Kubota BX2660 Parts Diagram for Easy Reference

In the realm of compact agricultural machinery, the intricate design and functionality of various models play a crucial role in enhancing productivity. Each unit is a combination of numerous elements, meticulously engineered to work in harmony. A comprehensive understanding of these components not only aids in maintenance but also in optimizing performance for a variety of tasks.

Exploring the layout of these systems is essential for both operators and technicians. By familiarizing oneself with the arrangement and interaction of parts, one can ensure that each element is functioning as intended. This knowledge serves as a foundation for effective troubleshooting and repairs, ultimately prolonging the life of the machinery.

In this discussion, we will delve into the various sections and configurations of a popular compact tractor model. Illustrations and guides provide invaluable insights into how these parts fit together, making it easier to identify and address any issues that may arise during operation. Whether you’re a seasoned professional or a newcomer, understanding the internal mechanics will enhance your efficiency and confidence in using this vital equipment.

Kubota BX2660 Overview

This section provides a comprehensive look at a versatile compact tractor designed for efficiency and functionality in various applications. With a blend of power and maneuverability, it caters to the needs of both residential and commercial users.

Key Features

The machine boasts a robust engine, offering reliable performance while maintaining fuel efficiency. Its compact design allows for easy navigation in tight spaces, making it ideal for landscaping and agricultural tasks. Additionally, a range of attachments can be utilized to enhance its versatility.

Performance and Usability

Users appreciate the intuitive controls and ergonomic design, which facilitate ease of operation. This equipment excels in both heavy-duty tasks and light maintenance, ensuring that it meets the demands of various projects efficiently.

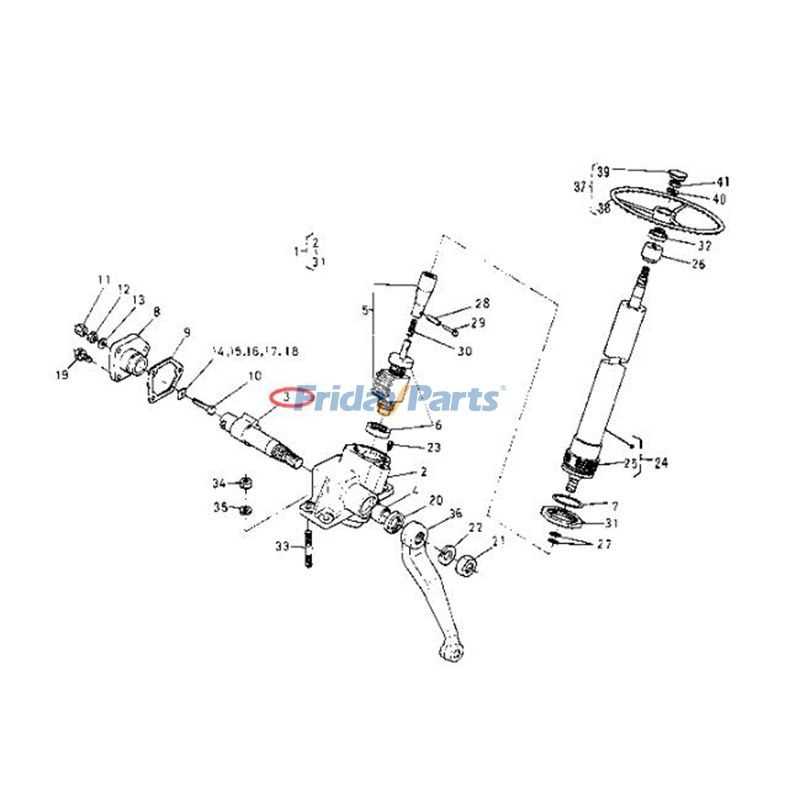

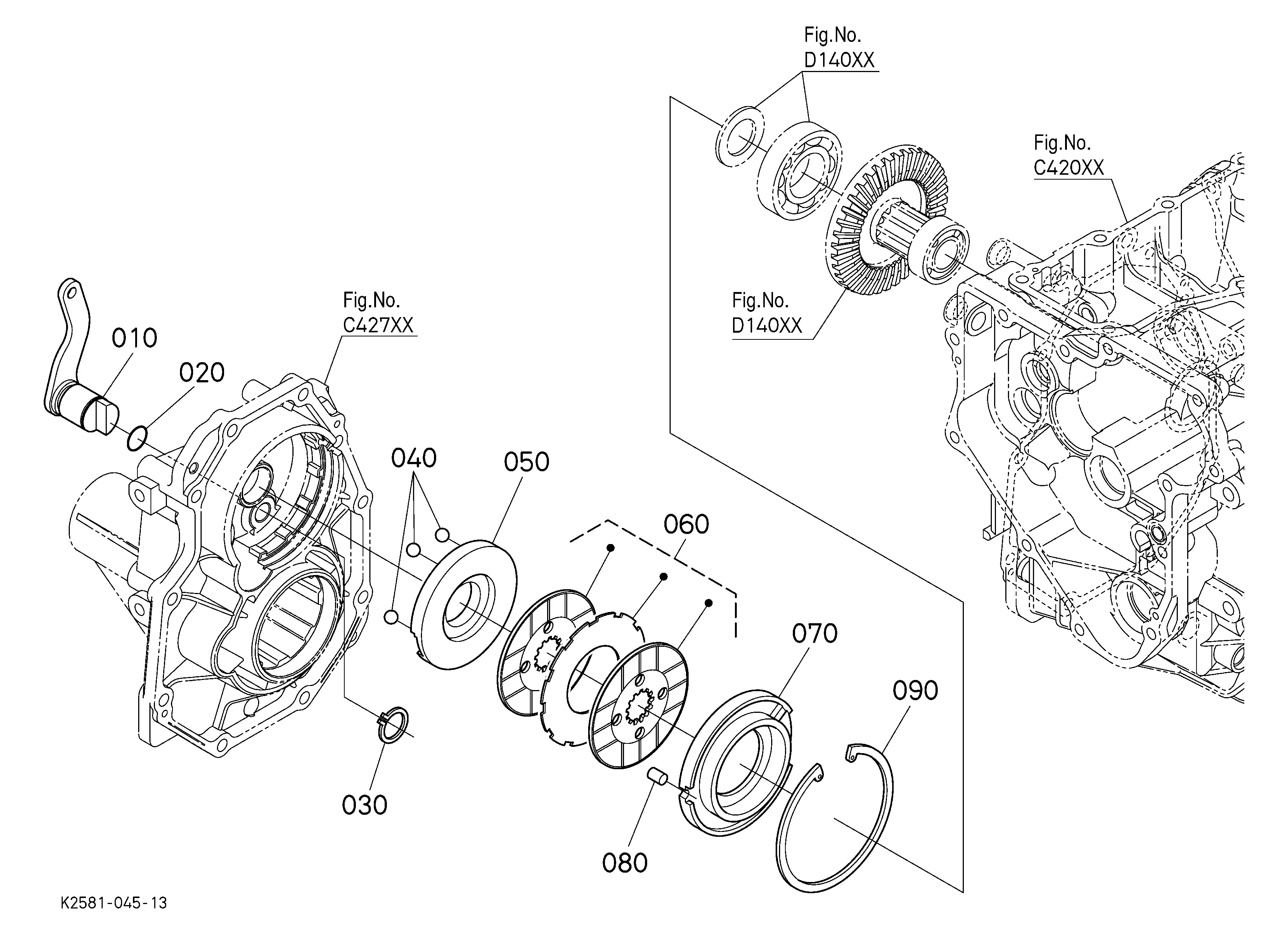

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations that detail each element provide valuable insight, enabling operators and technicians to identify issues quickly. These illustrations serve as a guide for disassembly and reassembly, ensuring that every part is correctly placed, which is vital for the equipment’s functionality.

Facilitating Repairs

When it comes to troubleshooting, having a clear visual reference can drastically reduce the time spent on identifying problems. Technicians can easily locate specific sections, allowing for swift action when addressing faults. This efficiency not only saves time but also minimizes the risk of further damage during repairs.

Enhancing Understanding

For those less familiar with the machinery, these visual aids enhance comprehension of complex systems. By breaking down the components into easily understandable sections, users can gain a better grasp of how the equipment operates. This knowledge empowers operators to perform basic maintenance tasks confidently, extending the life of the machinery.

Key Components of the BX2660

The effectiveness of a compact utility vehicle relies heavily on its essential elements, each designed to enhance performance and functionality. Understanding these critical components can help users optimize their experience and ensure proper maintenance.

Engine: The heart of the vehicle, providing the necessary power for various tasks. Its efficiency plays a vital role in overall performance.

Transmission: This system facilitates smooth gear shifts, allowing for adaptable speed control and improved handling on diverse terrains.

Hydraulic System: A crucial feature that enables various attachments to operate effectively, enhancing the vehicle’s versatility for different applications.

Chassis: The framework that supports the entire structure, ensuring stability and durability during operation.

Wheels and Tires: These elements are essential for traction and maneuverability, influencing the vehicle’s ability to navigate various landscapes.

By delving into these core components, users can achieve a deeper understanding of their vehicle’s capabilities and maintenance needs, ultimately enhancing their operational efficiency.

Common Repairs and Maintenance

Regular upkeep and timely repairs are essential for ensuring optimal performance and longevity of machinery. Understanding common issues and their solutions can help users maintain their equipment effectively, reducing downtime and enhancing efficiency.

Routine Maintenance Tasks

Routine maintenance typically includes checking fluid levels, changing filters, and inspecting belts and hoses for wear. Performing these tasks on a regular schedule can prevent more significant problems and keep machinery running smoothly.

Common Repairs

Frequent repairs may involve addressing hydraulic leaks, replacing worn-out tires, or fixing electrical components. Identifying these issues early can lead to simpler and less costly fixes, ultimately extending the life of the equipment.

Where to Find Parts Diagrams

Finding the right illustrations for components can significantly enhance your repair and maintenance efforts. These visual references help ensure you understand the layout and functionality of each part, allowing for effective troubleshooting and replacements.

Online Resources

The internet offers a plethora of websites dedicated to machinery and equipment, where you can access detailed illustrations. Many manufacturers provide downloadable resources directly on their official platforms, ensuring you have the most accurate and up-to-date information.

Community Forums and Groups

Engaging with fellow enthusiasts in online communities can be invaluable. These forums often feature shared resources, including visuals and personal insights that can lead you to the specific references you need. Don’t hesitate to ask for help; experienced members are usually eager to assist.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures compatibility, quality, and performance. These items are specifically designed for particular machinery, enhancing overall efficiency and longevity. When opting for such products, users can expect a seamless integration that aftermarket alternatives often fail to provide.

| Advantage | Description |

|---|---|

| Quality Assurance | Manufactured to strict standards, ensuring reliability and durability. |

| Optimal Performance | Designed to work perfectly with the original system, maximizing efficiency. |

| Warranty Protection | Often covered by warranties, providing peace of mind for users. |

| Long-Term Savings | Reduce the need for frequent replacements, ultimately saving money. |

Understanding the BX2660 Engine

The engine serves as the heart of any machinery, providing the necessary power and performance to accomplish various tasks efficiently. In this section, we will explore the essential features and functionalities of this specific engine model, highlighting its design and operational aspects.

Key Specifications

Examining the critical specifications can help users appreciate the capabilities of the engine. Below is a summary of its main features:

| Specification | Details |

|---|---|

| Type | 4-cycle, liquid-cooled |

| Displacement | 1.1 liters |

| Power Output | 25 horsepower |

| Torque | 50 Nm |

| Fuel Type | Diesel |

Operational Efficiency

This engine is designed for optimal performance and reliability. Its advanced technology ensures efficient fuel combustion and minimal emissions, making it suitable for various tasks while adhering to environmental standards. Users can expect longevity and low maintenance needs, allowing for consistent productivity over time.

Hydraulic System Essentials

The hydraulic system is a crucial component in many modern machinery, playing a significant role in enhancing performance and efficiency. By utilizing pressurized fluid, this system allows for the transmission of power to various implements, facilitating smooth and effective operations.

Key elements of hydraulic systems include pumps, cylinders, valves, and reservoirs. Each component works in harmony to convert mechanical energy into hydraulic energy, which is then used to execute tasks such as lifting, pushing, or steering. Understanding the functionality of these parts is essential for optimal performance and maintenance.

Pumps serve as the heart of the system, generating the necessary pressure to circulate fluid throughout the network. Without a reliable pump, the entire system’s efficiency would be compromised. Cylinders, on the other hand, are responsible for translating hydraulic energy back into mechanical movement, enabling various attachments to perform their designated functions.

Valves play a pivotal role in controlling fluid flow and directing pressure to specific components as needed. They ensure that the system operates smoothly and can be adjusted to meet varying operational demands. Lastly, the reservoir holds the hydraulic fluid, ensuring a steady supply to the system while also allowing for heat dissipation and air removal.

In summary, a comprehensive understanding of the hydraulic system’s components and their interrelationships is vital for anyone involved in machinery operation and maintenance. Proper attention to these elements can significantly enhance both performance and longevity.

Electrical System Insights

The electrical framework of compact machinery plays a crucial role in ensuring efficient operation and reliability. Understanding the components and their interconnections is essential for diagnosing issues and maintaining optimal performance.

Power Distribution: At the heart of the system lies the power distribution network, which channels electricity to various parts, including the ignition and lighting systems. Each element must be in harmony to prevent malfunctions.

Control Mechanisms: Various switches and sensors work together to manage the operation of electrical features. These control mechanisms are vital for user interaction and the overall functionality of the machine.

Maintenance Tips: Regular inspections of wiring and connections can help identify wear and tear. Keeping components clean and secure is essential for preventing electrical failures.

By delving into the intricacies of the electrical system, operators can enhance their understanding and improve the longevity of their machinery.

Implementing Attachments Effectively

Utilizing various implements can significantly enhance the efficiency and versatility of your machine. Understanding how to attach and operate these tools is crucial for maximizing productivity in different tasks. Proper implementation not only saves time but also ensures safety and optimal performance.

Choosing the Right Attachment

It’s essential to select the appropriate implement based on the specific job requirements. Factors such as size, weight, and functionality should guide your decision. Research different options to find the ultimate match for your needs.

Best Practices for Operation

When using attachments, always adhere to recommended practices for installation and operation. Regular maintenance is key to longevity and effectiveness. Make sure to familiarize yourself with the operation manual to ensure safety and efficiency during use.

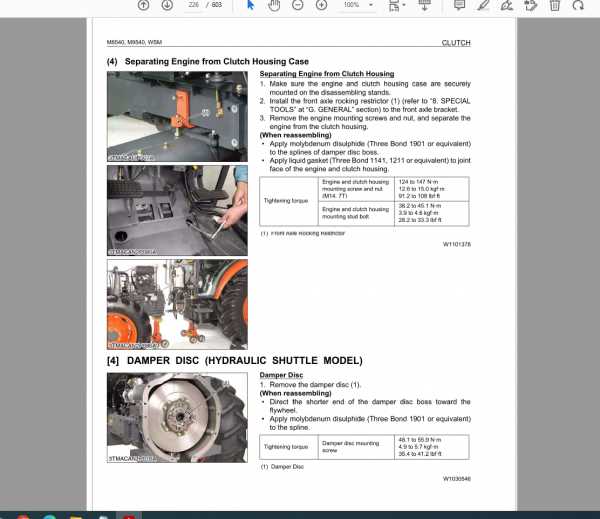

Step-by-Step Repair Guides

This section provides comprehensive guides to assist you in performing repairs on your machinery. By following these detailed instructions, you can effectively troubleshoot and resolve various issues, ensuring optimal performance and longevity.

Basic Maintenance Procedures

Advanced Repair Techniques

Troubleshooting Common Issues

When operating compact tractors, encountering problems can be a common experience for users. Understanding the typical issues that may arise, along with their potential solutions, can significantly enhance the efficiency and lifespan of the machine. This section will guide you through some frequent challenges and their remedies.

Starting Difficulties: If the engine fails to start, first check the battery for charge and connections. A faulty ignition switch or a blocked fuel line may also contribute to this issue. Ensure that the fuel is clean and that the air filter is not obstructed.

Hydraulic Problems: Insufficient hydraulic power can lead to performance issues. Inspect the hydraulic fluid level and look for leaks in hoses or fittings. Additionally, ensure that the filter is clean, as a clogged filter can restrict fluid flow.

Overheating: If the machine overheats, verify that the coolant levels are adequate. Inspect the radiator for debris or blockages that may hinder airflow. Regular maintenance of the cooling system is essential to prevent such occurrences.

Transmission Issues: Difficulty shifting gears can indicate low transmission fluid levels or worn components. Check the fluid condition and replace it if necessary. Pay attention to any unusual noises during operation, as they can signal deeper mechanical issues.

By proactively addressing these common issues, operators can maintain optimal performance and ensure their equipment operates smoothly for years to come.

Comparative Analysis with Other Models

This section explores the distinctions between a specific compact utility tractor and its competitors in the market. By examining various features, capabilities, and performance metrics, we aim to provide a clear understanding of how these machines stack up against one another.

- Performance: Evaluate horsepower, torque, and lifting capacity.

- Fuel Efficiency: Compare consumption rates and operational costs.

- Attachments: Assess compatibility with implements and ease of use.

- Maintenance: Discuss service intervals and part availability.

Each of these factors contributes significantly to the ultimate choice for users seeking efficiency and reliability in their equipment.