Kubota M9540 Parts Diagram Overview

In the world of heavy equipment, having a clear visual representation of various components is essential for effective maintenance and repair. This section aims to provide an in-depth exploration of the intricate systems that make up modern agricultural machinery, focusing on how each part interacts within the larger framework.

Identifying key elements can greatly enhance the efficiency of your operations. By familiarizing yourself with these components, you empower yourself to tackle repairs with confidence and precision. Understanding their layout not only facilitates troubleshooting but also aids in the optimization of performance.

As we delve into the specifics, this guide will illuminate the ultimate connections between each element, offering valuable insights that ensure your equipment remains in peak condition. Embrace this opportunity to deepen your knowledge and enhance your skills in machinery management.

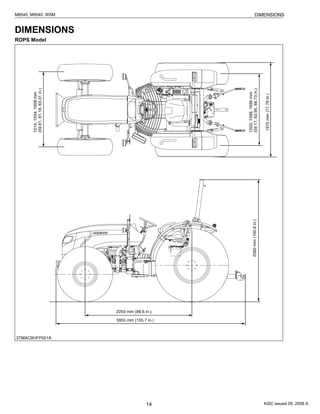

Kubota M9540 Overview

This section provides a comprehensive look at a powerful agricultural machine designed for a variety of tasks. Known for its reliability and efficiency, this equipment is favored by farmers and landscapers alike. Its robust build and advanced technology make it suitable for heavy-duty operations, ensuring optimal performance in diverse working conditions.

With a focus on user comfort and ease of operation, this model features a spacious cabin and intuitive controls, allowing operators to work for extended periods without fatigue. The innovative engine design not only enhances fuel efficiency but also reduces emissions, aligning with modern environmental standards.

Furthermore, the versatility of this machine is evident in its compatibility with various attachments, enabling users to tackle everything from tilling and mowing to loading and transporting materials. This adaptability makes it an invaluable asset for agricultural professionals seeking to maximize productivity and streamline their workflow.

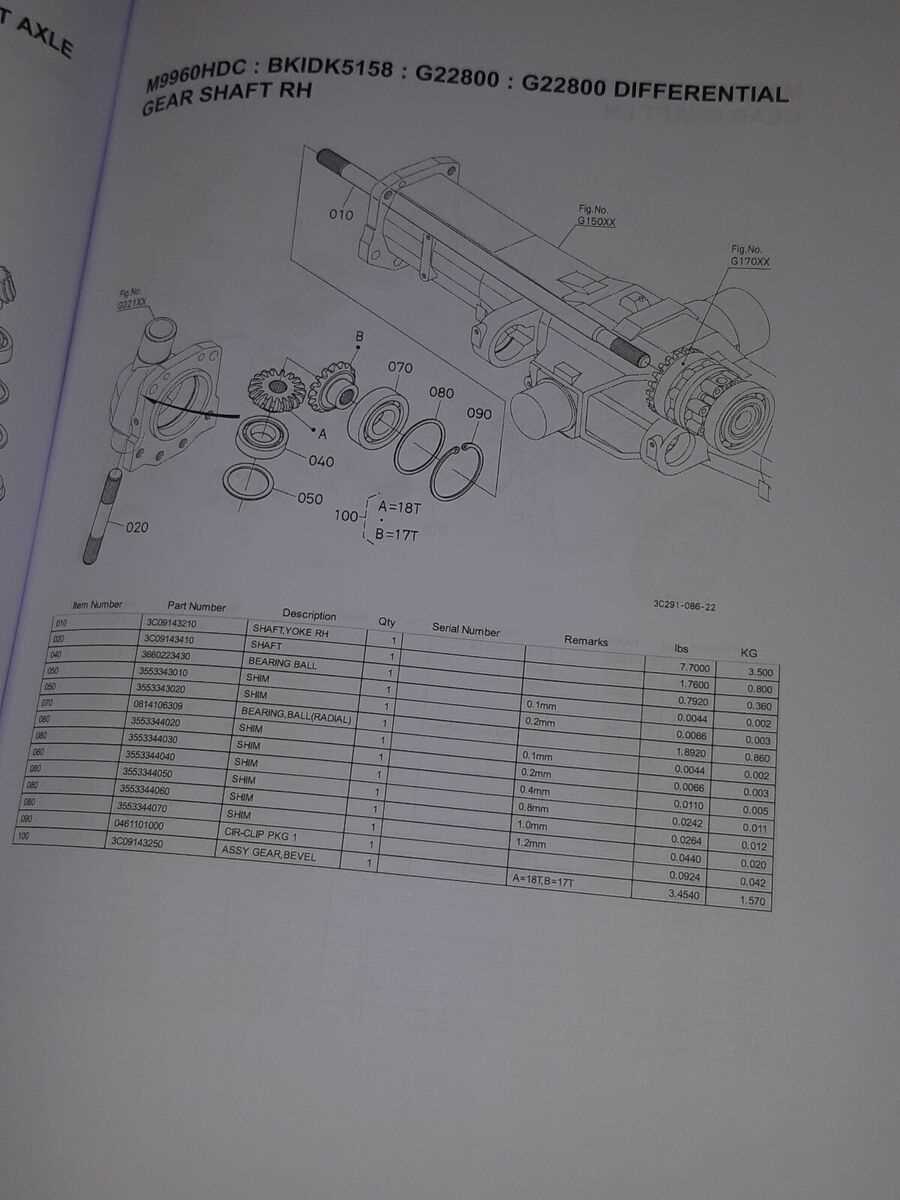

Understanding Parts Diagrams

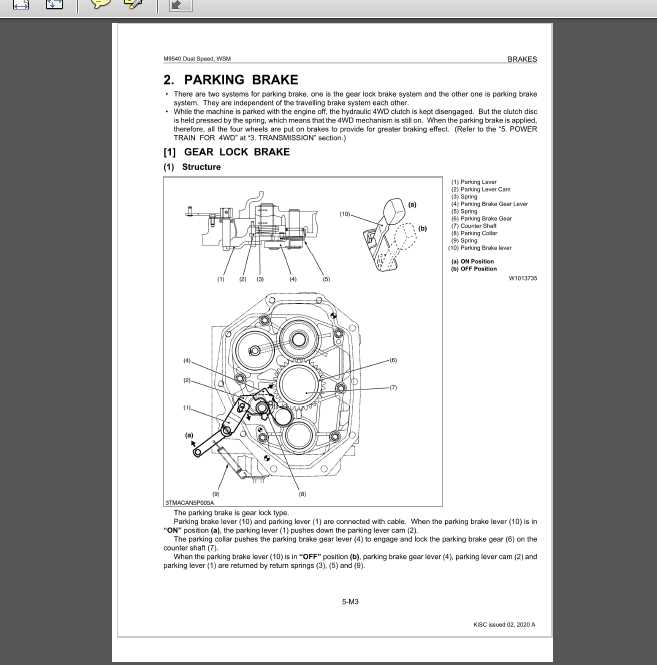

Illustrations of components serve as essential tools for users to identify and comprehend the various elements of machinery. These visual aids simplify the process of locating and understanding the individual pieces, promoting efficient maintenance and repair. By utilizing such resources, operators can enhance their familiarity with their equipment and streamline their tasks.

Typically, these visual representations are organized to showcase components in a clear and logical manner. This allows users to easily navigate through complex systems, ensuring that each part can be efficiently referenced and identified when needed. A well-structured illustration not only aids in the identification but also highlights the relationships between various components, making troubleshooting more manageable.

| Component | Description |

|---|---|

| Engine | The main source of power for the machinery. |

| Transmission | System that transfers power from the engine to the wheels. |

| Hydraulic System | Mechanism that utilizes fluid pressure to perform work. |

| Chassis | The framework that supports the entire structure. |

| Control Panel | Interface for the operator to manage functions and settings. |

By familiarizing oneself with these illustrations, operators can not only improve their understanding of machinery but also enhance their ability to perform effective repairs and maintenance. Ultimately, this knowledge leads to increased efficiency and longevity of the equipment.

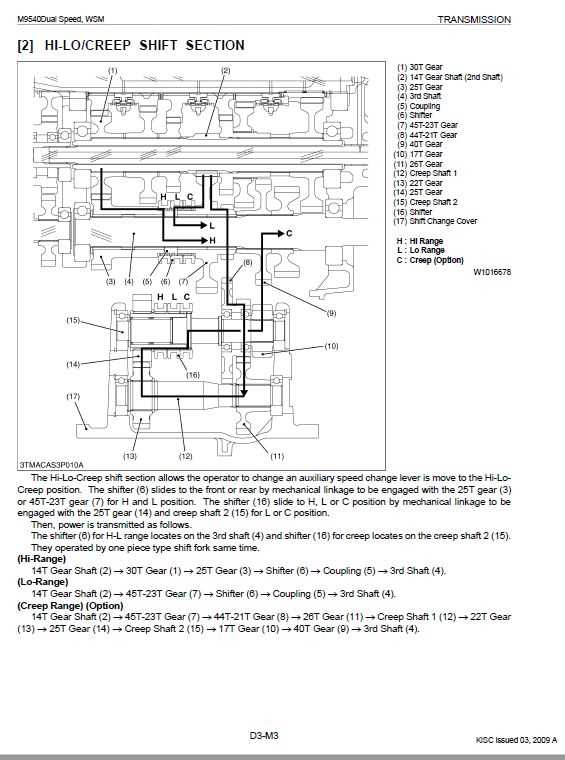

Key Components of Kubota M9540

Understanding the essential elements of agricultural machinery is crucial for efficient operation and maintenance. Each part plays a significant role in ensuring that the equipment runs smoothly and effectively, contributing to overall productivity. This section highlights the main components found in this specific model, offering insight into their functions and importance.

Engine and Transmission

The engine serves as the powerhouse, providing the necessary energy to drive the machine. Coupled with a reliable transmission system, it ensures optimal power delivery to the wheels, enabling smooth movement across various terrains. Regular maintenance of these components is vital to prevent downtime and enhance performance.

Hydraulic System

This machinery features a sophisticated hydraulic system that facilitates the operation of various attachments and implements. By utilizing hydraulic fluid to transmit power, it allows for precise control and adaptability in diverse agricultural tasks. Understanding the hydraulic components can significantly improve efficiency and responsiveness in the field.

Importance of Accurate Diagrams

Clear and precise illustrations play a crucial role in understanding complex machinery and systems. They serve as essential tools for maintenance and repair, helping users navigate the intricacies of components and their interactions. When accuracy is prioritized, efficiency in troubleshooting and assembly increases significantly.

Enhancing Efficiency

With well-detailed visual representations, technicians can quickly identify parts and their functions, streamlining the repair process. This reduces downtime and ensures that machines operate optimally, which is vital for productivity in any industry.

Minimizing Errors

Accurate visuals help prevent misunderstandings that could lead to incorrect assembly or repairs. By providing a reliable reference, they reduce the likelihood of costly mistakes and enhance the overall reliability of equipment.

Common Issues with Kubota Parts

When working with heavy machinery, various components can present challenges that affect performance and reliability. Understanding these potential issues is essential for effective maintenance and repair. This section delves into frequent problems encountered with machinery components and their implications.

Wear and Tear

Over time, components are subjected to intense operational stress, leading to degradation. This natural wear can result in decreased efficiency and increased risk of failure. Regular inspections can help identify these concerns early.

Compatibility Problems

Using incorrect components can cause significant issues, including improper fit and function. Ensuring that the right specifications are met is crucial to maintaining overall machinery integrity and performance.

Where to Find Parts Diagrams

Finding comprehensive illustrations and schematics for machinery components is crucial for efficient maintenance and repairs. Access to these resources can significantly streamline the troubleshooting process and ensure the correct parts are utilized. There are various avenues to explore when seeking detailed visual guides for your equipment.

Online Resources

The internet is a treasure trove of information. Manufacturer websites often provide downloadable resources, including schematics that illustrate component layouts. Additionally, numerous forums and community websites dedicated to machinery enthusiasts can offer insights and shared experiences from fellow users. These platforms frequently host discussions that can lead you to valuable diagrams.

Local Dealerships and Repair Shops

Visiting a local dealership or authorized service center can also be beneficial. These establishments typically have access to official manuals and diagrams not readily available online. Engaging with knowledgeable staff can enhance your understanding of specific components, and they may be willing to provide you with copies of relevant illustrations or direct you to where you can find them.

Maintenance Tips for M9540

Regular upkeep is essential to ensure optimal performance and longevity of your agricultural machinery. By following a few simple practices, you can prevent costly repairs and enhance efficiency.

Check Fluid Levels: Ensure that all essential fluids, such as engine oil, coolant, and hydraulic fluid, are at the appropriate levels. This not only protects components but also ensures smooth operation.

Inspect Filters: Regularly examine and replace air, fuel, and oil filters as needed. Clean filters promote better airflow and efficiency, ultimately prolonging the life of your equipment.

Clean Air Intake: Keeping the air intake system free from debris is crucial. A clean intake ensures optimal combustion and can improve fuel efficiency.

Tire Maintenance: Check tire pressure and tread regularly. Properly inflated and maintained tires enhance traction and reduce wear on other parts.

Routine Lubrication: Apply lubricant to moving parts according to the manufacturer’s recommendations. This minimizes friction and wear, contributing to overall functionality.

Monitor Belts and Hoses: Inspect belts for signs of wear and check hoses for leaks. Replacing damaged components promptly can prevent further issues down the line.

Keep a Maintenance Log: Documenting service activities and observations helps track performance trends and identify recurring issues, facilitating better decision-making for future maintenance.

Identifying Replacement Parts Easily

Understanding the components of your machinery is crucial for efficient maintenance and repair. By familiarizing yourself with the various elements, you can streamline the process of locating and acquiring necessary replacements. This knowledge not only saves time but also enhances the longevity and performance of your equipment.

Visual aids play a significant role in this journey. Utilizing clear illustrations or schematics can help pinpoint specific components quickly. When you can see the arrangement of parts, the task of identifying what needs to be replaced becomes more straightforward.

Furthermore, keeping a detailed record of previous repairs and replacements can provide insights into common issues and the parts that frequently wear out. This proactive approach equips you with the ultimate understanding of your machinery’s needs.

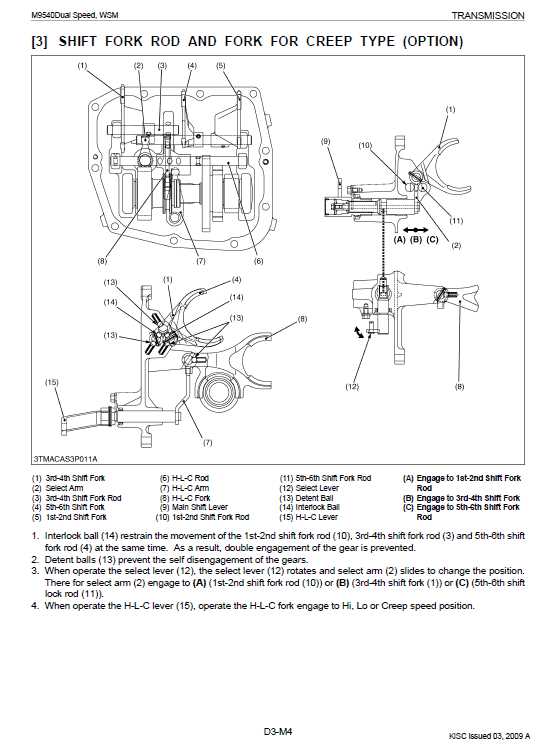

Using Diagrams for Troubleshooting

Visual representations play a crucial role in identifying and resolving issues within machinery. They offer a clear overview of components and their interconnections, enabling users to pinpoint faults more effectively. By studying these illustrations, technicians can streamline their diagnostic processes and enhance repair efficiency.

Benefits of Visual Guides

Utilizing visual aids can simplify complex mechanical systems. They help in understanding how parts interact, which is essential for isolating problems. Furthermore, these guides can save time by allowing for quick reference during inspections.

Effective Troubleshooting Techniques

When encountering difficulties, refer to these illustrations to trace the source of the issue. Begin with a systematic approach, focusing on the highlighted areas where faults are likely to occur. This method not only facilitates accurate repairs but also builds confidence in handling machinery.

Benefits of Genuine Kubota Parts

Using authentic components for machinery ensures optimal performance and longevity. These specialized items are designed to fit seamlessly, providing several advantages over generic alternatives.

- Quality Assurance: Genuine components are manufactured to high standards, ensuring reliability and durability.

- Perfect Fit: Designed specifically for your machinery, these items eliminate compatibility issues that can arise with aftermarket solutions.

- Enhanced Performance: Authentic components maintain the intended functionality of your equipment, leading to improved efficiency.

- Warranty Protection: Utilizing genuine items often keeps warranties intact, safeguarding your investment.

- Expert Support: Manufacturers provide better support and resources for authentic components, ensuring you have access to the necessary assistance.

Investing in original components not only enhances the machinery’s performance but also contributes to a smoother operational experience over time.

Enhancing Performance with Proper Parts

Optimal functioning of machinery relies heavily on the quality and compatibility of its components. When each piece is carefully selected and properly maintained, overall efficiency improves significantly, leading to increased productivity and reduced downtime. Understanding the importance of choosing the right elements can make a substantial difference in performance and longevity.

Key Factors in Component Selection

Choosing suitable elements involves several considerations. Compatibility with existing systems, quality standards, and the intended application play crucial roles. Here are some factors to keep in mind:

| Factor | Description |

|---|---|

| Compatibility | Ensuring new components work seamlessly with current systems. |

| Quality | Selecting high-grade materials for durability and performance. |

| Application | Considering the specific requirements and conditions of use. |

Benefits of Proper Component Integration

Integrating the right components offers multiple advantages. Enhanced efficiency leads to lower operational costs, while improved reliability minimizes maintenance needs. Additionally, well-matched elements can significantly boost overall machine performance, enabling users to achieve their objectives with greater ease.