Kawasaki FH430V Parts Diagram Overview

In the realm of small engines, comprehending the intricate layout of individual components is crucial for maintenance and repair. A thorough grasp of these elements ensures optimal performance and longevity of the machinery. The following section aims to explore this topic in detail.

By examining a comprehensive representation of the various elements involved, users can easily identify each part’s function and placement. This insight not only aids in troubleshooting but also enhances the ability to perform replacements or upgrades as necessary.

Whether you are a seasoned technician or a curious enthusiast, delving into this information will empower you with the knowledge needed to tackle engine-related tasks with confidence. The ultimate goal is to facilitate a deeper understanding of how these components interact within the overall system.

Understanding Kawasaki FH430V Engine Parts

Gaining insight into the components of a specific engine model is crucial for maintenance and repair. Each element plays a vital role in the overall functionality and efficiency of the system. Familiarity with these pieces not only enhances performance but also prolongs the lifespan of the machinery.

Key Components

- Fuel System

- Ignition System

- Cooling System

- Lubrication System

- Air Intake System

Maintenance Tips

- Regularly inspect the fuel system for leaks.

- Ensure the ignition system is free of corrosion.

- Check coolant levels to prevent overheating.

- Replace oil filters as recommended.

- Clean air filters periodically for optimal airflow.

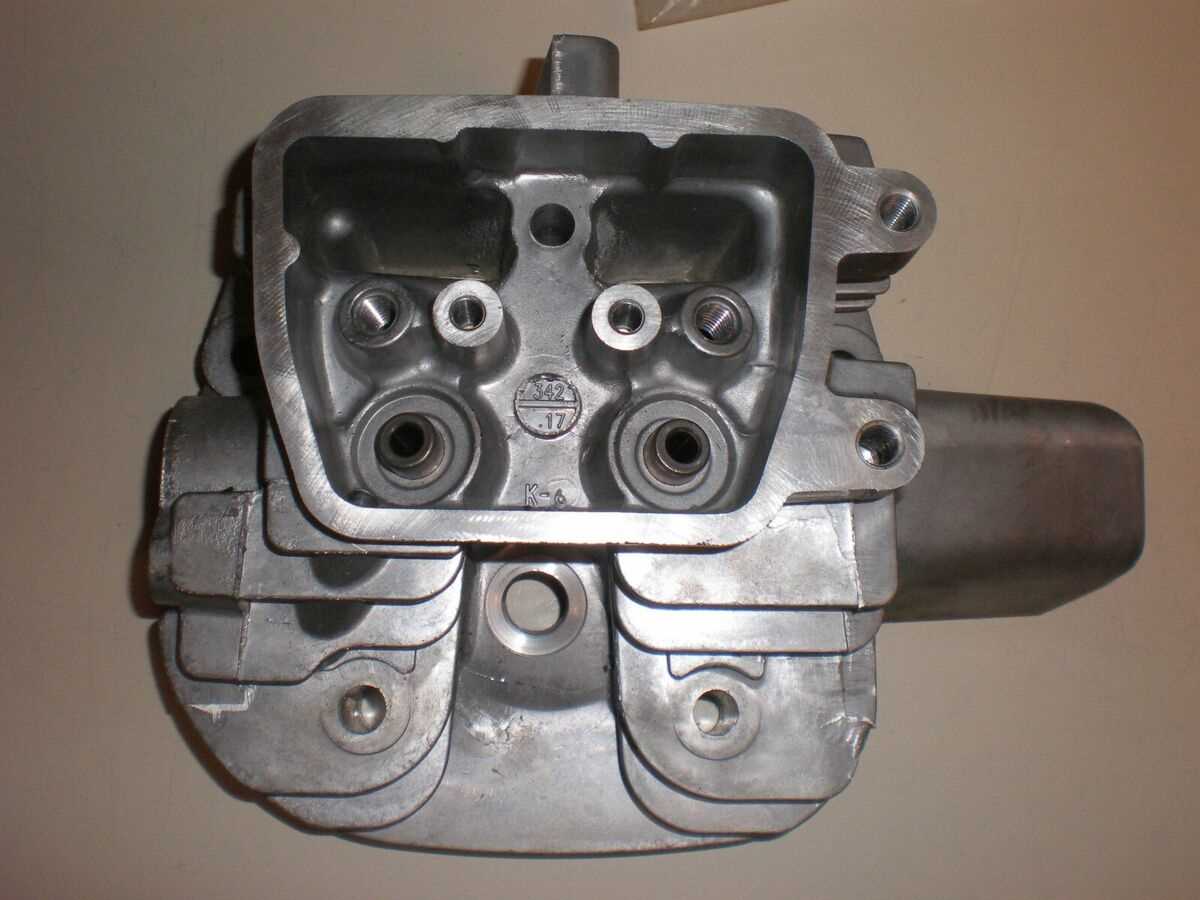

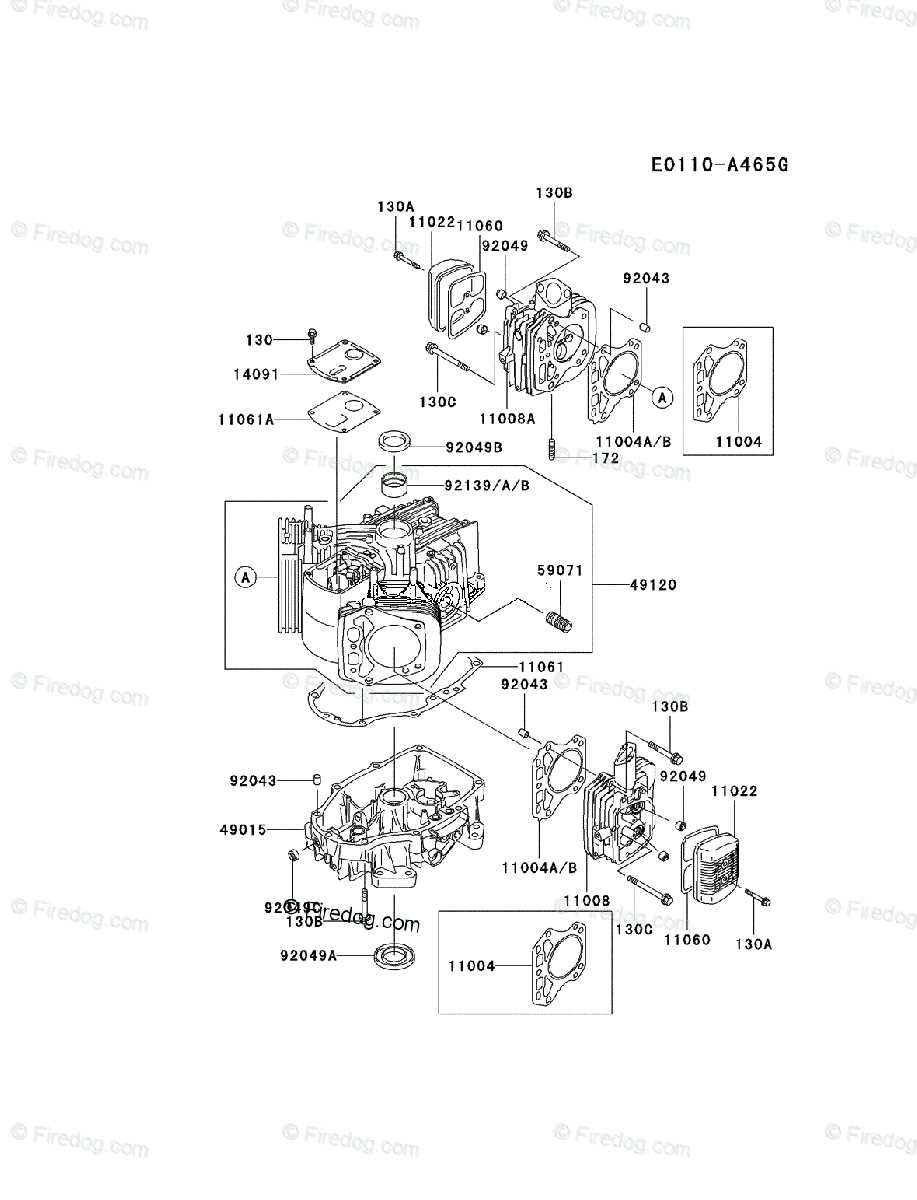

Overview of Engine Components

This section explores the essential elements that make up a small engine, highlighting their functions and significance in overall performance. Understanding these components is crucial for effective maintenance and troubleshooting.

Key Components

- Cylinder: The chamber where fuel and air mix and combust.

- Piston: Moves up and down within the cylinder, converting energy from combustion.

- Crankshaft: Transforms the piston’s linear motion into rotational energy.

- Camshaft: Controls the opening and closing of valves.

- Valves: Regulate the intake of air-fuel mixture and exhaust gases.

Supporting Elements

- Ignition System: Initiates combustion to power the engine.

- Fuel System: Delivers the necessary fuel for operation.

- Cooling System: Maintains optimal operating temperature to prevent overheating.

- Lubrication System: Reduces friction between moving parts.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations of these elements facilitate a clear comprehension of how each piece fits into the overall system. By offering a detailed layout, these resources empower users to diagnose issues accurately and streamline their repair processes.

Enhancing Maintenance Efficiency

Clear visual guides play a vital role in enhancing the efficiency of maintenance tasks. They allow technicians to identify specific components quickly, reducing the time spent on repairs. Furthermore, a well-organized illustration helps in assembling or disassembling parts with precision, minimizing the risk of damage.

Supporting Accurate Repairs

When it comes to fixing equipment, having a reliable reference is indispensable. A structured visual guide provides clarity on the arrangement and connection of elements, which is essential for troubleshooting. By referencing these images, users can ensure they are replacing the correct items, leading to more effective repairs.

| Benefit | Description |

|---|---|

| Time-saving | Reduces the duration of maintenance tasks by providing quick identification of components. |

| Clarity | Offers a clear view of how elements fit together, preventing confusion during repairs. |

| Accuracy | Ensures correct replacements and repairs by guiding users in the right direction. |

Common Issues with FH430V Parts

Understanding frequent complications related to engine components is crucial for maintenance and optimal performance. Several elements can lead to operational difficulties, impacting efficiency and longevity.

Typical Problems

- Wear and Tear: Components often degrade over time, leading to reduced efficiency.

- Fuel System Issues: Clogging in filters can restrict fuel flow, causing performance issues.

- Electrical Failures: Faulty wiring or connections can result in starting problems.

Troubleshooting Steps

- Inspect for visible damage or corrosion on parts.

- Check fuel lines for blockages and ensure proper flow.

- Test electrical connections with a multimeter for continuity.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining optimal performance and longevity. Whether you are a professional or a DIY enthusiast, knowing where to source these items can save you time and money.

- Authorized Dealers: Always start by checking with certified retailers. They provide genuine components and often have knowledgeable staff who can assist you.

- Online Marketplaces: Websites like eBay, Amazon, and specialized online shops offer a wide range of options. Make sure to read reviews and verify seller ratings.

- Local Repair Shops: Independent repair shops often have a selection of components and can sometimes order specific items for you.

- Manufacturer Websites: The official website of the manufacturer may have a section dedicated to spare components, making it easy to find what you need.

- Salvage Yards: For those looking for budget-friendly options, salvage yards can be a treasure trove of usable items. Just ensure that what you choose is in good condition.

By exploring these avenues, you can efficiently acquire the necessary components to keep your machinery running smoothly.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires regular care and attention. By adopting a few essential practices, you can significantly extend its lifespan and enhance overall functionality.

- Regular Cleaning: Keep surfaces free from debris and dirt to prevent wear and tear.

- Fluid Checks: Monitor and replace oils and other fluids at recommended intervals.

- Inspect Filters: Clean or replace air and fuel filters to maintain optimal airflow and performance.

- Tighten Bolts: Periodically check and tighten all fasteners to ensure stability and safety.

- Storage Practices: Store the equipment in a dry, sheltered area to protect it from the elements.

By implementing these strategies, you can delve deeper into the art of maintenance and achieve the ultimate performance from your machinery.

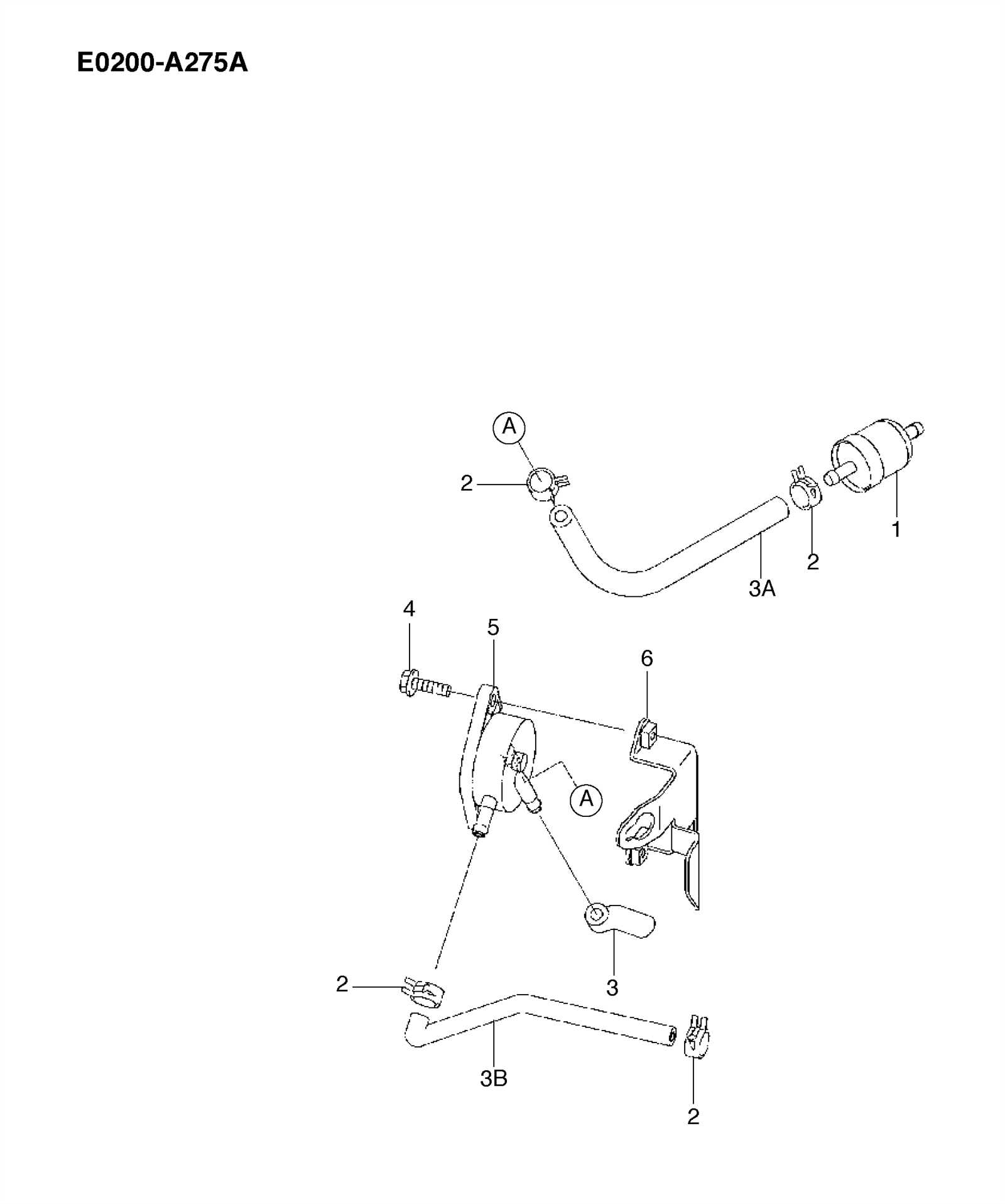

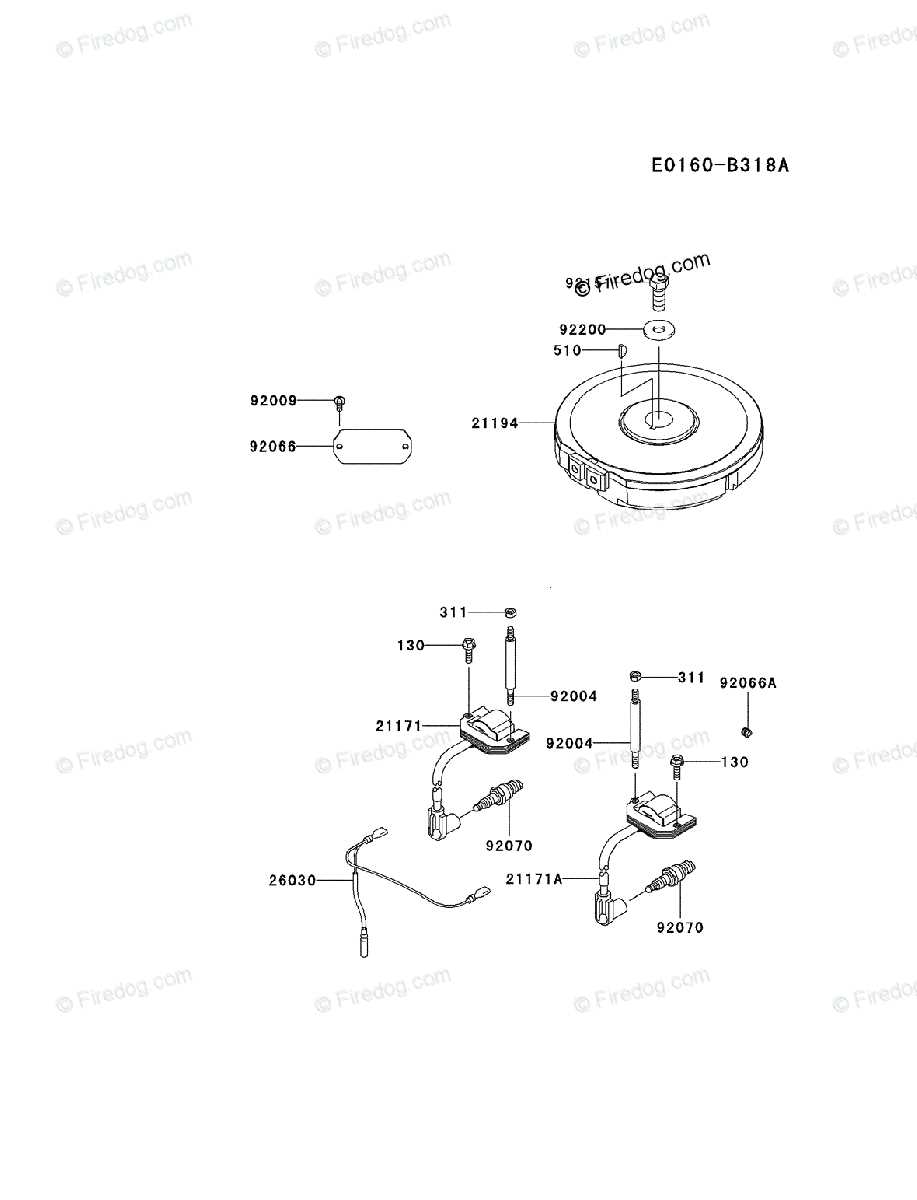

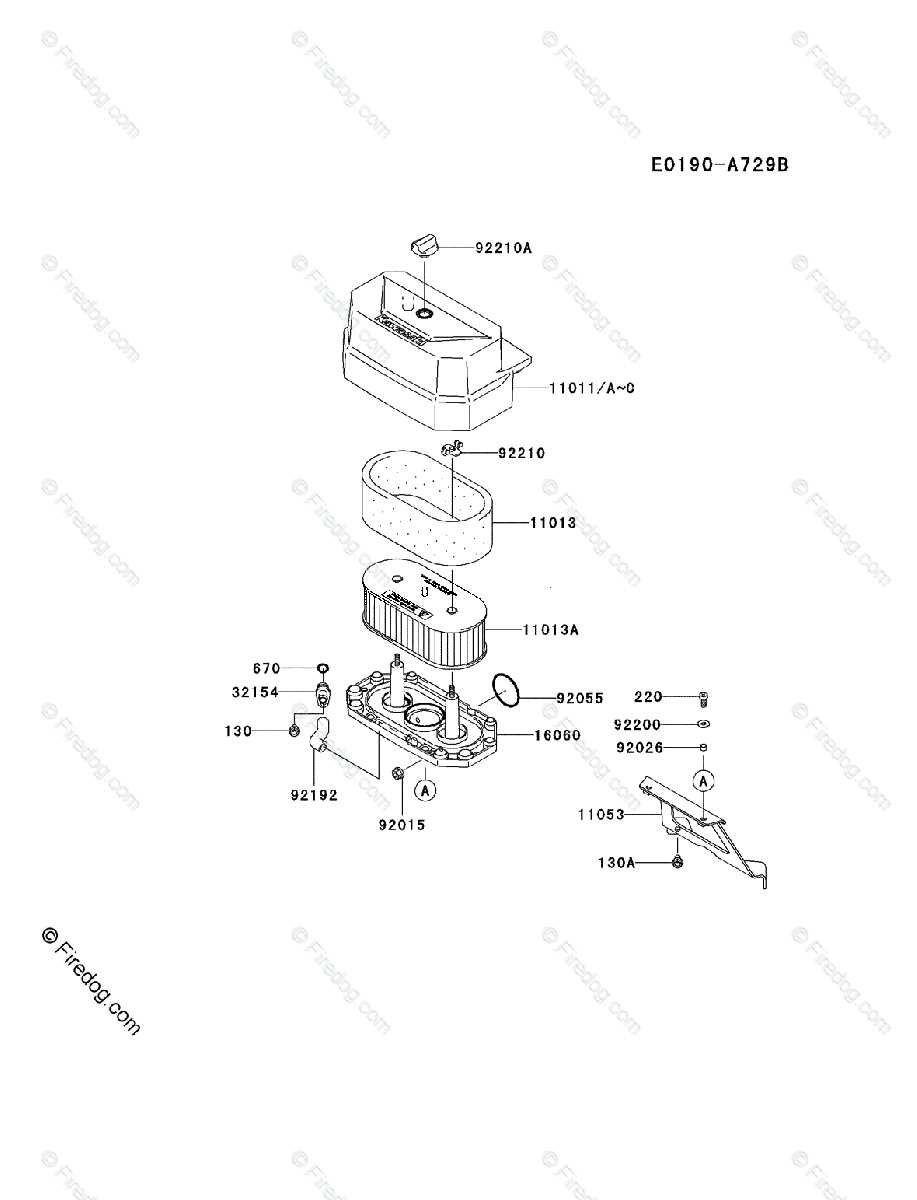

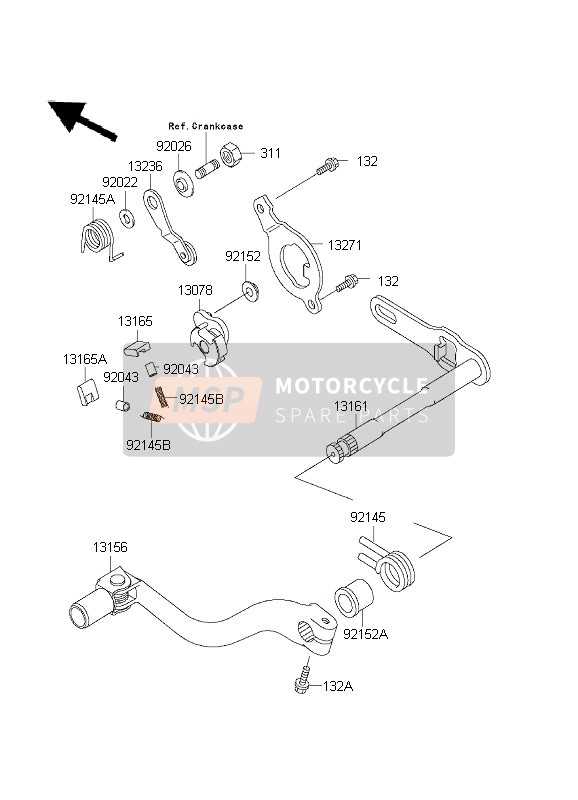

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visual guides provide a detailed overview of components and their relationships within a system, allowing users to identify specific items and their functions. By mastering the art of interpreting these visuals, you can streamline your repair processes and ensure accuracy in parts identification.

To successfully navigate these illustrations, familiarize yourself with the symbols and notations used. Each element often corresponds to a specific component, and accompanying legends may clarify their meanings. The following table outlines key elements to consider:

| Element | Description |

|---|---|

| Symbols | Represent various components, such as gears or bolts. |

| Lines | Indicate connections or relationships between elements. |

| Numbers | Refer to item codes or specific parts lists for ordering. |

| Legends | Provide explanations for symbols and additional details. |

By developing a keen eye for these aspects, you will enhance your ability to effectively use technical illustrations in your maintenance and repair tasks.

Comparing Genuine vs. Aftermarket Parts

When maintaining machinery, the choice between original components and their alternatives can significantly impact performance and longevity. Each option presents distinct advantages and disadvantages, influencing overall reliability and cost-effectiveness.

Original components are crafted by the manufacturer and typically offer a perfect fit and high quality. They often come with warranties, providing peace of mind regarding durability and performance. However, this assurance comes at a higher price point, which can be a considerable factor for budget-conscious consumers.

On the other hand, alternative components can be more affordable and readily available. Many aftermarket options are designed to meet or exceed the specifications of the originals. However, variability in quality exists, and some may not perform as reliably over time. It is crucial to conduct thorough research to ensure that the chosen replacements will not compromise the machine’s performance.

Ultimately, the decision hinges on individual priorities, including budget, quality expectations, and the specific application. Weighing these factors can help users make an informed choice that aligns with their needs.

Essential Tools for Repairs

Having the right equipment at hand is crucial for effective maintenance and repair tasks. A well-equipped workspace not only enhances efficiency but also ensures that repairs are carried out safely and accurately. Below are some of the fundamental tools you should consider having for any repair job.

- Wrenches: A variety of wrenches, including adjustable and socket types, are essential for loosening and tightening bolts and nuts.

- Screwdrivers: A set of both flathead and Phillips screwdrivers in various sizes will help in handling different screws.

- Pliers: Needle-nose and standard pliers are useful for gripping, bending, and cutting wires or small parts.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

Additionally, some other tools can significantly enhance your repair experience:

- Multimeter: Essential for electrical diagnostics, it helps in measuring voltage, current, and resistance.

- Safety Gear: Always prioritize safety by using gloves, goggles, and ear protection as needed.

- Lubricants: Keep various lubricants available to reduce friction and prevent wear on moving parts.

- Flashlight: A reliable light source is important for visibility in dark or cramped spaces.

Equipping yourself with these essential tools will not only streamline your repair process but also help you tackle a wide range of tasks with confidence.

Step-by-Step Repair Process

Repairing small engines can seem daunting, but with a clear guide, the task becomes manageable. This section will outline a systematic approach to restoring functionality, ensuring that you tackle each stage efficiently and effectively.

1. Gather Your Tools: Before you start, assemble all necessary tools and equipment. This will streamline the process and minimize interruptions.

2. Review the Manual: Consult the owner’s manual for specific instructions and troubleshooting tips related to your engine model. This resource is invaluable for understanding its components.

3. Disassemble the Engine: Carefully take apart the engine, keeping track of each piece. Organize parts in a manner that facilitates reassembly, using labeled containers if needed.

4. Inspect Each Component: Examine all parts for signs of wear or damage. Pay close attention to critical components that may require replacement or repair.

5. Clean Thoroughly: Remove any dirt, debris, or buildup from components. A clean surface ensures better performance and longevity of the engine.

6. Replace Damaged Parts: Use quality replacement components that match the specifications outlined in the manual. Proper fit is crucial for optimal function.

7. Reassemble the Engine: Carefully put the engine back together, following the reverse order of disassembly. Ensure that all parts are securely fastened.

8. Test the Engine: Once reassembled, conduct a thorough test to ensure everything operates smoothly. Address any issues immediately to avoid further complications.

9. Regular Maintenance: Establish a maintenance routine to keep the engine in top shape. Regular checks can prevent future breakdowns and extend its lifespan.

FAQs about Kawasaki FH430V

This section addresses common inquiries related to a specific engine model widely used in various outdoor equipment. Below are frequently asked questions that provide clarity on its features, maintenance, and troubleshooting.

- What is the recommended maintenance schedule?

- Regular oil changes every 50 hours of operation.

- Inspect and clean the air filter every 25 hours.

- Check the spark plug condition at the beginning of each season.

- How do I identify issues with the engine?

- Look for unusual noises during operation.

- Monitor for any leaks or excessive smoke.

- Check for vibrations that are out of the ordinary.

- What type of fuel is recommended?

- Use clean, unleaded gasoline with an octane rating of 87 or higher.

- Avoid fuels with more than 10% ethanol content.

- Where can I find replacement components?

- Authorized dealers often carry genuine replacement items.

- Online retailers provide a variety of aftermarket options.

- How can I enhance the performance?

- Regularly service the engine to keep it in top condition.

- Ensure proper air and fuel flow by maintaining filters.

- Use high-quality lubricants for optimal performance.

User Experiences and Reviews

This section explores the insights and feedback from individuals who have engaged with specific equipment components. Real-life encounters provide valuable perspectives on performance, durability, and overall satisfaction.

Users often share their thoughts on various aspects, including:

- Ease of installation

- Reliability in different conditions

- Comparative performance with alternative models

- Maintenance and service requirements

Many reviews highlight both positive experiences and areas for improvement, offering a well-rounded view. For instance, some users praise the efficiency and longevity, while others note challenges faced during setup.

- Efficiency: A common theme in reviews is enhanced productivity.

- Durability: Users frequently emphasize the robustness of components.

- Support: The availability of customer service is often highlighted.

Ultimately, gathering these insights allows potential buyers to make informed decisions based on collective experiences.

Resources for Further Learning

Exploring intricate machinery can be a rewarding experience, especially when you have access to valuable educational materials. Whether you are seeking in-depth technical knowledge or practical guidance, a variety of resources are available to enhance your understanding of engine components and their functionalities.

Online Tutorials and Videos

Video platforms and dedicated websites offer a wealth of tutorials that cover everything from basic maintenance to advanced repair techniques. These visual aids can provide step-by-step instructions, making complex processes easier to grasp.

Manuals and Technical Publications

Comprehensive manuals and technical documents serve as excellent references for those looking to deepen their expertise. They typically include detailed information about specifications, maintenance schedules, and troubleshooting tips, ensuring you have the right tools and knowledge at your disposal.