Kubota L4330 Parts Diagram for Easy Reference

The intricacies of machinery often lie within the details of their individual elements. A comprehensive grasp of these components not only enhances operational efficiency but also extends the lifespan of the equipment.

By exploring the various sections and configurations, operators can effectively identify and address potential issues before they escalate. This understanding fosters a proactive approach to maintenance and repairs, ultimately ensuring optimal performance.

Furthermore, having a clear visual representation of the internal structures can significantly simplify the repair process. Whether you are a seasoned mechanic or a novice, mastering these details equips you with the knowledge needed to navigate challenges with confidence.

Kubota L4330 Overview

This section provides a comprehensive look at a powerful and versatile machine designed for various agricultural and industrial tasks. Known for its efficiency and durability, this equipment is a favorite among professionals and enthusiasts alike.

Key Features

- Robust engine performance

- High lifting capacity

- User-friendly controls

- Compact design for maneuverability

Applications

- Farming operations

- Landscaping projects

- Construction tasks

- Property maintenance

Importance of Parts Diagrams

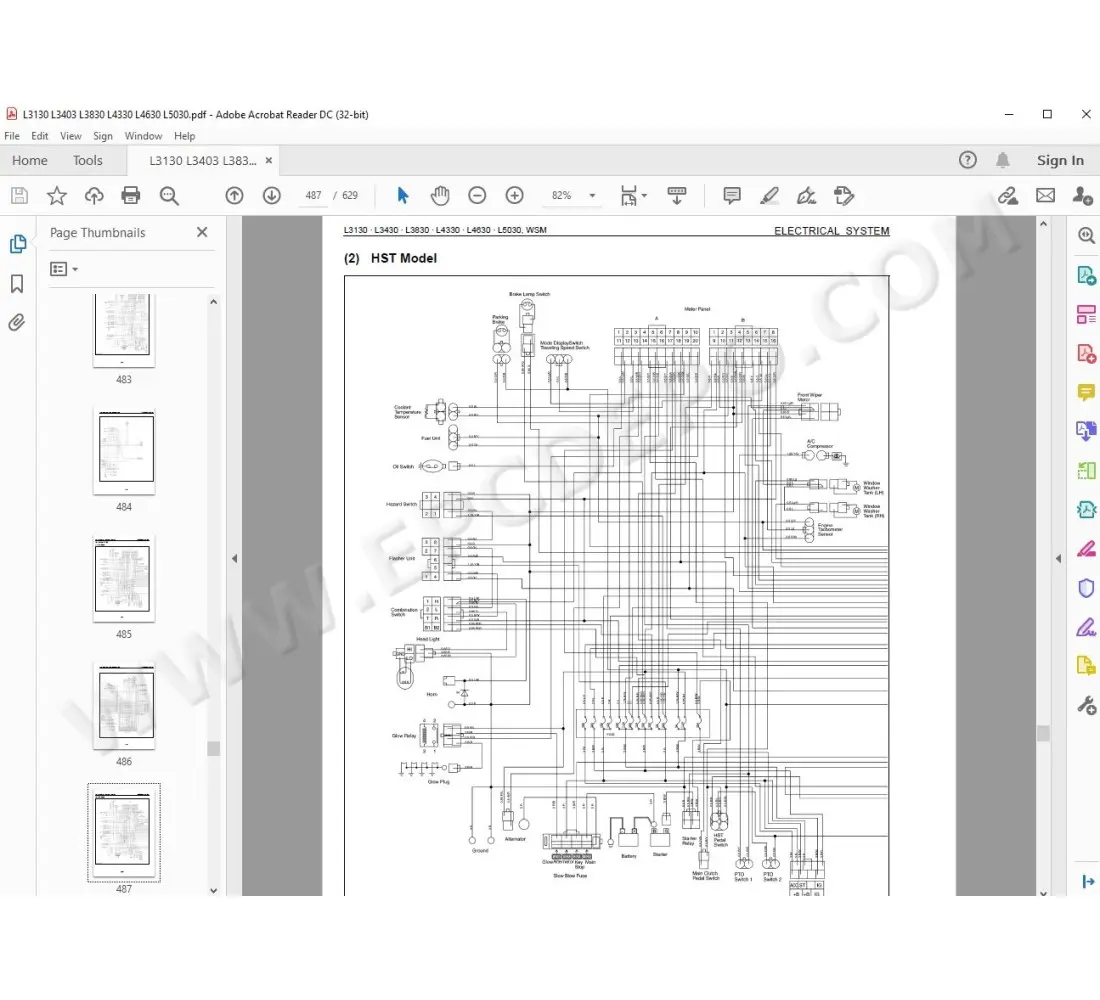

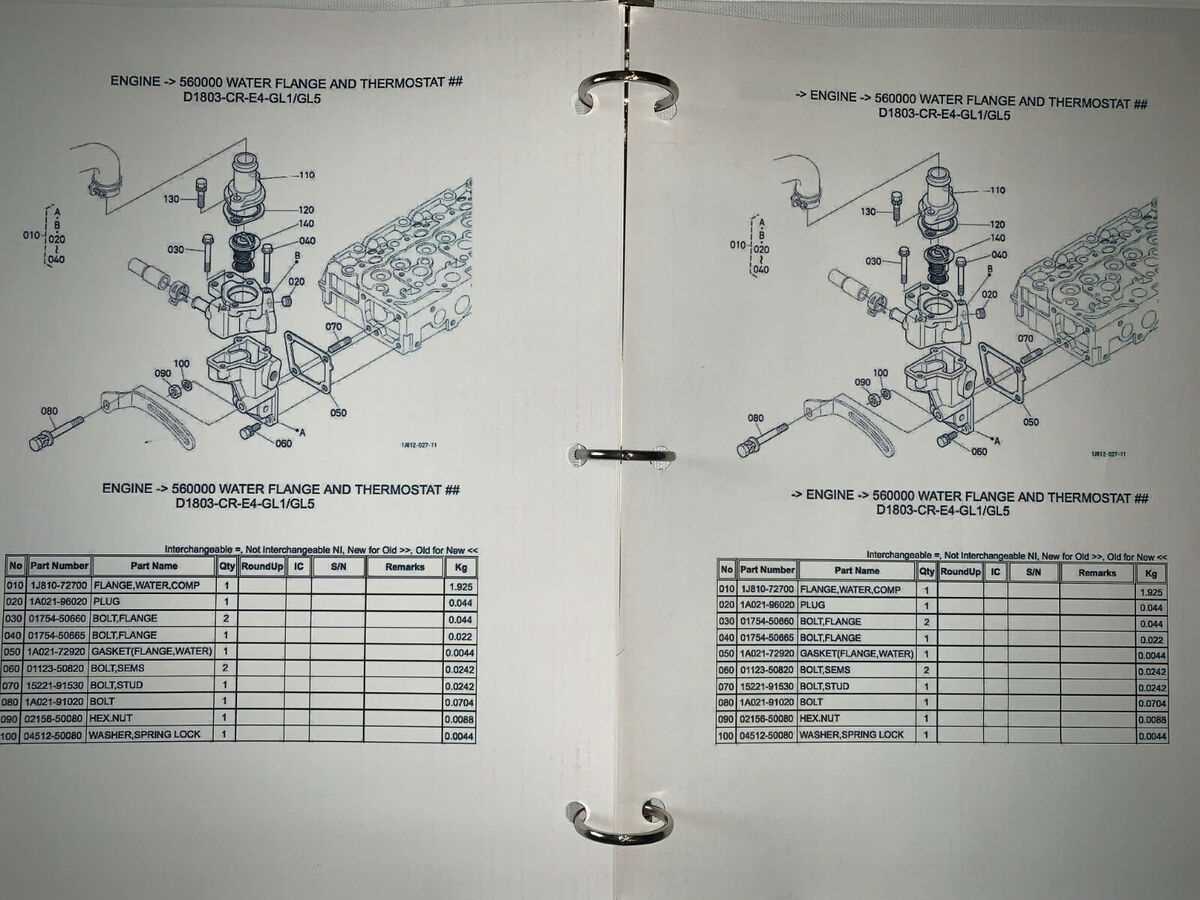

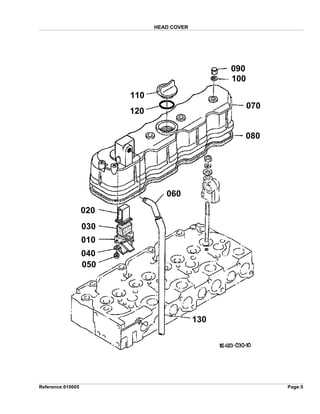

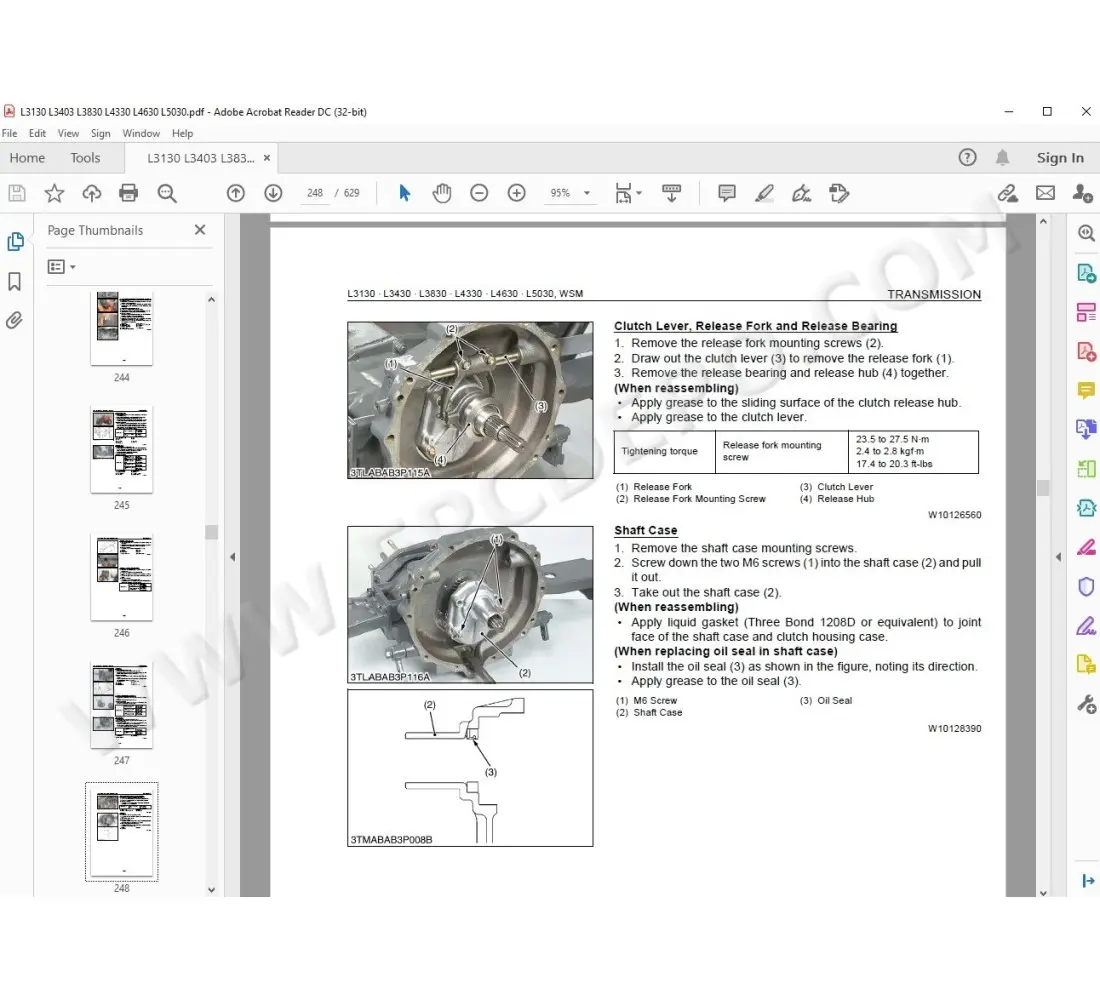

Understanding the layout and components of machinery is crucial for effective maintenance and repairs. Visual representations serve as essential tools that provide clarity on the various elements within a machine. By utilizing these illustrations, operators and technicians can quickly identify and locate specific items, ensuring efficient troubleshooting and replacement processes.

Enhanced Efficiency: Visual aids streamline the maintenance process by offering clear guidance on the arrangement and function of each component. This reduces the time spent searching for parts, allowing for quicker resolutions to mechanical issues.

Improved Communication: When discussing repairs with team members or suppliers, having a visual reference fosters better understanding. It enables all parties to be on the same page regarding which components are needed, minimizing the chances of errors.

Accurate Repairs: Detailed illustrations minimize the risk of incorrect installations. By providing precise information on how components fit together, these visual guides ensure that repairs are performed accurately, prolonging the lifespan of the machinery.

Learning Tool: For those new to machinery or specific models, visual representations serve as educational resources. They help users familiarize themselves with different components, enhancing their overall knowledge and confidence in handling equipment.

Common Issues with Kubota L4330

When operating heavy machinery, users often encounter a range of challenges that can affect performance and efficiency. Understanding these common problems is crucial for maintenance and troubleshooting, ensuring longevity and reliability of the equipment.

Hydraulic System Problems

A frequent concern involves the hydraulic system, where issues such as leaks or inadequate pressure can lead to decreased functionality. Regular checks and timely repairs can prevent significant operational downtime.

Engine Performance Issues

Another typical issue relates to engine performance, which may manifest as hard starting or reduced power. Keeping up with routine maintenance, such as oil changes and air filter replacements, is essential for optimal operation.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations provide a clear layout of various elements, helping users identify and locate specific items. Mastering this skill can significantly enhance your ability to address mechanical issues effectively.

Key Elements to Identify

When analyzing these visuals, focus on the labels and numbering systems used. Each component typically has a unique identifier, which corresponds to a list or catalog. Recognizing these identifiers is crucial for ordering the correct replacements or conducting repairs.

Tips for Effective Interpretation

Familiarize yourself with the common symbols and notations utilized in these visuals. Pay attention to any accompanying notes or legends, as they provide important context. Taking the time to delve into the details will ultimately lead to more efficient troubleshooting and part selection.

Where to Find OEM Parts

Locating original equipment manufacturer components can be essential for maintaining the efficiency and longevity of your machinery. These authentic parts are specifically designed to fit seamlessly and perform optimally, ensuring reliability during operation.

Start your search through authorized dealers who specialize in genuine replacements. They often provide the most accurate selections tailored to your equipment’s specifications. Additionally, exploring online platforms dedicated to machinery can yield a wide range of options, often at competitive prices.

Another valuable resource is community forums or groups where enthusiasts and professionals share insights on sourcing these components. Recommendations from experienced users can guide you to trustworthy suppliers and help you avoid imitations.

Lastly, consider manufacturer websites that frequently feature directories for their official distributors. This ensures you’re purchasing components that meet the necessary standards and specifications for your machine.

Understanding Maintenance Needs

Regular upkeep is essential for optimal performance and longevity of machinery. Familiarity with the components and their specific requirements allows for timely interventions, preventing larger issues down the line. By assessing wear and tear, operators can ensure efficiency and safety in operation.

Each machine comes with a unique set of specifications that dictate maintenance intervals and procedures. Recognizing these guidelines helps in creating a comprehensive maintenance schedule tailored to individual needs. This proactive approach minimizes downtime and enhances productivity.

Moreover, understanding the common failure points can assist in identifying potential problems before they escalate. Routine inspections and timely replacements not only preserve functionality but also protect your investment. Knowledge of the machinery’s intricacies empowers users to make informed decisions regarding care and repair.

Tools Required for Repairs

When undertaking maintenance or restoration tasks, having the right instruments at your disposal is crucial for achieving optimal results. These tools not only facilitate efficiency but also ensure that the job is done safely and correctly.

Essential Tools

- Wrenches (various sizes)

- Screwdrivers (flat and Phillips)

- Socket set

- Pliers

- Torque wrench

Safety Equipment

- Gloves

- Safety goggles

- Ear protection

- Dust mask

Upgrading Components for Performance

Enhancing machinery performance can significantly improve efficiency and durability. By focusing on specific elements, operators can ensure that their equipment operates at its peak, minimizing downtime and maximizing output. This process involves selecting high-quality replacements that offer better resilience and functionality.

Identifying Key Areas for Improvement

To achieve optimal results, it’s essential to assess various parts that influence overall performance. Common areas for enhancement include the engine, transmission, and hydraulic systems. Upgrading these components can lead to better power delivery and increased responsiveness, providing a noticeable boost in productivity.

Choosing Quality Replacements

When selecting upgrades, consider durability and compatibility with existing systems. High-performance alternatives often feature advanced materials and technology, which can result in enhanced functionality and lifespan. Investing in quality components ultimately leads to greater reliability and efficiency in operations.

Comparison with Other Kubota Models

This section explores how one particular tractor variant stacks up against its counterparts within the same brand. By examining features, specifications, and applications, we can better understand the unique position it occupies in the lineup.

| Model | Engine Power (HP) | Weight (lbs) | Transmission Type |

|---|---|---|---|

| Model A | 40 | 2900 | Hydrostatic |

| Model B | 50 | 3500 | Gear |

| Model C | 60 | 4200 | Hydrostatic |

By comparing specifications, users can identify which model best suits their specific needs, whether for agricultural tasks, landscaping, or other applications.

Tips for DIY Repairs

When it comes to tackling repairs on your machinery, a thoughtful approach can save both time and money. Understanding the components involved and planning your tasks effectively will ensure smoother and more efficient fixes. Whether you are a seasoned mechanic or a novice, these practical tips can enhance your repair experience.

Preparation is Key

Before starting any repair, gather all necessary tools and materials. Create a checklist of components to inspect, and organize your workspace to avoid distractions. Having a clear plan can significantly reduce frustration during the process.

Utilize Resources Wisely

Take advantage of manuals, online forums, and instructional videos. These resources provide valuable insights and can guide you through complex tasks. Additionally, keeping a record of past repairs helps you identify patterns and improve future efforts.

| Tip | Description |

|---|---|

| Stay Organized | Label parts and tools as you work to prevent confusion. |

| Safety First | Always wear appropriate protective gear. |

| Take Breaks | Rest periodically to maintain focus and avoid mistakes. |

| Consult Experts | Don’t hesitate to ask for help or advice when needed. |