Kubota L2250 Parts Diagram Overview

When maintaining heavy equipment, a comprehensive grasp of its intricate parts is essential. This knowledge not only aids in effective repairs but also enhances overall performance and longevity. By delving into the structure of these machines, operators can ensure they are functioning at their best, minimizing downtime and maximizing productivity.

To achieve this, visual aids can be invaluable. They provide a clear representation of the various components, facilitating easier identification and understanding of how each piece contributes to the machine’s operation. Such illustrations serve as a crucial resource for both seasoned technicians and those new to machinery maintenance.

In this guide, we will explore detailed visual representations that highlight the essential elements of your equipment. This resource will empower you to troubleshoot issues, perform routine checks, and ultimately extend the lifespan of your agricultural investment.

This section provides a comprehensive overview of a specific agricultural machine, highlighting its significance in various farming operations. Understanding the main components and their functions can enhance maintenance practices and operational efficiency.

- Machine Description: A brief introduction to the equipment, including its capabilities and common applications in agriculture.

- Key Features: An outline of the primary features that distinguish this machinery from others, focusing on power, efficiency, and usability.

- Historical Context: Insight into the evolution of this type of equipment and its impact on modern farming techniques.

- Technical Specifications: A detailed list of specifications such as engine size, weight, and dimensions.

This foundational knowledge sets the stage for a deeper exploration of individual components and their configurations, facilitating better understanding and management of the machine.

Key Features of the L2250

This section highlights the essential characteristics of a compact agricultural machine designed for efficiency and reliability. Understanding these features can enhance user experience and performance in various farming tasks.

Powerful Engine: The machine is equipped with a robust engine that delivers optimal horsepower, making it suitable for a range of demanding applications.

Compact Design: Its compact structure allows for maneuverability in tight spaces, making it ideal for smaller farms or landscapes.

Versatile Attachments: The ability to utilize various implements increases its functionality, enabling users to tackle diverse agricultural tasks with ease.

Hydraulic System: An advanced hydraulic system enhances lifting capability, providing efficient operation for attachments and implements.

User-Friendly Controls: Intuitive controls simplify operation, allowing both novice and experienced users to navigate tasks effectively.

Durability: Built with high-quality materials, the machine is designed to withstand harsh working conditions, ensuring long-lasting performance.

Fuel Efficiency: The engine’s design promotes lower fuel consumption, helping to reduce operational costs over time.

Overall, these standout features contribute to a reliable and efficient tool for modern agricultural practices.

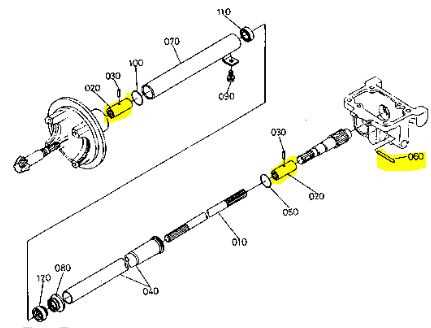

Understanding Parts Diagram Basics

Familiarizing oneself with the visual representation of mechanical components is essential for effective maintenance and repair. These illustrations serve as a guide, helping users identify each element and its function within the larger system.

Key Components of Visual Representations

- Labels: Clear naming conventions are crucial for easy identification.

- Numbers: Reference numbers often correlate with lists of components.

- Connections: Arrows or lines may indicate how elements are linked.

Benefits of Using Visual Guides

- Enhanced understanding of the overall assembly.

- Streamlined troubleshooting and repair processes.

- Improved communication among technicians and users.

Importance of Accurate Diagrams

Clear representations are essential in understanding complex machinery. They serve as vital tools for maintenance and troubleshooting, ensuring that users can effectively navigate the intricacies of mechanical systems.

Enhanced Understanding

Precise illustrations facilitate a better grasp of components and their relationships. When individuals can visualize how parts fit together, it reduces the risk of errors during assembly or repairs.

Streamlined Maintenance

Accurate schematics allow for efficient servicing and replacement of components. By providing clear references, they help technicians quickly identify issues and implement solutions, saving both time and resources.

| Benefit | Description |

|---|---|

| Clarity | Improves understanding of complex systems. |

| Efficiency | Reduces time spent on repairs. |

| Accuracy | Minimizes risk of assembly errors. |

Main Components of the L2250

Understanding the primary elements of this agricultural machine is crucial for effective operation and maintenance. Each part plays a significant role in the overall functionality, contributing to the efficiency and reliability expected from modern farming equipment.

Engine and Transmission

The heart of the vehicle lies in its engine, which powers all operations. Coupled with a robust transmission system, these components work together to deliver the necessary torque and speed for various tasks. The engine’s design ensures optimal fuel efficiency, while the transmission provides smooth gear shifts, enhancing maneuverability in diverse terrains.

Hydraulic System

A vital feature of this machine is its hydraulic system. This setup enables the lifting and manipulation of implements with ease. By utilizing hydraulic fluid, it generates the force needed for attachments, making it indispensable for tasks like plowing and lifting. Regular maintenance of this system ensures longevity and consistent performance.

Engine Specifications and Parts

This section delves into the vital components and characteristics of the power unit that drives the machinery. Understanding these elements is crucial for maintenance and optimal performance, ensuring longevity and efficiency in operation.

Key Specifications

The following table outlines essential specifications that define the engine’s capabilities, including horsepower, displacement, and fuel type. Familiarity with these metrics assists in making informed decisions regarding repairs and upgrades.

| Specification | Details |

|---|---|

| Horsepower | 22 HP |

| Displacement | 1123 cc |

| Cylinder Arrangement | Vertical, 3-cylinder |

| Fuel Type | Diesel |

| Cooling System | Liquid-cooled |

Major Components

Understanding the principal parts of the engine aids in troubleshooting and maintenance. Each element plays a vital role in the overall functionality and performance of the machinery.

| Component | Function |

|---|---|

| Cylinder Head | Houses the combustion chamber and valves |

| Crankshaft | Converts linear motion to rotational motion |

| Piston | Creates compression and power during combustion |

| Fuel Injector | Sprays fuel into the combustion chamber |

| Oil Pump | Distributes lubrication to engine components |

Transmission and Drive System

The transmission and drive system play a crucial role in the overall performance of agricultural machinery. These components work together to convert engine power into usable force, enabling efficient movement and operation across various terrains. Understanding their functions and interactions is essential for optimal maintenance and operation.

Key Components

The primary elements of the drive system include the gearbox, differential, and axles. Each part is designed to handle specific loads and facilitate smooth transitions of power. The gearbox, for instance, adjusts the torque and speed, while the differential allows for variations in wheel speed, particularly during turns.

System Efficiency

Maintaining the efficiency of the transmission and drive system is vital for enhancing the machine’s overall productivity. Regular inspection and timely replacement of worn-out components can prevent costly repairs and ensure reliable performance in the field.

| Component | Function |

|---|---|

| Gearbox | Modulates torque and speed |

| Differential | Facilitates wheel speed variation |

| Axles | Transfer power to the wheels |

Hydraulic System Elements Explained

The hydraulic system in machinery plays a crucial role in enabling efficient movement and power transfer. By utilizing fluid under pressure, it allows various components to work together seamlessly, providing enhanced performance and functionality. Understanding the key elements of this system is essential for anyone involved in maintenance or operation.

Pumps are the heart of the hydraulic system, responsible for generating flow and pressure. They convert mechanical energy into hydraulic energy, pushing fluid through the system to perform tasks such as lifting or pushing heavy loads.

Hydraulic Cylinders are pivotal components that translate hydraulic energy into linear motion. When pressurized fluid enters the cylinder, it moves a piston, creating force that can be harnessed for various applications.

Valves control the flow and direction of hydraulic fluid. By regulating pressure and ensuring that the fluid reaches the correct components, they play a vital role in maintaining system efficiency and safety.

Hoses and Fittings connect different parts of the system, ensuring that fluid can flow freely between components. They must be durable and resistant to high pressure to prevent leaks and failures.

Lastly, filters are essential for maintaining the cleanliness of hydraulic fluid. By removing contaminants, they help prolong the life of the system and prevent damage to other components.

Each element of the hydraulic system works in harmony, contributing to the overall effectiveness of machinery. A thorough understanding of these components is fundamental for optimal operation and maintenance.

Maintenance Tips for L2250

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. Proper maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some key practices to consider.

Routine Checks

Conducting frequent inspections is crucial. Focus on checking fluid levels, filters, and belts. Replace any worn components promptly to avoid further damage.

Cleaning and Lubrication

Keep all surfaces clean and free from debris. Regular lubrication of moving parts reduces friction and wear. This simple step can significantly extend the lifespan of your equipment.

Finding Replacement Parts Easily

Locating essential components for your machinery can be a daunting task, but with the right approach, it becomes manageable. Understanding how to efficiently search for these items not only saves time but also ensures you find high-quality replacements.

Steps to Simplify Your Search

- Identify the specific component you need.

- Consult the manufacturer’s resources or online platforms.

- Join forums and community groups for advice and recommendations.

Where to Look for Components

- Official dealer websites.

- Specialty online retailers.

- Local hardware stores that stock machinery supplies.

- Second-hand marketplaces for affordable options.

Common Issues and Troubleshooting

When working with machinery, encountering challenges is a common occurrence. Understanding the typical problems and knowing how to address them can significantly enhance performance and longevity. This section delves into prevalent issues and offers insights for effective troubleshooting.

Frequent Problems

| Issue | Possible Causes | Solutions |

|---|---|---|

| Starting Difficulty | Weak battery, fuel blockage | Check battery charge, inspect fuel lines |

| Overheating | Low coolant, clogged radiator | Inspect coolant levels, clean radiator |

| Unusual Noises | Worn components, loose fittings | Examine parts for wear, tighten connections |

Preventive Measures

Regular maintenance is crucial to avoid common issues. Scheduled inspections and timely replacements of worn parts can prevent significant downtime and costly repairs. Always refer to the user manual for specific maintenance guidelines to ensure optimal operation.

Resources for Repair Manuals

When it comes to maintaining and repairing machinery, having access to reliable documentation is essential. These manuals provide detailed instructions, schematics, and troubleshooting tips that can simplify the repair process and enhance overall efficiency. By leveraging these resources, operators and mechanics can ensure that they are equipped with the knowledge needed to perform tasks effectively.

Online Platforms

Numerous websites specialize in providing access to repair manuals. These platforms often feature searchable databases where users can find specific documents related to various machinery models. Some sites may require a subscription or a one-time purchase, while others offer free resources. Always ensure that the source is credible and that the manuals are up-to-date to avoid any discrepancies during repairs.

Community Forums

Online communities and forums can be invaluable resources for finding repair manuals and exchanging information. Enthusiasts and professionals alike share their experiences, often posting links to helpful documentation. Engaging with these communities can lead to valuable insights and recommendations, enhancing your ability to troubleshoot and repair equipment.