Comprehensive Guide to the International 574 Parts Diagram

In the realm of heavy machinery, a clear understanding of the individual components is essential for efficient operation and maintenance. Each element plays a pivotal role in the overall functionality of the equipment, contributing to its performance and reliability. A comprehensive overview of these parts can empower operators and technicians to address issues swiftly and effectively.

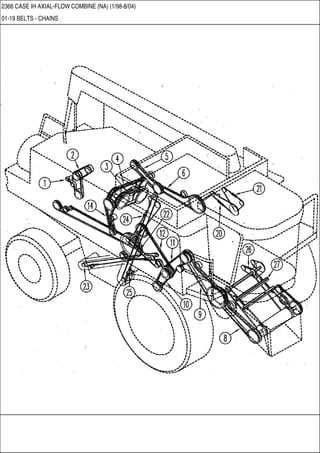

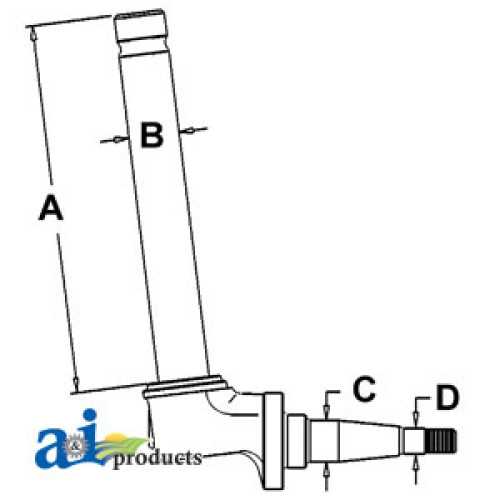

Visual aids serve as invaluable resources in this context, providing clarity and enhancing comprehension. By illustrating the various components and their interconnections, such resources facilitate better troubleshooting and repair processes. This visual representation can demystify the intricate workings of machinery, making it more accessible to those who work with it.

Moreover, grasping the layout of each element can aid in identifying potential wear points and maintenance needs. An informed approach not only extends the lifespan of the equipment but also ensures safety during operation. As we delve deeper into the specifics, we will explore the significance of understanding these crucial aspects for optimal machinery performance.

Overview of International 574 Parts

This section provides a comprehensive look at the components that make up a certain agricultural machine, highlighting their significance and interconnectivity. Understanding each element is crucial for maintenance and efficient operation, ensuring optimal performance in the field.

Key Components

Essential elements include the engine, transmission, and hydraulic systems. Each plays a vital role in the functionality of the machinery, contributing to overall efficiency and productivity.

Maintenance Tips

Regular inspections and timely replacements of worn components can prolong the lifespan of the equipment. Familiarity with the different parts enhances the ability to diagnose issues effectively.

| Component | Description |

|---|---|

| Engine | Provides power to the machine. |

| Transmission | Transfers power to the wheels. |

| Hydraulics | Controls lifting and lowering functions. |

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding in various fields. Clear and reliable illustrations facilitate seamless collaboration, ensuring that all stakeholders are on the same page regarding components and their functionalities.

Moreover, detailed schematics enhance troubleshooting processes, allowing technicians to identify issues swiftly and implement solutions efficiently. Without these accurate visuals, errors can occur, leading to increased downtime and costs.

In addition, high-quality illustrations serve as valuable training resources, enabling newcomers to grasp complex systems more quickly. Ultimately, the importance of well-crafted visuals cannot be overstated, as they form the foundation of effective operation and maintenance.

Common Issues with International 574

This section highlights frequent problems encountered with a specific agricultural machine, focusing on maintenance and repair concerns that operators often face. Understanding these issues can help in proactive management and enhance the machine’s performance.

| Issue | Description | Possible Solutions |

|---|---|---|

| Overheating | Engine may run hot due to coolant leaks or blockages. | Check coolant levels, inspect hoses, and clean radiators. |

| Poor Starting | Difficulty starting the machine, often linked to battery or fuel issues. | Test battery voltage and check fuel filters. |

| Hydraulic Problems | Reduced lift capacity or unresponsive hydraulics. | Inspect fluid levels and look for leaks in hoses. |

| Transmission Slippage | Difficulty in shifting gears, indicating wear or low fluid. | Check transmission fluid levels and inspect linkage. |

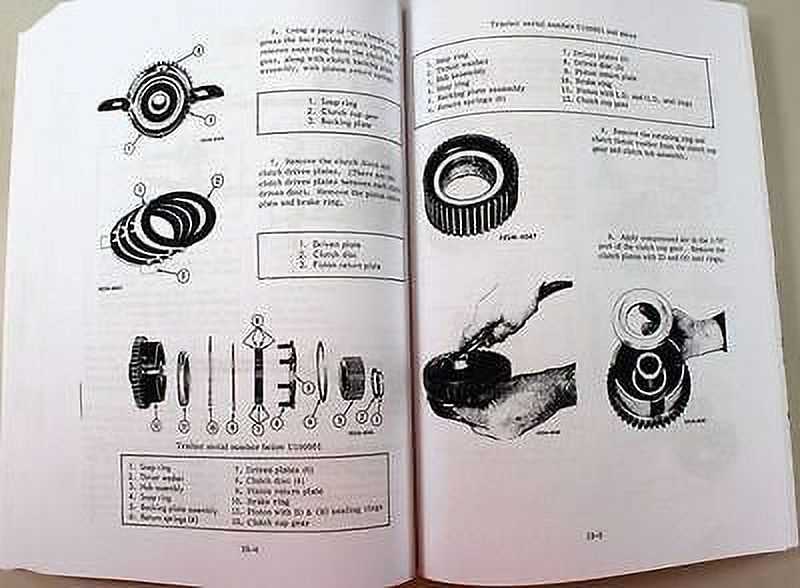

Parts Identification Techniques

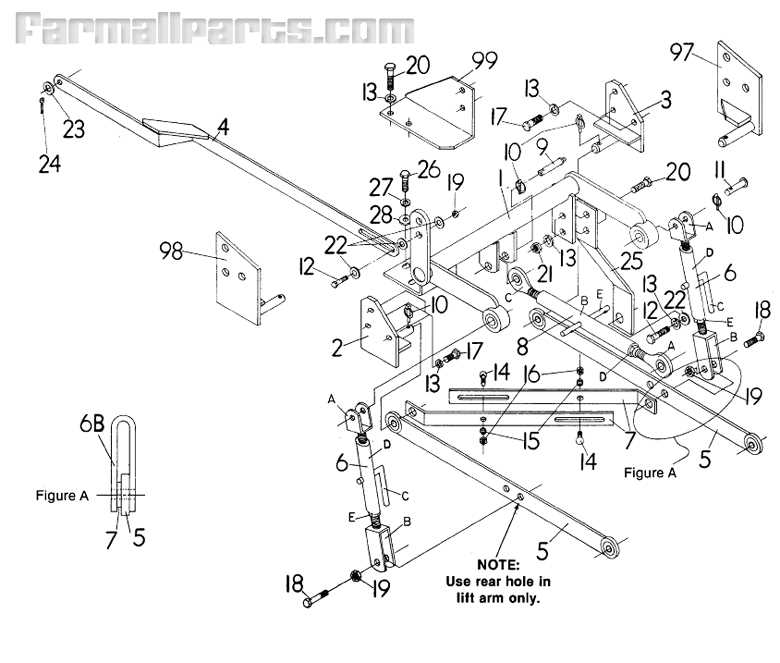

Effective identification of components is crucial for maintenance and repair tasks. Utilizing systematic approaches can significantly enhance the efficiency of this process, ensuring that each element is accurately recognized and handled. Here are several methods to aid in the identification of essential components:

- Visual Inspection: Examine the item closely to identify any markings, labels, or distinctive features.

- Reference Manuals: Consult manufacturer manuals or technical documents that provide detailed descriptions and specifications.

- Online Resources: Utilize websites and forums that specialize in equipment to access diagrams and user-contributed information.

- Cross-Referencing: Compare the item with known counterparts or catalog listings to verify its identity.

- Measurement Tools: Use calipers or micrometers to measure dimensions, which can help match the component to specific models.

By employing these techniques, individuals can streamline their workflow and ensure that all necessary elements are correctly identified and sourced.

Where to Find Quality Diagrams

Finding reliable illustrations for machinery components can significantly enhance your understanding and maintenance efforts. Accessing high-quality visuals is crucial for both enthusiasts and professionals who seek accurate information and clarity in their projects.

One of the best resources is manufacturer websites, where official documents often include comprehensive visuals and specifications. These sites typically provide access to detailed manuals and charts that can aid in identifying and troubleshooting various elements.

Another excellent option is online forums and communities. Enthusiasts and experts frequently share their knowledge, including valuable links to resources that contain intricate visuals. Engaging with these communities can provide insights that are not readily available elsewhere.

Additionally, specialized online retailers often offer manuals and reference materials for sale or download. These platforms usually focus on specific brands or types of equipment, ensuring that the illustrations are tailored to your needs.

Lastly, consider library resources or educational institutions. Many libraries maintain collections of technical documents and can offer access to rare or hard-to-find resources that may not be available online.

Understanding Engine Components

Engines are intricate systems composed of various elements that work in harmony to convert fuel into mechanical energy. Each component plays a critical role in the overall functionality, contributing to efficiency, power output, and longevity.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and is where fuel combustion occurs. |

| Piston | Moves up and down, converting combustion energy into mechanical force. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Camshaft | Controls the opening and closing of valves, regulating airflow. |

| Fuel Injector | Delivers fuel into the combustion chamber for ignition. |

| Exhaust Manifold | Channels exhaust gases away from the engine after combustion. |

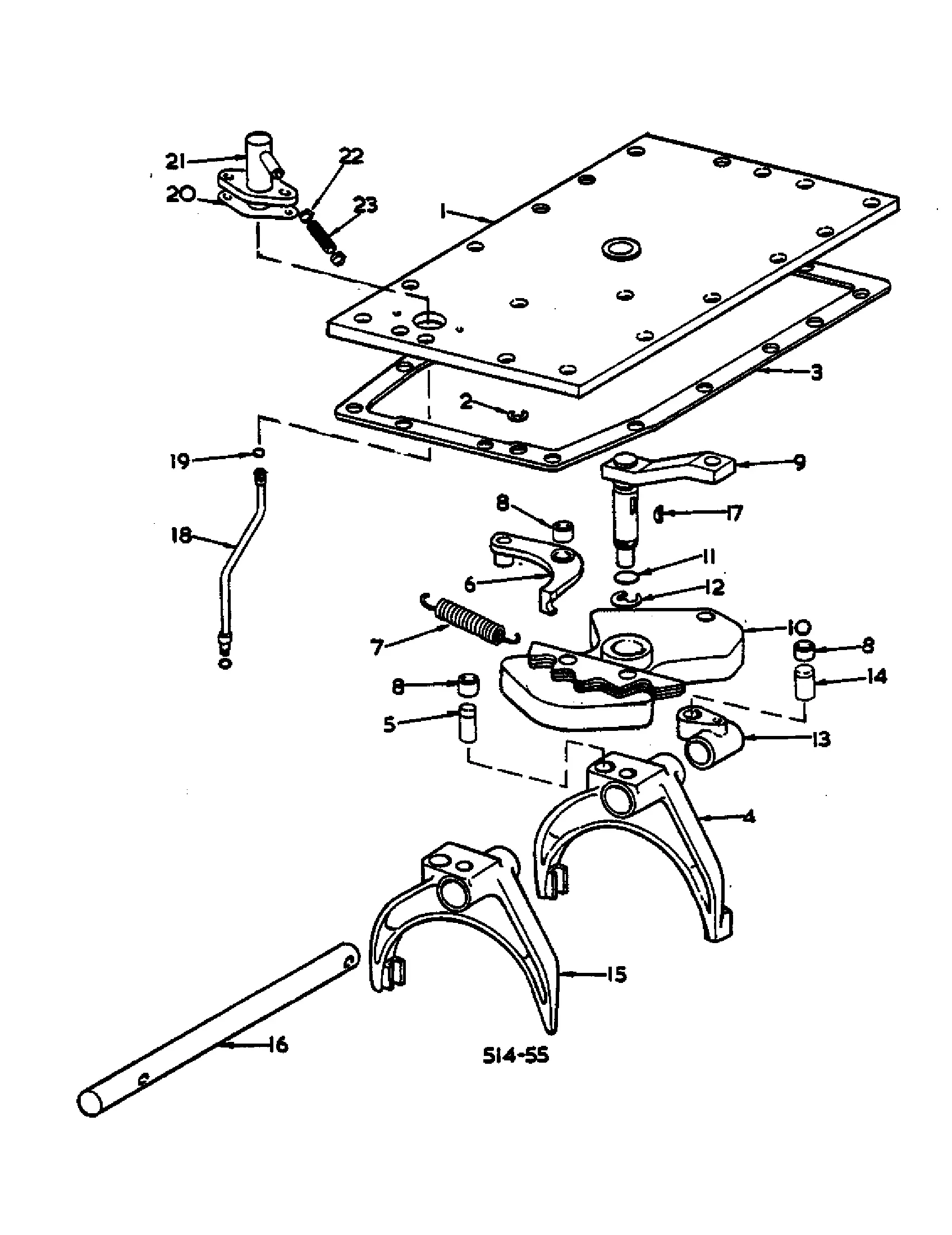

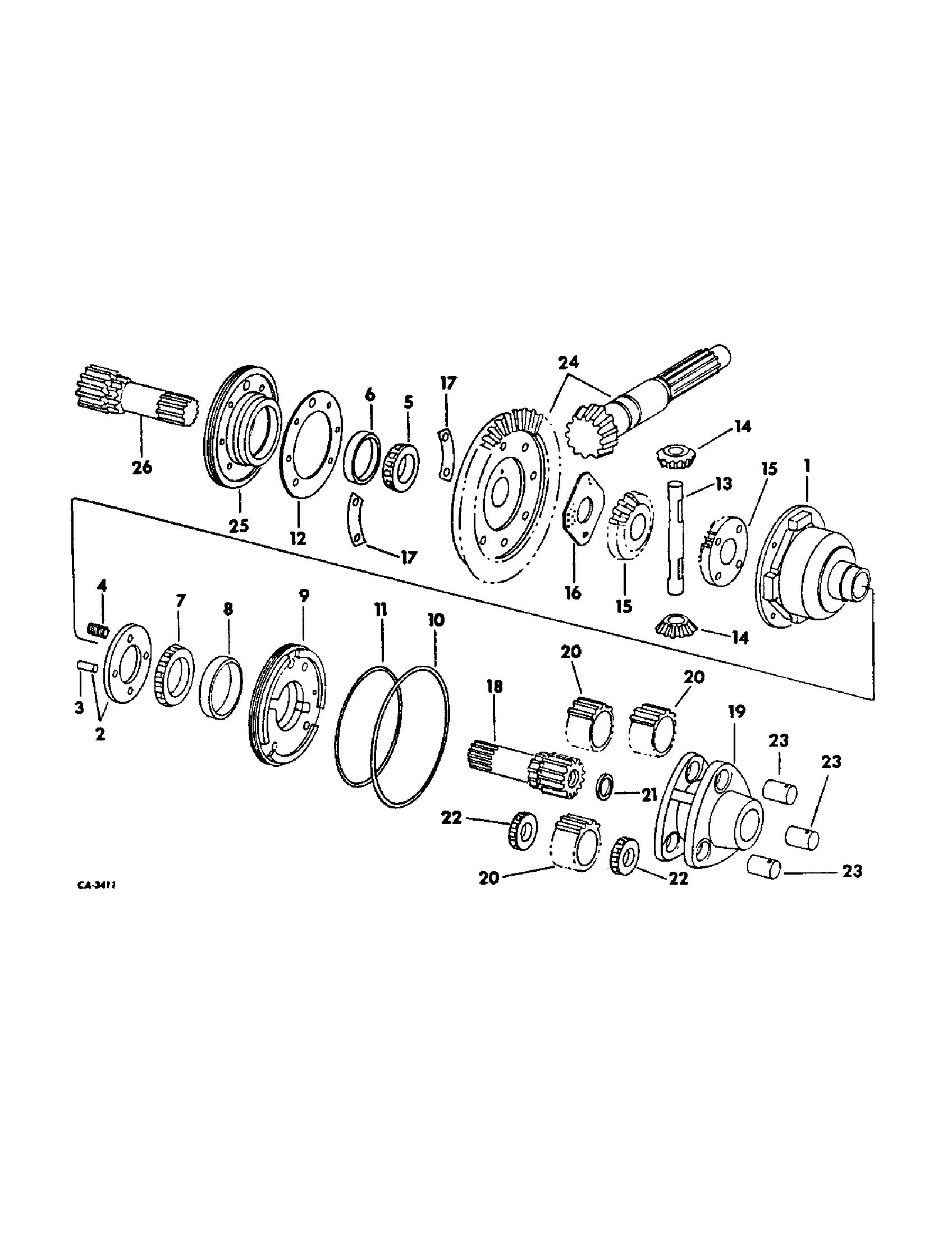

Transmission and Drive System Explained

The efficiency of a vehicle’s movement relies heavily on its transmission and drive mechanism. This system plays a crucial role in converting the engine’s power into motion, ensuring that the vehicle can operate smoothly under various conditions. Understanding the components and their functions can provide valuable insights into the overall performance and reliability of the machinery.

Key Components

The drive mechanism consists of several essential elements that work in harmony. These include:

- Transmission: This component regulates the power output from the engine, allowing the vehicle to change speeds effectively.

- Driveshaft: A critical link that transfers power from the transmission to the wheels.

- Differential: This device enables the wheels to rotate at different speeds, especially during turns.

- Axles: These support the vehicle’s weight and help in transferring power to the wheels.

Functionality Overview

Each element within the drive system has a specific role:

- The engine generates power, which is transmitted to the transmission.

- The transmission modifies the engine’s output, ensuring the vehicle can accelerate or decelerate as needed.

- The driveshaft carries this adjusted power to the differential.

- The differential distributes the power to the wheels, enabling smooth movement and improved traction.

By understanding how these components interact, operators can better maintain their equipment and enhance its operational lifespan.

Electrical System Breakdown

The electrical framework of machinery plays a crucial role in ensuring optimal functionality and performance. Understanding its components and their interactions is essential for efficient maintenance and troubleshooting. This section delves into the intricacies of the system, highlighting key elements that contribute to its overall operation.

Components of the Electrical Framework

At the heart of the system are several vital components, each serving a specific purpose. The battery acts as the primary power source, supplying energy to start the engine and operate various electrical devices. Following this, the alternator generates electricity while the engine runs, recharging the battery and powering the electrical systems. Additionally, the starter motor initiates engine operation by converting electrical energy into mechanical energy.

Troubleshooting Common Issues

When faced with electrical malfunctions, a systematic approach is necessary. Begin by inspecting the wiring harness for any signs of wear or damage, as this can lead to intermittent connections. Additionally, testing the battery voltage can help determine if it holds a charge, while checking the fuses ensures that all circuits are functioning correctly. By understanding these components and their roles, operators can effectively address and resolve electrical challenges.

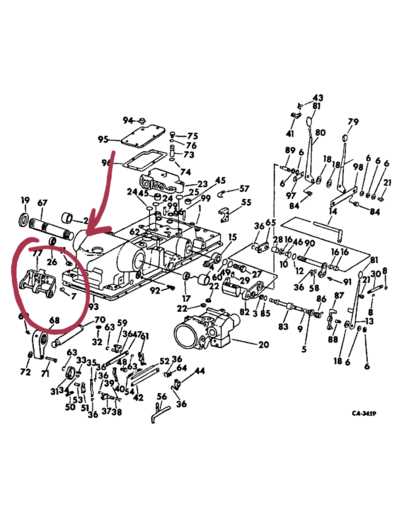

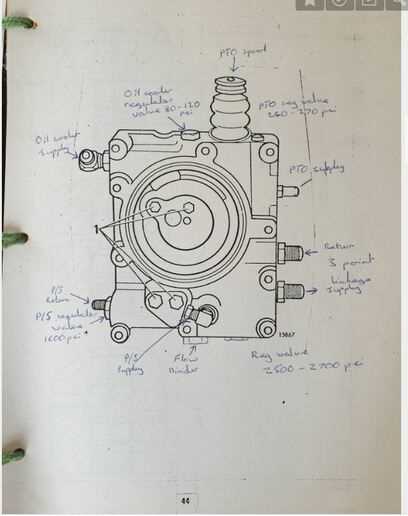

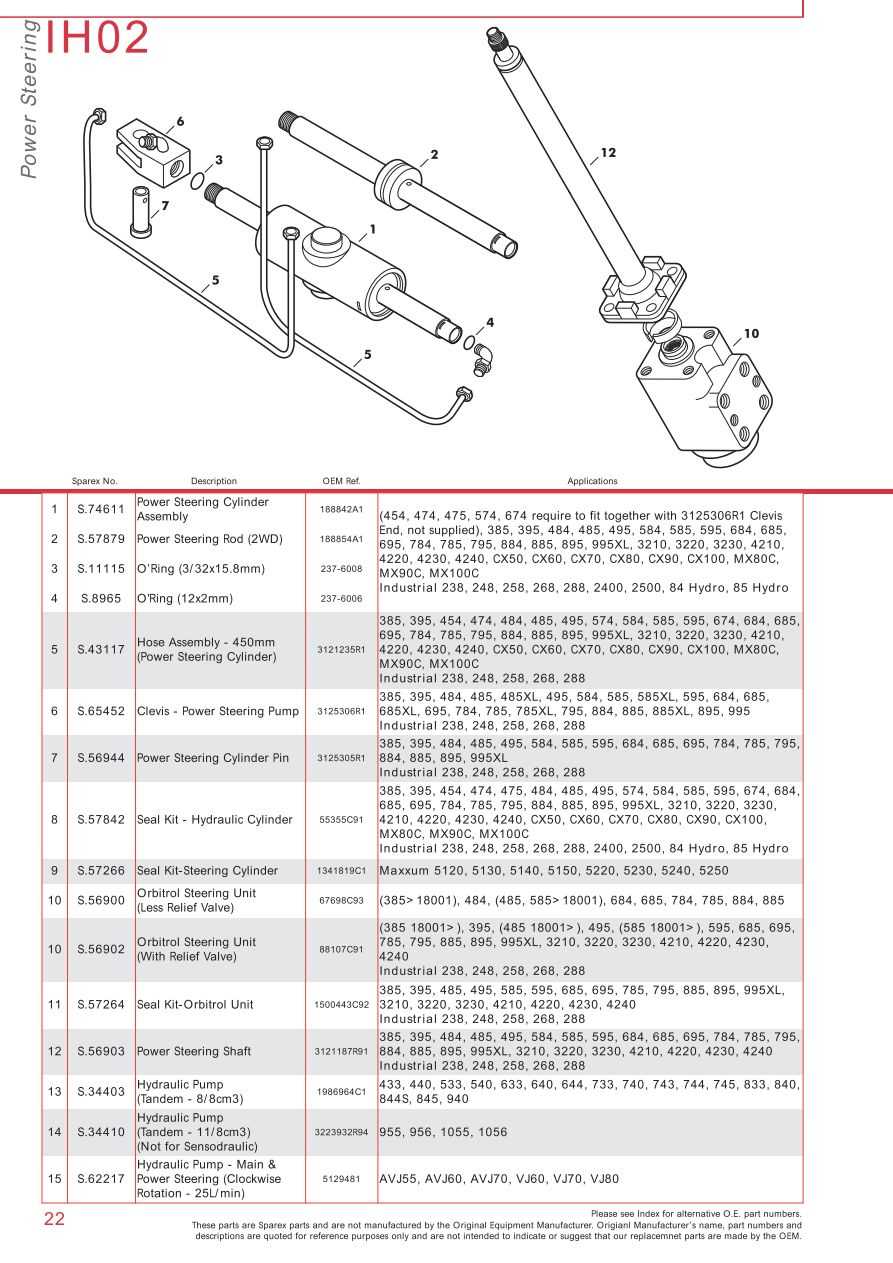

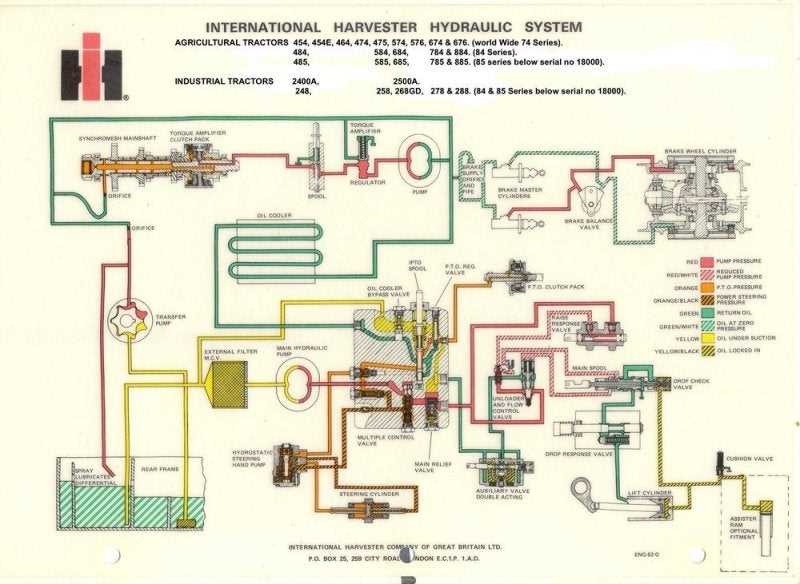

Hydraulic System Overview

The hydraulic system serves as a critical component, utilizing fluid power to facilitate various functions within machinery. This intricate network relies on hydraulic fluid to transfer energy, enabling smooth operation and efficiency in tasks such as lifting, steering, and driving implements. Understanding its components and functionality is essential for optimal performance.

Components of the Hydraulic System

The primary elements of this system include pumps, cylinders, valves, and reservoirs. Each part plays a vital role in controlling fluid flow and pressure, allowing for precise movements and actions. Regular maintenance of these components ensures longevity and reliability in operations.

Operational Principles

This system operates based on Pascal’s principle, where pressure applied to a confined fluid is transmitted uniformly in all directions. This principle enables the system to multiply force effectively, making it ideal for heavy-duty applications. Mastering these concepts is crucial for anyone involved in the maintenance or operation of hydraulic machinery.

Aftermarket vs. OEM Parts

When considering replacement components for machinery, users often face a crucial decision between two categories: original manufacturer offerings and third-party alternatives. Each option presents unique advantages and potential drawbacks that can significantly influence performance, cost, and overall satisfaction.

Advantages of OEM Components

- Designed specifically for optimal compatibility

- Guaranteed quality and performance standards

- Often backed by warranty from the manufacturer

Benefits of Aftermarket Alternatives

- Typically more cost-effective solutions

- Wider variety of options and enhancements

- Potential for improved performance in specific applications

Ultimately, the choice depends on individual needs, budget, and the desired level of assurance in quality and performance.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your machinery requires consistent care and attention. Implementing a few essential practices can significantly enhance durability and functionality, ultimately leading to a more efficient operation.

Regular Inspections: Conducting routine checks can help identify wear and tear before it escalates into major issues. Pay close attention to all moving components and connections, ensuring they remain in optimal condition.

Lubrication: Keeping parts adequately lubricated is crucial for reducing friction and preventing premature deterioration. Use the recommended oils and greases, and follow the schedule for application to maintain smooth operation.

Cleaning: Regularly cleaning your equipment removes debris and contaminants that can hinder performance. Make it a habit to clean filters, air intakes, and surfaces to promote better airflow and efficiency.

Fluid Levels: Monitor and maintain proper fluid levels, including coolant and hydraulic fluids. Low levels can lead to overheating and component failure, so check them frequently and refill as necessary.

Storage Practices: When not in use, store your equipment in a dry, sheltered area to protect it from environmental elements. Use covers to shield against dust and moisture, further extending its lifespan.

By adhering to these fundamental maintenance practices, you can significantly improve the longevity and reliability of your machinery, ensuring it remains a valuable asset for years to come.

Resources for Parts Replacement

When it comes to maintaining machinery, having access to reliable resources for component replacement is essential. Knowing where to find the right supplies can ensure that equipment operates efficiently and reliably. This section provides valuable information on various avenues to explore when seeking out replacements for essential machinery components.

Authorized Dealers and Suppliers

One of the most dependable sources for obtaining quality components is through authorized dealers. These suppliers often provide original equipment manufacturer (OEM) items, ensuring compatibility and durability. Establishing a relationship with a reputable dealer can also lead to better service and access to exclusive products.

Online Marketplaces and Forums

The internet offers a wealth of resources for finding replacement components. Online marketplaces host a variety of sellers, providing options for both new and refurbished items. Additionally, forums dedicated to machinery enthusiasts can be invaluable for advice on sourcing specific components, as well as recommendations on trustworthy vendors.

Using Diagrams for Repairs

Visual aids play a crucial role in facilitating effective maintenance and restoration tasks. By offering a clear representation of components and their interconnections, these resources help users navigate complex systems with ease. Utilizing such illustrations can significantly enhance the repair process, ensuring that each step is executed with precision and confidence.

| Benefit | Description |

|---|---|

| Clarity | Illustrations provide a straightforward view of components, minimizing confusion. |

| Efficiency | With visual references, repair times can be reduced as users quickly locate parts. |

| Accuracy | Detailed visuals guide users in ensuring proper installation and alignment. |

| Accessibility | Visual aids make technical information more approachable for users of varying skill levels. |