Kawasaki FC540V Parts Diagram Overview

The intricate design of small engines requires a clear understanding of their various elements and how they interact. A comprehensive overview of these components aids in efficient maintenance and repair, ensuring optimal performance.

In this section, we will explore the essential parts of a specific engine model, highlighting their functions and placements. This knowledge is invaluable for both enthusiasts and professionals aiming to enhance their mechanical skills.

By delving into the layout of engine components, one can gain insights into troubleshooting and replacement procedures. Familiarity with each part not only streamlines repairs but also fosters a deeper appreciation for the engineering behind these machines.

Understanding the Kawasaki FC540V Engine

This section explores the intricacies of a specific engine model known for its reliability and efficiency. By examining its components and functionality, one can appreciate the engineering behind its performance in various applications.

At the heart of this engine lies a robust structure designed to deliver optimal power and torque. Its design incorporates advanced features that enhance fuel efficiency and reduce emissions, making it suitable for both residential and commercial use.

| Component | Description |

|---|---|

| Cylinder | Houses the piston and facilitates combustion. |

| Piston | Converts fuel energy into mechanical energy. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Carburetor | Mixes air and fuel for efficient combustion. |

Understanding these elements is crucial for maintenance and troubleshooting, ensuring the engine operates at its ultimate potential throughout its lifespan.

Key Features of the FC540V Model

This model is renowned for its exceptional reliability and performance in various applications. Designed for efficiency, it incorporates advanced engineering principles that ensure optimal functionality and longevity.

| Feature | Description |

|---|---|

| Power Output | Delivers impressive horsepower, making it suitable for demanding tasks. |

| Fuel Efficiency | Engineered to maximize fuel usage, providing cost-effective operation. |

| Durability | Constructed with high-quality materials to withstand rigorous conditions. |

| Maintenance Accessibility | Designed for easy access to components, facilitating quick servicing. |

| Versatility | Compatible with various attachments, enhancing its utility across different tasks. |

Common Applications for the Engine

This engine type is widely utilized across various sectors due to its robust performance and reliability. Its versatility makes it ideal for multiple applications, catering to both professional and recreational needs.

| Application | Description |

|---|---|

| Landscaping Equipment | Used in mowers and trimmers for efficient grass cutting and maintenance. |

| Agricultural Machinery | Powers equipment such as tillers and harvesters for effective crop management. |

| Construction Tools | Drives generators and heavy machinery, enhancing productivity on job sites. |

| Utility Vehicles | Commonly found in ATVs and utility carts for versatile off-road capabilities. |

| Recreational Equipment | Employed in go-karts and small boats for thrilling outdoor experiences. |

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as valuable resources, aiding users in identifying each element’s function and relationship within the system. This clarity can prevent costly errors and enhance operational efficiency.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids provide a straightforward view of the machinery’s structure. |

| Efficient Repairs | Users can quickly locate and address issues without guesswork. |

| Improved Training | New users can learn system components more effectively through visual guides. |

| Parts Identification | Accurate identification of components aids in sourcing replacements. |

Overview of Engine Components

Understanding the fundamental elements of an engine is crucial for grasping how it operates effectively. Each part plays a significant role in the overall functionality, contributing to the performance and reliability of the machinery. From the power source to the various auxiliary systems, every component is intricately designed to work harmoniously.

The heart of the engine is the combustion chamber, where fuel and air mix to generate power. Surrounding this core are various systems, including the ignition system, which ensures that combustion occurs at the right moment, and the cooling system, which prevents overheating. Additionally, the lubrication system plays a vital role in minimizing friction between moving parts, thereby enhancing longevity and efficiency.

Supporting structures, such as the crankshaft and camshaft, convert linear motion into rotational energy, enabling the machinery to perform its intended tasks. Other essential elements include filters and exhaust systems, which help maintain optimal operation and reduce environmental impact. Each of these components is engineered with precision, highlighting the complexity and sophistication of modern engine design.

Finding OEM Parts for Repair

Locating original equipment manufacturer components is crucial for maintaining the efficiency and longevity of your machinery. Utilizing authentic parts ensures compatibility and optimal performance, preventing potential issues that may arise from using aftermarket alternatives. Understanding how to source these components can save both time and money in the long run.

Researching Reliable Suppliers

When searching for genuine components, start by identifying reputable suppliers. Look for authorized dealers or well-established distributors that specialize in your equipment’s brand. Reading customer reviews and verifying certifications can help ensure you’re purchasing high-quality items. Additionally, consider reaching out to local repair shops that may have insights into trusted sources.

Utilizing Online Resources

The internet offers a wealth of information for finding authentic components. Manufacturer websites often provide lists of authorized sellers, while forums and online communities can be valuable resources for recommendations. Online marketplaces can also have listings, but ensure they specify the originality of the items. Always cross-check any details to avoid counterfeit goods.

Aftermarket Parts vs. OEM

When maintaining machinery, the choice between replacement components from the original manufacturer and third-party alternatives is crucial. Each option has its own set of advantages and drawbacks, impacting performance, durability, and cost.

- OEM Components:

- Guaranteed compatibility with your equipment.

- Typically come with a warranty.

- Often manufactured to the highest standards of quality.

- Aftermarket Alternatives:

- Usually more affordable, providing cost savings.

- Can offer innovative features not found in original parts.

- Variety in brands allows for broader options and comparisons.

Ultimately, the decision hinges on your specific needs, budget, and the importance of maintaining manufacturer specifications.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent care and attention. Proper maintenance not only enhances performance but also prevents costly repairs down the line. By adhering to a regular upkeep routine, you can keep your machinery in optimal condition, maximizing its efficiency and reliability.

Regular Inspections

Frequent checks on various components are crucial for identifying potential issues early. Inspect belts, filters, and fluids to ensure they are clean and in good condition. Look for signs of wear or damage, as early detection can save time and resources.

Scheduled Maintenance

Creating a maintenance schedule tailored to your specific equipment is essential. This schedule should include tasks like oil changes, air filter replacements, and spark plug inspections. Following a consistent timeline helps maintain performance and prevents unexpected breakdowns.

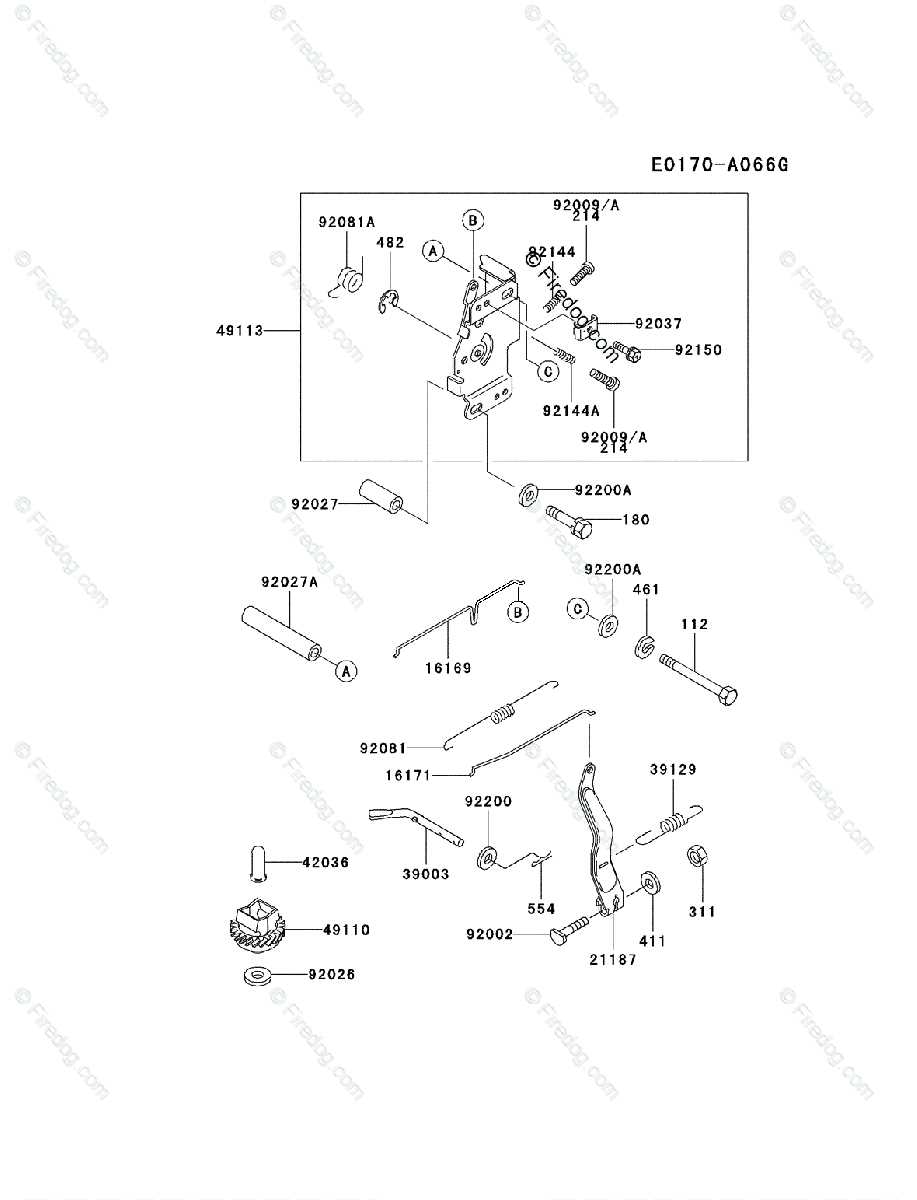

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. Such visual aids simplify the identification of individual elements, showcasing their relationships and placements within a larger assembly. Familiarizing yourself with these illustrations can enhance your troubleshooting skills and streamline the replacement process.

Firstly, examine the legend or key that typically accompanies the illustration. This guide provides essential information about symbols and notations used, enabling you to interpret the drawing accurately. Look for indicators that denote various components, which may include numbers or letters corresponding to specific parts.

Next, pay attention to the layout of the image. Often, elements are organized in a way that reflects their actual arrangement in the machinery. Understanding the spatial relationships can help you visualize how each part fits into the whole, which is crucial for any repair work.

Additionally, consider the lines and arrows that connect different items. These markings often represent pathways, such as flow or connectivity, and can indicate how components interact. Recognizing these connections is vital for diagnosing issues effectively.

Finally, always cross-reference the schematic with a list of components if available. This will ensure you are using the correct identifiers and can assist in locating replacements. By mastering these skills, you can navigate technical illustrations with confidence, ultimately leading to more efficient repairs and maintenance tasks.

Identifying Replacement Parts Easily

Finding the right components for machinery can be a daunting task. However, by utilizing systematic approaches and resources, one can streamline the identification process. This section will explore effective methods to help you recognize the necessary items swiftly and efficiently.

Utilizing Visual References

Visual aids, such as illustrations or schematics, serve as invaluable tools in pinpointing specific elements. By comparing your equipment with labeled images, you can easily ascertain what is needed for maintenance or repair.

Consulting Expert Resources

Engaging with knowledgeable professionals or online forums can provide insights that simplify the identification of essential components. Such interactions often reveal tips and recommendations that enhance your understanding of the machinery.

Common Issues and Solutions

Understanding potential problems that may arise in outdoor power equipment is crucial for maintaining optimal performance. This section outlines typical challenges users may encounter, along with effective strategies to resolve them.

Frequent Problems

- Engine does not start

- Inconsistent power delivery

- Overheating

- Excessive vibrations

- Fuel leaks

Effective Solutions

- Engine does not start: Check the fuel level, inspect the spark plug for wear, and ensure the ignition system is functioning correctly.

- Inconsistent power delivery: Clean or replace the air filter, and inspect the fuel lines for blockages.

- Overheating: Ensure adequate ventilation, clean cooling fins, and check coolant levels if applicable.

- Excessive vibrations: Tighten loose components and inspect for any damaged or worn parts.

- Fuel leaks: Inspect all fuel connections and seals, replacing any damaged components as necessary.

Addressing these common issues promptly can enhance the longevity and efficiency of the equipment.

Where to Buy Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Choosing reliable suppliers can make a significant difference in the functionality of your machinery.

Authorized Dealers

One of the best options for acquiring original components is through authorized dealers. These retailers are certified to sell genuine items and often provide expert advice on compatibility and installation.

Online Marketplaces

Numerous online platforms specialize in high-quality components. When shopping online, look for sellers with excellent ratings and reviews to ensure you receive authentic products. Always verify the return policy and warranty information for added peace of mind.

Upgrading Your FC540V Performance

Enhancing the capabilities of your small engine can lead to improved efficiency and responsiveness. By focusing on specific modifications and quality components, you can unlock the full potential of your machine, ensuring it operates at its best for longer periods.

| Upgrade | Description |

|---|---|

| Air Filter | Switching to a high-performance air filter can increase airflow, resulting in better combustion and power output. |

| Exhaust System | Upgrading the exhaust can reduce back pressure, enhancing engine efficiency and sound quality. |

| Fuel System | Installing a performance fuel injector ensures optimal fuel delivery for increased horsepower and torque. |

| Ignition System | A higher-quality ignition coil can improve spark consistency, promoting better engine performance and fuel economy. |