Kubota RTV-X1120D Parts Diagram Overview

The efficiency and longevity of any utility vehicle heavily rely on its internal mechanisms. Having a comprehensive understanding of these elements is crucial for optimal performance and maintenance. This section aims to unravel the intricate relationships between various components, providing you with the knowledge needed to ensure your machine runs smoothly.

By exploring the individual elements, you can identify potential areas for improvement and address issues before they escalate. This approach not only enhances functionality but also extends the lifespan of your vehicle. Understanding how each part interacts within the system is key to achieving the ultimate efficiency.

As you delve into the details, you will gain valuable insights that empower you to make informed decisions regarding repairs and upgrades. Mastering the layout of these components enables you to tackle challenges with confidence and precision, ultimately enhancing your overall experience with your utility vehicle.

Kubota RTV-X1120D Overview

This section provides a comprehensive look at a versatile utility vehicle designed for various tasks in agriculture, landscaping, and recreational activities. With a focus on efficiency and reliability, this model stands out for its robust build and innovative features that cater to the needs of both professional users and enthusiasts.

Key Features

One of the standout characteristics of this utility machine is its powerful engine, which ensures high performance and excellent towing capacity. The spacious cargo bed allows for transporting tools, equipment, or materials effortlessly. Additionally, the four-wheel drive system enhances stability and traction, making it suitable for diverse terrains.

Comfort and Usability

Designed with user comfort in mind, this vehicle includes ergonomic seating and intuitive controls, facilitating easy operation even in demanding conditions. The cab offers protection from the elements, while the ample storage options provide convenience for everyday tasks. Overall, this utility vehicle represents a blend of functionality and comfort, making it a preferred choice for many applications.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for efficient maintenance and repair. Visual representations serve as invaluable tools, enabling users to grasp the relationships and functions of individual elements within complex systems.

Facilitating Repairs

These illustrations significantly enhance the repair process by providing clear insights into how each part interacts. With a detailed view, technicians can quickly identify issues, locate replacement components, and streamline their workflow, ultimately leading to faster turnaround times.

Improving Knowledge

Additionally, such visual aids foster deeper understanding. By studying these representations, users can delve into the mechanics of their equipment, empowering them with the knowledge needed to make informed decisions about maintenance and upgrades. This ultimate comprehension can lead to enhanced performance and longevity of the machinery.

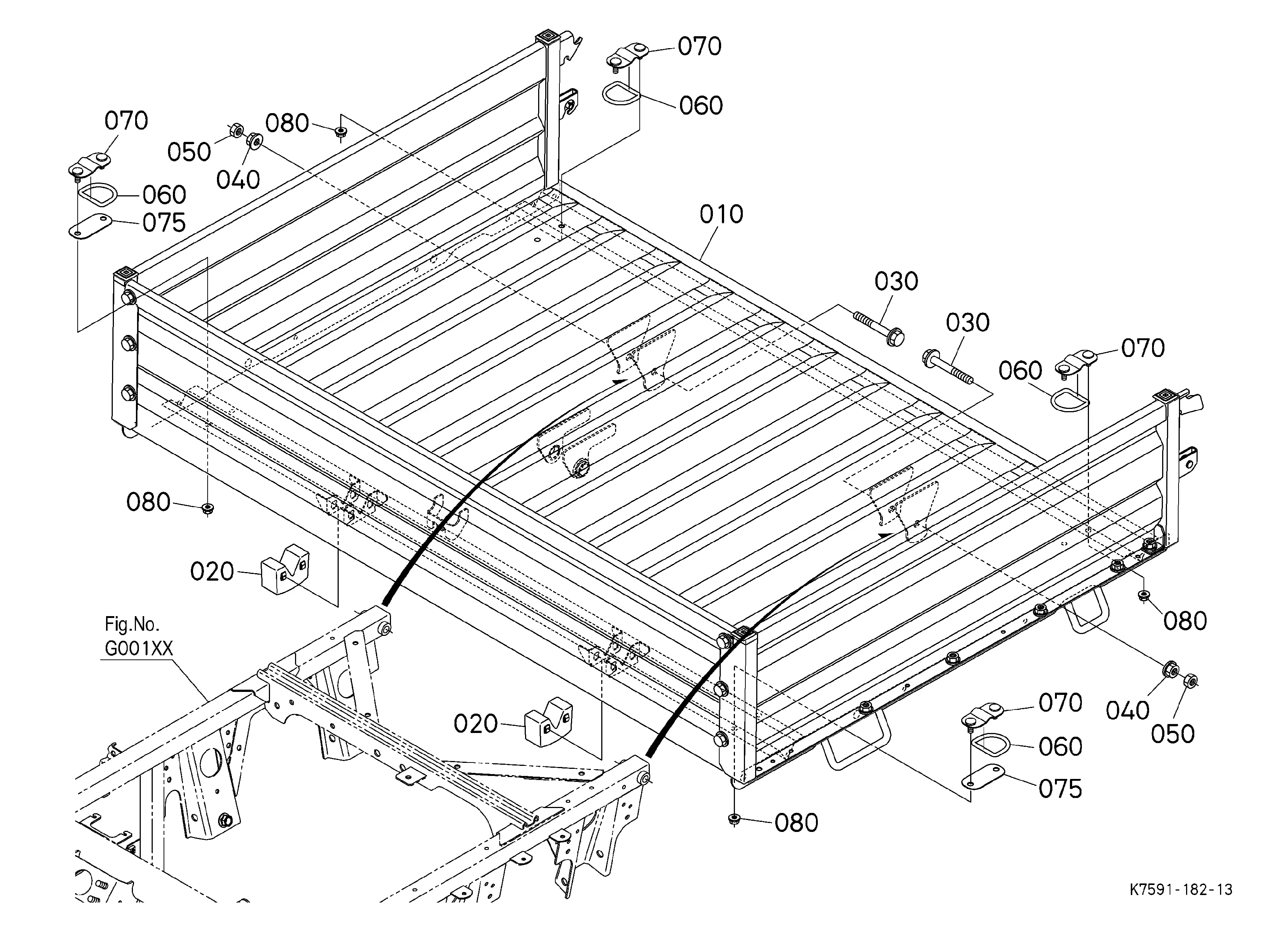

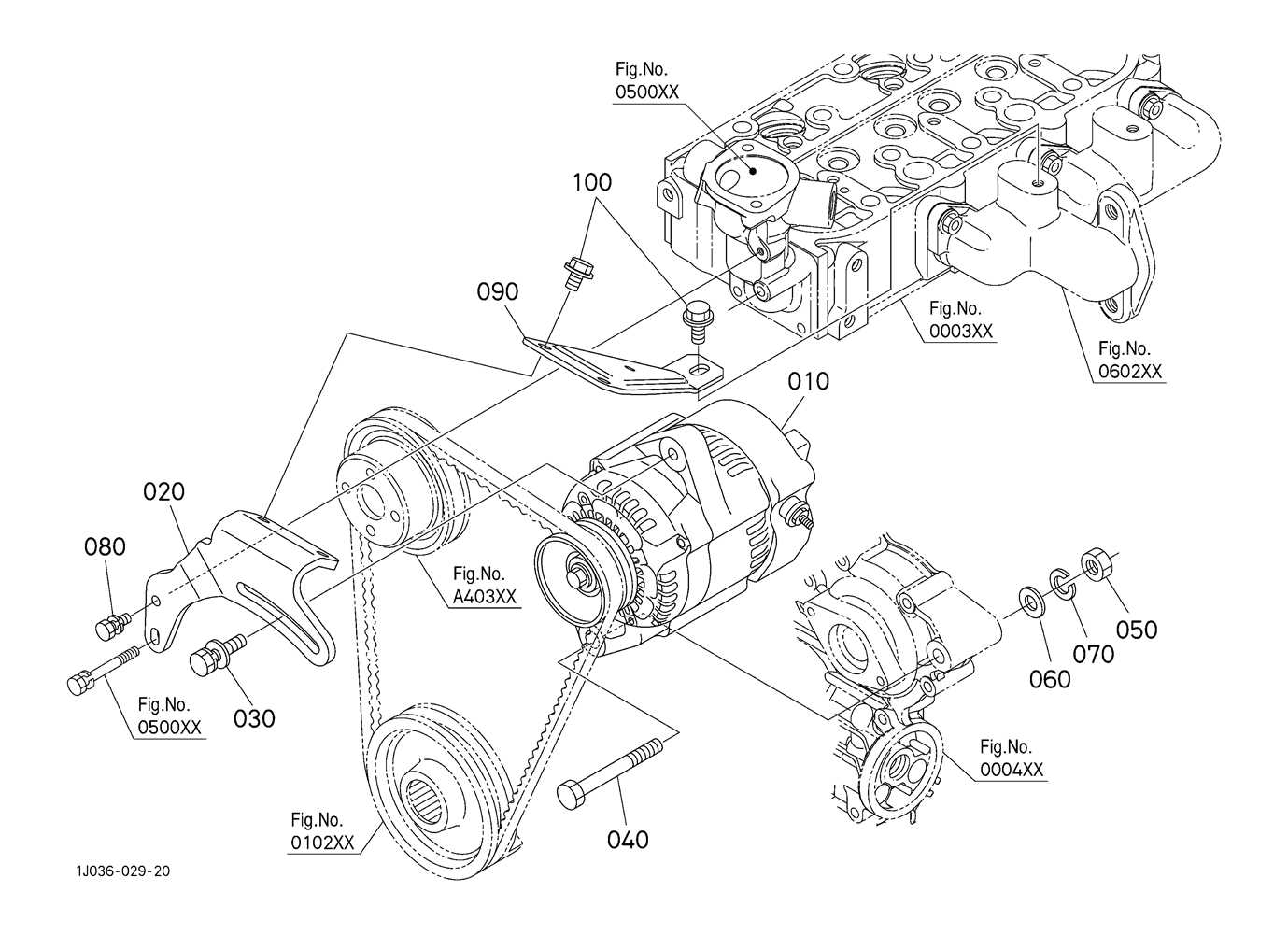

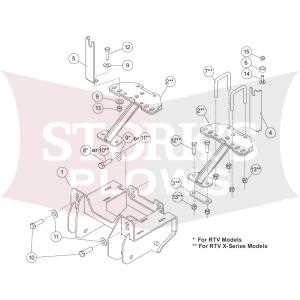

Main Components of RTV-X1120D

The robust utility vehicle features several essential elements that contribute to its functionality and efficiency. Each component plays a critical role in ensuring optimal performance, whether it’s for work or recreational use.

At the heart of the vehicle lies the powerful engine, providing the necessary torque and horsepower to tackle various terrains. Complementing this are the transmission and drivetrain systems, which ensure smooth acceleration and reliable handling. The chassis, built for durability, supports both passenger and cargo loads while enhancing stability.

Furthermore, the advanced suspension system absorbs shocks, improving ride comfort over rough surfaces. Essential for operation are the steering and braking mechanisms, which offer precise control and safety. Finally, various electrical systems manage lights, diagnostics, and accessories, ensuring everything operates seamlessly.

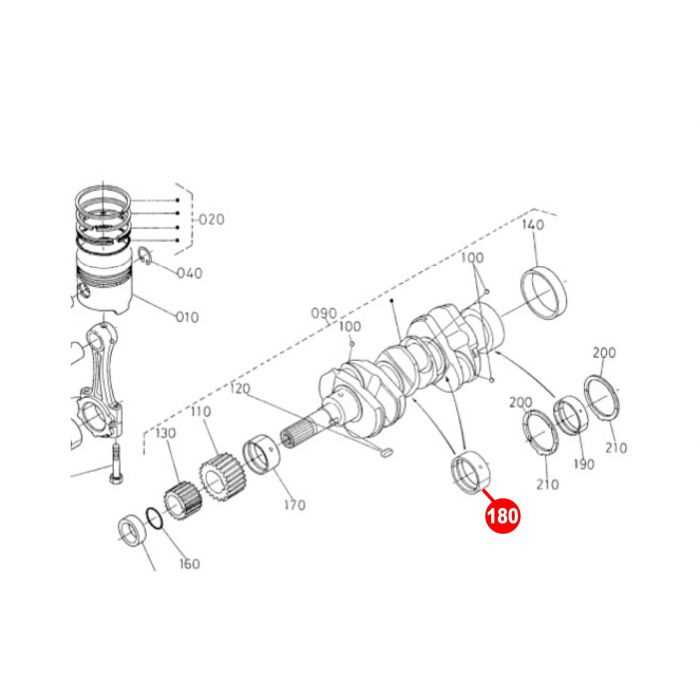

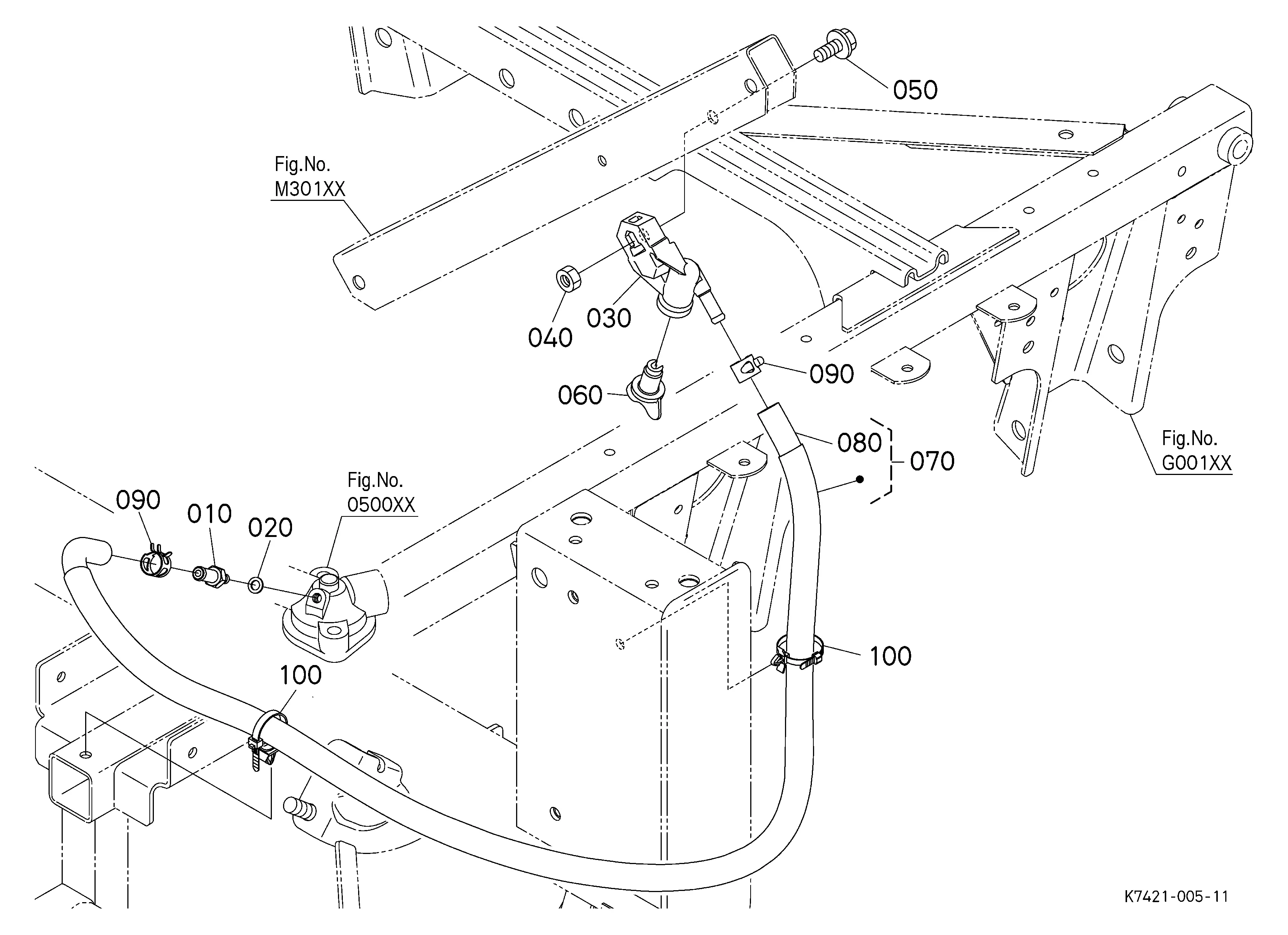

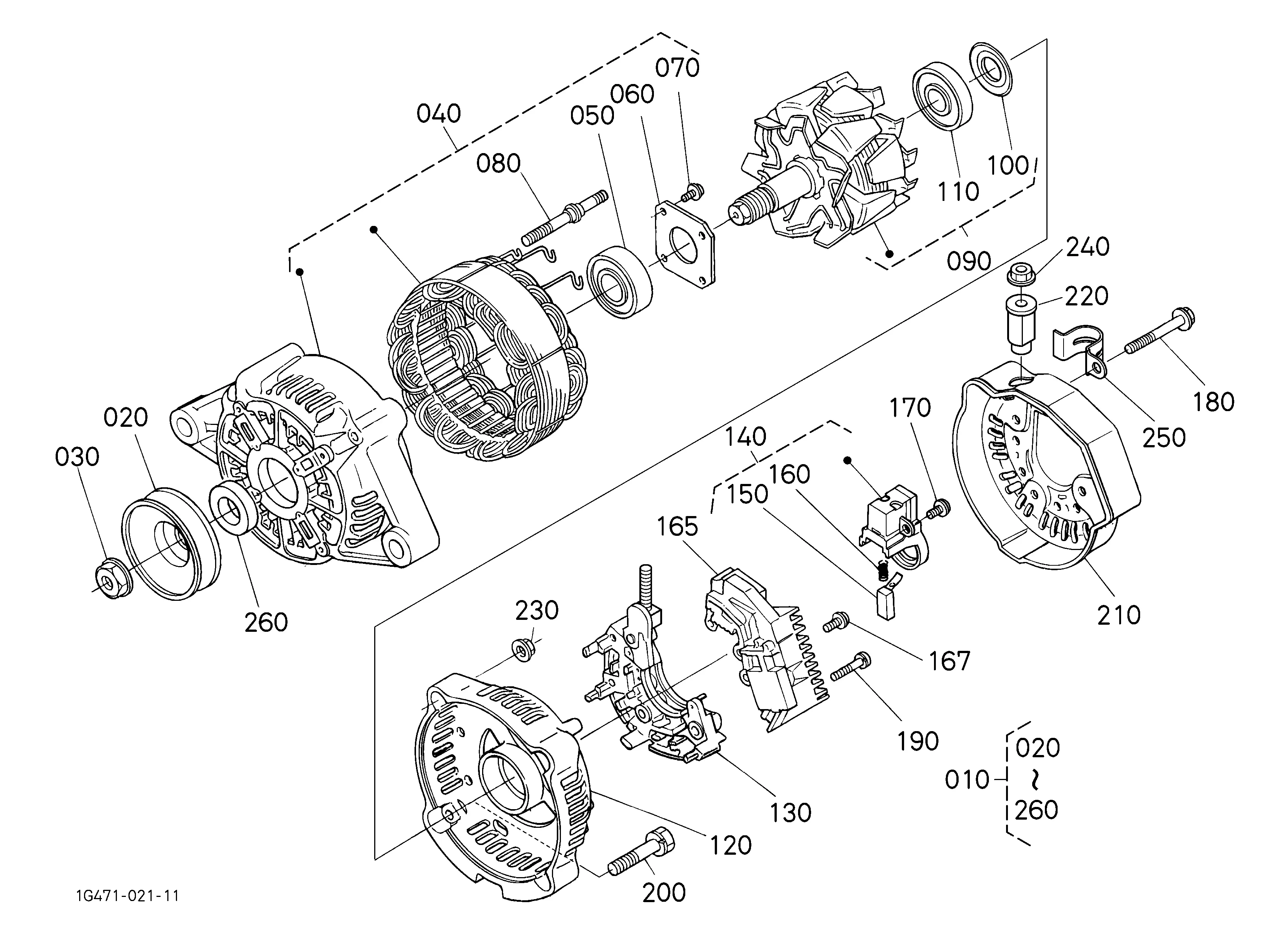

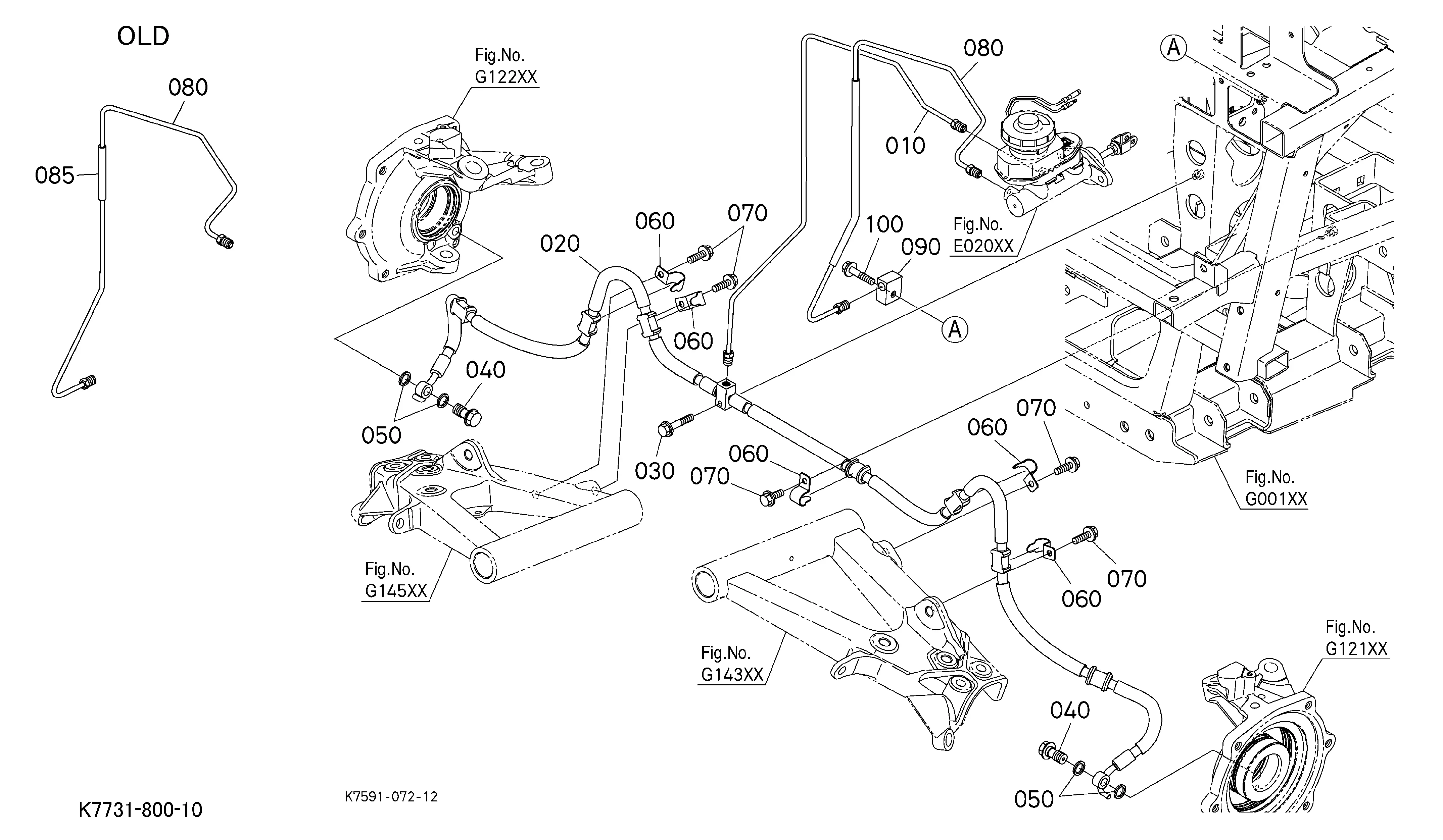

How to Read the Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repairs. These visuals provide a clear representation of components, allowing users to identify parts and their connections within the machinery.

Key Elements to Consider

- Labels: Each component is typically labeled with a unique identifier.

- Reference Numbers: These numbers correlate with parts lists, aiding in precise ordering.

- Connections: Arrows and lines indicate how parts fit together, illustrating the assembly process.

Steps for Effective Reading

- Start by familiarizing yourself with the overall layout.

- Identify and note the components you need.

- Cross-reference with the accompanying list to confirm details.

- Use the illustration as a guide during disassembly or assembly.

Common Replacement Parts Explained

When it comes to maintaining utility vehicles, understanding the frequently replaced components is crucial for optimal performance and longevity. Many parts endure significant wear and tear, necessitating timely replacements to ensure smooth operation and prevent further damage. This section delves into the essential elements that often require attention and offers insights into their roles and significance.

Engine Components

The engine is the heart of any vehicle, and its components play a vital role in performance. Commonly replaced items include filters, spark plugs, and belts. Regular maintenance of these elements ensures efficient fuel combustion and reduces the risk of engine failure. Neglecting these parts can lead to reduced power and increased emissions, making their upkeep essential for longevity.

Transmission Elements

The transmission system is equally important, with parts such as fluids, seals, and gears needing periodic replacement. Maintaining these components helps in smooth shifting and overall drivability. Over time, wear can cause slippage and delayed response, which can significantly affect performance. Regular checks and timely replacements are key to avoiding costly repairs and ensuring a reliable driving experience.

Tools Needed for Maintenance

Regular upkeep of your utility vehicle requires a selection of essential instruments to ensure optimal performance and longevity. These implements facilitate both routine checks and more extensive repairs, making them crucial for any operator.

First and foremost, a wrench set is indispensable for loosening and tightening various components. A socket set can further enhance efficiency, allowing access to tight spaces. Additionally, screwdrivers in multiple sizes and types are vital for adjusting smaller fittings and securing panels.

For fluid changes, a drain pan is necessary to collect used oils or fluids, while a filter wrench aids in the removal of old filters. Keeping a tire pressure gauge handy ensures that tires maintain proper inflation, contributing to safety and fuel efficiency. Lastly, a basic toolbox to store all these items will keep everything organized and accessible.

Identifying Parts by Model Number

Understanding how to pinpoint specific components for your machinery is crucial for maintenance and repairs. By utilizing model identifiers, you can streamline the process of sourcing the right items, ensuring compatibility and efficiency. This knowledge allows users to navigate catalogs and inventories with confidence, enhancing overall equipment longevity.

When looking for specific elements, follow these guidelines:

| Step | Description |

|---|---|

| 1 | Locate the model number on your equipment; it is typically found on the frame or engine. |

| 2 | Consult the manufacturer’s catalog or website, entering the model number to access a list of compatible components. |

| 3 | Cross-reference the found items with your current inventory to ensure you are acquiring the correct replacements. |

| 4 | Order the identified components from a reputable supplier to ensure quality and reliability. |

By following these steps, you can efficiently identify and acquire the necessary items, minimizing downtime and enhancing the performance of your equipment.

Where to Find Genuine Parts

When seeking authentic components for your machinery, it’s essential to ensure quality and reliability. Using original items not only guarantees compatibility but also enhances the performance and longevity of your equipment.

Authorized Dealers are the most trustworthy source. These retailers provide an extensive range of certified items, ensuring you receive what you need without compromise.

Additionally, Manufacturer Websites often have dedicated sections for replacement items. Browsing these platforms allows you to explore a complete catalog and check availability.

Another option is Online Marketplaces, where numerous sellers offer genuine components. However, it’s crucial to verify the seller’s reputation to avoid counterfeit products.

Finally, Local Repair Shops may have access to authentic inventory or be able to order directly from the manufacturer, ensuring you get the right items for your needs.

DIY Maintenance Tips

Regular upkeep is essential for ensuring the longevity and performance of your outdoor vehicle. Engaging in hands-on maintenance not only saves money but also enhances your understanding of the machinery. Here are some practical suggestions to keep your equipment in optimal condition.

- Regular Inspections: Check for any signs of wear or damage frequently.

- Fluid Levels: Ensure that oil, coolant, and fuel levels are adequate.

- Filter Replacement: Change air and fuel filters periodically to maintain efficiency.

- Clean the exterior and undercarriage to prevent rust and debris buildup.

- Inspect belts and hoses for cracks or fraying.

- Lubricate moving parts to reduce friction and wear.

By following these tips, you can significantly enhance the performance and lifespan of your machinery, making your DIY maintenance efforts truly rewarding.

Benefits of Regular Inspections

Conducting routine evaluations of machinery is essential for maintaining optimal performance and longevity. These assessments help identify potential issues before they escalate, ensuring that equipment operates efficiently and safely.

Increased Safety

Regular checks significantly enhance safety by minimizing the risk of malfunctions. Early detection of wear and tear allows for timely repairs, protecting operators and preventing accidents.

Cost-Effectiveness

Proactive maintenance leads to cost savings by reducing unexpected breakdowns and extending the lifespan of components. Investing in regular inspections ultimately saves resources and improves overall operational efficiency.

Customer Support for Parts Issues

Effective assistance is crucial when encountering challenges related to components. A dedicated support system can ensure that users receive the guidance needed to resolve any concerns promptly.

- Contact Methods

- Response Time

- Expertise of Support Staff

To enhance the experience, here are several avenues for reaching out:

- Phone Support: Direct communication allows for immediate feedback.

- Email Assistance: For less urgent matters, emailing provides a written record.

- Online Chat: Quick responses for real-time solutions.

Ensuring satisfaction in resolving component-related inquiries ultimately enhances the user experience and fosters trust in the service provided.

Resources for Further Information

Accessing accurate and detailed information is essential for anyone seeking to enhance their knowledge about specific machinery and its components. A variety of resources are available to assist users in understanding the intricacies of their equipment, ensuring optimal performance and maintenance.

Official Manufacturer Websites

One of the most reliable sources of information is the official website of the manufacturer. Here, users can find technical specifications, maintenance guidelines, and user manuals. These resources often include updates and announcements that can be crucial for keeping equipment in top condition.

Online Forums and Communities

Engaging with online communities dedicated to machinery can provide valuable insights and real-world experiences. Forums allow users to ask questions, share knowledge, and discuss common issues, fostering a sense of collaboration among enthusiasts and professionals alike. Additionally, many of these platforms feature sections for sharing tips and troubleshooting advice.

For those looking to deepen their understanding, exploring various resources can significantly enhance both the knowledge and efficiency in managing machinery.