Kubota RCK54-22BX Parts Diagram Overview

In the realm of machinery maintenance, comprehending the intricate relationship between various elements is crucial for ensuring optimal performance. A well-organized overview of these individual segments not only enhances the efficiency of repairs but also aids in the proper functioning of the entire system. By delving into the specific configurations and functions of each part, operators can develop a deeper appreciation for the mechanics involved.

Having access to a clear visual representation of these components serves as a valuable resource for both novices and seasoned technicians alike. Such illustrations provide clarity, making it easier to identify each piece and understand how they interconnect within the larger framework. This knowledge empowers users to execute maintenance tasks with confidence, ultimately extending the lifespan of their equipment.

Moreover, a detailed examination of these assemblies can uncover potential issues that might arise during operation. Recognizing wear and tear on specific sections enables proactive measures, preventing costly downtime and ensuring seamless functionality. By prioritizing an informed approach to equipment management, users can enhance reliability and overall performance.

Kubota RCK54-22BX Overview

This section provides an insightful look into a specific type of lawn maintenance equipment designed for efficiency and performance. Aimed at enhancing the mowing experience, this model showcases advanced engineering and thoughtful design, making it a reliable choice for homeowners and professionals alike.

Features: This machine is equipped with a robust cutting system that ensures precision and durability. Its user-friendly interface allows for easy operation, catering to various landscaping needs.

Maintenance: Regular upkeep is essential for optimal performance. Understanding the components involved will help in identifying necessary services and prolonging the lifespan of the equipment.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations help users quickly identify and locate essential elements, streamlining the process and reducing the risk of errors. This clarity can significantly enhance the overall performance and longevity of equipment.

| Benefit | Description |

|---|---|

| Enhanced Clarity | Visual guides provide an intuitive understanding of assembly and disassembly procedures. |

| Time Efficiency | Quick reference aids in faster repairs, minimizing downtime. |

| Reduced Errors | Clear visuals lower the chances of mistakes during maintenance tasks. |

| Improved Communication | Facilitates better discussions between technicians and support staff. |

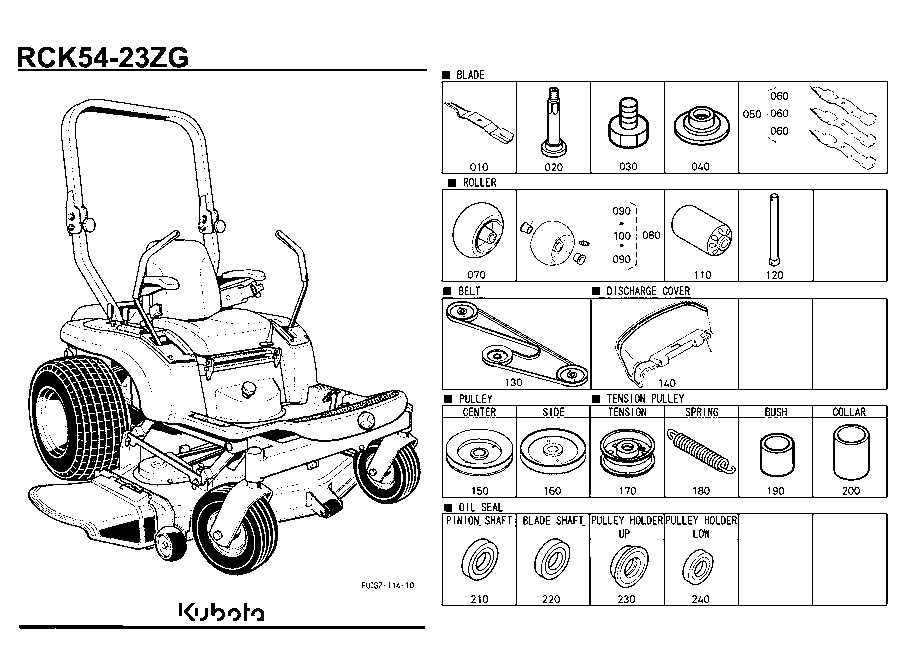

Key Components of the RCK54-22BX

Understanding the essential elements of this mowing attachment is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficiency and effectiveness during operation.

Cutting Deck: The primary feature, designed for precision, offers various height adjustments to suit different grass types.

Blades: Sharp and durable, these are engineered to provide a clean cut, promoting healthy grass growth.

Drive System: This mechanism ensures smooth power transfer, enhancing maneuverability and reducing strain on the equipment.

Mounting Hardware: Essential for stability, this includes brackets and fasteners that securely attach the mower to the tractor.

Chassis: The robust frame supports all components, ensuring durability and resistance to wear over time.

Wheels: Designed for easy navigation, they help maintain balance and stability across varying terrains.

Each of these parts contributes to the overall functionality, making it vital to keep them in good condition for peak performance.

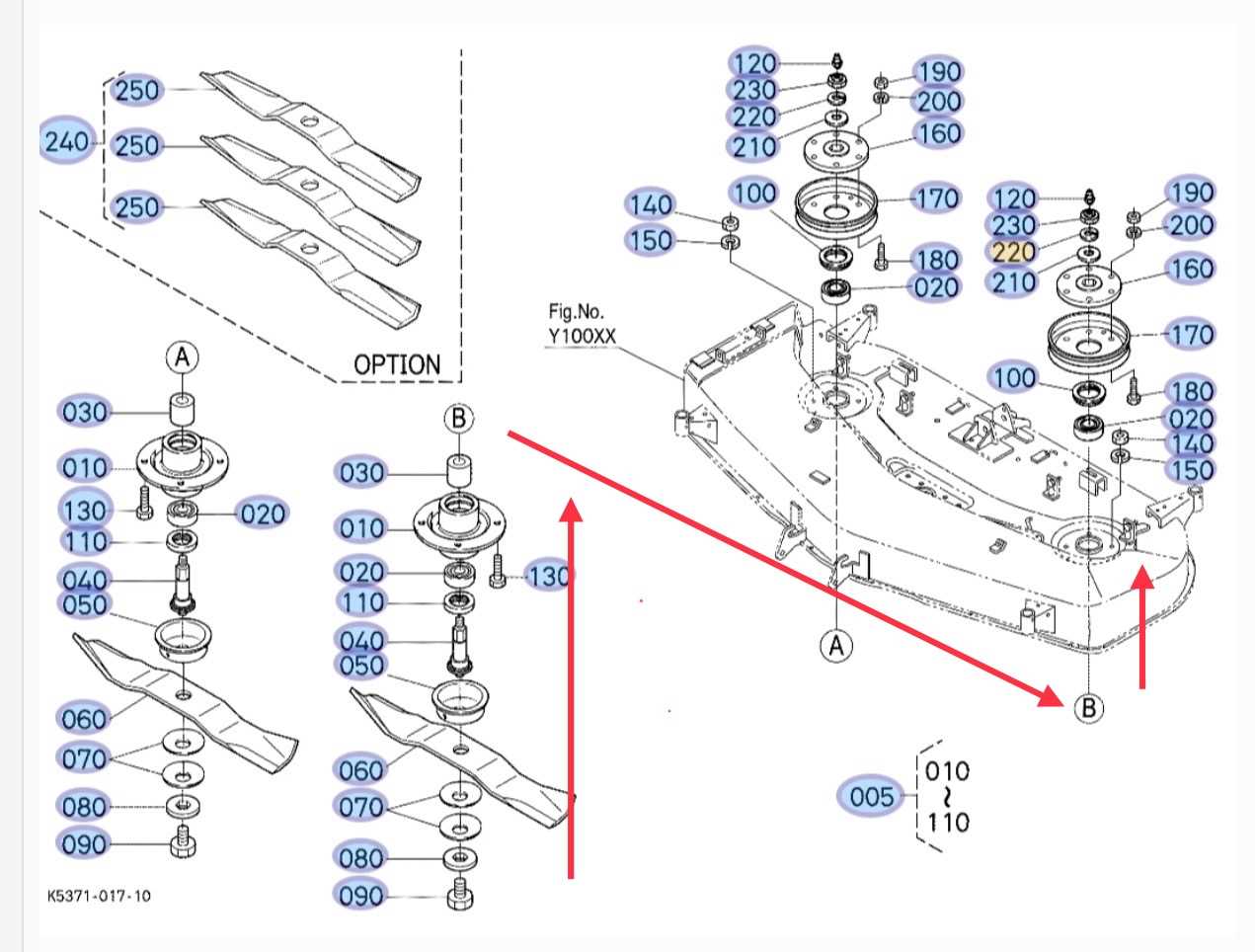

How to Read a Parts Diagram

Understanding the visual representation of components is crucial for effective maintenance and repairs. These illustrations offer insights into how various elements fit together and function within a system. By mastering the key features of these visuals, users can enhance their troubleshooting skills and streamline repair processes.

Key Elements to Identify

- Labels: Look for clear identifiers that correspond to each component.

- Connections: Pay attention to how different parts are linked, as this reveals the assembly structure.

- Numbering: Often, items are numbered to correspond with a list that provides detailed descriptions.

Tips for Effective Interpretation

- Start with an overview to grasp the entire system layout.

- Refer to the accompanying list for clarification on each labeled item.

- Use a magnifying glass for intricate details if necessary.

Common Issues and Solutions

When operating lawn care machinery, users may encounter various challenges that can impact performance and efficiency. Identifying these common problems and implementing effective solutions is crucial for maintaining optimal functionality and prolonging the life of the equipment.

Common Challenges

- Overheating during operation

- Uneven cutting results

- Difficulty starting the engine

- Excessive vibrations

- Clogged discharge areas

Potential Solutions

-

Overheating:

- Ensure proper lubrication of moving parts.

- Check coolant levels and consider flushing the cooling system.

-

Uneven Cutting:

- Inspect and sharpen the blades regularly.

- Adjust the cutting height for consistency across the lawn.

-

Starting Issues:

- Verify fuel quality and replace old fuel if necessary.

- Examine the battery and connections for corrosion or damage.

-

Vibrations:

- Check for loose bolts and tighten as needed.

- Inspect the frame and components for wear or misalignment.

-

Clogs:

- Regularly clean the discharge area to prevent buildup.

- Ensure the cutting deck is free from debris and grass clippings.

By addressing these issues promptly and effectively, users can enhance the longevity and reliability of their equipment, ensuring a smoother and more productive experience during lawn maintenance tasks.

Maintenance Tips for RCK54-22BX

Regular upkeep is essential for ensuring the longevity and optimal performance of your lawn care equipment. By following a systematic approach to maintenance, you can prevent issues before they arise and keep your machine running smoothly. This section offers valuable insights into the best practices for maintaining your gear, ensuring it remains reliable throughout the seasons.

Routine Inspections

Conducting routine inspections is vital for identifying any wear and tear early on. Check all moving components for signs of damage or excessive wear. Pay special attention to belts, blades, and filters, ensuring they are clean and in good condition. Regularly verifying fluid levels and replacing them as necessary will also help maintain optimal performance.

Cleaning and Storage

After each use, clean your equipment thoroughly to remove grass clippings, dirt, and debris. This practice not only enhances performance but also prevents rust and corrosion. When storing your machine, ensure it is kept in a dry, sheltered location. Using a cover can also protect it from dust and moisture, prolonging its lifespan.

Where to Find Replacement Parts

Finding the right components for your equipment is essential for maintaining its performance and longevity. With a variety of options available, knowing where to look can save you time and money. Below are some reliable sources to help you locate the necessary replacements efficiently.

Online Retailers

- Dedicated machinery websites often offer extensive catalogs.

- Major e-commerce platforms provide user reviews and competitive pricing.

- Specialized forums may connect you with sellers of used or hard-to-find items.

Local Dealerships and Repair Shops

- Authorized dealers can provide genuine components and expert advice.

- Local repair shops may have parts in stock or can order them for you.

- Networking with professionals in the field can yield recommendations for trusted sources.

By exploring these avenues, you can ensure that you find the appropriate components to keep your equipment in optimal condition.

Understanding Part Numbers and Codes

Deciphering the alphanumeric sequences used in machinery can be crucial for maintenance and repair. These codes serve as a universal language, providing insights into specifications, compatibility, and sourcing. A thorough comprehension of these identifiers enables users to effectively navigate inventory and ensures the correct selection of components for various tasks.

The Structure of Identification Codes

Typically, these codes consist of a series of letters and numbers that convey specific information about the item. The initial characters often indicate the category or type of equipment, while subsequent digits may represent size, model variations, or production dates. Recognizing this structure can significantly streamline the process of finding the right components.

Why Accurate Identification Matters

Choosing the appropriate identifiers is essential to maintain the efficiency and longevity of machinery. Using the wrong components can lead to malfunctions, increased wear, and potentially costly repairs. By understanding how to read and interpret these codes, users can make informed decisions, ensuring their equipment operates at optimal levels.

DIY Repairs for Lawn Equipment

Maintaining your lawn machinery can significantly enhance its performance and longevity. Engaging in do-it-yourself repairs not only saves money but also empowers you with the knowledge to troubleshoot issues effectively. Whether it’s sharpening blades or replacing worn-out components, taking a hands-on approach can ensure your equipment remains in top shape throughout the seasons.

Before embarking on any repair project, it’s essential to gather the necessary tools and familiarize yourself with the machinery’s workings. Basic tools like wrenches, screwdrivers, and safety gear are crucial for any repair task. Understanding the components involved will allow you to diagnose problems accurately and make informed decisions about repairs.

Routine maintenance tasks, such as cleaning air filters and changing oil, can prevent more significant issues down the line. Regularly inspecting belts and cables for wear will help identify potential failures early. When tackling repairs, always refer to the manufacturer’s guidelines for best practices and specifications.

Embracing a DIY mindset fosters confidence and can lead to a deeper appreciation for your equipment. Many online resources, including tutorials and forums, provide invaluable insights and troubleshooting tips. By learning to repair and maintain your lawn tools, you’ll not only save money but also contribute to a healthier, greener environment.

Professional Service Options Available

For those seeking reliable maintenance and repair solutions, a variety of expert services are accessible. These options ensure that your equipment functions efficiently and remains in top condition throughout its lifespan.

- Comprehensive Inspections

- Routine Maintenance Packages

- Expert Repair Services

- Customized Upgrades

- Emergency Support

Engaging with professional service providers can enhance the performance of your machinery. Here are some key offerings to consider:

- Comprehensive Inspections: Regular assessments to identify potential issues before they become major problems.

- Routine Maintenance Packages: Scheduled services that include cleaning, lubrication, and necessary adjustments.

- Expert Repair Services: Skilled technicians available to address specific mechanical failures or malfunctions.

- Customized Upgrades: Options for enhancing functionality through the latest technology and improvements.

- Emergency Support: Rapid response services for urgent repairs, minimizing downtime and disruptions.

Investing in professional assistance not only prolongs the life of your equipment but also optimizes its overall performance, ensuring you get the most out of your investment.

Comparing RCK54-22BX with Other Models

When evaluating different mowing equipment, it’s essential to consider various models and their unique features. Each machine is designed with specific purposes in mind, and understanding the distinctions can greatly influence your choice for lawn care. This section will delve into the comparative aspects of one particular model against its peers, highlighting key functionalities and performance metrics.

Performance and Efficiency

One of the main factors to consider is the performance level of the equipment. Certain models may offer superior cutting efficiency, while others excel in speed or maneuverability. Performance metrics can include factors such as horsepower, blade width, and overall cutting height adjustment. It’s important to assess how these features align with your landscaping needs.

Durability and Maintenance

Another significant aspect to compare is the durability of the equipment and the ease of maintenance. Some models come equipped with robust materials and construction, ensuring a longer lifespan. Maintenance requirements can vary greatly; some machines may need frequent servicing, while others are designed for minimal upkeep. Evaluating these elements will help you choose a model that suits your long-term usage plans.

Customer Reviews and Experiences

In this section, we delve into the insights and feedback shared by users regarding their experiences with various equipment and accessories. These reviews offer valuable perspectives, highlighting performance, durability, and overall satisfaction. Understanding these firsthand accounts can guide potential buyers in making informed decisions.

Many customers appreciate the reliability and effectiveness of their machinery. Here are some common themes found in the reviews:

- Performance: Users often note how well the equipment meets their needs, particularly in maintaining their lawns or gardens.

- Ease of Use: Feedback frequently mentions the intuitive design, making operation simple for both novices and experienced users.

- Durability: A significant number of reviews highlight the longevity of the product, with many reporting years of effective service without major issues.

- Customer Support: Many customers express satisfaction with the assistance received from service teams when needed, noting prompt responses and helpful guidance.

In addition to positive experiences, some users provide constructive criticism, which can be just as informative:

- Assembly Challenges: A few reviews point out difficulties encountered during setup, suggesting clearer instructions could enhance the experience.

- Maintenance Needs: Some customers mention the need for regular upkeep, emphasizing the importance of understanding care requirements.

- Availability of Replacement Components: Several users have raised concerns about finding specific items, indicating that access to replacements can sometimes be limited.

Ultimately, these experiences reflect a diverse range of opinions that can help future customers make well-rounded choices. Engaging with these reviews can lead to a better understanding of what to expect and how to maximize the potential of their equipment.

Future Upgrades and Accessories

As technology and user needs evolve, enhancing your equipment can significantly improve its functionality and efficiency. Exploring innovative upgrades and accessories can transform standard operations into a more streamlined and enjoyable experience. Whether you seek to boost performance, increase versatility, or simply make tasks easier, the options are abundant.

Performance Enhancements

Investing in performance upgrades can lead to noticeable improvements in speed and efficiency. Consider options such as advanced cutting systems or high-efficiency engines that not only optimize productivity but also reduce fuel consumption. These enhancements ensure that your machinery remains competitive and reliable in various conditions.

Convenience Accessories

Accessories designed for convenience can make operation more user-friendly and less physically demanding. Items like ergonomic handles, easy-connect attachments, and enhanced navigation systems can greatly improve the overall user experience. Additionally, protective covers and storage solutions help maintain your equipment in top condition, prolonging its lifespan and usability.