Kawasaki FH721V Parts Diagram Guide

In the realm of small engine maintenance, comprehending the intricate layout of various elements is essential for efficient operation and repair. A clear representation can significantly enhance the troubleshooting process, enabling users to identify and address issues swiftly.

These visual guides serve as invaluable resources, offering insights into the arrangement and functionality of each part. By delving into these illustrations, one can gain a better understanding of how different components interact, leading to more effective upkeep.

For enthusiasts and professionals alike, having access to detailed schematics ensures that all necessary components are accounted for during maintenance or replacement. This knowledge not only fosters improved performance but also contributes to the ultimate longevity of the machinery.

Kawasaki FH721V Overview

This section provides an insightful look into a powerful engine model known for its reliability and efficiency in various applications. Designed to meet the demands of both residential and commercial users, it combines performance with durability.

Key features include:

- Robust construction for longevity

- High-performance capabilities suitable for tough tasks

- Efficient fuel consumption for cost savings

Applications often include:

- Lawn care equipment

- Landscaping machinery

- Industrial tools

This engine stands out in its category, providing the ultimate combination of power and efficiency, making it a preferred choice for many users. Understanding its components and functionality is crucial for optimal performance and maintenance.

Key Features of FH721V Engine

The engine in question is renowned for its exceptional performance and reliability in various applications. Designed to meet the demands of both commercial and residential use, it combines advanced technology with robust engineering to deliver outstanding results.

Power Output: This power unit boasts a significant horsepower rating, ensuring it can handle a variety of tasks with ease. Its ability to deliver consistent torque at different RPMs makes it versatile for numerous settings.

Fuel Efficiency: With a focus on reducing fuel consumption, this engine incorporates features that optimize combustion efficiency. This not only minimizes operating costs but also lowers emissions, making it an environmentally friendly choice.

Durability: Constructed from high-quality materials, the engine is built to withstand rigorous use. Its robust design contributes to longevity, reducing the need for frequent maintenance and repairs.

Easy Maintenance: Designed with user convenience in mind, this engine allows for straightforward maintenance procedures. Accessible components ensure that users can perform routine checks and services with minimal effort.

Advanced Cooling System: The innovative cooling mechanism effectively manages temperature, preventing overheating during prolonged operation. This feature enhances overall performance and reliability.

Noise Reduction: This unit incorporates sound-dampening technology, making it quieter during operation. This is particularly beneficial in residential areas where noise levels are a concern.

In summary, the engine’s combination of power, efficiency, durability, and user-friendly features makes it an excellent choice for various applications, from landscaping to commercial equipment.

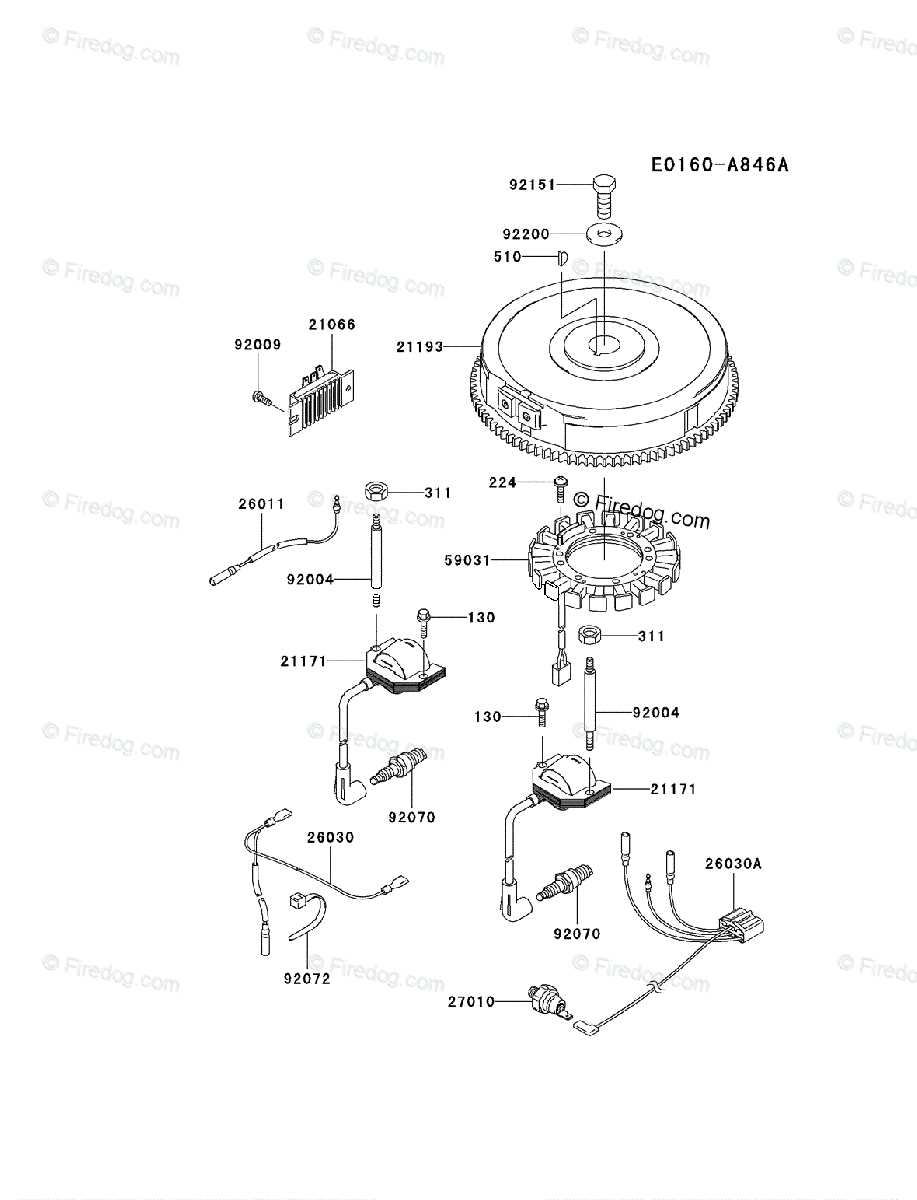

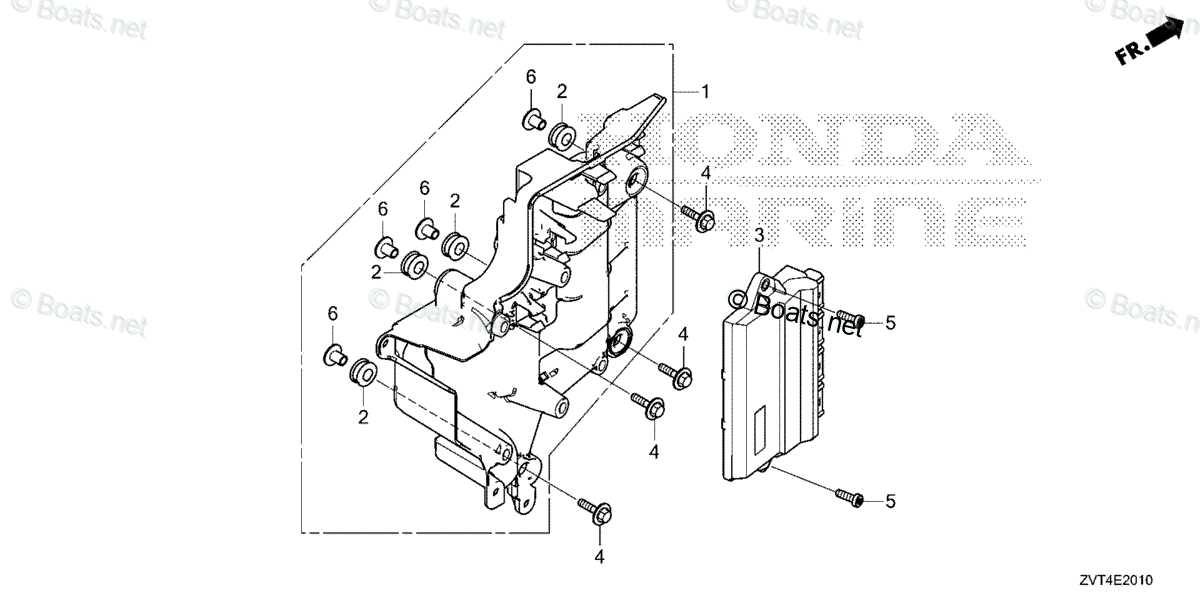

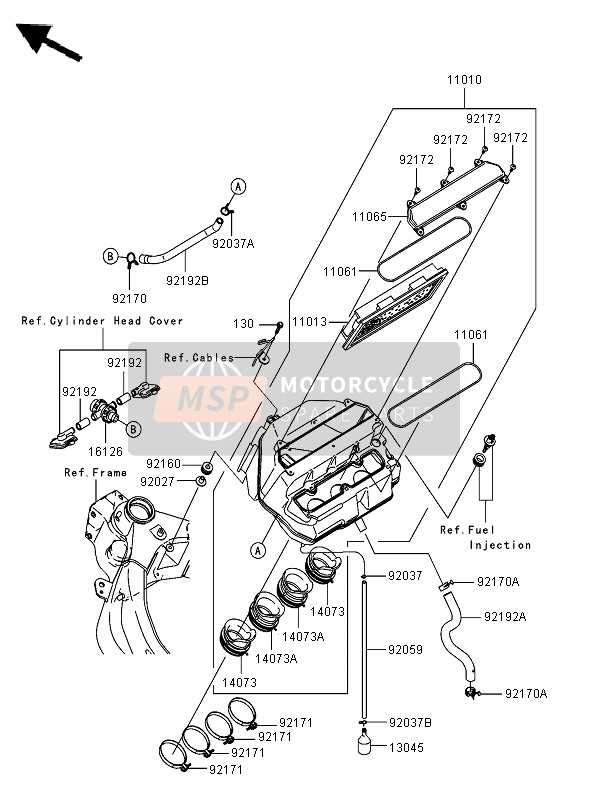

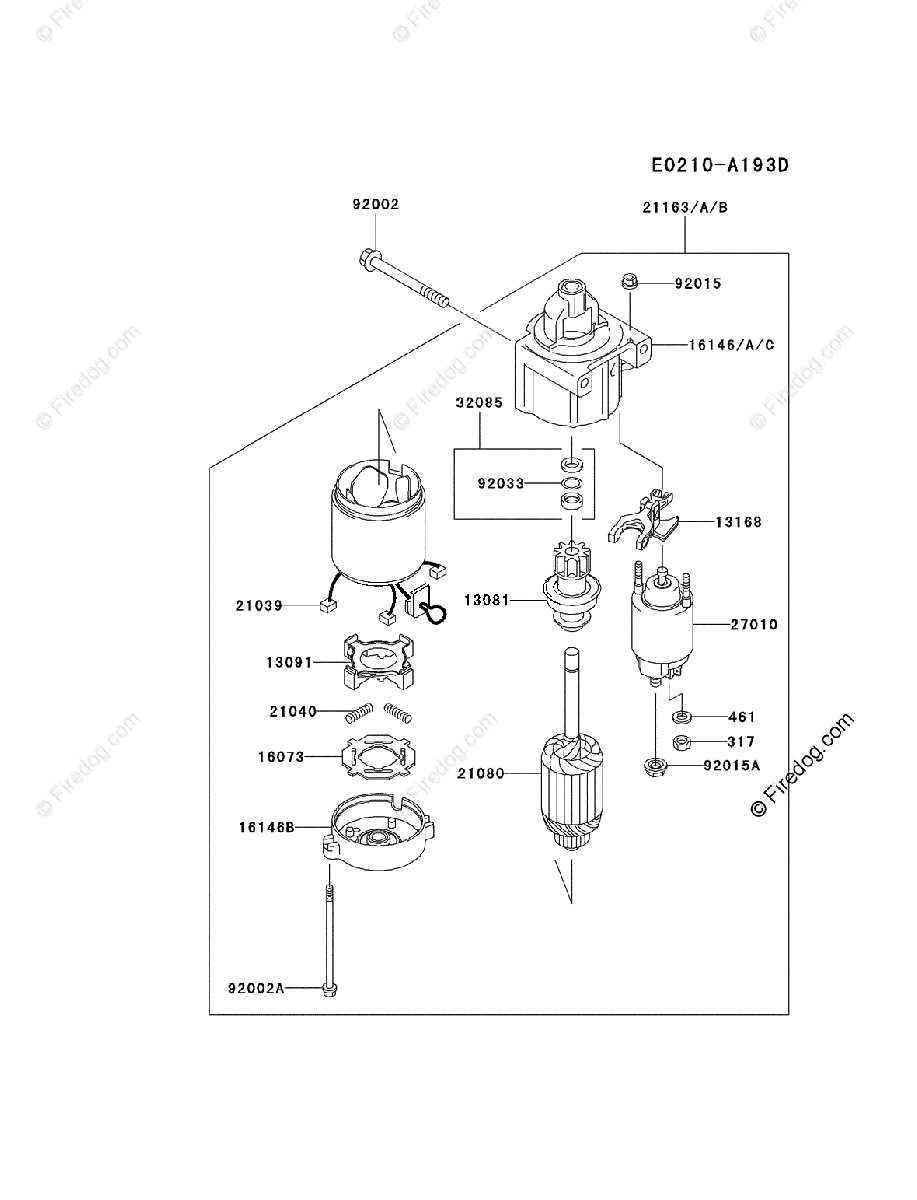

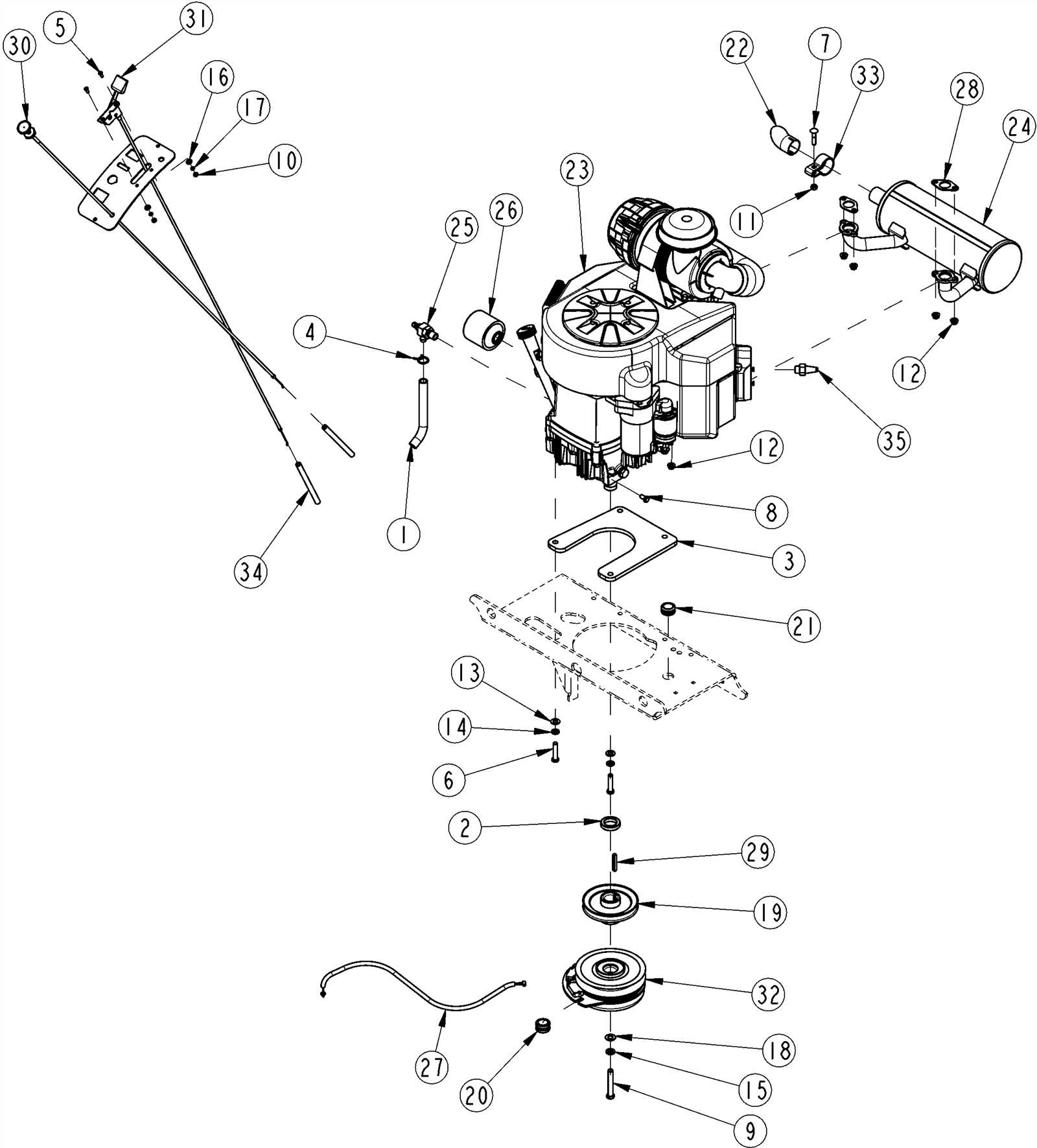

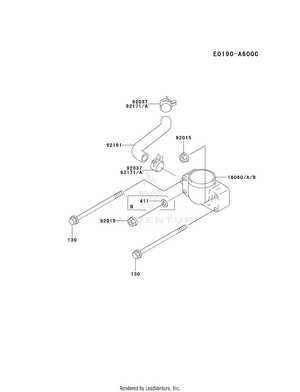

Understanding Parts Diagrams

Grasping the intricacies of component illustrations is essential for anyone involved in maintenance and repair tasks. These visual aids serve as invaluable resources, providing detailed insights into the various elements that constitute a machine. By deciphering these representations, users can effectively identify parts, understand their relationships, and facilitate smoother assembly or disassembly processes.

Benefits of Using Illustrations

Component visualizations enhance comprehension by clearly depicting how individual parts fit together. They reduce ambiguity and guide users in locating specific items, making troubleshooting and replacement more efficient. Additionally, these illustrations often include annotations that offer critical information regarding part numbers and specifications.

Interpreting Visual Aids

To maximize the utility of these representations, it’s crucial to familiarize oneself with the symbols and layout commonly used. Understanding the orientation, grouping, and connectivity of elements can significantly streamline repair efforts. Below is a table outlining common symbols found in these visual tools:

| Symbol | Description |

|---|---|

| Fastener | |

| ⚙️ | Gear |

| Tool Required | |

| Rotational Part |

Common Components in FH721V

This section explores the essential elements found in the engine model, highlighting their functions and significance in overall performance. Understanding these components helps in maintenance and troubleshooting, ensuring optimal operation.

Key Elements

- Engine Block: The core structure housing critical internal components.

- Cylinder Head: Plays a vital role in the combustion process.

- Piston: Translates fuel energy into mechanical motion.

- Crankshaft: Converts linear motion from the piston into rotational force.

Supporting Components

- Fuel System: Delivers the necessary fuel mixture for combustion.

- Ignition System: Initiates the combustion process efficiently.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

Maintenance Tips for Kawasaki Engines

Regular upkeep is essential for ensuring the longevity and performance of small power units. By following a few key practices, you can enhance efficiency and minimize the risk of breakdowns. Understanding how to care for your equipment will ultimately lead to better results and prolonged service life.

1. Regular Oil Changes: Changing the lubricant at recommended intervals helps to keep internal components clean and lubricated, reducing wear.

2. Air Filter Maintenance: Inspect and clean or replace the air filter periodically to ensure proper airflow, which is crucial for optimal combustion and performance.

3. Spark Plug Inspection: Regularly check the spark plug for wear or deposits. A clean spark plug improves ignition and fuel efficiency.

4. Fuel System Care: Use fresh fuel and consider adding a fuel stabilizer to prevent deterioration and keep the system free from contaminants.

5. Cooling System Check: Ensure that the cooling system is functioning properly to avoid overheating. Clean any debris from cooling fins and check coolant levels.

6. Regular Inspections: Perform routine checks on belts, hoses, and connections to catch potential issues before they escalate.

By adhering to these maintenance guidelines, you will significantly enhance the reliability and effectiveness of your power equipment.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as guides, helping users identify various elements and their interconnections, ultimately streamlining the troubleshooting process.

Familiarize Yourself with the Key

Before diving into the visuals, take a moment to study the legend. The key provides crucial information about symbols and numbering, making it easier to decipher the layout. Knowing what each icon represents enhances your ability to navigate the illustration effectively.

Follow the Flow of Assembly

Observe how components are arranged in relation to one another. This sequential layout often reflects the assembly process, allowing you to understand how parts interact. Pay attention to groupings and connections, as they indicate where each piece fits in the overall system.

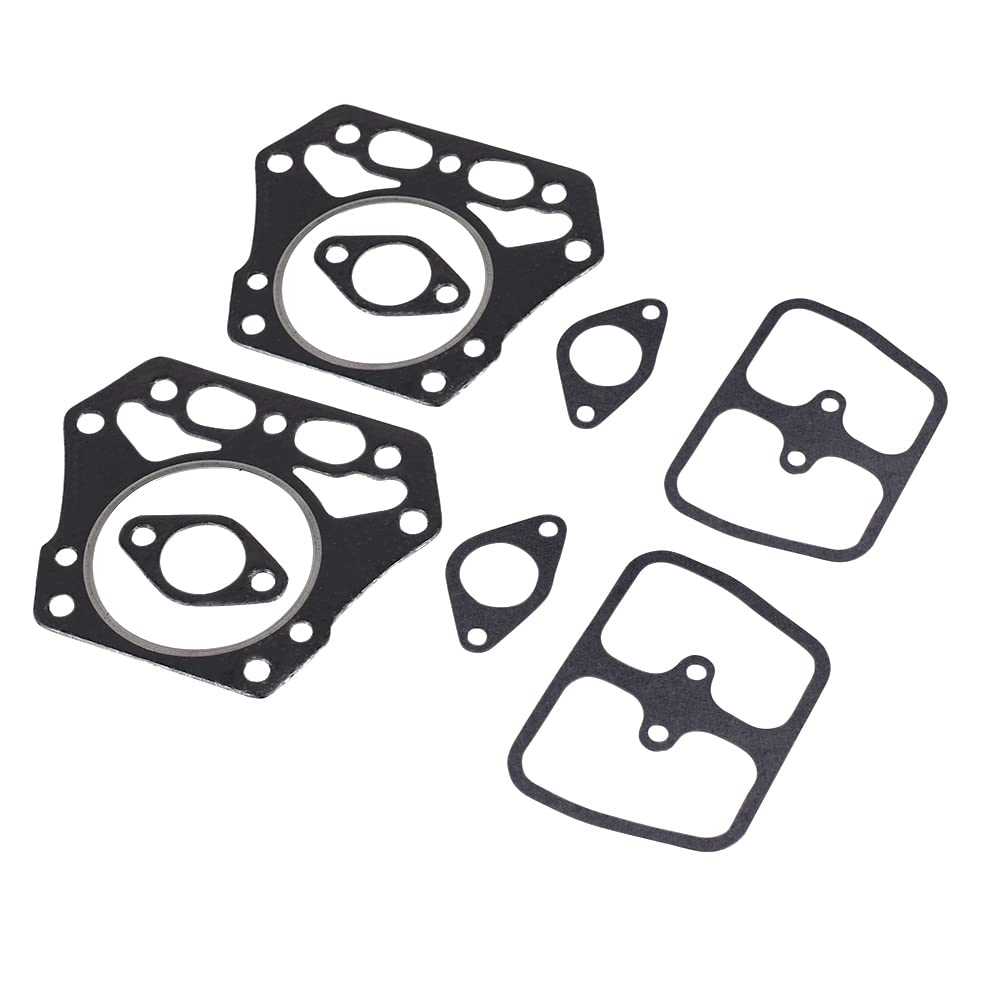

Importance of Genuine Parts

When it comes to maintaining and enhancing machinery, the choice of components plays a crucial role in ensuring optimal performance and longevity. Utilizing authentic replacements is essential for achieving the best results, as these items are specifically designed to fit and function seamlessly within the system.

Quality Assurance: Authentic components undergo rigorous testing and quality checks, guaranteeing that they meet high standards. This commitment to excellence translates to reliable operation and reduced risk of failure, which can lead to costly repairs or downtime.

Compatibility: Genuine replacements are engineered to match the specifications of the original machinery. This precise compatibility minimizes the likelihood of issues arising from improper fit or performance, ensuring smooth and efficient operation.

Warranty Protection: Many manufacturers provide warranties that only apply when original components are used. By choosing authentic items, users not only secure their investment but also gain peace of mind, knowing that they are protected against potential defects or malfunctions.

Long-Term Savings: While imitation parts may appear to offer immediate cost savings, they often lead to increased maintenance expenses and shorter lifespans. Investing in genuine items can yield greater financial benefits over time through enhanced durability and performance.

In summary, selecting authentic components is vital for the reliability, efficiency, and overall success of machinery. Prioritizing quality not only supports optimal functioning but also safeguards long-term investments.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process when you know where to look. Numerous resources are available, ranging from online retailers to local dealerships, ensuring you can find the necessary items to keep your machinery in top condition.

Online marketplaces often offer a wide selection, allowing you to compare prices and availability easily. Additionally, specialized websites dedicated to machinery provide detailed catalogs that can help you identify the right components for your needs.

If you prefer a more personal touch, visiting local dealers or repair shops can be beneficial. These establishments typically have knowledgeable staff who can assist you in finding the exact items you require, often with the added advantage of immediate availability.

Lastly, don’t overlook community forums and social media groups focused on machinery enthusiasts. These platforms can be invaluable for recommendations and even second-hand options from fellow users.

Popular Aftermarket Options Available

Exploring the realm of replacement components reveals a plethora of choices designed to enhance performance and reliability. Enthusiasts often seek alternatives that not only meet quality standards but also provide improved durability and efficiency. These options can significantly affect the overall functionality and longevity of your equipment.

Among the favored selections are high-performance filters, which ensure optimal airflow and filtration, contributing to better engine health. Additionally, heavy-duty belts are popular for their resistance to wear and ability to handle increased loads, making them ideal for demanding applications. Moreover, upgraded ignition systems can lead to enhanced responsiveness and smoother operation, appealing to those who prioritize performance.

When considering aftermarket options, it’s essential to focus on reputable brands that offer warranties and positive reviews. This ensures that the chosen components align with the expectations for quality and performance, providing peace of mind in every use.

Common Issues with FH721V Parts

In the realm of small engine maintenance, various components can present challenges that affect performance and longevity. Understanding these frequent concerns can help in diagnosing problems efficiently and ensuring smooth operation. Whether it’s wear and tear or compatibility issues, recognizing the signs early can save time and resources.

1. Overheating: A prevalent issue often arises from inadequate cooling mechanisms. This can lead to engine stress, resulting in decreased efficiency and potential damage. Regular checks of the cooling fins and ensuring proper airflow are crucial.

2. Fuel System Blockages: Accumulation of debris or old fuel can hinder the flow, causing stalling or poor acceleration. Regularly cleaning fuel lines and filters is essential to maintain optimal fuel delivery.

3. Electrical Failures: Issues with wiring or connectors can disrupt the ignition system, leading to starting problems. Inspecting electrical connections for corrosion or wear can prevent these interruptions.

4. Wear and Tear: Regular usage can lead to degradation of various components, including seals and gaskets. Periodic replacement of these items can prevent leaks and maintain engine integrity.

5. Vibration Damage: Excessive vibrations can cause loose fittings or misalignments, impacting overall performance. Ensuring that all components are securely fastened can mitigate this risk.

Being aware of these common challenges can help in maintaining efficiency and prolonging the life of the engine. Proactive maintenance and timely interventions are key to preventing minor issues from escalating into major repairs.

Assembly Instructions for Key Components

This section provides a comprehensive guide for assembling essential elements of a small engine system. Following these instructions will ensure that each part is correctly positioned and securely fastened, leading to optimal performance and longevity.

Preparation of Components

Before beginning the assembly, gather all necessary components and tools. It is vital to inspect each part for any damage or defects. Clean surfaces where components will be joined to ensure a proper fit. Lay out the items systematically to facilitate an organized assembly process.

Assembly Process

Start with the core components, aligning them according to the designated specifications. Utilize appropriate fasteners, ensuring they are tightened to the manufacturer’s recommended torque settings. Refer to the specific assembly order to avoid misalignment and ensure that all pieces fit together seamlessly. During this process, it’s important to check for any obstructions or interferences that may affect the functionality of the assembled unit.

Once the initial components are in place, proceed to attach secondary parts, such as linkage and covers. Double-check connections to ensure stability and security. A thorough inspection at each stage will help prevent issues later on.

Safety Precautions During Maintenance

When performing upkeep on machinery, adhering to safety measures is crucial to ensure both personal safety and the proper functioning of the equipment. By following these guidelines, operators can minimize risks and promote a secure working environment.

Personal Protective Equipment (PPE)

Wearing the appropriate protective gear is essential. This includes items such as gloves, safety goggles, and helmets, which help safeguard against potential hazards. Proper footwear should also be worn to provide traction and support during maintenance tasks.

Work Area Safety

Maintaining a clean and organized workspace significantly reduces the likelihood of accidents. Ensure that tools are stored properly, spills are cleaned promptly, and any obstructions are removed. It is also advisable to work in a well-ventilated area to prevent inhalation of harmful fumes.

| Safety Equipment | Purpose |

|---|---|

| Gloves | Protect hands from cuts and chemicals |

| Safety Goggles | Shield eyes from debris and splashes |

| Helmets | Guard against head injuries |

| Non-slip Footwear | Prevent slips and falls |

Benefits of Regular Engine Servicing

Maintaining a machine’s power source is crucial for ensuring its longevity and optimal performance. Routine check-ups and care can significantly enhance efficiency and reliability, leading to a smoother operation overall.

Enhanced Performance: Regular maintenance allows for the identification and resolution of potential issues before they escalate. This proactive approach keeps the engine running smoothly, ultimately improving its efficiency and responsiveness.

Increased Longevity: Just like any complex system, a well-cared-for engine tends to last longer. Consistent servicing helps prevent wear and tear, ensuring that components remain in top condition for extended periods.

Cost Savings: While some may view regular servicing as an expense, it can save money in the long run. Addressing minor problems early prevents them from developing into costly repairs or replacements.

Environmental Responsibility: A well-maintained engine operates more cleanly, reducing emissions and minimizing the environmental impact. Regular servicing contributes to a more sustainable operation.

Peace of Mind: Knowing that an engine is regularly serviced provides reassurance. This confidence allows users to focus on their tasks without worrying about unexpected breakdowns or performance issues.