Kubota R420 Parts Diagram Overview

Maintaining and repairing machinery can be a complex process, especially when it comes to identifying and sourcing the right elements. A well-structured layout of technical elements is essential for ensuring the efficiency and longevity of equipment. Knowing how to interpret the arrangement of mechanical components allows for easier maintenance, saving both time and effort.

For technicians and operators, having access to a visual representation of all essential elements significantly simplifies tasks. By using these detailed references, one can pinpoint the necessary mechanical pieces, making repairs and replacements more manageable. Such clarity in the structure promotes smoother operations and reduces the chance of errors during maintenance.

In this guide, we’ll explore how to approach technical representations, ensuring that every vital component is accurately understood and properly maintained. This helps in keeping the machinery running at peak performance, ensuring a long and productive life for the equipment.

Overview and Key Features

This versatile machine is designed to handle a variety of tasks with efficiency and precision. Its compact size, combined with a powerful engine, allows it to excel in both confined spaces and larger work areas. The vehicle is well-suited for industries such as construction, agriculture, and landscaping, offering reliability and durability in demanding conditions.

Performance Capabilities

The equipment is engineered for optimal productivity. With a robust powertrain, it ensures steady performance across different terrains. The machine’s agility and maneuverability make it easy to operate, enhancing user comfort while reducing fatigue during prolonged use. Durable components and intelligent design features contribute to its long-lasting performance.

Key Functional Elements

Equipped with an efficient hydraulic system, the machine offers smooth and responsive control. This ensures precise handling of various tools and attachments, allowing it to adapt quickly to different tasks. The ergonomic design of the controls further enhances operational efficiency, making the equipment highly user-friendly. Enhanced visibility and safety features also contribute to a safer work environment

Understanding the Kubota R420 Engine Components

The heart of any construction equipment lies in its motor. A proper grasp of the elements that make up this critical system can significantly aid in maintaining and optimizing performance. By familiarizing yourself with its various internal mechanisms, you can ensure the machine runs efficiently and identify potential issues early on.

Below is a breakdown of key elements you need to understand:

- Cooling system: This ensures the motor doesn’t overheat during prolonged use, protecting essential components from damage.

- Fuel injectors: These devices control the flow of fuel into the combustion chamber, ensuring a precise air-fuel mixture for optimal efficiency.

- Exhaust system: Responsible for expelling gases after combustion, this system is vital for maintaining air quality and preventing engine blockages.

- Pistons: Located within the combustion chamber, these parts drive the motion that powers the machine, converting energy from fuel into mechanical movement.

Understanding these systems not only helps with basic maintenance but also prepares you for handling potential repairs, ensuring your machinery stays in top working condition.

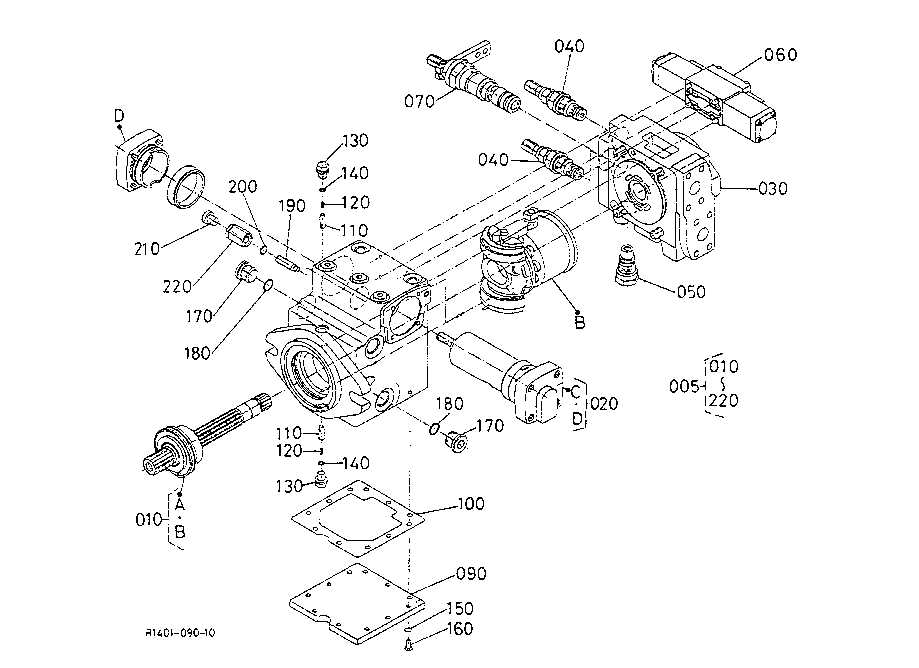

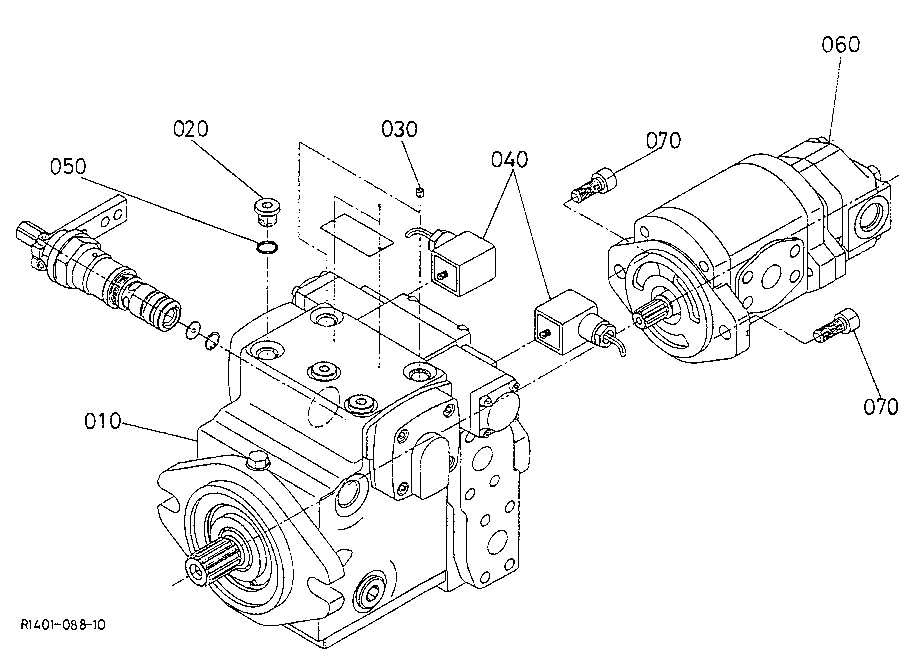

Hydraulic System Parts and Functions

The hydraulic system plays a vital role in the operation of various machinery, ensuring efficient transfer of power through fluid. This system relies on multiple interconnected components that work together to manage fluid pressure and movement. Understanding the roles of these elements is essential for maintaining optimal performance and addressing potential issues.

At the core of the system is the hydraulic pump, responsible for converting mechanical energy into hydraulic pressure. The fluid is then directed through valves, which regulate flow and pressure to various actuators. These actuators, such as cylinders and motors, convert the fluid pressure back into mechanical motion, enabling different operations to be carried out smoothly and with precision.

Another key element is the reservoir, which stores the hydraulic fluid and helps maintain consistent pressure throughout the system. Filters are also crucial, as they remove contaminants from the fluid, protecting the components from wear and extending the system’s lifespan. Each part has a specific function, and together they form a cohesive system designed for reliable and efficient performance.

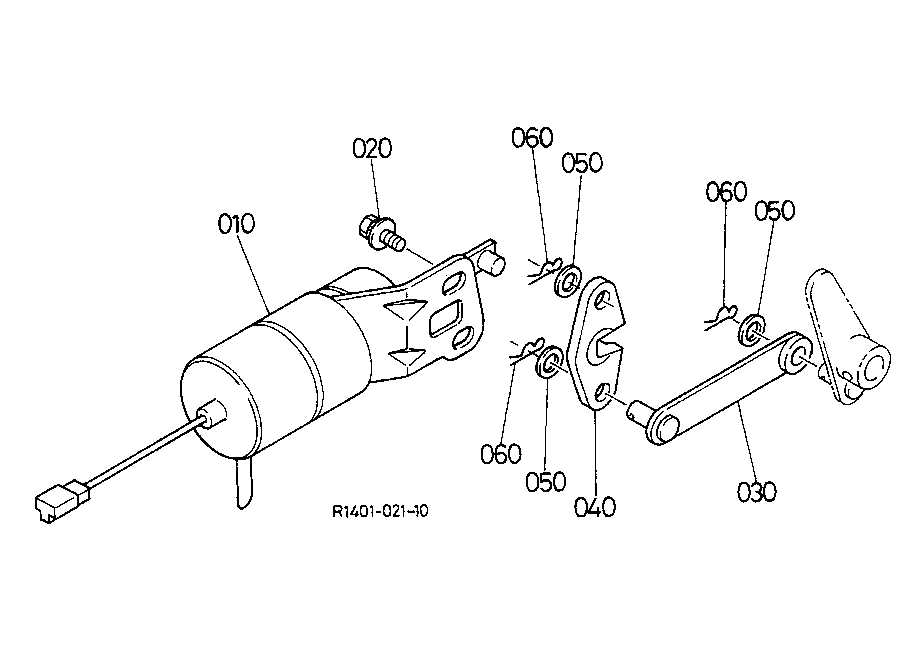

Transmission Assembly and Its Maintenance

The transmission assembly plays a crucial role in the overall functionality of machinery, ensuring efficient power transfer from the engine to the wheels. Proper maintenance of this assembly is essential to enhance performance, prolong lifespan, and prevent costly repairs. Regular inspections and servicing can help identify potential issues before they escalate, ensuring that the equipment operates smoothly and reliably.

To maintain the transmission assembly effectively, consider the following key practices:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Level Check | Every 100 hours | Ensure transmission fluid is at the recommended level to prevent overheating and wear. |

| Fluid Change | Every 500 hours | Replace old fluid with fresh to maintain proper lubrication and performance. |

| Filter Replacement | Every 1000 hours | Replace the transmission filter to ensure contaminants do not interfere with fluid flow. |

| Inspection for Leaks | Monthly | Check for any fluid leaks around seals and connections to prevent loss of lubrication. |

| Overall Condition Assessment | Every 100 hours | Inspect the transmission assembly for wear and tear, ensuring all components are functioning properly. |

Following these maintenance guidelines will help ensure the transmission assembly operates efficiently, minimizing downtime and enhancing overall equipment productivity.

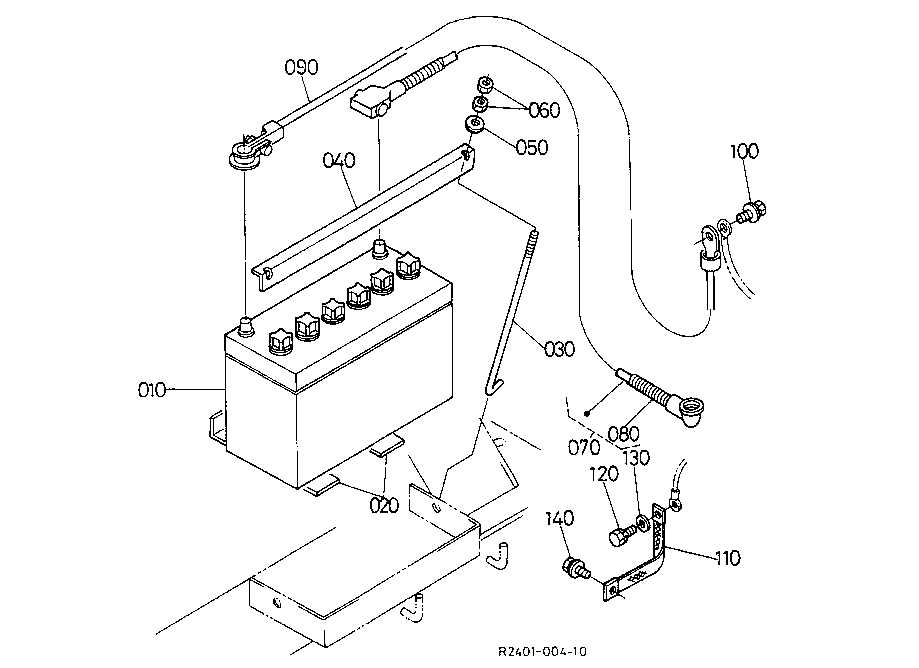

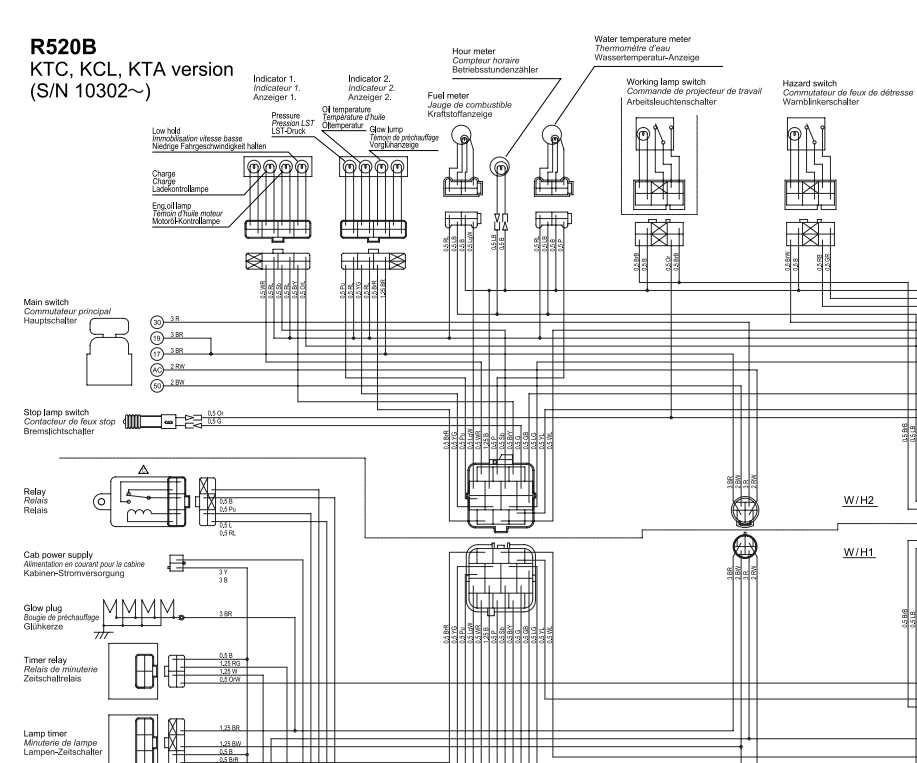

Electrical Wiring and Battery Setup

Proper electrical connections and battery installation are crucial for the optimal performance of your machinery. Understanding the layout and components of the electrical system ensures that all parts work harmoniously together, reducing the risk of malfunction and enhancing efficiency.

Here are key elements to consider when setting up the electrical wiring and battery:

- Battery Selection: Choose a battery that meets the required specifications for voltage and capacity to ensure reliable power supply.

- Wiring Components: Use high-quality wires and connectors to maintain a secure and efficient electrical flow.

- Grounding: Proper grounding of the electrical system is essential to prevent electrical faults and ensure safety.

- Fuses and Circuit Breakers: Incorporate fuses or circuit breakers to protect the electrical system from overload and potential damage.

To set up the battery effectively:

- Disconnect the negative terminal before installation to avoid short circuits.

- Connect the positive terminal first, followed by the negative terminal to ensure safety.

- Secure the battery in its compartment to prevent movement and potential disconnection.

Regular maintenance checks of the wiring and battery connections can help identify potential issues before they lead to significant problems. Keeping the electrical system clean and well-organized will contribute to the longevity and reliability of your equipment.

Cooling System Diagram and Components

The cooling mechanism in machinery is essential for maintaining optimal operating temperatures. This system ensures that various components do not overheat, enhancing performance and prolonging the lifespan of the equipment. Understanding the layout and individual elements of this system is crucial for effective maintenance and troubleshooting.

Key Components of the Cooling Mechanism

- Radiator: Responsible for dissipating heat from the coolant.

- Water Pump: Circulates coolant throughout the system, ensuring consistent flow.

- Thermostat: Regulates the temperature by controlling coolant flow.

- Cooling Hoses: Facilitate the movement of coolant between components.

- Cooling Fan: Helps to draw air through the radiator for additional cooling.

Functionality of the Cooling System

The cooling system operates by circulating coolant through the engine and radiator. As the engine generates heat, the coolant absorbs this heat and transports it to the radiator. Here, the heat dissipates into the air, allowing the coolant to return to the engine at a lower temperature. This cycle maintains an efficient operating temperature, preventing overheating and ensuring optimal performance.

Brake System Parts in Detail

The braking mechanism is a critical component of any vehicle, ensuring safety and control during operation. Understanding the various elements involved in this system can enhance maintenance practices and improve performance. This section delves into the essential components that make up the braking assembly, providing insights into their functions and importance.

Main Components

The braking system consists of several key components, each playing a vital role in the overall functionality. These elements work together to create the necessary friction for slowing down or stopping the vehicle.

| Component | Description |

|---|---|

| Brake Pedal | The lever that the driver presses to initiate braking action. |

| Brake Booster | Enhances the force applied to the brake pedal, allowing for more efficient braking. |

| Master Cylinder | Converts pedal force into hydraulic pressure to activate the brakes. |

| Brake Lines | Hoses that carry hydraulic fluid from the master cylinder to the brake calipers or drums. |

| Brake Calipers | Housings that contain the brake pads and apply pressure to the brake rotor or drum. |

| Brake Pads | Friction material that presses against the rotor to slow down the vehicle. |

| Brake Rotors | Discs that the brake pads grip to create the necessary stopping force. |

Importance of Regular Maintenance

Regular inspections and maintenance of the braking components are essential for ensuring optimal performance and safety. Worn or damaged parts can significantly affect the efficiency of the braking system, leading to potential hazards on the road. Keeping track of the condition of each element can help prevent costly repairs and enhance the longevity of the entire mechanism.

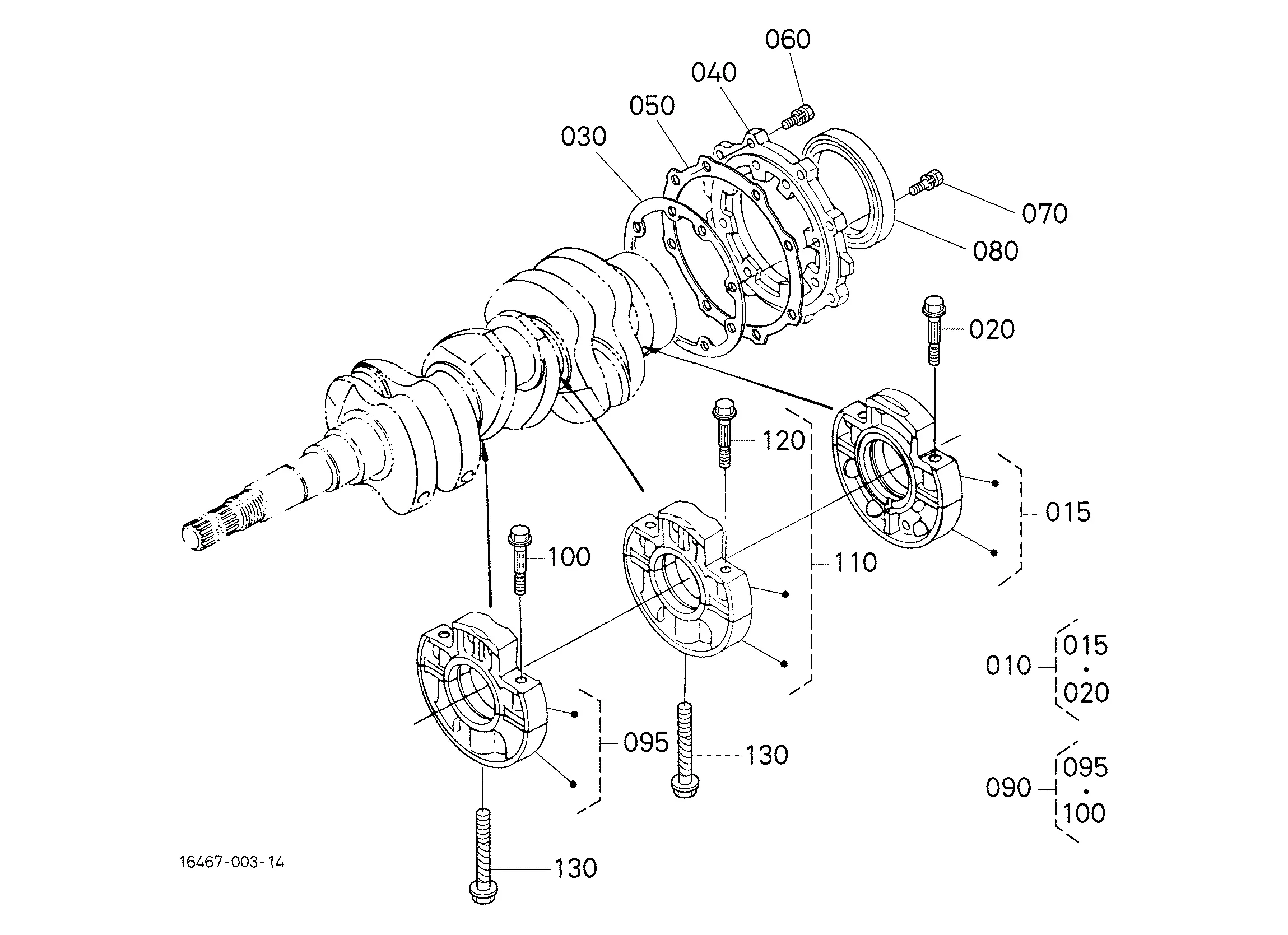

Axle and Wheel Assembly Breakdown

The axle and wheel assembly is a critical component that ensures stability and mobility for various vehicles and machinery. Understanding the structure and function of this assembly can enhance maintenance practices and improve operational efficiency. This section delves into the essential elements that make up the axle and wheel system, highlighting their roles and interconnections.

Key Components of the Assembly

- Axle Shaft: A central rod that transfers torque and supports the weight of the machine.

- Wheel Hubs: These components attach the wheels to the axle and allow for rotation.

- Bearings: Essential for smooth wheel movement, they reduce friction between the axle and the wheel hubs.

- Brake Assemblies: Vital for controlling speed and ensuring safety, these components work in conjunction with the wheels.

- Spindles: These parts connect the wheels to the axle and facilitate steering and turning.

Maintenance Tips

- Regularly inspect the axle and wheel assembly for signs of wear and damage.

- Lubricate bearings and other moving parts to ensure smooth operation.

- Check brake functionality to ensure safe stopping capabilities.

- Monitor wheel alignment to prevent uneven tire wear and enhance handling.

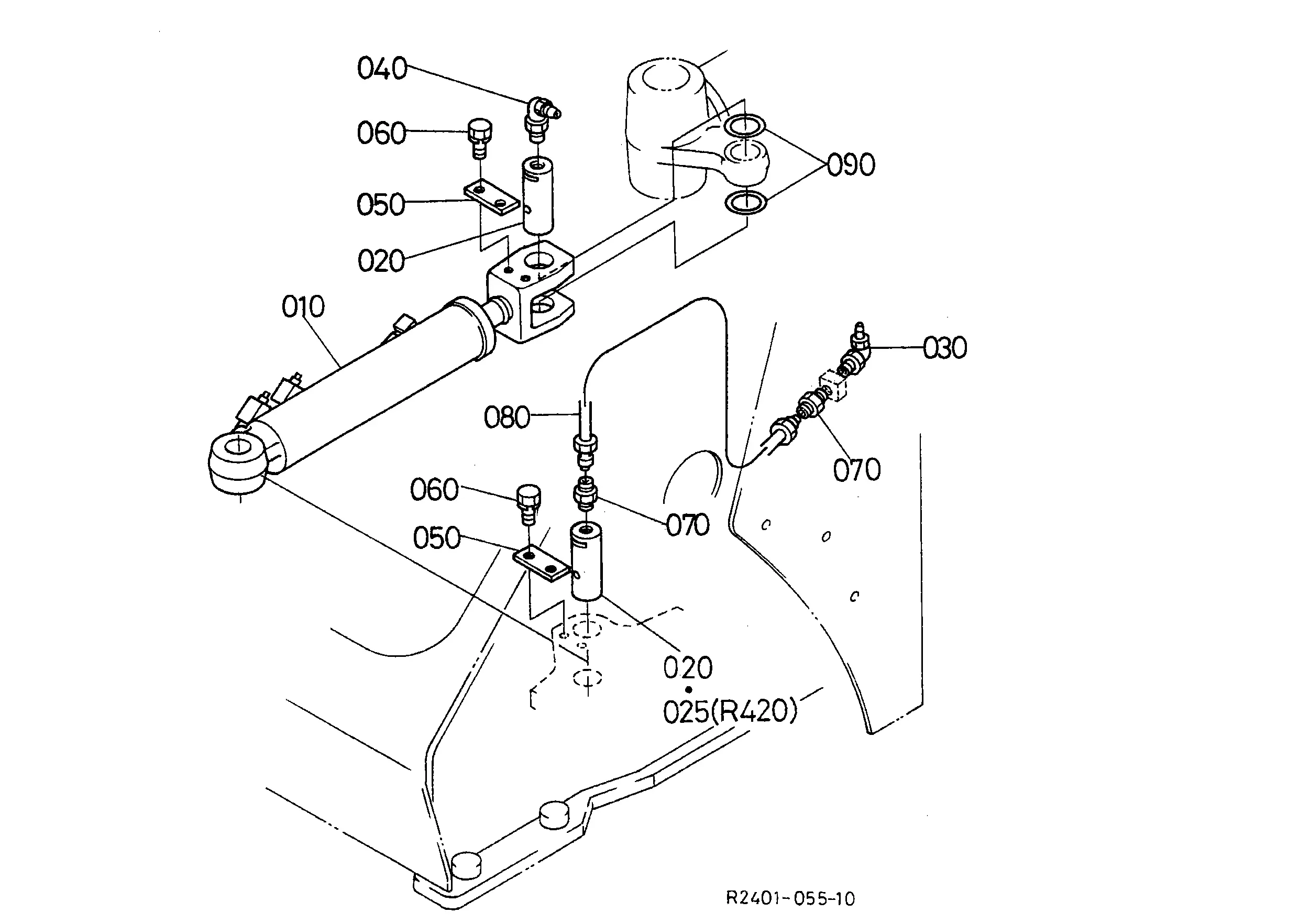

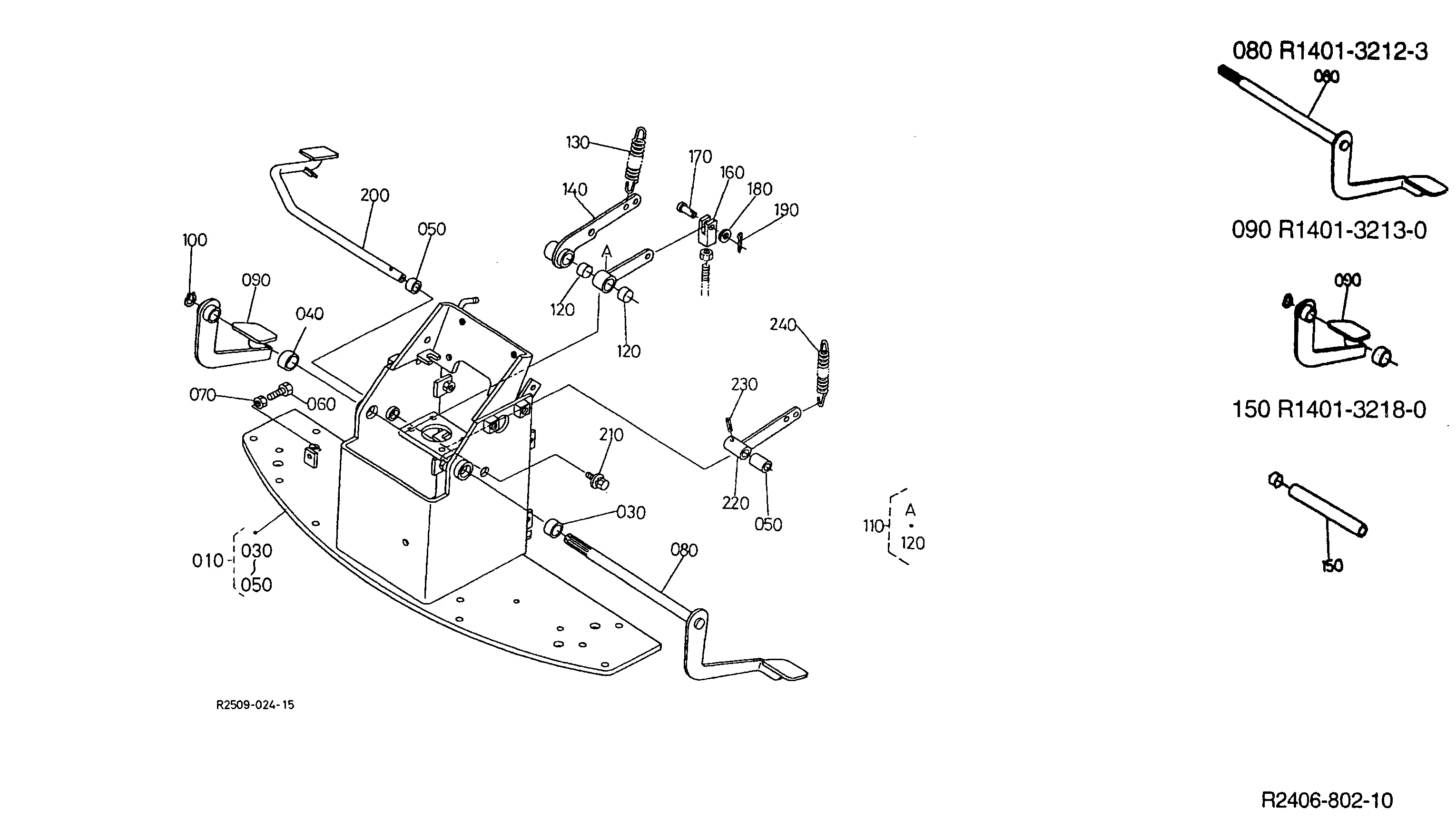

Loader Arm and Bucket Mechanism

The loader arm and bucket mechanism is a crucial component of many earth-moving machines, providing the necessary strength and flexibility to handle a variety of materials. This system facilitates the lifting, tilting, and dumping of loads, making it essential for efficient operation in construction and agricultural tasks.

Functionality

This mechanism consists of several key elements that work together to ensure smooth operation:

- Loader Arms: These structures connect the bucket to the main frame, allowing for movement and stability.

- Hydraulic Cylinders: These components control the extension and retraction of the arms, providing the necessary force to lift heavy loads.

- Bucket: The attachment that holds and transports materials, designed for optimal capacity and shape for specific tasks.

Benefits

Employing an efficient loader arm and bucket system provides several advantages:

- Increased productivity through faster loading and unloading cycles.

- Improved maneuverability in tight spaces, allowing for precise material handling.

- Enhanced durability, reducing wear and tear during operation.

Cabin Interior and Control Panel Parts

The interior of the operator’s compartment plays a crucial role in ensuring comfort and functionality during operation. A well-designed layout enhances user experience and allows for efficient control of the machine. Understanding the various components within this area is essential for maintenance and repairs, ensuring that everything functions smoothly and effectively.

Essential Components

Key elements of the cabin’s interior and control interface contribute to the overall effectiveness of the equipment. Each part serves a specific function, working in harmony to create a seamless operating environment.

| Component | Description | Function |

|---|---|---|

| Dashboard | Control interface displaying vital information | Monitors performance and operational status |

| Control Levers | Handles for operating different functions | Enables precise control of movement and implements |

| Seating | Operator’s chair with adjustable settings | Provides comfort and support during operation |

| Foot Pedals | Pedals for controlling speed and direction | Facilitates smooth operation and maneuverability |

Maintenance Considerations

Regular inspection and upkeep of the components within the operator’s area are essential to prolong their lifespan and ensure safety. Addressing any wear and tear promptly will prevent more significant issues and enhance the overall performance of the equipment.

Proper Care for Filters and Fluids

Maintaining the cleanliness and efficiency of various systems in machinery is essential for optimal performance and longevity. Proper attention to filters and fluids ensures that engines run smoothly, preventing wear and tear that can lead to costly repairs. Understanding the best practices for upkeep can significantly enhance reliability and efficiency.

Importance of Regular Maintenance

Regular maintenance of filters and fluids is crucial for the following reasons:

- Prevention of contaminants that can cause damage.

- Improvement of overall system performance.

- Extension of the equipment’s lifespan.

Best Practices for Filters and Fluids

To ensure the longevity and effectiveness of your machinery, follow these guidelines:

- Check fluid levels regularly to maintain optimal performance.

- Replace filters according to the manufacturer’s recommendations.

- Use high-quality fluids to enhance efficiency and protect components.

- Inspect filters for damage or clogs and clean them if necessary.

- Keep a maintenance log to track replacements and inspections.