Kubota LA1055 Parts Diagram and Maintenance Guide

The efficient operation of any agricultural machine relies on a clear understanding of its various elements. Identifying and maintaining these elements is essential for ensuring long-term performance and preventing costly repairs. Whether you’re working with complex systems or simple mechanisms, having a visual reference helps streamline the repair process.

In this guide, we explore how to interpret and utilize visual aids designed to show the assembly of key mechanical components. By carefully studying these guides, users can easily locate specific elements, understand their function, and ensure proper upkeep. With these insights, machine efficiency and longevity can be significantly improved.

Maintaining modern equipment can often seem daunting. However, with the right resources and knowledge, even the most intricate configurations can be simplified. This comprehensive approach allows for timely intervention and reduces downtime, helping to keep operations running smoothly.

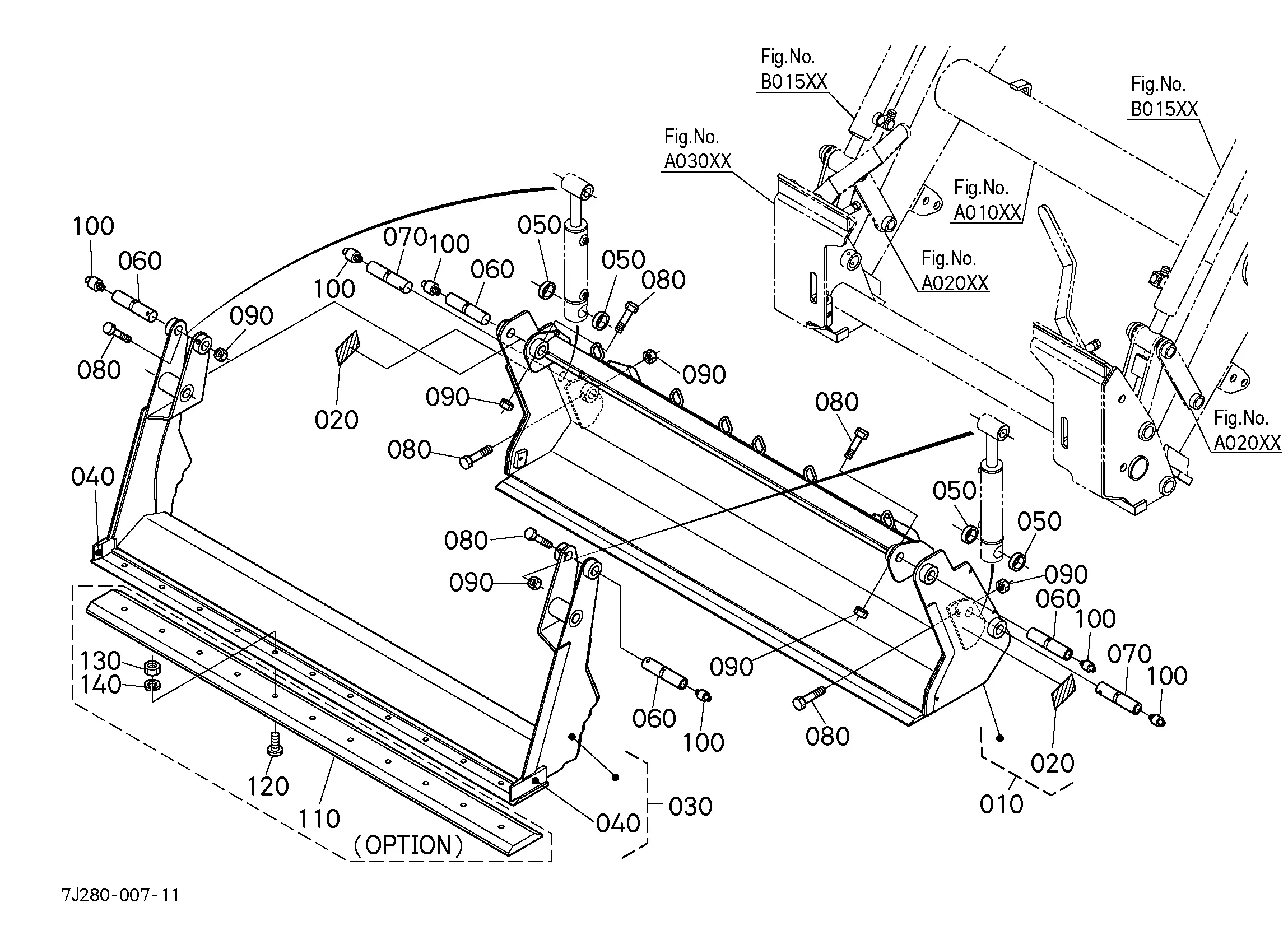

Kubota LA1055 Parts Diagram Overview

In this section, we will explore the various mechanical components that come together in this versatile equipment. Understanding the structure and functionality of each component is crucial for proper maintenance and repairs. By examining the detailed schematics, users can easily identify each element and its purpose.

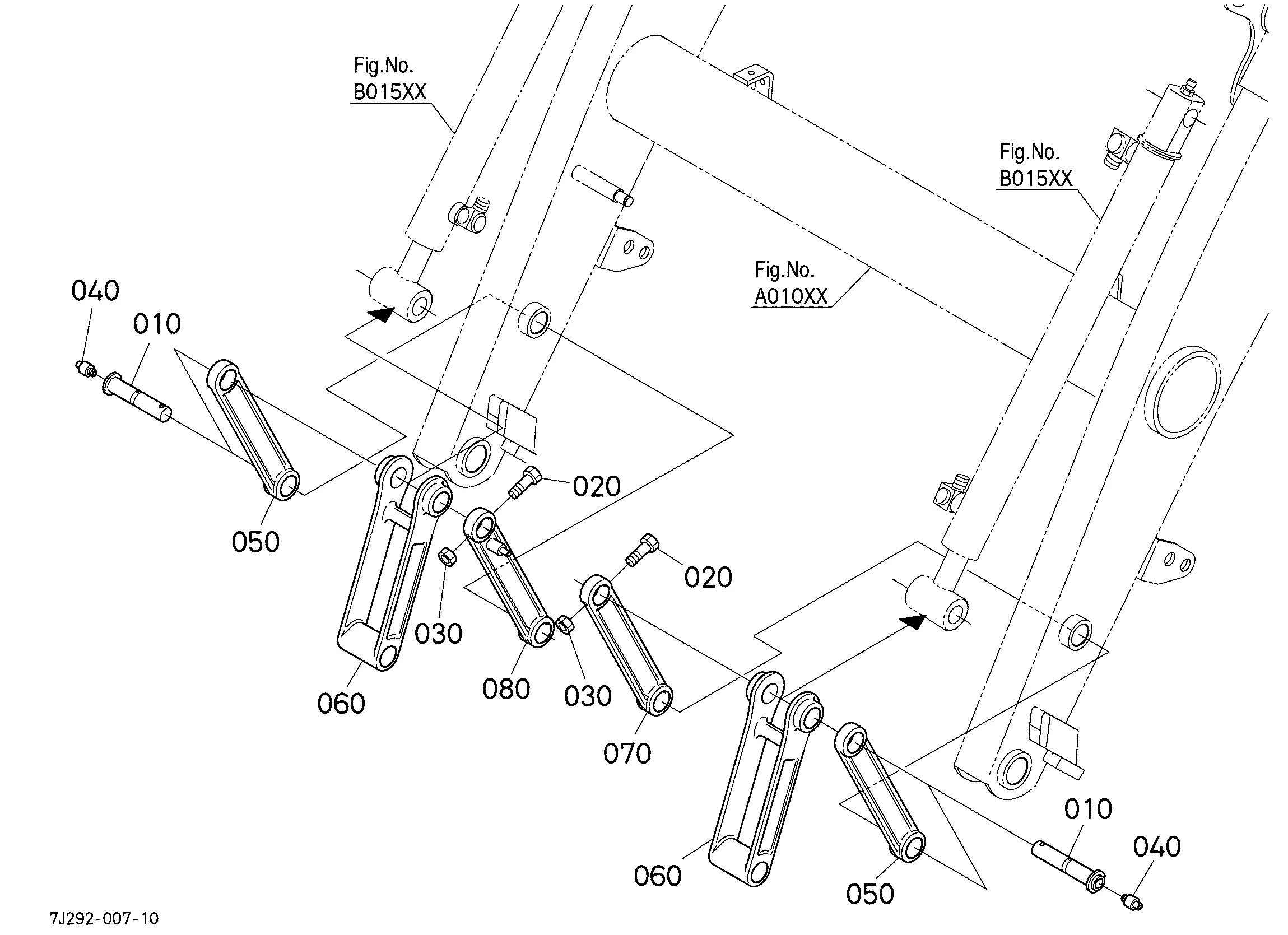

Main Structural Components

The system is built from essential parts that provide stability and efficiency during operations. These core elements include support structures, hydraulic mechanisms, and control units. Each component works in unison to ensure smooth performance in demanding conditions.

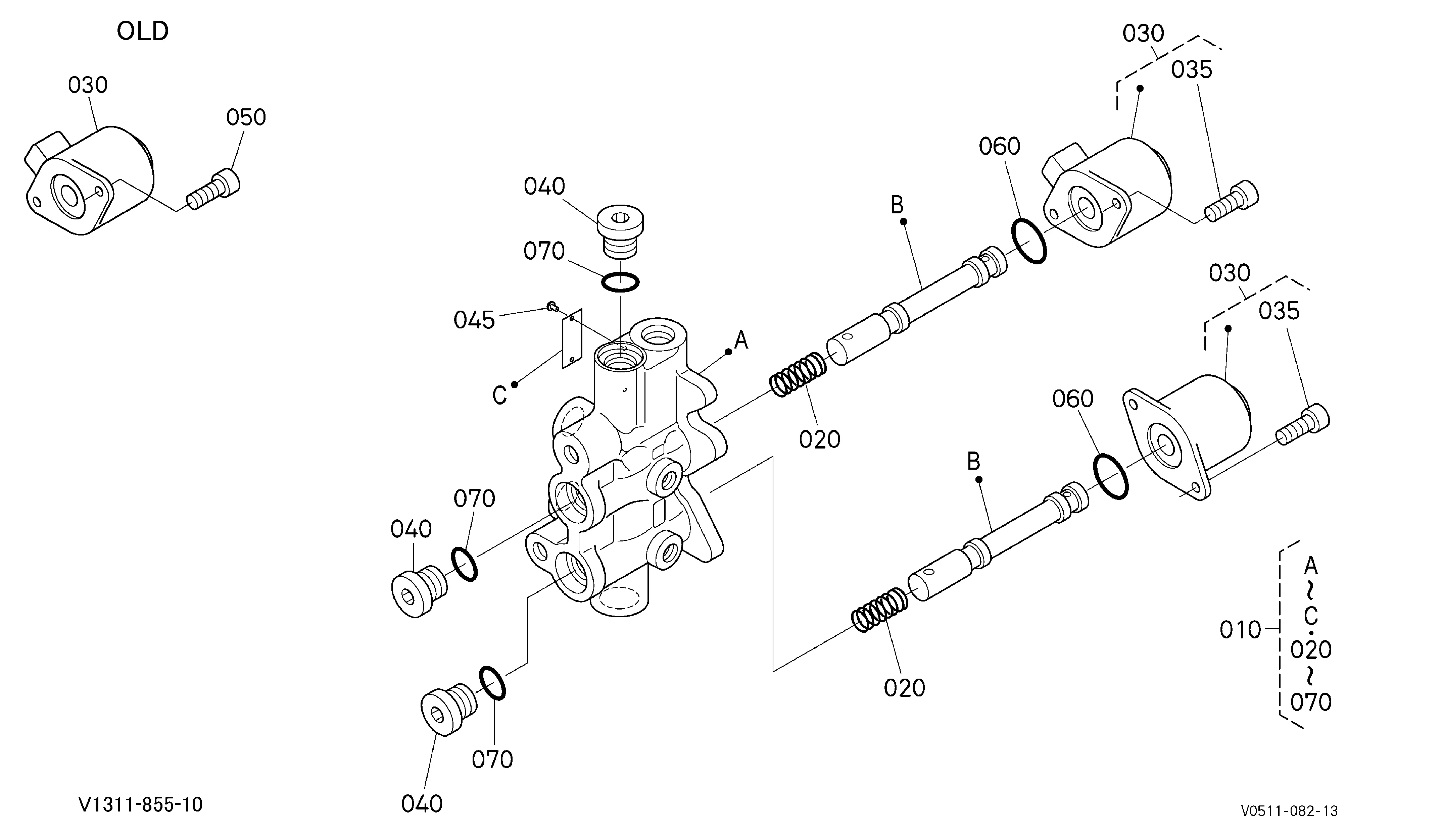

Hydraulic and Control Systems

The hydraulic section plays a key role in powering the machinery. Efficient control systems ensure precise movements, enabling users to handle various tasks with accuracy. A clear understanding of these systems helps in troubleshooting and optimizing performance.

Essential Components of the Kubota LA1055

The hydraulic loader system consists of numerous crucial elements that ensure smooth operation and reliability in various tasks. Each part plays a pivotal role in delivering effective performance, making the entire assembly robust and versatile for heavy-duty applications.

Hydraulic Cylinders

Hydraulic cylinders are responsible for lifting and lowering the arms of the loader. These components convert hydraulic energy into mechanical force, enabling precise control over movement. Regular maintenance ensures their longevity and optimal function during demanding tasks.

Control Valve Assembly

The control valve assembly directs the hydraulic fluid to different parts of the system, providing seamless transitions between operations. Its proper function is essential for the loader’s overall efficiency and ensures that all movements are well-coordinated and

How to Identify Critical Tractor Parts

Recognizing key components of agricultural machinery is essential for ensuring its optimal performance and preventing costly repairs. Understanding where these elements are located and how they function can help with routine maintenance and troubleshooting. Below is a guide on how to pinpoint some of the most important elements of your equipment.

- Engine: The powerhouse of the machine, responsible for generating the energy required for various tasks. Check for any unusual sounds or leaks as early signs of issues.

- Hydraulic System: This mechanism is crucial for lifting and operating attachments. Regularly inspect hoses and connections for wear and fluid levels to avoid performance loss.

- Transmission: This part is responsible for delivering power to the wheels and controlling speed. Smooth shifting and proper lubrication are key indicators of a well-maintained system.

- Steering System: Steering control is critical for maneuverability. Pay attention to steering response and any unusual resistance, which may indicate alignment or mechanical problems.

- Cooling System: Prevent overheating by ensuring the radiator, hoses, and coolant levels are functioning correctly. Clean the cooling system regularly to avoid blockages.

By regularly checking these essential elements, you can maintain the reliability of your machinery and extend its working life.

Maintenance Tips for Kubota LA1055 Parts

Regular upkeep is essential for ensuring long-lasting performance and efficiency of your equipment. Adopting a consistent maintenance schedule helps prevent wear and extends the lifespan of various components. Below are some practical suggestions to keep your machinery in optimal condition.

| Tip | Description |

|---|---|

| Check Fluid Levels | Monitor engine oil, hydraulic fluid, and coolant levels regularly to prevent damage caused by low levels or contamination. |

| Inspect Belts and Hoses | Ensure all belts and hoses are in good condition, free from cracks, and properly tensioned to avoid operational issues. |

| Grease Moving Parts | Lubricate joints, pivots, and other moving parts regularly to reduce friction and wear, ensuring smooth operation. |

| Practice | Description |

|---|---|

| Regular Inspections | Conduct routine checks to identify signs of wear and tear early, allowing for timely replacements before issues escalate. |

| Consult Documentation | Refer to the manufacturer’s manual for guidelines on replacement intervals and specific instructions for the components in question. |

| Use Quality Replacements | Select high-quality substitutes that meet or exceed original specifications to ensure compatibility and performance. |

| Document Changes | Keep a detailed log of all replacements and repairs performed, which can aid in tracking the equipment’s maintenance history. |

| Seek Professional Assistance | If unsure about the replacement process, consult with professionals who can provide expert guidance and ensure proper installation. |

Detailed Look at Electrical System Components

The electrical system of machinery plays a crucial role in its overall functionality. This section delves into the various elements that comprise this system, focusing on their importance and interconnections. Understanding these components can enhance maintenance practices and improve operational efficiency.

Key Electrical Elements

- Batteries: Serve as the primary power source, providing energy for starting the engine and powering electrical accessories.

- Alternators: Generate electricity to recharge the battery and supply power to the electrical system while the engine runs.

- Wiring Harness: A network of cables that connects various electrical components, ensuring the proper flow of electricity.

- Fuses: Protect the electrical circuits by breaking the connection in case of overload, preventing damage to components.

- Switches: Control the flow of electricity to different parts of the system, allowing for selective operation of components.

Importance of Regular Inspection

Regular inspection of the electrical components is vital for maintaining reliability. Identifying wear and tear early can prevent unexpected failures and prolong the lifespan of the machinery. Key areas to check include:

- Inspecting battery terminals for corrosion.

- Ensuring wiring is intact and free from fraying.

- Testing the functionality of switches and fuses.

How to Use the Kubota LA1055 Parts Diagram Effectively

Understanding the visual representation of components can significantly enhance your maintenance and repair processes. This illustration serves as a crucial tool for identifying individual elements, ensuring you have the necessary parts on hand for efficient servicing.

To maximize the utility of this schematic, start by familiarizing yourself with the layout. Each section is labeled, allowing for quick reference. Pay attention to the numbers and symbols used; these often correspond to specific components and can guide you in ordering replacements or conducting repairs.

Another effective approach is to cross-reference the visual guide with your manual. This can provide additional context and help clarify any ambiguities in the visual representation. Taking notes or marking sections can aid in tracking the necessary parts as you go through your maintenance tasks.

Finally, keep the diagram accessible during repairs. Having it on hand will facilitate quicker decisions and reduce downtime. Regular review of the schematic can also deepen your understanding of the equipment’s functionality, ultimately improving your maintenance skills.