Comprehensive Guide to International 37 Disc Harrow Parts Diagram

In the realm of modern farming, the efficiency and productivity of machinery play a pivotal role in successful crop management. A thorough comprehension of the various elements that constitute these implements is essential for both maintenance and optimal performance. Each component serves a specific function, contributing to the overall effectiveness of the equipment.

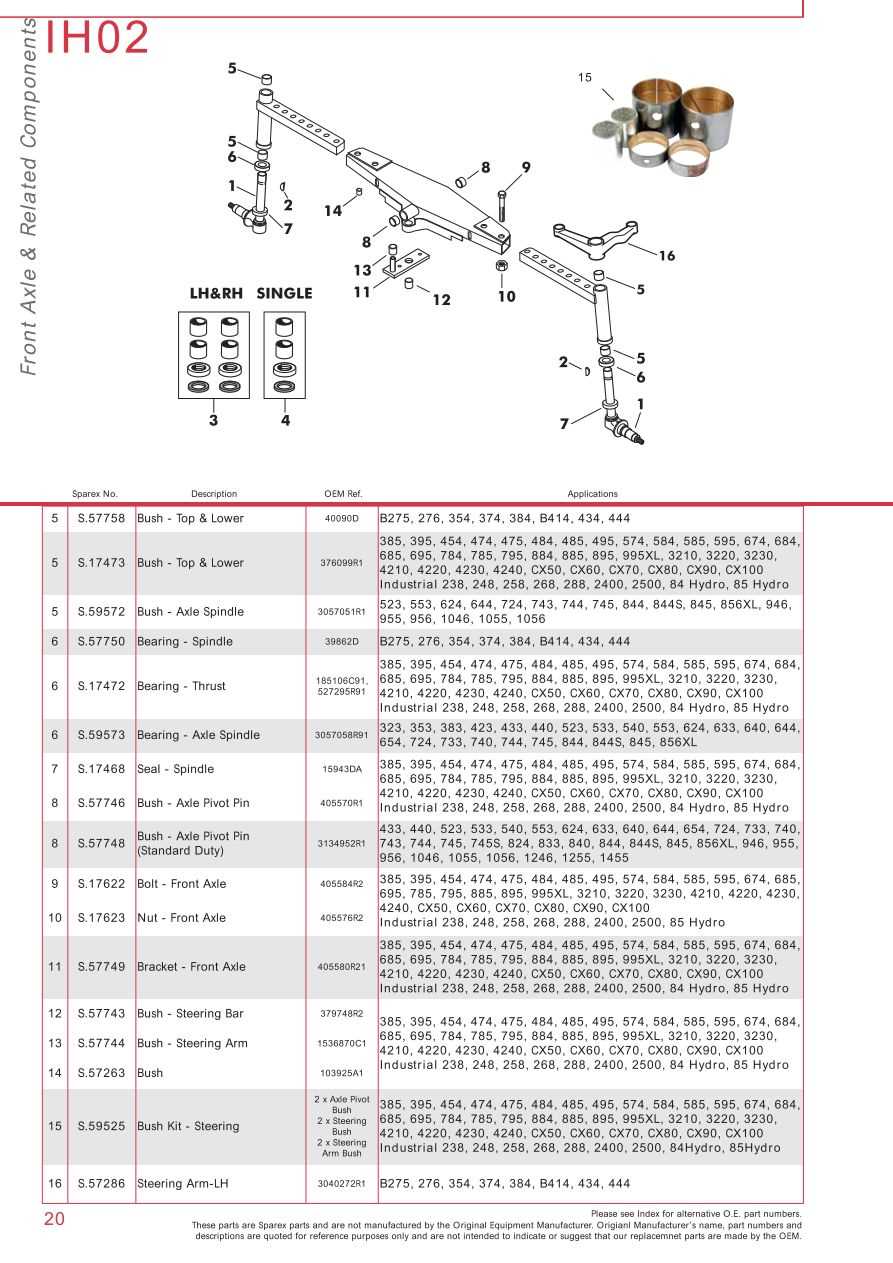

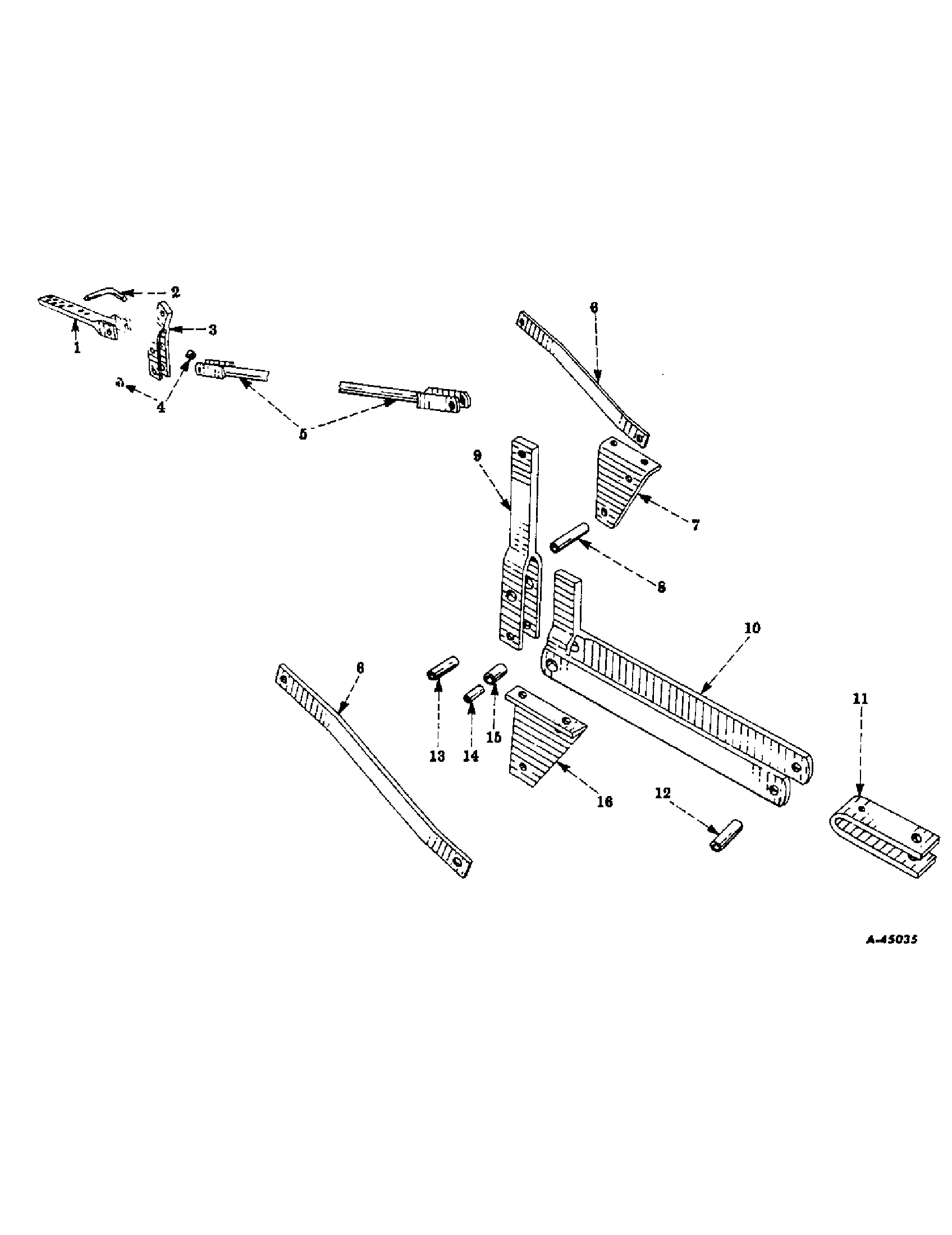

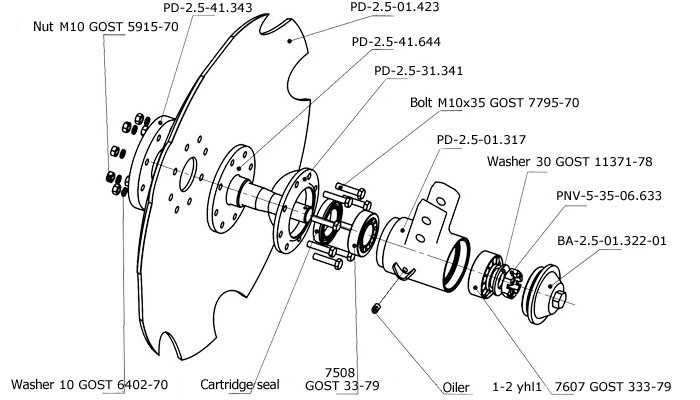

Visual representations can greatly enhance our understanding of these intricate systems. By examining detailed layouts, operators can easily identify crucial features and mechanisms. This not only aids in troubleshooting issues but also facilitates a smoother operation during various farming activities.

As we delve deeper into the intricacies of these agricultural tools, it becomes evident that knowledge of their construction is indispensable. Familiarity with individual components ensures that users can perform necessary adjustments and repairs, ultimately leading to a more efficient farming process and better yields.

Understanding Disc Harrows

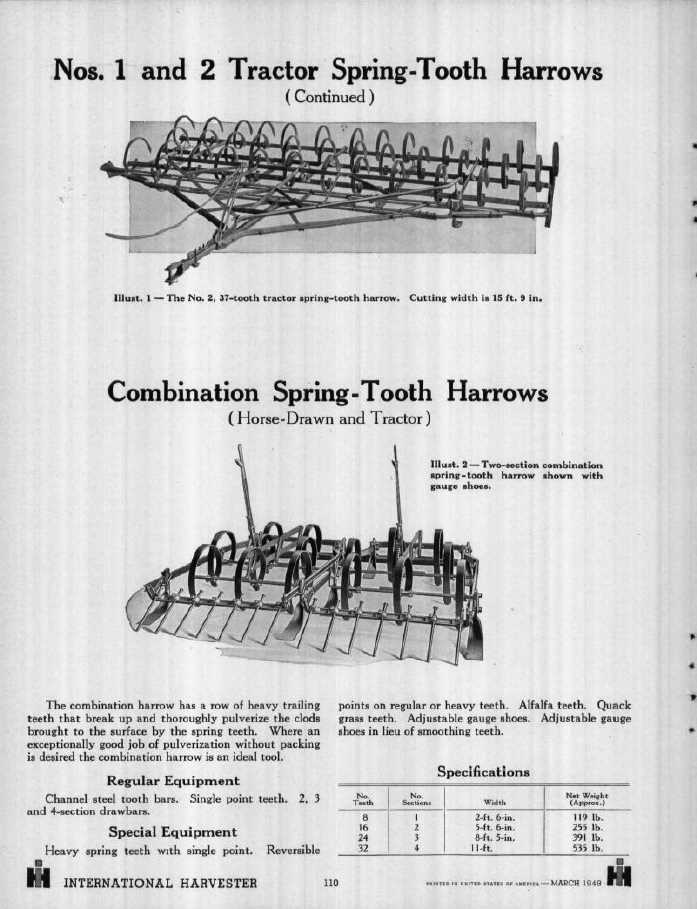

This section explores essential tools used in agricultural practices, focusing on their design, functionality, and the advantages they offer for soil preparation and cultivation.

These implements play a crucial role in land management. They help achieve optimal soil conditions through various mechanisms:

- Breaking up compacted soil

- Incorporating organic matter

- Improving drainage and aeration

Farmers and agricultural professionals can benefit from understanding the components of these tools:

- Frames and mounting systems

- Cutting blades and their arrangement

- Adjustability features for different soil types

By grasping these concepts, users can make informed decisions about maintenance and optimal usage for enhanced agricultural productivity.

Overview of International 37 Model

This section provides a comprehensive look at a specific agricultural implement, highlighting its design, functionality, and applications in modern farming. Understanding this model’s unique features and specifications can help operators maximize its efficiency and performance in various soil conditions.

Design Features

The implement is crafted with robust materials, ensuring durability and longevity. Its structure is optimized for ease of use, allowing for smooth operation across diverse terrains. Key components work in harmony to achieve the ultimate soil preparation.

Applications in Agriculture

This machinery is widely utilized in preparing fields for planting, effectively breaking up soil and incorporating residues. Its versatility makes it suitable for different crops and soil types, enhancing overall agricultural productivity.

Essential Components of Disc Harrows

Understanding the key elements of soil tillage equipment is crucial for achieving optimal agricultural results. These tools are designed to prepare the land by breaking up and turning over soil, ensuring better aeration and nutrient distribution. Each component plays a vital role in enhancing performance and efficiency in various field conditions.

Key Elements

The primary elements include cutting blades, frames, and wheels. Blades are engineered for efficient soil penetration and residue incorporation. The frame provides structural integrity, while wheels facilitate mobility and adjustability across different terrains.

Additional Features

Many units also incorporate adjustable depth controls and unique attachment options. These features allow operators to tailor the equipment to specific soil types and agricultural practices, ultimately enhancing productivity.

Functionality of Each Part Explained

Understanding the roles of various components within agricultural equipment is essential for effective operation and maintenance. Each element contributes to the overall efficiency and effectiveness of soil preparation, ensuring optimal conditions for planting and growth. Below, we delve into the specific functions of these integral parts.

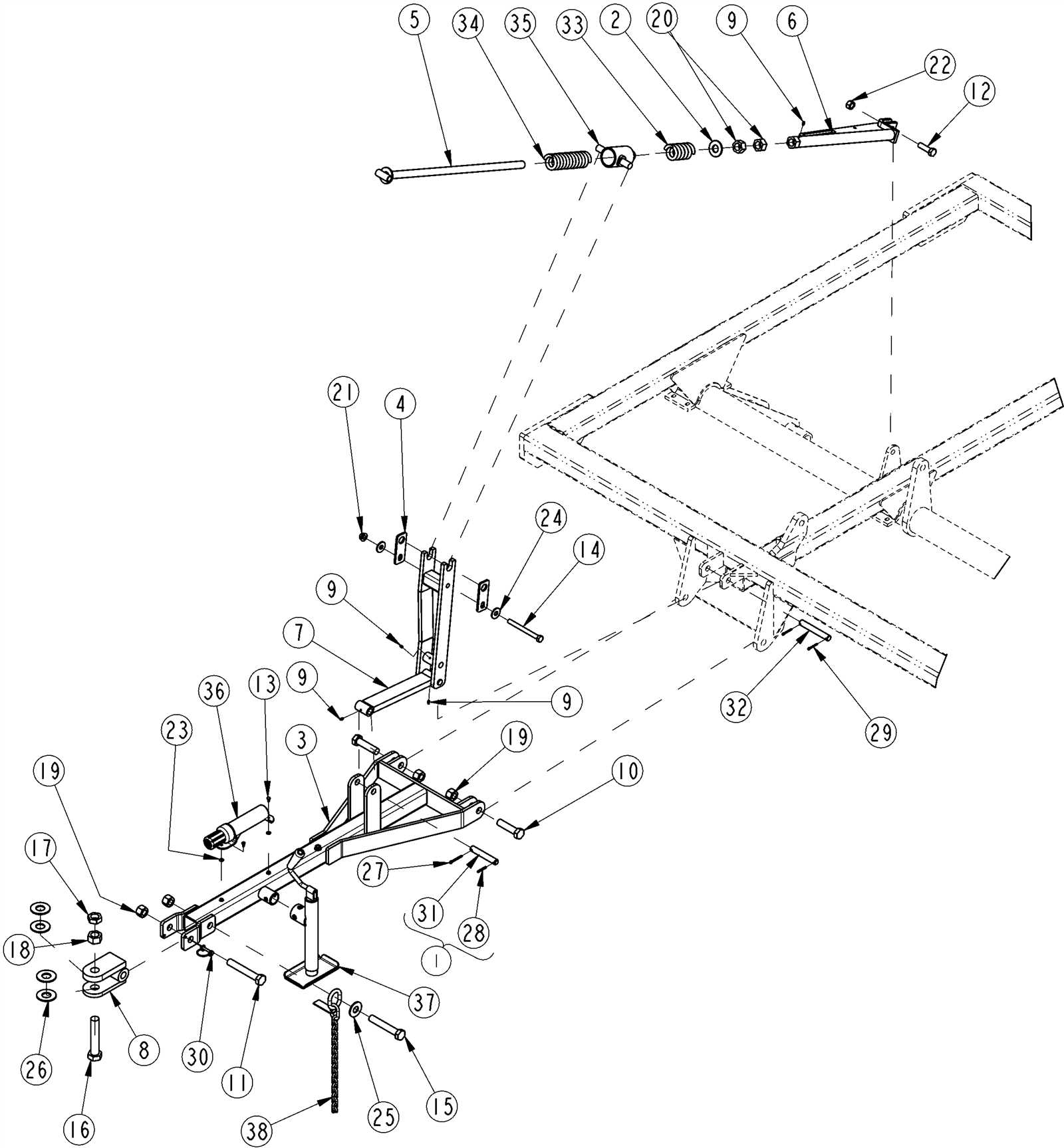

Frame: The backbone of the machinery, the frame provides structural integrity and stability during operation. It supports all other components, ensuring they work in harmony while withstanding the rigors of fieldwork.

Blades: These cutting elements are designed to slice through the soil, breaking up clumps and aerating the ground. Their design and angle are crucial for achieving the desired soil texture, promoting healthy root development.

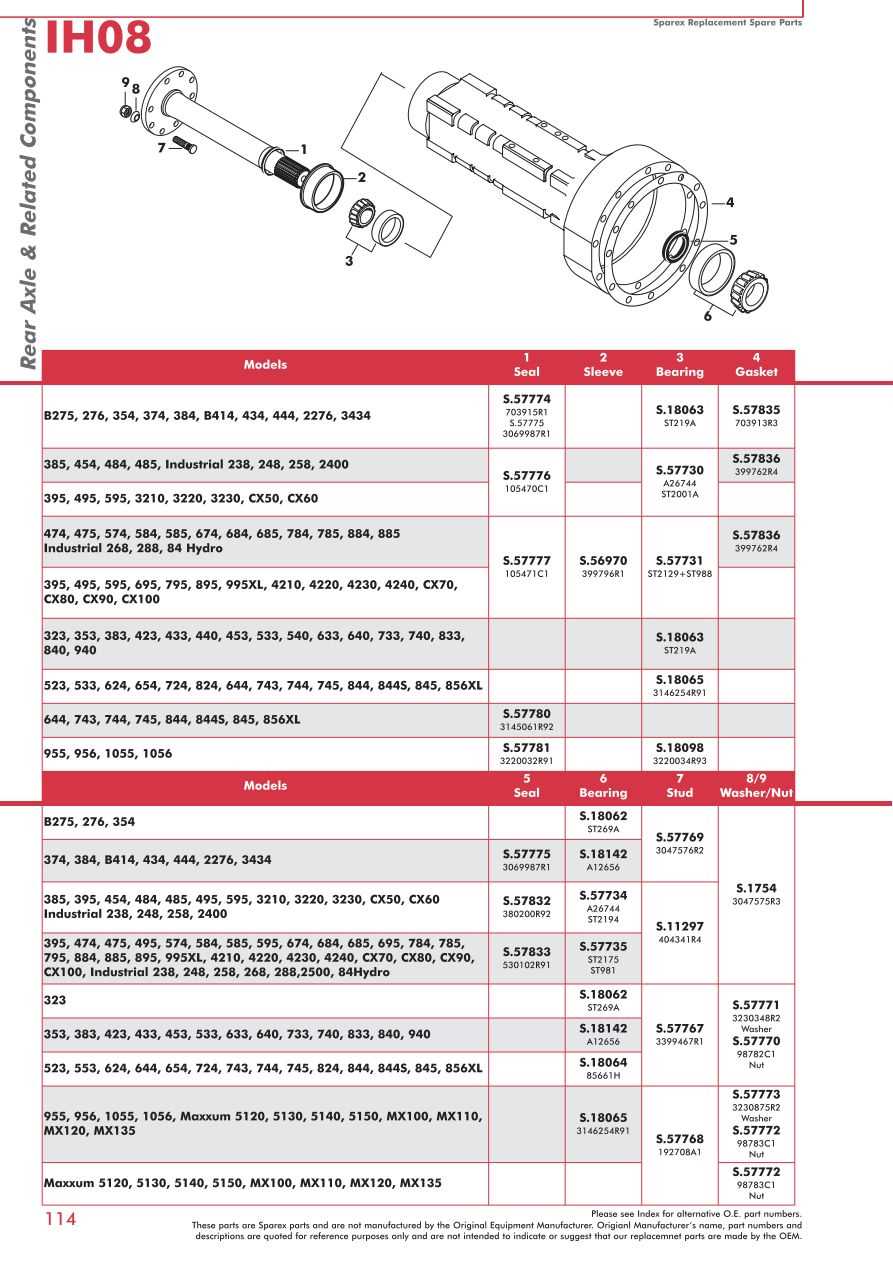

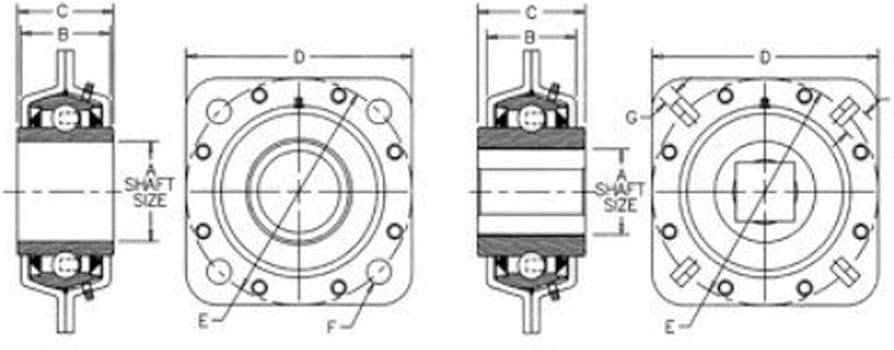

Bearings: Vital for smooth operation, bearings reduce friction between moving parts. They ensure that the blades rotate freely and efficiently, minimizing wear and extending the lifespan of the equipment.

Depth Control Wheels: These wheels allow operators to adjust the working depth of the blades. Proper depth control is essential for achieving uniform soil cultivation, impacting moisture retention and seed placement.

Hitch: The hitch connects the equipment to the towing vehicle, facilitating easy maneuverability. A robust hitch ensures a secure attachment, allowing for safe transport and operation across various terrains.

Scrapers: Positioned near the blades, scrapers prevent soil buildup on the cutting edges. By maintaining blade efficiency, they help ensure consistent soil engagement and optimal performance throughout the operation.

Adjustable Links: These components provide flexibility in configuring the machine for different tasks. They enable operators to adapt the setup according to specific soil conditions and crop requirements, enhancing overall versatility.

In summary, a comprehensive understanding of each component’s functionality not only aids in effective usage but also supports timely maintenance, ultimately leading to improved agricultural outcomes.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the extended lifespan of agricultural machinery. Proper care not only enhances performance but also minimizes the risk of unexpected failures that can disrupt operations.

Consistent inspections and timely repairs play a vital role in maintaining efficiency. Neglecting these practices can lead to wear and tear, ultimately resulting in costly downtime and repairs.

Additionally, well-maintained equipment often retains its value better over time, making it a smart investment for any agricultural business. A proactive approach to maintenance can save time, resources, and enhance productivity in the long run.

Common Issues and Troubleshooting Tips

When operating agricultural machinery, several challenges may arise that can impact performance. Identifying these issues early and employing effective solutions can enhance efficiency and longevity of the equipment.

Frequent Problems

Common problems include uneven tilling, excessive wear on components, and mechanical failures. Understanding the root causes can facilitate timely interventions.

Troubleshooting Steps

| Issue | Possible Cause | Solution |

|---|---|---|

| Uneven Tilling | Improper adjustment | Check and calibrate depth settings |

| Excessive Wear | Poor quality materials | Replace with high-quality components |

| Mechanical Failure | Lack of maintenance | Establish a regular servicing schedule |

How to Replace Worn Parts

Maintaining agricultural equipment is essential for optimal performance and longevity. When components begin to show signs of wear, timely replacement is crucial to prevent further damage and ensure efficiency. This guide provides practical steps to identify and substitute these elements effectively.

First, assess the condition of the equipment. Look for signs such as cracks, excessive rust, or unusual noises during operation. These indicators can help pinpoint which items need attention.

Next, gather the necessary tools and replacement items. Having the right equipment on hand simplifies the process. Refer to the user manual or manufacturer’s guidelines to confirm specifications for replacements.

When ready, start the replacement process by disconnecting power sources and securing the equipment. Carefully remove the worn components, taking note of their arrangement for proper installation of the new ones.

Install the new elements according to the guidelines, ensuring a snug fit. Double-check all connections and fasteners before reassembling and testing the machinery.

Regular maintenance and timely replacement of worn items will enhance performance and prolong the life of your equipment, making these tasks an essential part of responsible upkeep.

Benefits of Using Genuine Parts

Opting for authentic components in agricultural machinery ensures optimal performance and longevity. These original elements are specifically designed to fit and function seamlessly with the equipment, providing numerous advantages over alternatives.

Quality Assurance

Genuine components undergo rigorous testing and quality control processes, guaranteeing their reliability. Here are some key points about their quality:

- Manufactured to exact specifications

- Durable materials that withstand heavy use

- Consistent performance under various conditions

Enhanced Efficiency

Using authentic components can significantly improve the efficiency of your machinery. Consider the following benefits:

- Better compatibility with existing systems

- Reduced risk of malfunctions or breakdowns

- Improved fuel efficiency due to optimized design

Investing in genuine components is a smart choice for maintaining equipment performance and reliability over time.

Comparing Different Disc Harrow Models

When evaluating various agricultural implements designed for soil cultivation, it’s crucial to analyze the unique features and functionalities of each model. This comparison helps farmers make informed decisions based on their specific needs and field conditions.

| Model | Weight | Width | Blade Size | Adjustability |

|---|---|---|---|---|

| Model A | 1500 lbs | 8 ft | 22 in | Manual |

| Model B | 1800 lbs | 10 ft | 20 in | Hydraulic |

| Model C | 2000 lbs | 12 ft | 24 in | Manual |

Each model offers distinct advantages, and understanding these differences allows for optimal performance in diverse agricultural environments.

How to Adjust Disc Harrow Settings

Properly fine-tuning the implement’s settings is crucial for achieving optimal soil preparation and crop yield. Adjustments can significantly affect the tool’s effectiveness, influencing factors such as depth of penetration and soil mixing. Understanding the mechanics and settings will empower operators to enhance performance and adapt to varying soil conditions.

Step 1: Begin by assessing the working depth required for your specific soil type. Use the adjustment mechanism to set the desired depth, ensuring even penetration across the field.

Step 2: Next, evaluate the angle of the blades. A steeper angle can improve soil incorporation, while a shallower angle is suitable for lighter tasks. Adjust accordingly to meet the operational goals.

Step 3: Finally, check the spacing between the blades. Tighter spacing can provide more thorough mixing, whereas wider spacing is effective for less intensive soil engagement. Make adjustments as needed based on the conditions you are working with.

By regularly reviewing and modifying these settings, you can ensure the implement operates at its ultimate efficiency, promoting healthier soil and stronger crops.

Safety Precautions When Operating Equipment

Ensuring safety during the use of agricultural machinery is paramount. Proper precautions can significantly reduce the risk of accidents and injuries, promoting a secure working environment. Familiarity with safety protocols and equipment functionality is essential for all operators.

Always wear appropriate personal protective equipment (PPE). This includes helmets, gloves, goggles, and steel-toed boots, which serve as a barrier against potential hazards. Being properly dressed minimizes the risk of injury from moving parts or debris.

Conduct a pre-operation inspection of the machinery. Check for any visible damage, loose components, or leaks. Ensuring that all safety features are operational can prevent malfunctions during use. Regular maintenance is also crucial to keep equipment in optimal condition.

Be aware of your surroundings. Before starting the machinery, ensure the area is clear of obstacles and bystanders. This awareness helps in avoiding collisions and ensures that everyone in the vicinity is safe from harm.

Follow operational guidelines provided by the manufacturer. Understanding the machinery’s controls and functions is essential. Always refer to the user manual for specific instructions and recommendations for safe use.

Maintain a safe distance from other individuals while operating equipment. Establish a clear boundary to prevent accidents, especially in crowded or confined spaces. Communication with nearby personnel is key to ensure everyone is aware of potential hazards.

Never bypass safety mechanisms or operate the machinery under the influence of drugs or alcohol. Such actions can lead to catastrophic accidents. It’s vital to remain alert and focused while handling equipment to ensure safe operation.

Implementing these safety measures can lead to a more secure working environment and reduce the likelihood of accidents. Always prioritize safety when engaging with heavy machinery.

Harvesting Efficiency and Performance Insights

Optimizing agricultural practices is essential for enhancing productivity and ensuring sustainable yields. This section explores the pivotal elements that contribute to improved operational effectiveness in the field, focusing on machinery performance and its impact on overall harvesting processes.

Key Factors Influencing Efficiency

Several factors significantly influence harvesting effectiveness, including equipment calibration, soil conditions, and crop characteristics. Proper adjustment of machinery ensures that it operates at its ultimate potential, reducing waste and maximizing output. Moreover, understanding soil types and moisture levels can lead to more strategic decision-making, ultimately enhancing productivity.

Performance Metrics to Consider

Monitoring performance metrics such as throughput, fuel consumption, and downtime is crucial for evaluating operational success. By analyzing these indicators, farmers can delve into areas needing improvement, ensuring that equipment functions optimally throughout the harvesting season. Emphasizing these metrics fosters a more efficient approach to agricultural practices, ultimately leading to better yields and profitability.

Where to Find Replacement Parts Online

In the quest for maintaining agricultural machinery, sourcing components can often be a daunting task. Fortunately, the internet offers a wealth of resources that make locating and purchasing these essentials more manageable. With a few clicks, users can access numerous platforms dedicated to supplying machinery components, ensuring that operations remain smooth and efficient.

Here are some effective strategies for finding the necessary components online:

| Source Type | Description |

|---|---|

| Manufacturer Websites | Visiting the official sites of equipment manufacturers often yields original components tailored for specific machinery models. |

| Online Retailers | Large e-commerce platforms offer a broad selection of components, often at competitive prices, along with user reviews and ratings. |

| Specialized Suppliers | Many companies focus exclusively on agricultural equipment and can provide expert advice along with quality parts. |

| Marketplace Websites | Platforms where individuals can buy and sell items may have listings for used or surplus components at lower costs. |

| Forums and Communities | Joining online groups related to agricultural machinery can lead to recommendations and sometimes direct sales from other users. |

By utilizing these sources, operators can effectively find the necessary components to keep their equipment running efficiently, minimizing downtime and ensuring productivity.