Comprehensive Guide to the International 584 Parts Diagram

In the world of agricultural equipment, comprehending the intricate layout and functionality of various elements is essential for effective maintenance and operation. This knowledge empowers operators and technicians to troubleshoot issues efficiently and ensures optimal performance in the field.

The exploration of machinery layouts offers invaluable insights into how each component interacts within the system. By grasping the connections and purposes of individual pieces, one can enhance both productivity and longevity of the equipment.

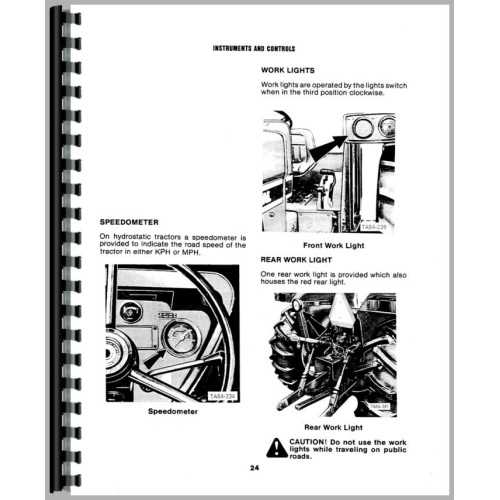

Moreover, visual representations play a crucial role in this understanding. They provide a clear framework for identifying parts, allowing for easier navigation through complex assemblies. As a result, individuals can make informed decisions regarding repairs, replacements, and upgrades.

Understanding the International 584 Model

This section explores the intricacies of a well-known agricultural machine, emphasizing its design and functionality. A comprehensive grasp of its features and mechanisms can enhance operational efficiency and longevity.

Identifying key components is crucial for optimal performance. Each element plays a specific role, contributing to the overall effectiveness of the equipment.

Maintenance is essential for sustaining functionality. Regular checks and timely replacements can prevent significant issues, ensuring reliable operation in various conditions.

Moreover, familiarity with the machinery fosters a deeper appreciation for its engineering. Understanding how each part interacts can empower users to make informed decisions and troubleshoot effectively.

Key Components of the 584 Tractor

This section delves into the essential elements that constitute a popular agricultural vehicle, focusing on their roles and significance in enhancing performance and efficiency. Understanding these fundamental components is crucial for operators and technicians alike, as it helps in maintaining and optimizing functionality.

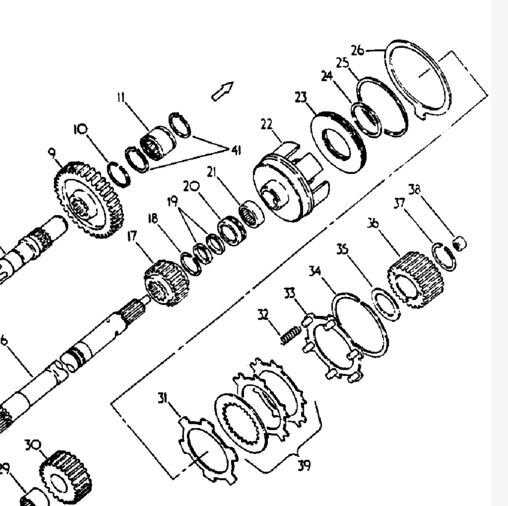

The engine serves as the powerhouse, delivering the necessary torque and horsepower to tackle various farming tasks. Its design ensures reliability and durability, even under challenging conditions. Coupled with the transmission system, it provides seamless power delivery and maneuverability, enabling the vehicle to navigate diverse terrains effortlessly.

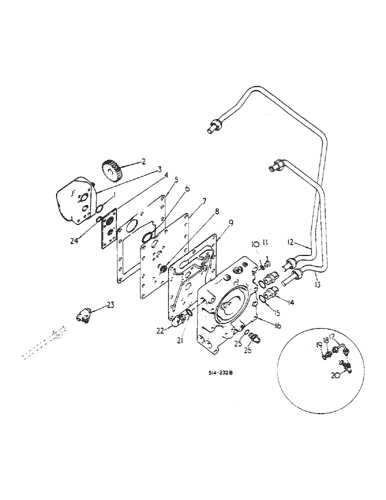

The hydraulic system is another vital feature, facilitating a range of functions from lifting implements to powering attachments. This capability significantly enhances productivity by allowing for quick adjustments and versatile operations. The braking system, integral for safety, ensures effective stopping power, essential for both transport and fieldwork.

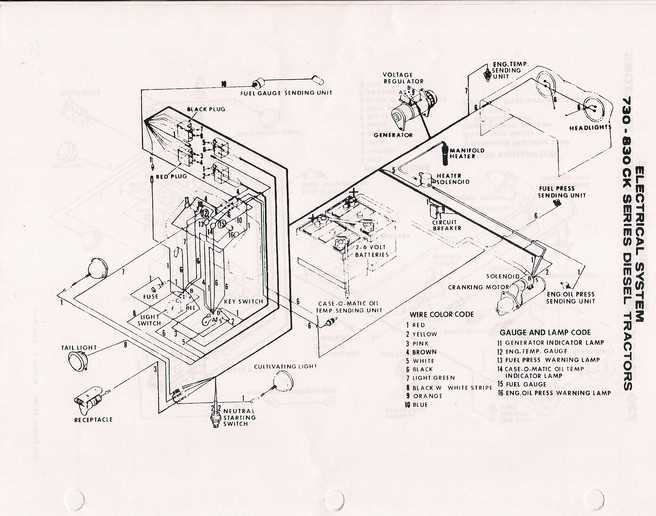

The chassis and frame provide structural integrity, supporting the vehicle’s weight and load capacity while withstanding the stresses of operation. Additionally, the electrical system powers various accessories and implements, ensuring that all components function harmoniously.

Understanding these critical components not only aids in effective operation but also in troubleshooting and maintenance, ensuring longevity and optimal performance of the machinery.

Importance of Accurate Parts Diagrams

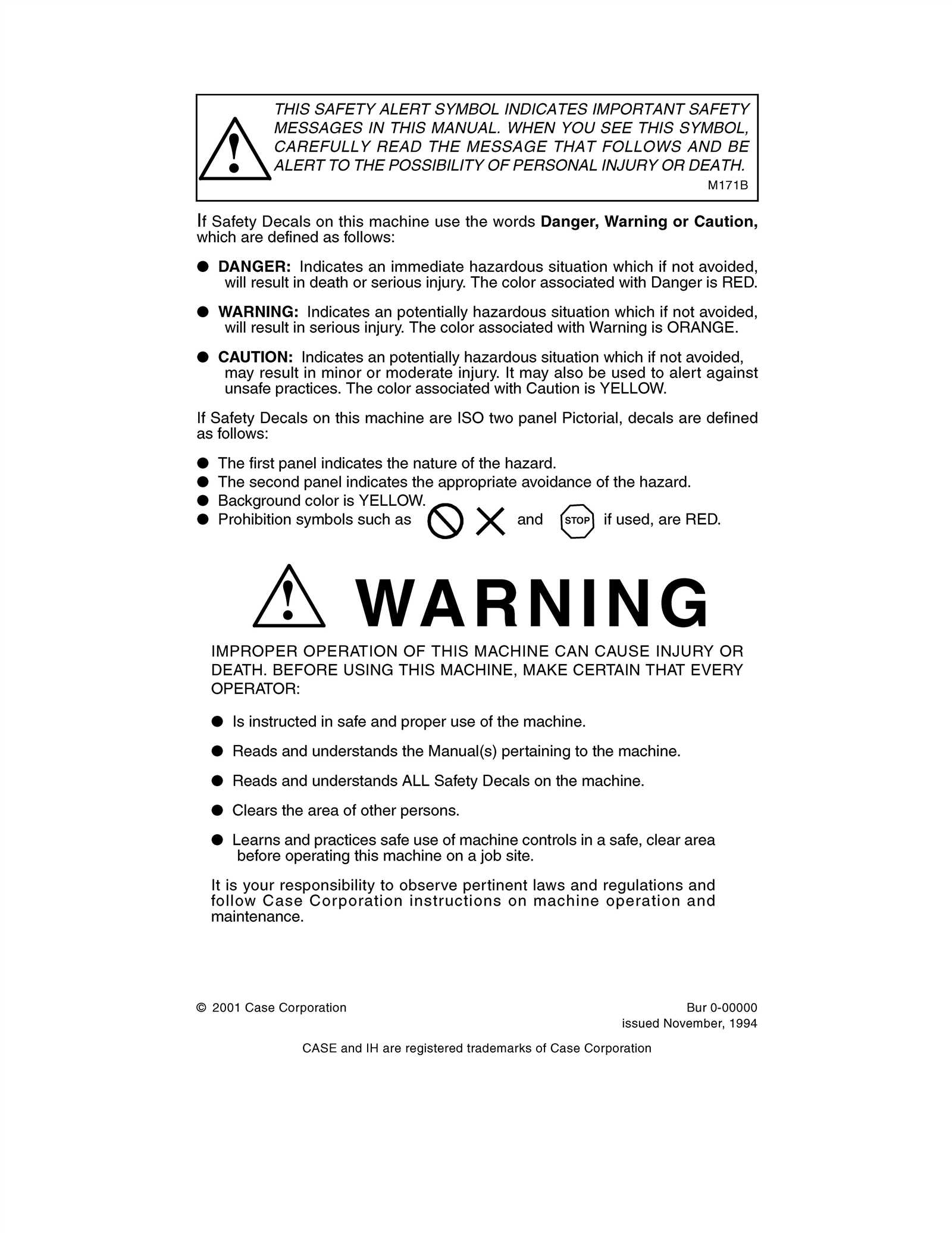

Precision in visual representations of components is crucial for effective maintenance and repairs. These illustrations serve as essential references, enabling users to identify and understand the intricate relationships between various elements. When accuracy is prioritized, it facilitates efficient problem-solving and enhances the overall functionality of machinery.

| Benefits | Description |

|---|---|

| Improved Efficiency | Clear visuals help technicians locate issues quickly, reducing downtime. |

| Enhanced Safety | Accurate representations prevent errors that could lead to accidents. |

| Streamlined Communication | Consistent visuals aid collaboration among team members, ensuring everyone is on the same page. |

| Cost Savings | Reduced mistakes and faster repairs lead to lower maintenance costs. |

Common Repairs for the International 584

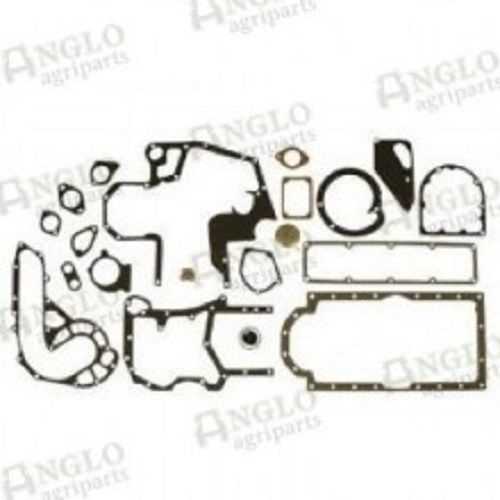

Regular maintenance and timely repairs are essential for ensuring optimal performance and longevity of agricultural machinery. Understanding the most frequent issues and their solutions can save time and resources, allowing operators to keep their equipment running smoothly.

One common area requiring attention is the hydraulic system. Leaks or reduced efficiency can often be resolved by replacing seals or hoses. Routine inspection of these components helps identify potential problems before they escalate.

The engine is another critical component that may require repairs. Common issues include overheating or difficulty starting. Regular checks on the cooling system, including the radiator and thermostat, as well as routine oil changes, can help maintain engine health.

Transmission problems can also arise, often manifesting as unusual noises or difficulty in shifting gears. Addressing fluid levels and replacing filters can frequently resolve these issues, ensuring smooth operation.

Lastly, the electrical system is vital for overall functionality. Battery issues, wiring faults, and faulty switches are common concerns. Conducting regular inspections and ensuring proper connections can prevent many electrical failures.

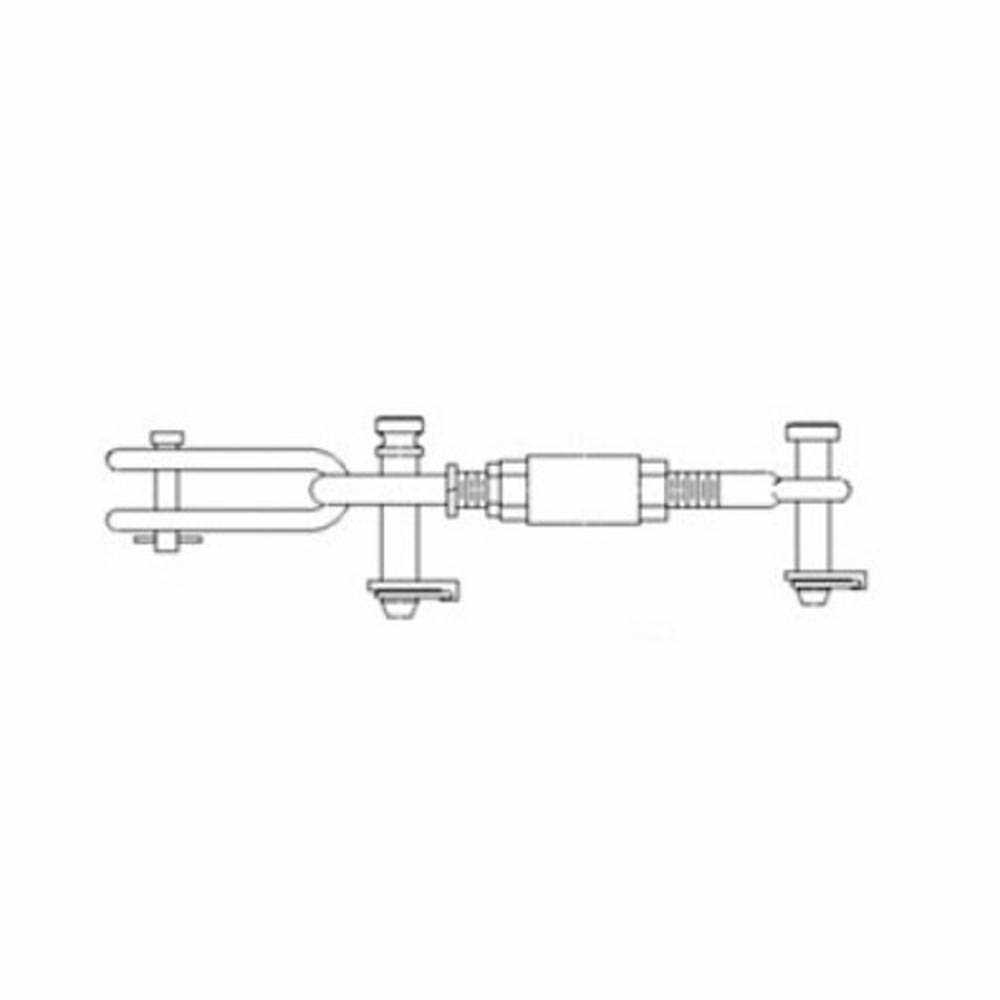

How to Interpret Parts Diagrams

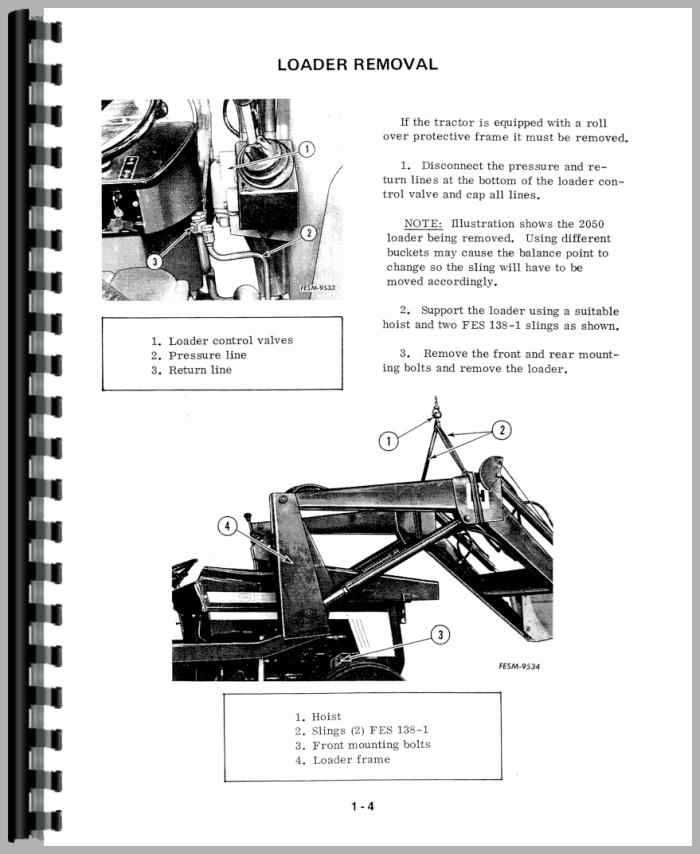

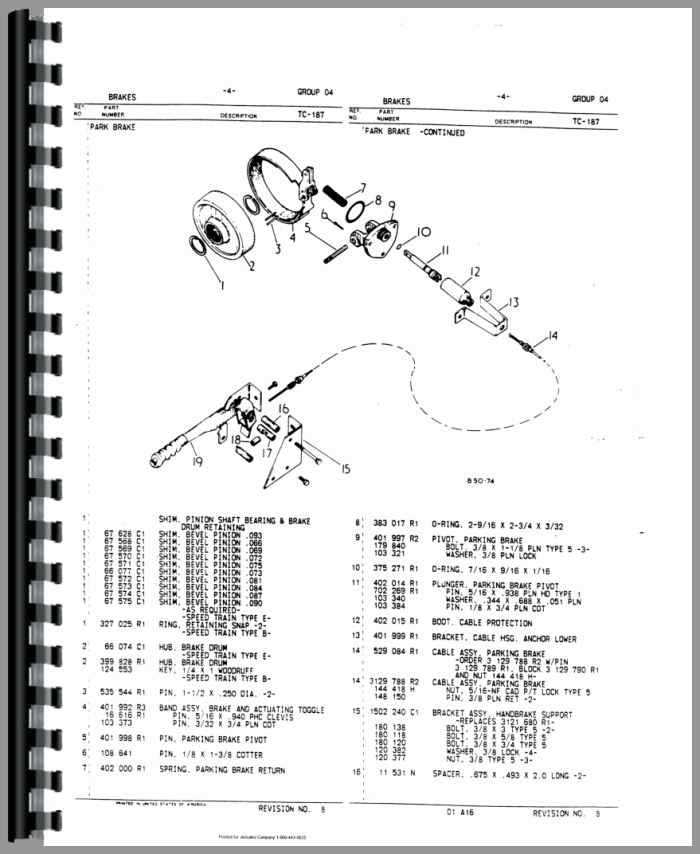

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations serve as valuable guides, detailing how each element fits together and functions within a larger system.

Key Elements to Focus On

- Labels: Each part is typically marked with a specific identifier, helping to easily locate components.

- Legend: Many representations include a legend that explains symbols and markings.

- Connections: Pay attention to lines and arrows that indicate how parts are connected and interact.

Steps to Follow

- Identify the main components and their positions within the system.

- Cross-reference labels with the accompanying list to ensure accurate identification.

- Note any special instructions or precautions indicated in the legend.

- Use the visual to plan disassembly or assembly efficiently.

Where to Find Replacement Parts

Locating suitable components for machinery can be a straightforward task if you know where to look. A variety of sources offer access to high-quality substitutes, ensuring that your equipment remains operational and efficient.

- Authorized Dealers: Visit certified distributors who specialize in the brand. They typically carry an extensive selection and can provide expert advice.

- Online Retailers: Websites dedicated to machinery supplies often feature a wide array of components. Look for reputable platforms that offer user reviews.

- Local Supply Stores: Check nearby shops that cater to agricultural or industrial needs. Personal interaction can sometimes lead to valuable recommendations.

- Second-Hand Markets: Consider browsing auctions, classifieds, or specialized websites for pre-owned items, which can be cost-effective.

Before making a purchase, ensure that the chosen item is compatible with your specific machinery model. This step is crucial to avoid unnecessary complications during installation.

Additionally, networking with fellow operators or joining forums can provide insights and suggestions for finding reliable sources. Sharing experiences often leads to discovering hidden gems in the market.

Maintenance Tips for the International 584

Proper upkeep of machinery is crucial for ensuring longevity and optimal performance. Regular attention not only enhances efficiency but also prevents unexpected breakdowns and costly repairs. Here are some essential suggestions to help maintain your equipment effectively.

1. Regular Oil Changes: Frequent oil changes are vital. Use high-quality lubricants suited for your machine to ensure smooth operation and reduce wear.

2. Check Fluid Levels: Regularly inspect and top up coolant, hydraulic fluid, and fuel. Maintaining appropriate levels is essential for functionality and overheating prevention.

3. Clean Air Filters: Keeping air filters clean ensures proper airflow and prevents engine strain. Replace them when necessary to enhance performance.

4. Inspect Belts and Hoses: Regularly examine belts and hoses for wear or cracks. Replacing damaged components can avert serious issues down the line.

5. Tire Maintenance: Ensure that tires are properly inflated and show no signs of excessive wear. This not only improves safety but also enhances fuel efficiency.

6. Scheduled Inspections: Adhere to a routine inspection schedule. This proactive approach can help identify potential problems early and extend the life of your machine.

Implementing these tips will ultimately contribute to the reliability and efficiency of your equipment, ensuring it remains in top condition for years to come.

Comparing 584 with Other Models

This section delves into the distinctions and similarities between a specific agricultural vehicle and its counterparts. By examining key features, performance metrics, and user experiences, we aim to provide a comprehensive overview that highlights the unique aspects of the model in question, while also acknowledging the strengths of alternative options in the market.

Performance and Efficiency

When assessing performance, the vehicle stands out for its balance of power and fuel efficiency. Compared to other models in its class, it often showcases superior handling and operational versatility, making it a favorite among farmers who require reliability across diverse tasks. However, certain competitors may offer enhanced horsepower or advanced technology that caters to specific agricultural needs.

Design and Usability

The design elements of this vehicle prioritize user-friendliness and accessibility. Its layout simplifies maintenance and repairs, setting it apart from some other options that may require specialized tools or knowledge. While aesthetic differences exist among various models, practicality often reigns supreme, ensuring that operators can focus on their work without unnecessary complications.

Benefits of Using Official Diagrams

Utilizing authorized illustrations for machinery components offers numerous advantages that enhance the overall maintenance and repair processes. These resources provide clarity and accuracy, ensuring that users can effectively understand and address various issues with their equipment.

Enhanced Understanding

- Official illustrations break down complex systems into manageable sections, making it easier for users to grasp how components interact.

- Visual representations help identify parts quickly, reducing confusion during troubleshooting and repairs.

- Clear labeling and detailed views support effective communication among technicians and operators.

Improved Accuracy

- Authorized resources are created by experts, ensuring that the information is precise and up-to-date.

- Using reliable illustrations minimizes the risk of errors, leading to more effective repairs and maintenance.

- Access to correct specifications helps in sourcing the right components, avoiding costly mistakes and delays.

Tools Needed for Repairs

Having the right equipment is essential for effective maintenance and restoration tasks. The appropriate tools not only enhance efficiency but also ensure the quality of the work performed. Below is a list of necessary implements that can facilitate various repair activities.

- Wrenches

- Screwdrivers

- Socket sets

- Pliers

- Jack and jack stands

In addition to basic tools, specialized equipment may be required for certain tasks:

- Torque wrench

- Multimeter

- Diagnostic scanner

- Grease gun

Investing in quality tools will ultimately lead to a more successful and efficient repair process.

Understanding Hydraulic Systems in Tractors

Hydraulic systems play a crucial role in enhancing the functionality and efficiency of agricultural machinery. These systems enable operators to perform a variety of tasks with precision and ease, utilizing fluid power to transmit energy. Understanding the components and operations of these systems is essential for effective maintenance and troubleshooting.

Key Components of Hydraulic Systems

- Pump: Generates fluid flow and pressure.

- Reservoir: Stores hydraulic fluid.

- Actuators: Convert hydraulic energy into mechanical movement.

- Valves: Control the direction and flow of the fluid.

- Hoses and Fittings: Connect various components and transport fluid.

Working Principles

Hydraulic systems operate based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. This allows for significant force multiplication and precise control over machinery operations.

- The pump draws fluid from the reservoir.

- Pressure is built and directed through valves.

- Fluid moves actuators, enabling movement of attachments.

By delving into these elements, operators can ensure optimal performance and longevity of their machinery, ultimately enhancing productivity on the field.

Frequently Asked Questions about the 584

This section addresses common inquiries related to a specific model known for its robust performance and reliability. Here, we provide answers to typical concerns that users may have regarding maintenance, compatibility, and functionality.

What are the most common maintenance issues?

Users often encounter challenges related to engine performance, hydraulic system efficiency, and electrical components. Regular checks can help mitigate these issues.

Where can I find replacement components?

Replacement parts are widely available through specialized suppliers, local dealers, and online marketplaces. It’s advisable to ensure compatibility with your specific model.

How can I improve the performance of my machine?

Regular maintenance, timely oil changes, and using quality fuel can significantly enhance overall performance. Upgrades or adjustments may also be beneficial depending on usage.

What is the best way to troubleshoot problems?

Systematic troubleshooting involves checking fluid levels, inspecting for leaks, and testing electrical systems. Referencing a service manual can also provide valuable insights.

Are there any community forums for support?

Yes, numerous online communities and forums exist where users share experiences, tips, and solutions. Engaging with fellow operators can be a great resource for troubleshooting and advice.

Online Resources for Tractor Owners

In today’s digital age, having access to reliable information is crucial for equipment enthusiasts. Various platforms offer essential tools, guides, and community support, making maintenance and repairs more manageable. These resources empower users to enhance their knowledge and skills, ultimately ensuring their machinery remains in optimal condition.

Forums and Communities: Online discussion boards serve as invaluable spaces for sharing experiences and troubleshooting advice. Engaging with fellow operators can lead to innovative solutions and practical tips.

Instructional Videos: Many creators share detailed tutorials that cover everything from basic upkeep to complex repairs. Visual aids can simplify even the most challenging tasks.

Manufacturer Websites: Official platforms often provide downloadable manuals and technical specifications, offering a wealth of information directly from the source.

Parts Retailers: Online shops specializing in agricultural machinery make it easy to find components, often with detailed descriptions to ensure compatibility.

Blogs and Articles: Numerous writers share insights and best practices, helping owners stay informed about the latest trends and technologies in the field.