Parts Diagram for International 300 Utility

The efficient operation of agricultural machinery relies on a comprehensive understanding of its various components. These elements play a critical role in ensuring that equipment functions smoothly, facilitating seamless agricultural processes. Familiarity with these parts can enhance maintenance practices and improve overall performance, leading to increased productivity.

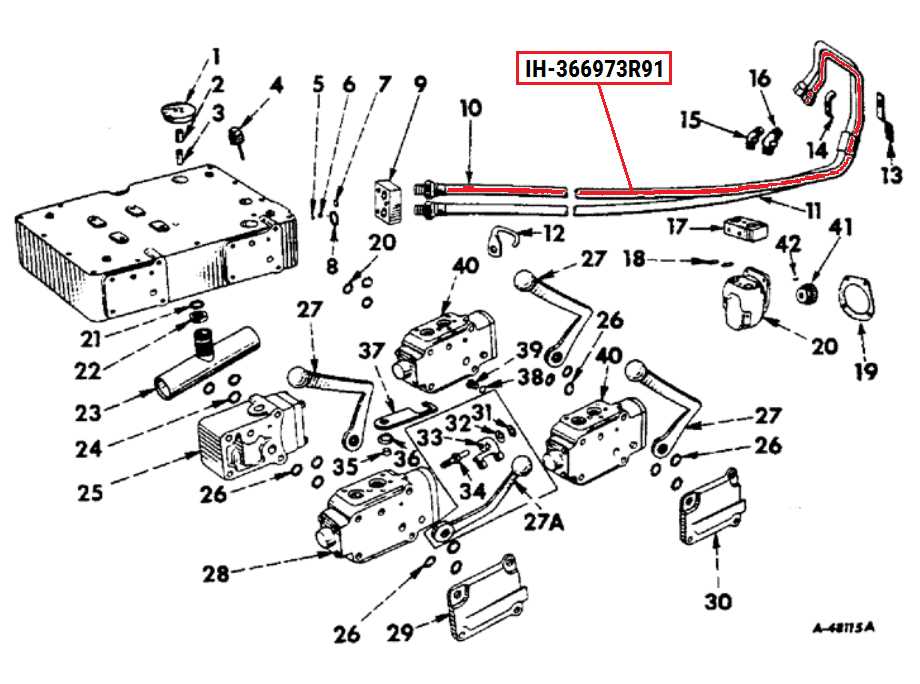

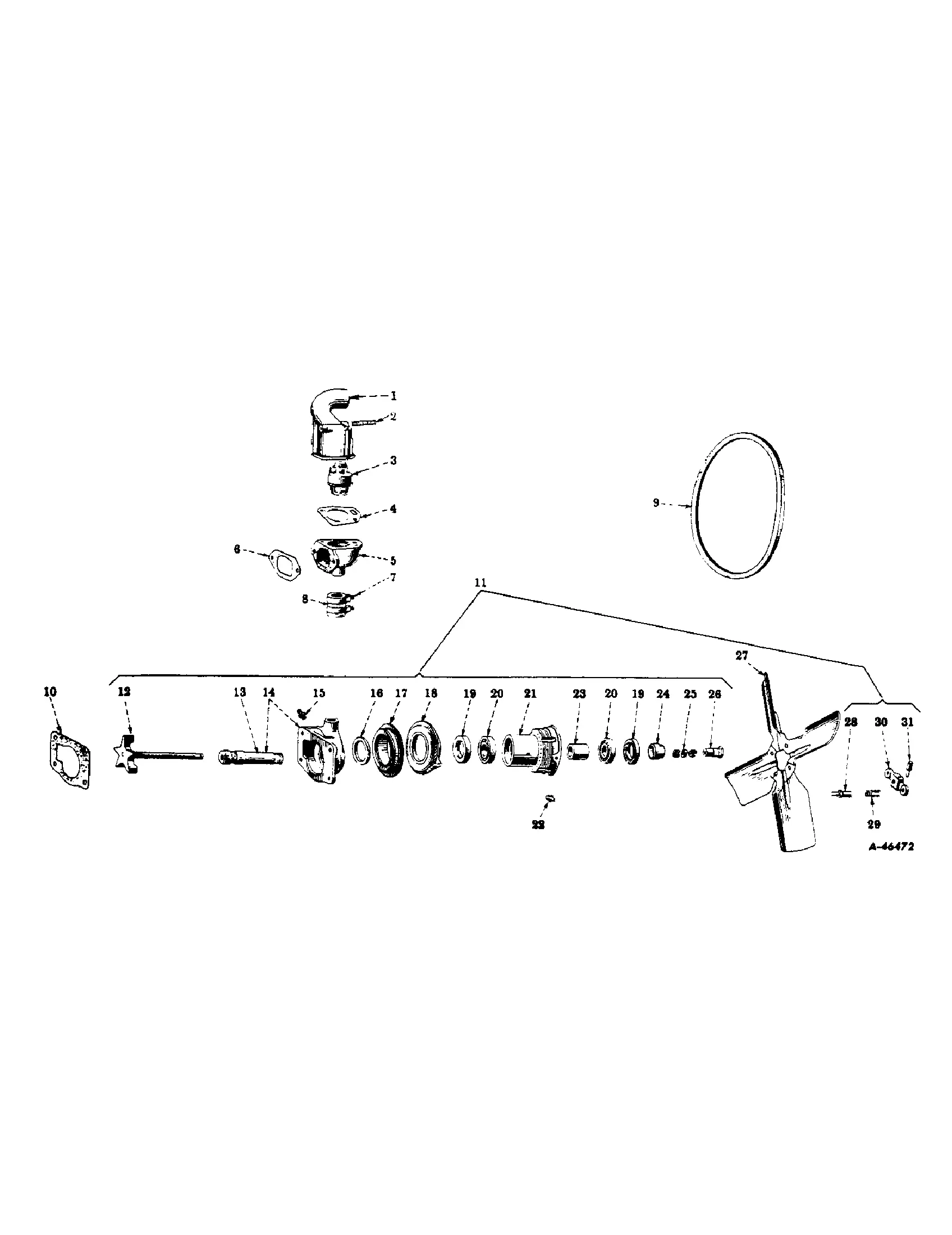

In this section, we will explore a visual representation that outlines the essential elements of a specific model of machinery. This representation serves as a valuable reference for operators and technicians alike, helping them identify each component’s function and significance. By grasping the relationship between different parts, users can make informed decisions regarding repairs and upgrades.

Having access to a clear illustration of these elements aids in troubleshooting and prevents costly downtime. Understanding how each component interacts within the larger system empowers users to optimize their equipment’s capabilities. Ultimately, this knowledge contributes to more effective management and operational efficiency in agricultural practices.

The utility model is designed to enhance operational efficiency and functionality in various applications. It encompasses several noteworthy attributes that contribute to its effectiveness and usability.

- Robust Design: The structure is engineered to withstand demanding conditions, ensuring longevity and reliability.

- Versatile Applications: It can be utilized across diverse fields, making it suitable for a wide range of tasks.

- Ease of Maintenance: The model is designed for straightforward upkeep, minimizing downtime and service costs.

- User-Friendly Interface: Controls and functions are intuitively arranged, facilitating ease of use for operators.

These characteristics make the model an indispensable choice for professionals seeking efficiency and reliability in their operations.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. They provide a clear overview, allowing users to grasp the relationships between various elements efficiently. This understanding is essential for maintenance, repair, and overall operation.

Enhanced Clarity and Communication

Having a visual guide simplifies complex information, making it accessible to both seasoned professionals and novices. This clarity promotes effective communication among team members and facilitates smoother workflow during repairs and replacements.

Facilitating Maintenance and Repairs

Illustrations serve as invaluable tools during maintenance tasks. They enable technicians to identify the correct components swiftly, ensuring that replacements are accurate and timely. By following these visual aids, individuals can reduce the likelihood of errors and enhance the overall reliability of the equipment.

Understanding the Component Layout

This section aims to provide a comprehensive overview of the arrangement of essential elements within the machinery. Grasping the configuration of these components is crucial for effective operation and maintenance. A well-structured layout can greatly enhance the functionality and efficiency of the equipment.

Importance of Each Element

Every part plays a significant role in the overall performance of the system. Recognizing the function of each component enables users to troubleshoot issues effectively and ensure smooth operation. By understanding the interaction between various elements, one can achieve optimal performance.

Visual Representation for Clarity

A visual representation of the layout helps clarify the relationships between different parts. This not only aids in identifying components quickly but also facilitates a better understanding of how the machine operates as a whole. Utilizing such illustrations can be beneficial during repairs and routine checks.

Common Parts and Their Functions

This section provides an overview of essential components found in various machinery and their respective roles in ensuring optimal performance. Understanding these elements is crucial for effective maintenance and troubleshooting.

- Engine: The heart of the machine, responsible for converting fuel into mechanical energy.

- Transmission: Facilitates the transfer of power from the engine to the wheels, allowing for movement.

- Hydraulic System: Utilizes fluid power to operate various attachments and functions, enhancing versatility.

- Cooling System: Regulates the engine temperature to prevent overheating and maintain efficiency.

- Electrical System: Powers all electronic components, including lights, ignition, and control systems.

Each component plays a vital role in the overall functionality of the machinery, contributing to its effectiveness and reliability.

- Chassis: The framework that supports the entire structure, ensuring stability and strength.

- Fuel System: Delivers fuel to the engine, ensuring it runs smoothly and efficiently.

- Brake System: Provides safety by enabling the operator to slow down or stop the machine when necessary.

- Steering Mechanism: Allows for directional control, facilitating maneuverability in various conditions.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These illustrations serve as a visual guide, helping individuals identify and locate various elements within a system. By mastering the art of interpreting these visuals, one can efficiently troubleshoot issues and ensure proper functionality.

Familiarize yourself with the symbols used in the illustration. Each icon typically represents a specific component, and knowing their meanings can significantly enhance your comprehension. Often, manufacturers include a legend or key to assist users in deciphering these symbols.

Pay attention to the layout of the representation. The arrangement of components often reflects their physical positioning within the machinery. By analyzing the spatial relationships, you can gain insight into how the different parts interact with each other, aiding in both diagnosis and repair.

Additionally, consider the accompanying annotations or notes, which may provide valuable information regarding assembly, disassembly, or troubleshooting procedures. These details can be crucial for anyone looking to undertake repairs or modifications.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By implementing effective maintenance practices, you can enhance performance and extend the lifespan of your machinery. Simple measures can prevent costly repairs and downtime, allowing you to maximize productivity.

First and foremost, routine inspections are crucial. Regularly checking for wear and tear can help identify potential issues before they escalate. Pay close attention to critical components, such as belts and filters, replacing them as needed to maintain optimal functionality.

Additionally, keeping your machinery clean is essential. Dirt and debris can hinder performance and cause unnecessary strain on parts. Establish a cleaning schedule to remove buildup, ensuring that all surfaces remain free of contaminants.

Lubrication is another key aspect of maintenance. Applying the appropriate lubricants to moving parts reduces friction and prevents overheating. Follow the manufacturer’s guidelines for lubricant types and application intervals to achieve the best results.

Lastly, storing equipment properly when not in use can significantly impact its longevity. Protecting your machinery from harsh weather conditions and moisture helps prevent rust and deterioration. Always ensure that equipment is covered and stored in a dry environment.

Finding Replacement Parts Easily

Locating suitable components for your machinery can often be a straightforward task if approached correctly. Understanding where to look and how to navigate available resources is key to ensuring a seamless repair or maintenance process.

Several avenues exist for sourcing the necessary items, ranging from online platforms to local suppliers. Each option provides unique benefits, making it essential to explore different methods to determine what works best for your situation.

| Source Type | Description | Advantages |

|---|---|---|

| Online Retailers | Websites dedicated to selling machine components. | Convenience and wide selection. |

| Local Dealers | Physical stores that specialize in machinery supplies. | Immediate availability and personal assistance. |

| Manufacturer Websites | Official sites that offer specific components for their models. | Guaranteed compatibility and quality assurance. |

| Online Marketplaces | Platforms where various sellers offer used and new items. | Competitive pricing and diverse options. |

By utilizing these resources effectively, you can ensure that your machinery remains operational without unnecessary delays. Always consider factors such as quality, price, and delivery options when making your selection.

Comparing Diagrams with Other Models

Analyzing schematics of various machinery can provide invaluable insights into their functionality and design principles. By contrasting these visual representations, one can uncover similarities and differences that may influence maintenance and repair practices. Understanding these nuances is crucial for both novice and experienced technicians.

When evaluating schematics from different models, it is essential to consider factors such as component layout and connection methods. These elements can vary significantly across models, impacting the ease of access and the complexity of repairs. For instance, a specific layout might allow for quicker troubleshooting, while another could complicate the process.

Moreover, recognizing trends in design across various schematics can highlight advancements in technology and engineering. This comparative analysis not only aids in selecting the most efficient model for specific tasks but also enhances overall operational knowledge.

Common Issues and Troubleshooting

This section addresses frequent challenges that operators may encounter with their machinery, along with effective solutions to resolve these issues. Understanding these common problems can significantly enhance performance and prolong the lifespan of the equipment.

Here are some typical concerns:

- Engine Starting Problems: Difficulty in starting may arise from various factors.

- Fluid Leaks: Unwanted leaks can lead to efficiency losses and safety hazards.

- Poor Performance: Reduced power output might indicate underlying mechanical issues.

To troubleshoot these issues, consider the following steps:

- Check the fuel supply and ensure there are no blockages in the fuel line.

- Inspect all hoses and seals for signs of wear or damage that could lead to leaks.

- Examine the air filter for clogs, which can restrict airflow and affect performance.

- Verify the battery connections and charge to ensure proper starting power.

By systematically addressing these concerns, operators can maintain optimal functionality and reliability.

Resources for Technical Support

Accessing the right resources is crucial for effective technical assistance and maintenance of machinery. A variety of options are available to ensure users can find the information they need to address issues and optimize performance.

| Resource Type | Description | Link/Contact |

|---|---|---|

| Online Manuals | Comprehensive guides providing instructions and troubleshooting tips. | Visit Manuals |

| Support Forums | A platform for users to share experiences and solutions. | Join Forum |

| Customer Service | Direct assistance from qualified professionals for personalized help. | Email: [email protected] |

| Parts Suppliers | Information on where to purchase necessary components. | Find Suppliers |

Owner Experiences and Reviews

This section focuses on the insights and feedback from individuals who have utilized a specific model of agricultural machinery. The reflections shared here provide valuable perspectives on performance, reliability, and overall satisfaction.

Many users appreciate the robust construction and ease of operation, noting how these features enhance productivity in various tasks. However, some have encountered challenges that highlight the importance of regular maintenance and understanding the machine’s capabilities.

| Aspect | Feedback |

|---|---|

| Performance | Reliable and efficient for multiple tasks. |

| Comfort | Operator-friendly design with good visibility. |

| Maintenance | Regular upkeep is crucial for longevity. |

| Value | Offers great performance for its price range. |

| Customer Support | Responsive service for parts and inquiries. |

Future Upgrades and Modifications

The prospect of enhancing and altering machinery can lead to significant improvements in performance and efficiency. Whether for personal use or commercial applications, these modifications can adapt equipment to meet evolving needs. This section explores potential advancements that could be integrated into existing systems, focusing on boosting functionality and extending the lifespan of the machinery.

| Upgrade/Modification | Description | Benefits |

|---|---|---|

| Engine Enhancements | Upgrading components for improved power output. | Increased efficiency and performance. |

| Hydraulic System Improvements | Implementing more advanced hydraulic systems for better control. | Enhanced responsiveness and precision. |

| Transmission Upgrades | Installing a modern transmission for smoother operation. | Improved gear shifting and overall drive quality. |

| Cabin Comfort Modifications | Adding ergonomic seats and modern controls for better user experience. | Increased comfort and reduced operator fatigue. |