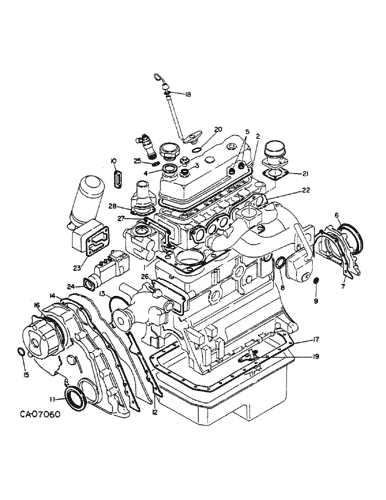

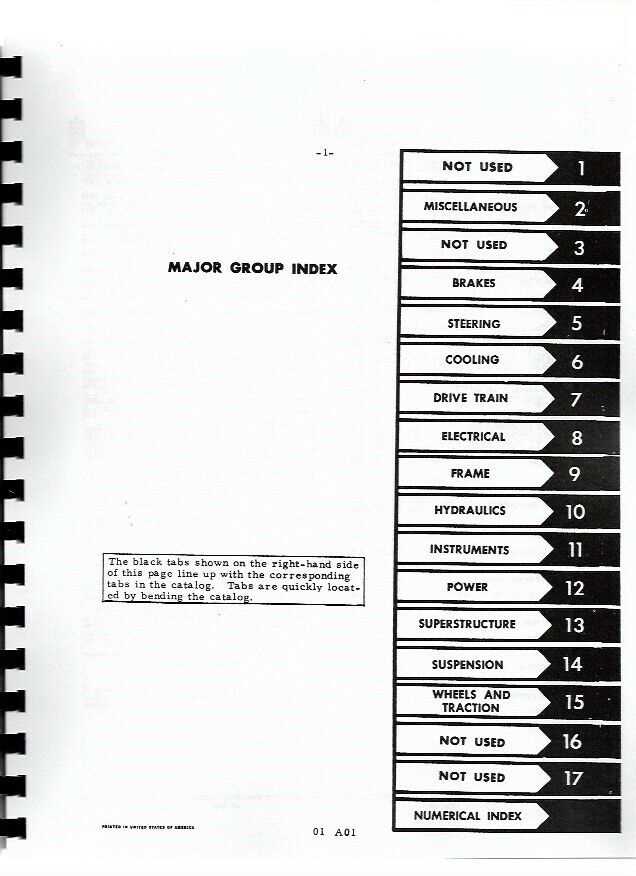

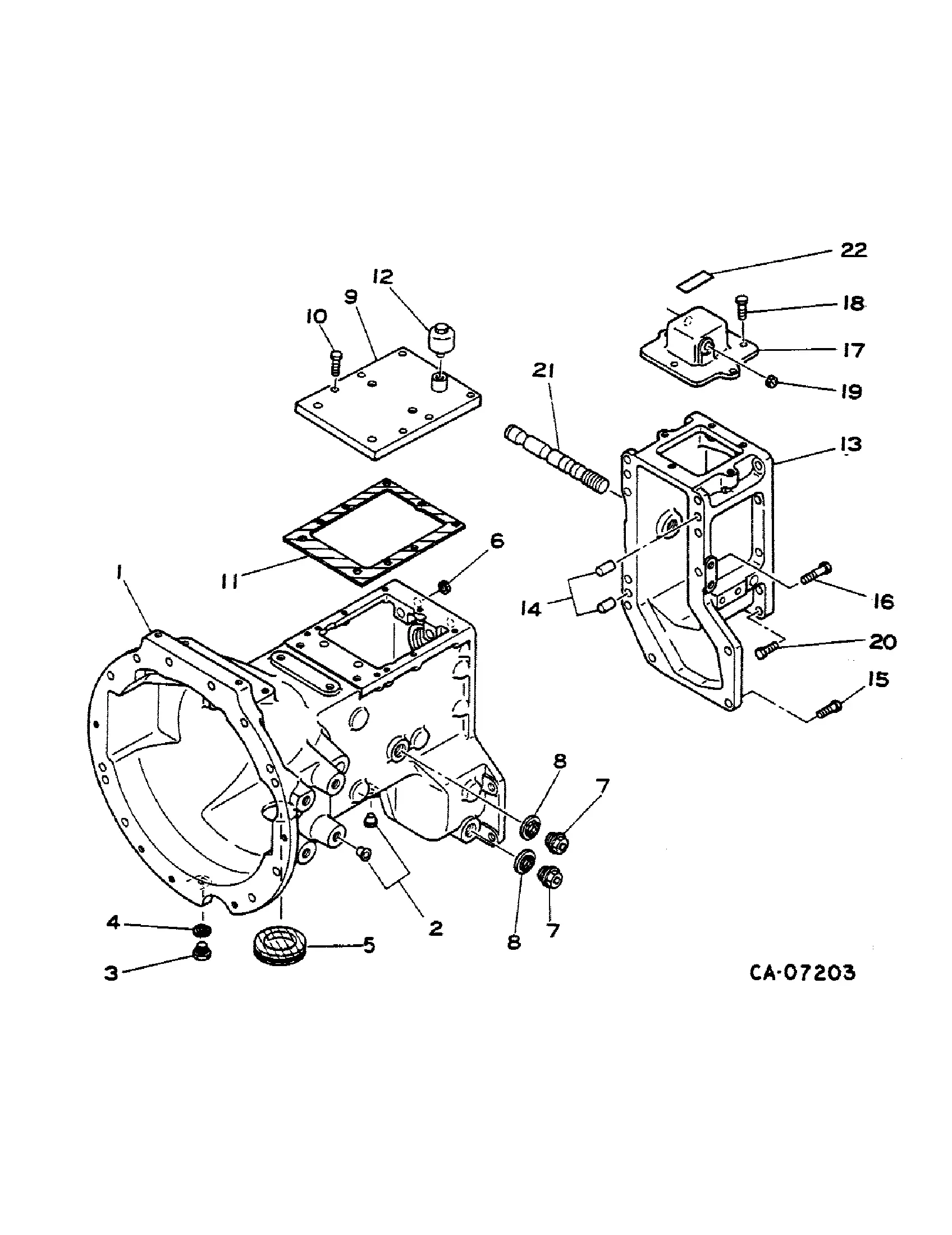

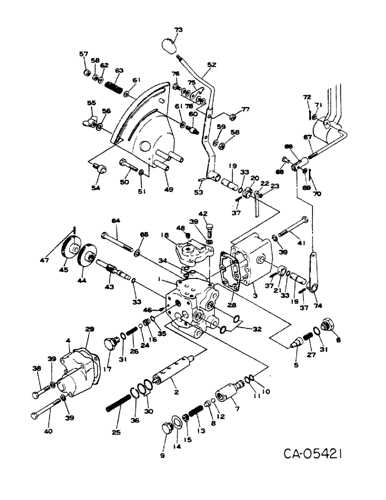

Visual representations of machinery elements serve as invaluable tools for both novice and experienced users. These illustrations break down complex systems into manageable parts, allowing for a clearer understanding of how each component interacts within the larger framework. By examining these detailed visuals, one can gain insight into the operational intricacies that drive agricultural implements.

Equipped with this understanding, farmers and technicians can make informed decisions regarding upkeep and modifications. Whether it’s enhancing performance or addressing specific concerns, familiarity with each segment leads to more efficient problem-solving strategies. Thus, engaging with these resources not only aids in maintenance but also fosters a deeper appreciation for the engineering behind modern agricultural practices.

Understanding the International 284 Tractor

This section explores a well-regarded agricultural machine known for its efficiency and reliability. With a robust design and user-friendly features, this vehicle has become a staple on farms, providing essential support in various tasks.

The engine of this remarkable machine is a testament to engineering prowess, delivering ample power for a range of applications. Its mechanical components are crafted to withstand the rigors of daily use, ensuring longevity and optimal performance.

One of the standout characteristics of this tractor is its versatility. Equipped with various attachments, it can seamlessly transition from plowing fields to transporting goods. This adaptability makes it an invaluable asset for farmers seeking to maximize productivity.

Maintenance is crucial for sustaining the performance of this equipment. Regular checks and timely replacements of essential components help prevent downtime and extend the lifespan of the machinery. Understanding the layout and function of each part is key for efficient upkeep.

In summary, this machine embodies a blend of power, versatility, and reliability, making it an indispensable tool in modern agriculture. Proper knowledge of its functionality and care practices ensures that it continues to serve its purpose effectively for years to come.

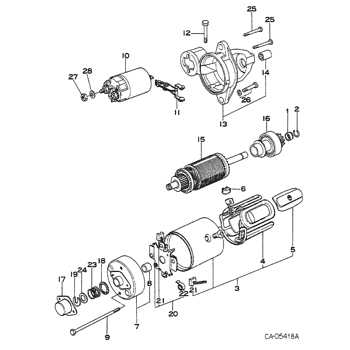

Key Components of the International 284

This section explores the essential elements that contribute to the functionality and performance of a particular agricultural machine. Understanding these components is crucial for effective maintenance and operation.

- Engine: The powerhouse that drives the entire system.

- Transmission: Ensures smooth power delivery to the wheels.

- Hydraulic System: Facilitates the operation of various attachments and implements.

- Chassis: Provides structural integrity and support for all components.

- Electrical System: Powers essential features and controls.

Each of these elements plays a vital role, contributing to the ultimate efficiency and reliability of the machine.

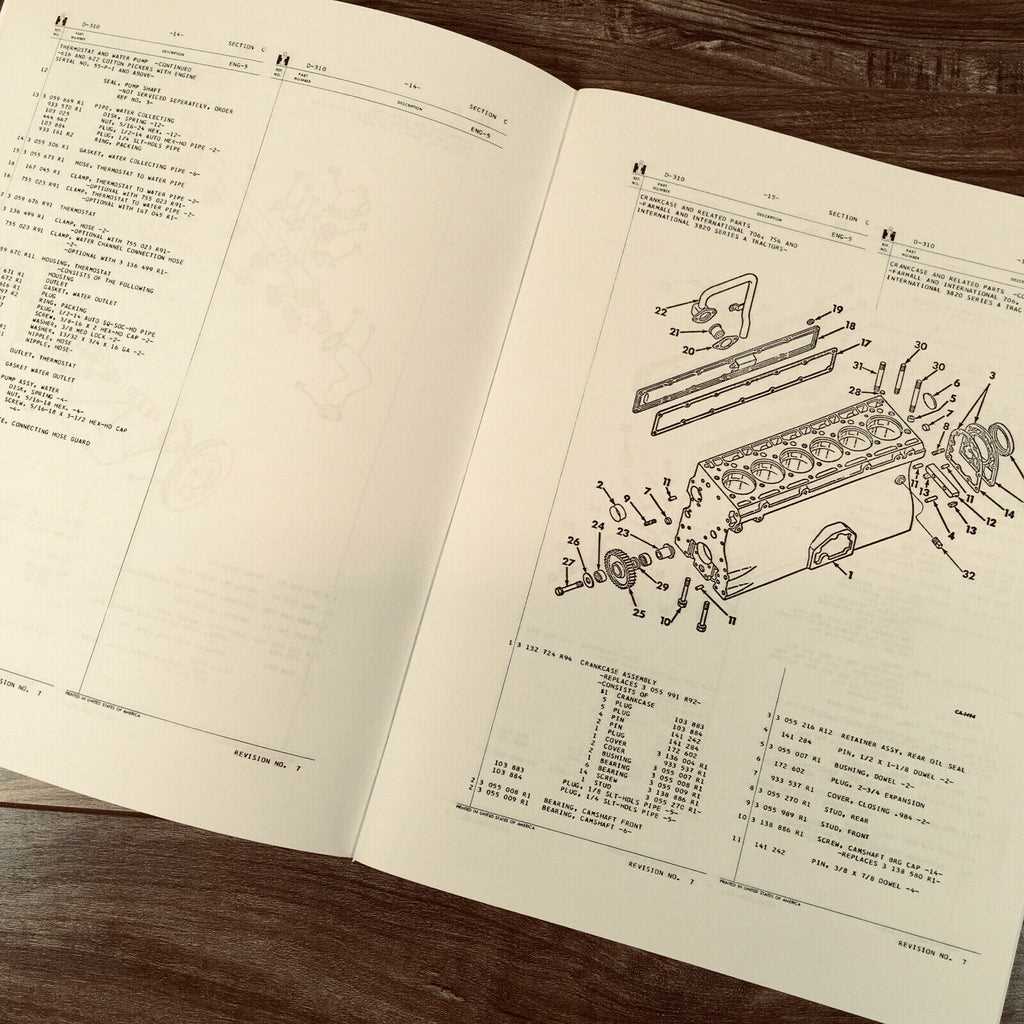

Importance of Parts Diagrams in Maintenance

Understanding the components of machinery is crucial for effective upkeep and repair. Visual representations serve as invaluable tools for technicians, enhancing their ability to identify and replace elements efficiently. This clarity reduces downtime and minimizes errors during maintenance tasks.

Benefits of Visual Representations

- Improved Accuracy: Technicians can pinpoint specific components, ensuring the correct parts are addressed.

- Time Efficiency: Quick reference reduces the time spent searching for information.

- Enhanced Communication: Visual aids facilitate better discussions among team members.

Application in Maintenance Procedures

- Identification of Components: Clear visuals help in recognizing worn or damaged elements.

- Guiding Reassembly: Diagrams provide step-by-step instructions for reassembling machinery.

- Training Tool: New technicians can learn faster by referencing detailed illustrations.

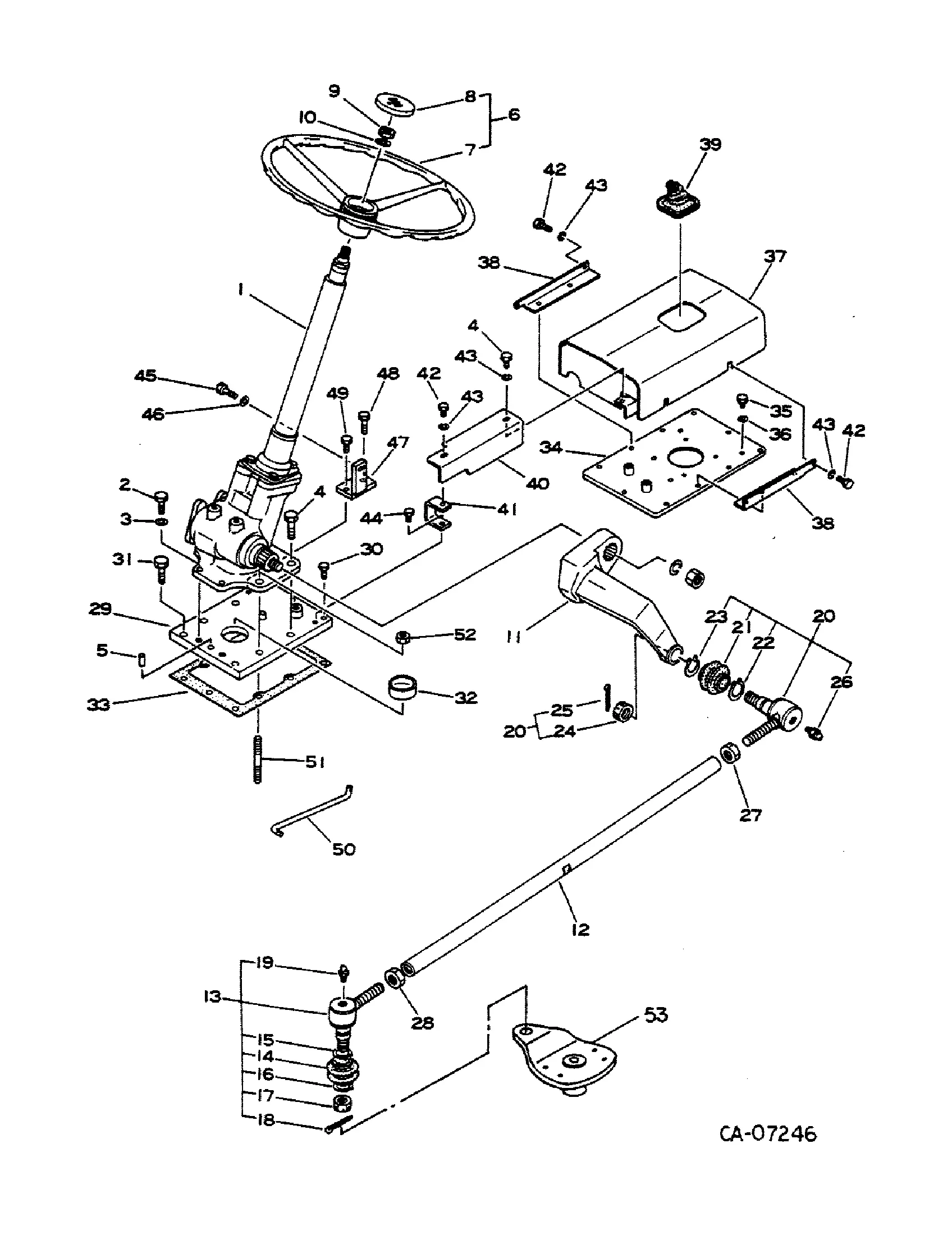

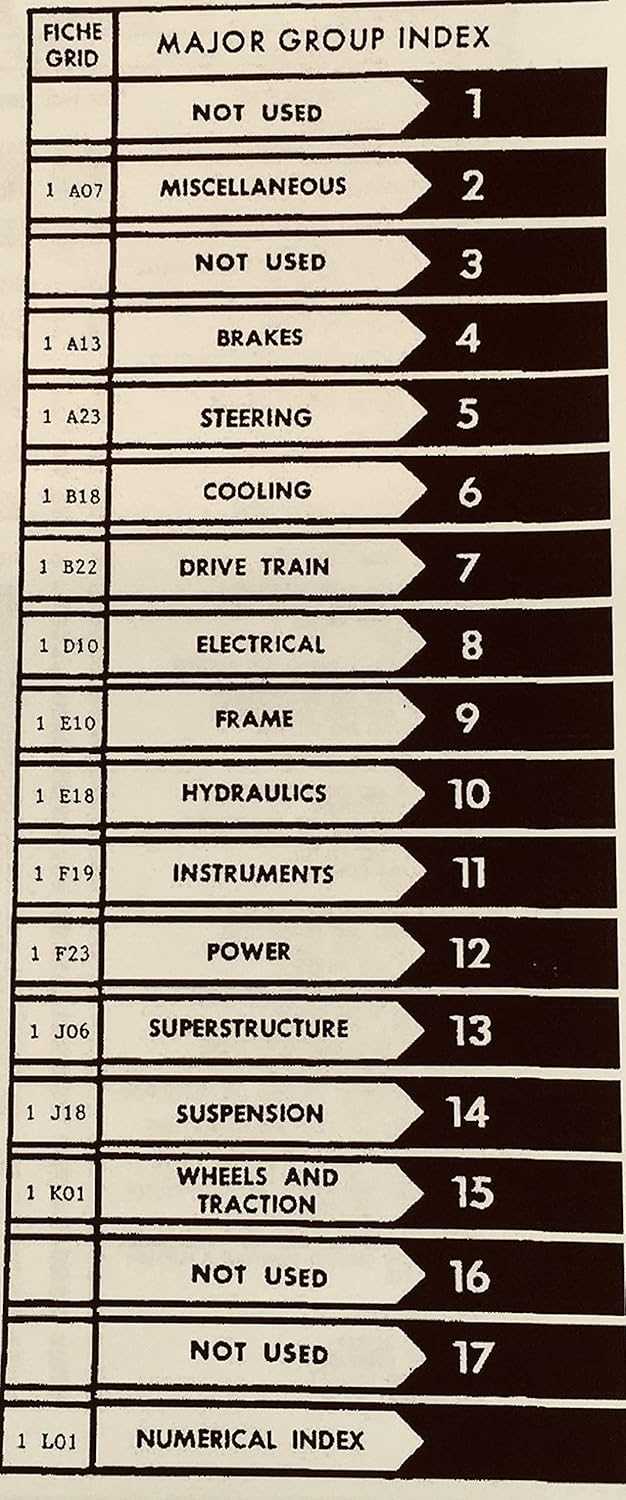

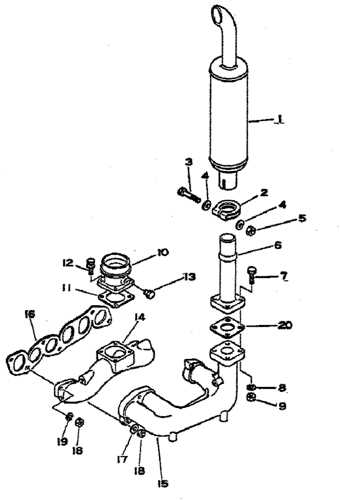

How to Read a Parts Diagram

Understanding a visual representation of components can greatly enhance your ability to service and maintain machinery. By grasping the layout and relationships of different elements, you can identify what needs to be repaired or replaced, streamlining your workflow and ensuring optimal performance.

Key Components of a Visual Representation

When examining a schematic, consider the following aspects:

- Labels: Look for annotations that indicate the names and specifications of each component.

- Connections: Pay attention to lines or arrows that show how different parts interact with one another.

- Numbering: Components are often numbered for easy reference in accompanying documentation.

- Symbols: Familiarize yourself with standard icons that represent various types of parts, such as fasteners, electrical components, or hydraulic elements.

Steps to Analyze the Visual Guide

- Start by identifying the main assembly or section depicted in the visual guide.

- Break down the components by focusing on individual parts, using the labels and numbers for clarity.

- Trace the connections to understand how each component functions within the larger system.

- Refer to additional documentation if needed for specific part details and specifications.

With practice, interpreting these visual aids will become second nature, allowing you to tackle maintenance tasks more efficiently.

Common Issues with International 284 Parts

When dealing with machinery components, users often encounter a variety of challenges that can affect performance and longevity. Understanding these common issues can aid in effective troubleshooting and maintenance, ensuring optimal operation.

Frequent Wear and Tear

Components may suffer from gradual degradation over time, leading to decreased efficiency. Regular inspections are crucial to identify signs of worn parts and to implement timely replacements.

Compatibility Challenges

Using incompatible components can result in operational failures. It’s essential to verify that all replacements meet the required specifications to avoid complications during use.

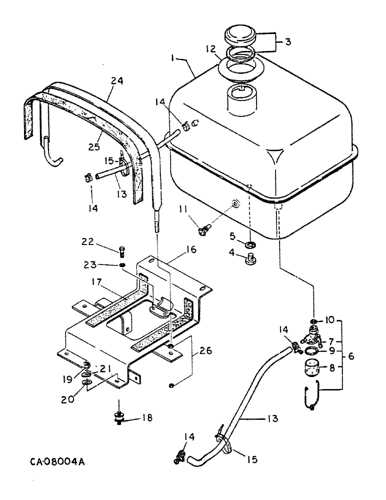

Where to Find Replacement Parts

Locating suitable components for your machinery can be essential for maintaining its functionality and longevity. Various sources are available to ensure you find what you need, ranging from online retailers to specialized suppliers.

Online Marketplaces

Web platforms offer a vast array of options for acquiring components. Websites like eBay and Amazon often have listings from different sellers, making it easy to compare prices and availability. Always check the seller’s ratings and reviews to ensure quality.

Local Dealers and Salvage Yards

Visiting local distributors or salvage yards can provide unique opportunities to find rare components. Establishing a relationship with local suppliers can lead to discovering hidden gems and possibly even better pricing.

Step-by-Step Repair Guide for Owners

This guide is designed to assist owners in effectively managing repair tasks for their machinery. By following a structured approach, you can ensure that maintenance and troubleshooting are performed efficiently, ultimately prolonging the lifespan of your equipment.

Begin by familiarizing yourself with the various components of your machine. Understanding how each part functions will empower you to identify issues quickly. Start with a thorough inspection, checking for any visible signs of wear, leaks, or damage. Document your findings to keep track of any problems that need addressing.

Next, gather the necessary tools and replacement items before commencing repairs. Having everything on hand will save time and reduce frustration. Always refer to the manufacturer’s specifications to ensure you are using the correct parts and techniques during the repair process.

When performing repairs, follow a systematic approach. Disassemble the affected areas carefully, taking note of how parts fit together. It may be helpful to take pictures or label components to simplify reassembly. After replacing or fixing the faulty parts, ensure everything is securely reattached and check that all connections are tight.

Once repairs are completed, conduct a test run to verify that the machine operates correctly. Monitor for any unusual sounds or performance issues. Regular maintenance checks after repairs will help prevent future problems and keep your equipment in optimal condition.

By adhering to this guide, you can effectively manage repairs and enhance the reliability of your machinery, ensuring it remains operational for years to come.

Comparing International 284 to Other Models

This section explores the distinctions and similarities among various agricultural machines, focusing on their performance, features, and usability. By examining these aspects, we can better understand how one particular model stands against its counterparts in the market.

Key Features Comparison

When analyzing machinery, key attributes such as engine power, efficiency, and durability play crucial roles. Each model has unique specifications that cater to different farming needs.

| Model | Engine Power (HP) | Weight (lbs) | Fuel Capacity (gallons) |

|---|---|---|---|

| Model A | 45 | 3200 | 12 |

| Model B | 50 | 3500 | 15 |

| Model C | 40 | 3000 | 10 |

Performance Analysis

Performance metrics such as fuel efficiency and handling capabilities significantly impact operational costs and user satisfaction. Understanding these can guide potential buyers in making informed decisions.

Aftermarket vs. Original Parts Explained

In the world of machinery and vehicles, choosing between replacement components can significantly impact performance and longevity. Understanding the differences between factory-manufactured items and those produced by third-party suppliers is crucial for making informed decisions. Each option comes with its own set of advantages and drawbacks that can influence maintenance strategies and overall costs.

Original components, crafted by the original manufacturer, are typically designed to meet specific quality standards and specifications. These items are often associated with reliability and a perfect fit, ensuring seamless integration with existing systems. However, they may come with a higher price tag, which can be a deciding factor for many users.

On the other hand, aftermarket options can offer a variety of choices, often at a lower cost. These products are produced by independent companies, and while they may not always match the original in terms of quality, many are engineered to meet or exceed industry standards. Buyers often appreciate the competitive pricing and availability of diverse brands, allowing for more flexibility in repairs and upgrades.

Ultimately, the choice between these two categories depends on individual needs, budget constraints, and the specific requirements of the equipment in question. Understanding the nuances of each can lead to better performance and satisfaction in the long run.

Resources for International 284 Enthusiasts

For those passionate about classic machinery, having access to reliable materials and information is crucial for maintenance and restoration projects. This section aims to guide enthusiasts in finding valuable resources that enhance their experience and knowledge about their beloved equipment.

Online Forums and Communities: Engaging with fellow enthusiasts can provide insights and support. Various online platforms host discussions, tips, and shared experiences. Joining these communities allows members to ask questions and exchange ideas.

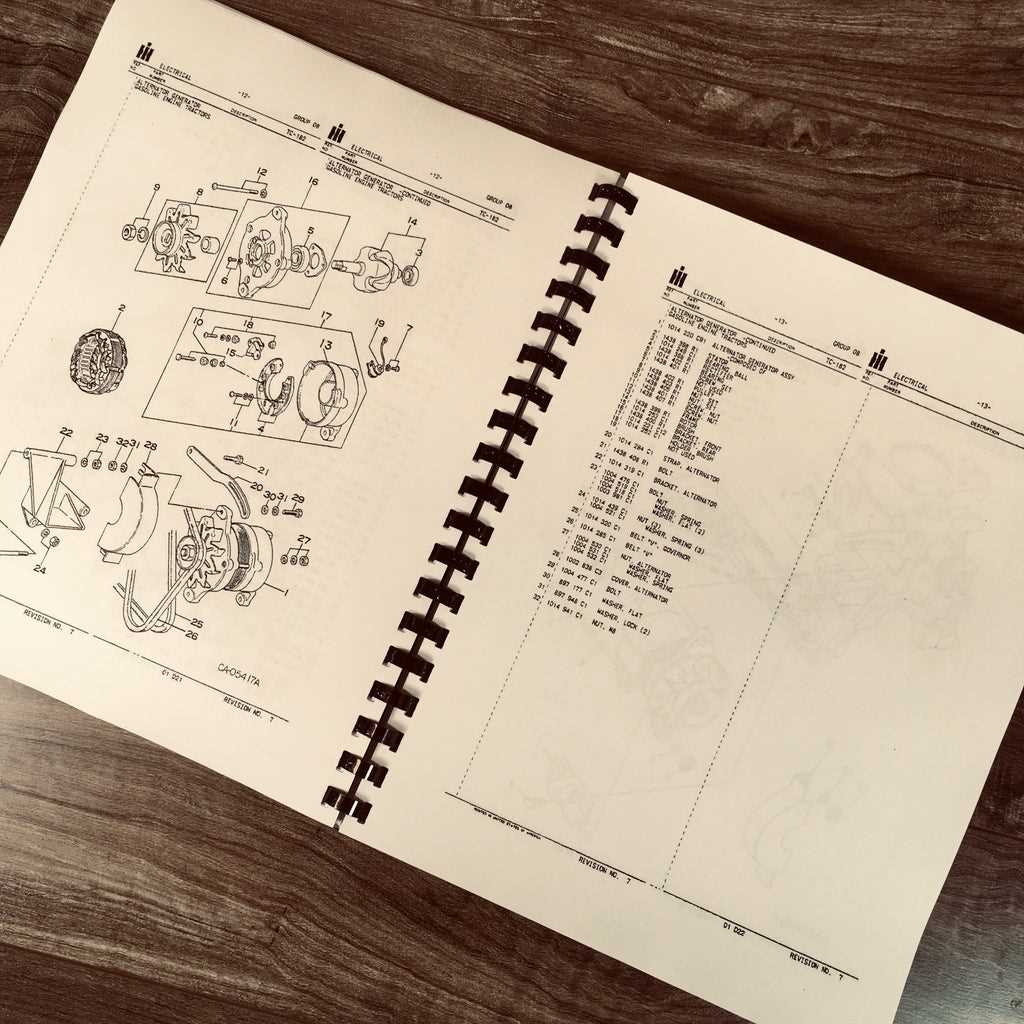

Repair Manuals and Guides: Detailed manuals offer essential information on maintenance procedures, troubleshooting, and repairs. These resources are often available in digital formats, making them easily accessible for quick reference.

Parts Suppliers: Finding quality components is vital for keeping machinery in optimal condition. Numerous suppliers specialize in aftermarket and original components, catering specifically to classic models. These suppliers often provide catalogs and diagrams that simplify the ordering process.

Local Clubs and Events: Participating in local organizations or attending events can foster a sense of community and shared passion. These gatherings often feature workshops, showcases, and opportunities to connect with experts in the field.

Restoration Projects: Documenting personal restoration journeys through blogs or social media can inspire others. Sharing successes and challenges not only creates a record but also builds a supportive network.

By utilizing these resources, enthusiasts can deepen their understanding and appreciation of their machinery, ensuring these classic pieces continue to thrive for years to come.

Expert Tips for Tractor Longevity

Maintaining the performance and durability of agricultural machinery is crucial for ensuring optimal productivity. By following a few essential practices, you can extend the lifespan of your equipment significantly. Proper care not only enhances functionality but also minimizes the risk of costly repairs.

Regular Maintenance: Establish a routine for checking and servicing your machine. This includes oil changes, filter replacements, and inspecting belts and hoses for wear. Consistent upkeep can prevent minor issues from escalating into major problems.

Fluid Checks: Ensure that all fluids, including engine oil, coolant, and hydraulic fluid, are at appropriate levels. Using the correct type of fluids will help maintain the efficiency of your engine and hydraulic systems.

Cleanliness: Keep your equipment clean, both externally and internally. Regularly remove dirt and debris to prevent corrosion and facilitate better heat dissipation. A clean machine is less prone to breakdowns.

Proper Storage: When not in use, store your machinery in a dry, sheltered area to protect it from the elements. If possible, cover it with a tarp or use a dedicated storage facility to reduce exposure to moisture and dust.

Fuel Quality: Use high-quality fuel to ensure smooth operation. Contaminated or low-grade fuel can lead to performance issues and engine damage over time. Always store fuel properly and be mindful of its expiration date.

Operator Training: Educate all operators on best practices for handling and operating the machinery. Proper training can prevent misuse and increase overall efficiency, leading to less wear and tear on components.

By implementing these strategies, you can ensure that your agricultural equipment remains reliable and efficient for years to come. Taking proactive steps today will pay off in the long run, keeping your operations running smoothly.