Kubota Skid Steer Parts Diagram for Ultimate Maintenance

In the world of heavy machinery, efficient operation relies heavily on the intricate assembly of various elements. Each component plays a crucial role in ensuring the functionality and reliability of these powerful machines. A clear visualization of these elements can significantly enhance maintenance practices and repair strategies.

For those involved in the operation and upkeep of compact loaders, comprehending the layout and relationship between different parts is essential. This knowledge not only aids in troubleshooting but also helps in identifying the right replacements when needed. Detailed schematics serve as invaluable resources for operators and technicians alike.

Exploring the composition of these machines reveals how each section contributes to overall performance. Whether you are a seasoned professional or a newcomer, understanding these assemblies will empower you to maximize the efficiency and lifespan of your equipment.

Kubota Skid Steer Overview

This section provides an insight into a versatile type of machinery designed for a range of applications, particularly in construction and agriculture. These compact vehicles are engineered to handle various tasks, offering exceptional maneuverability and efficiency in tight spaces.

Featuring a robust structure, these machines are equipped with powerful engines that deliver impressive performance. Their ability to switch between attachments allows operators to easily adapt to different jobs, enhancing productivity on-site.

Durability is a key characteristic, ensuring longevity even under demanding conditions. The intuitive controls make it accessible for users of varying skill levels, providing a balance of power and ease of use.

In summary, this machinery represents a significant investment for businesses seeking reliability and flexibility in their operations, making it an essential tool in modern-day tasks.

Key Components of Skid Steers

Understanding the essential elements of compact machinery is crucial for optimal performance and maintenance. These vehicles consist of various parts that work in harmony to provide versatility and efficiency in diverse tasks. Each component plays a significant role in the overall functionality, ensuring that operations are smooth and effective.

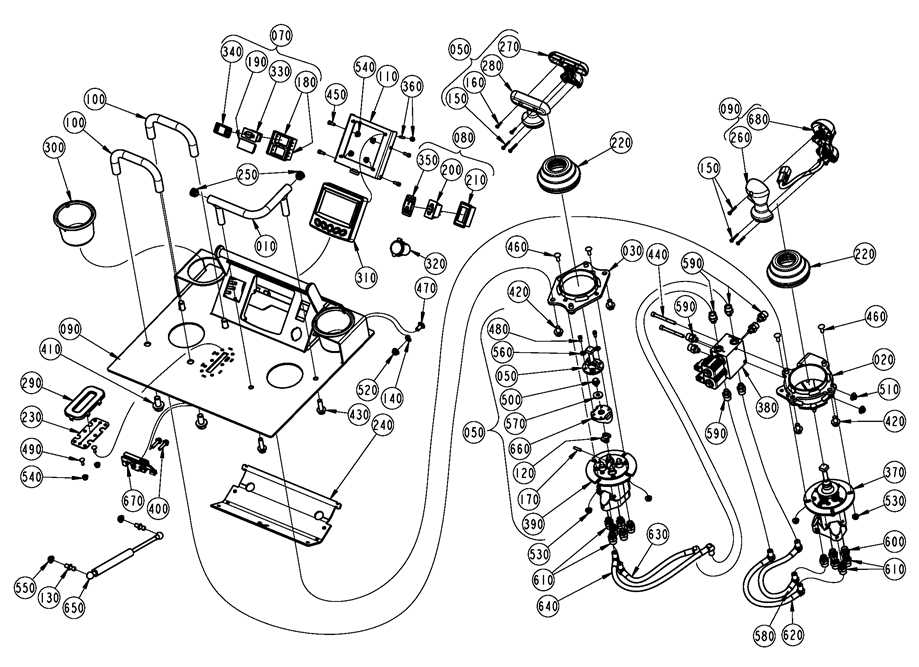

The engine serves as the powerhouse, delivering the necessary energy for movement and operation. Coupled with a robust hydraulic system, it enables precise control of attachments and implements. The chassis forms the backbone, providing stability and durability during operation, while the wheels or tracks ensure traction across various terrains.

Furthermore, the operator’s cabin is designed for comfort and visibility, allowing users to maneuver with ease. Control mechanisms, including levers and pedals, facilitate seamless interaction with the machine. Understanding these key elements is essential for anyone looking to maximize the capabilities of this versatile equipment.

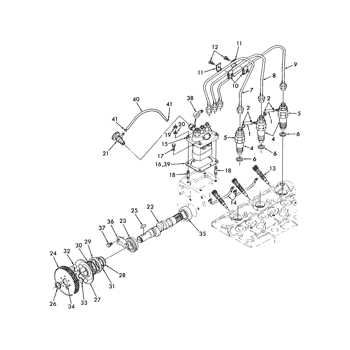

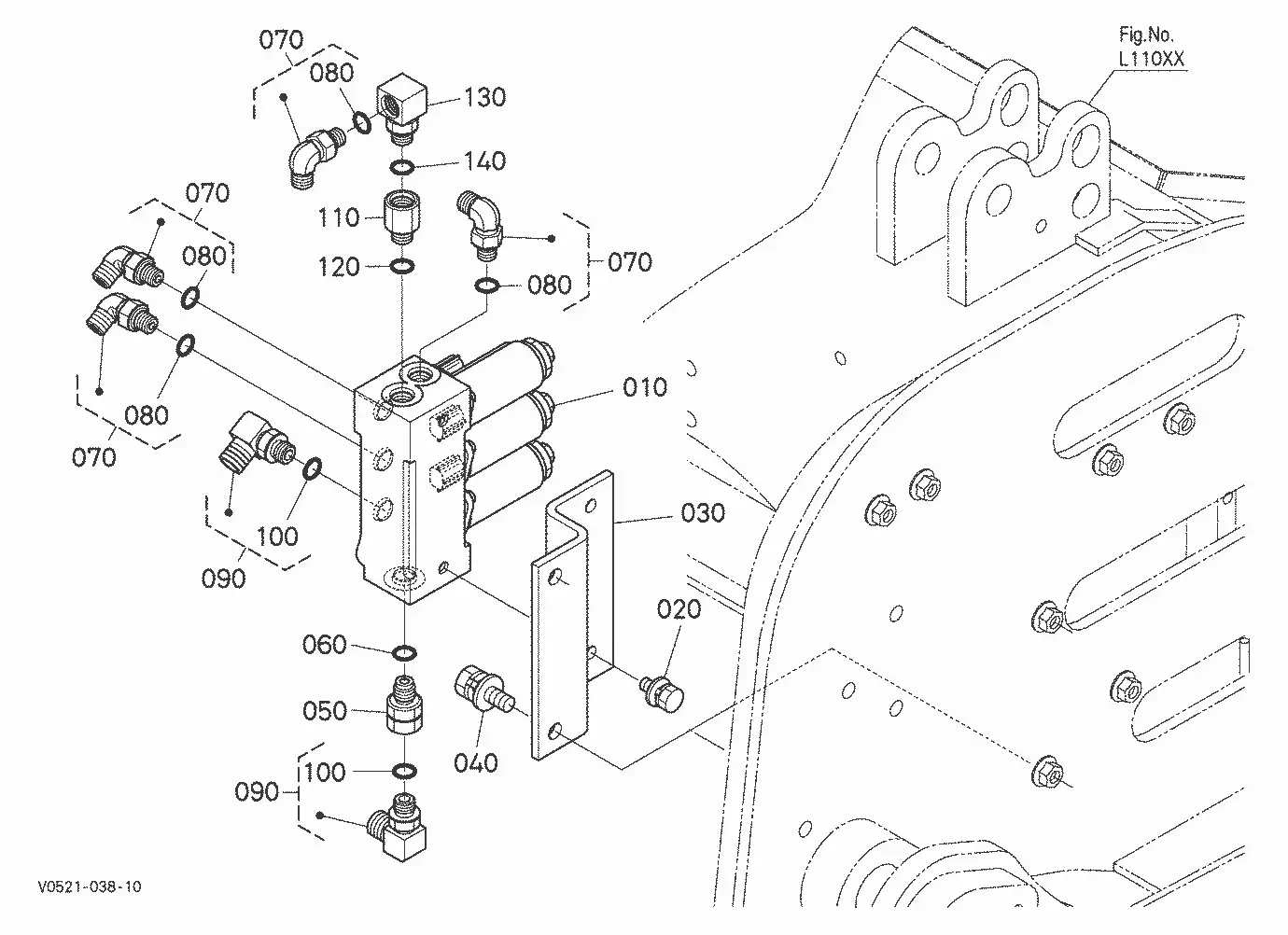

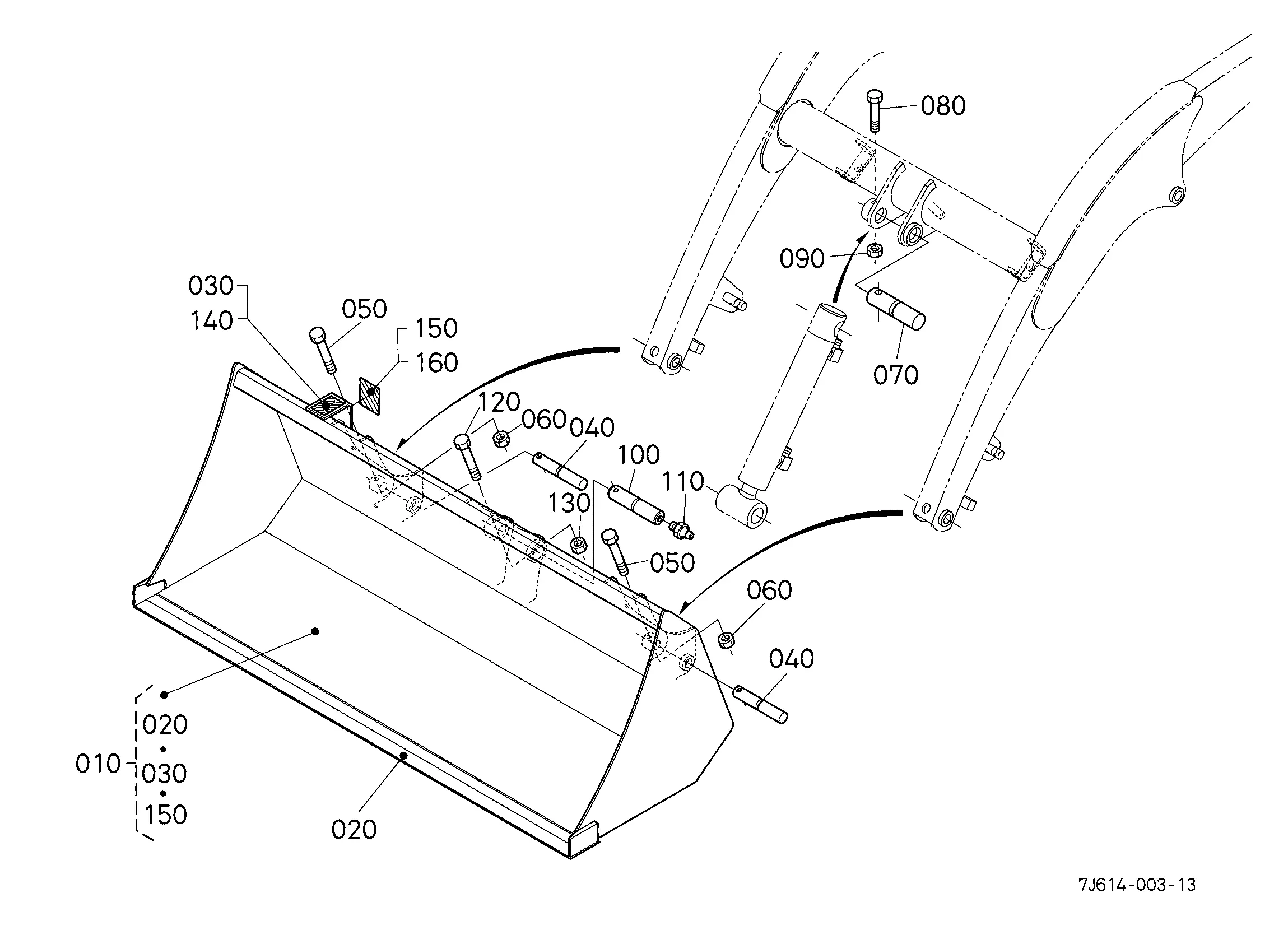

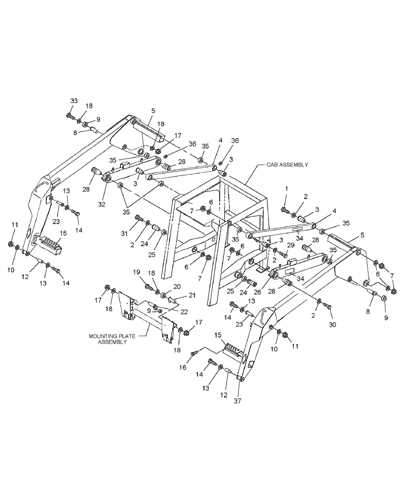

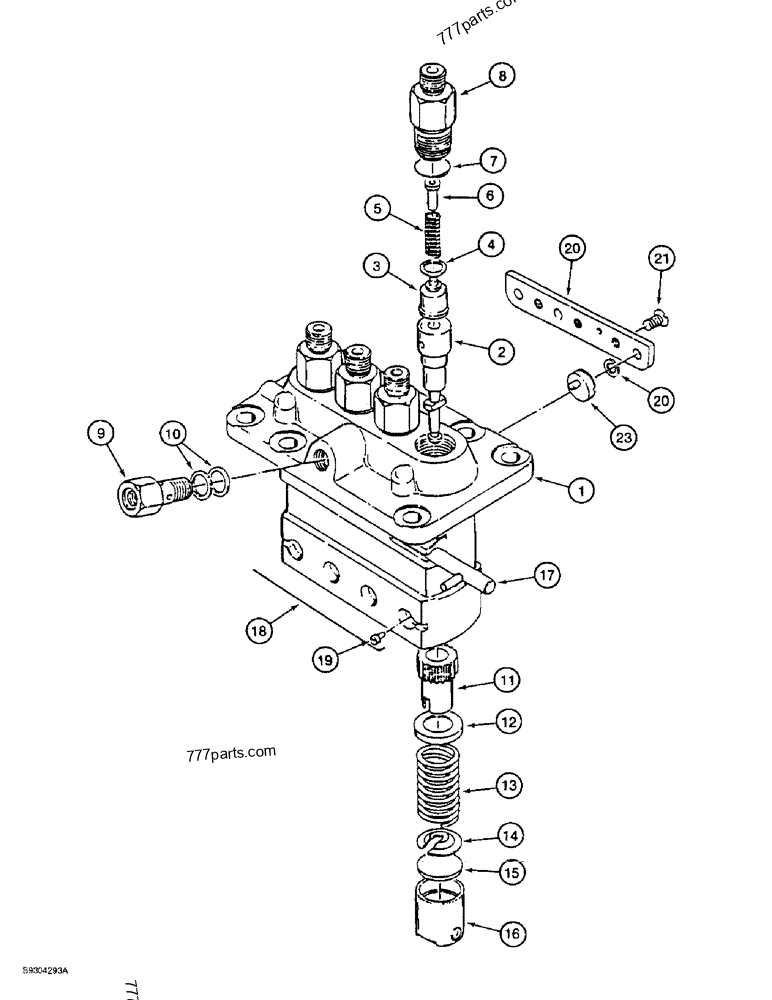

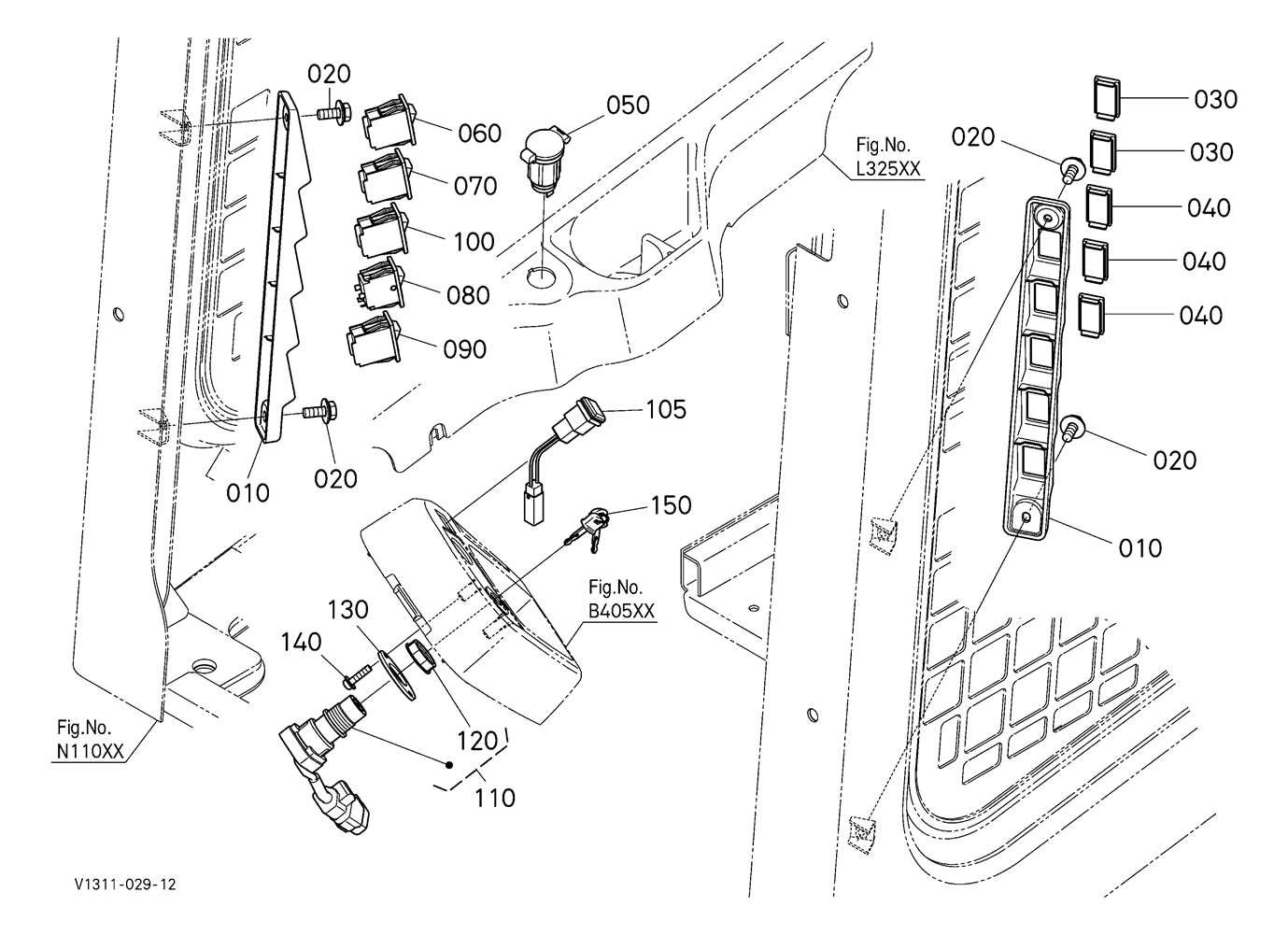

Understanding Parts Diagrams

Comprehending assembly visuals is crucial for anyone working with machinery. These illustrations serve as guides, helping users identify components and their arrangements, ultimately aiding in maintenance and repairs.

Key benefits of mastering these visuals include:

- Enhanced troubleshooting capabilities

- Improved accuracy during repairs

- Streamlined maintenance processes

When analyzing these visuals, consider the following aspects:

- Component Labels: Each part is usually labeled for easy identification.

- Relationship Indicators: Arrows or lines may show how pieces interact.

- Reference Numbers: Corresponding numbers help locate items in manuals or catalogs.

By delving into these elements, users can achieve a more thorough understanding of their equipment and ensure its longevity.

Benefits of Using Genuine Parts

Opting for authentic components offers numerous advantages that enhance the longevity and performance of machinery. These original items are specifically designed to fit seamlessly, ensuring optimal functionality and reducing the risk of breakdowns. Moreover, they often come with warranties, providing peace of mind for operators and owners alike.

| Advantage | Description |

|---|---|

| Quality Assurance | Genuine components undergo rigorous testing to meet high standards. |

| Longevity | Designed for durability, they tend to last longer than aftermarket alternatives. |

| Performance | Ensure optimal performance by maintaining the intended specifications of the machinery. |

| Warranty Coverage | Often include warranty protection, safeguarding your investment. |

| Resale Value | Using authentic components can enhance the resale value of the equipment. |

Common Issues with Kubota Skid Steers

Operating compact machinery can lead to various challenges, often stemming from wear and tear or improper maintenance. Identifying these common problems is crucial for ensuring optimal performance and longevity. Below are some frequent concerns that operators may encounter.

Mechanical Failures

- Hydraulic leaks: These can cause reduced lifting capacity and compromised control.

- Engine overheating: Insufficient coolant or faulty thermostats can lead to severe damage.

- Electrical issues: Battery problems or faulty wiring may result in starting difficulties or operational malfunctions.

Performance Issues

- Reduced power: This may indicate fuel system blockages or air filter obstructions.

- Inconsistent movement: Worn out drive belts or under-inflated tires can impact mobility and stability.

- Unusual noises: Grinding or clunking sounds might suggest the need for gearbox inspections or bearing replacements.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of machinery. Regular maintenance not only enhances efficiency but also minimizes unexpected breakdowns and costly repairs. Below are several strategies to maintain equipment effectively.

- Regular Inspections: Schedule frequent checks to identify wear and tear. Look for any signs of leaks, unusual noises, or other irregularities.

- Clean Components: Keep all parts clean to prevent dirt and debris from causing damage. Use appropriate cleaning agents and tools to avoid harmful residues.

- Fluid Levels: Monitor and maintain the correct levels of oil, hydraulic fluids, and coolants. Regularly change fluids as recommended to ensure smooth operation.

- Filter Replacement: Change filters as per the manufacturer’s recommendations. Clogged filters can lead to reduced efficiency and potential damage.

- Check Belts and Hoses: Inspect belts for cracks and wear, and hoses for signs of deterioration. Replace any damaged components promptly.

Implementing these tips will contribute significantly to the longevity and reliability of your machinery, ensuring it remains a valuable asset for years to come.

Finding Replacement Parts Easily

Locating suitable components for machinery can often be a daunting task, especially when facing unexpected breakdowns. However, with the right approach and resources, the process can be streamlined significantly. Understanding the layout and specifications of each element can save time and ensure compatibility.

Start by consulting reliable online resources that provide detailed illustrations and lists of necessary components. Websites dedicated to machinery maintenance often feature user-friendly interfaces that allow for easy navigation. Utilizing these platforms can help identify the exact items required for repairs.

Another effective strategy is to join forums and communities of enthusiasts and professionals in the field. These groups can offer invaluable advice, share experiences, and even recommend trusted suppliers. Networking with others can lead to discovering hard-to-find items and obtaining insights on quality brands.

Moreover, local dealers and specialized shops are valuable assets when searching for replacements. Establishing a good relationship with these vendors can lead to better service and access to inventory that may not be available online. Don’t hesitate to inquire about ordering specific components or alternative solutions.

Lastly, keeping an organized inventory of your current supplies and past purchases will facilitate future searches. Documenting the details of components, including part numbers and specifications, can save significant effort when the need arises again.

Importance of Accurate Diagrams

Precise visual representations play a crucial role in understanding complex machinery. They serve as essential tools for technicians and operators, facilitating effective maintenance and troubleshooting.

Enhancing Efficiency

Accurate illustrations contribute significantly to operational efficiency by:

- Providing clear guidance on assembly and disassembly.

- Minimizing errors during repairs.

- Speeding up the identification of components.

Facilitating Learning

Well-crafted visuals are invaluable for educational purposes, as they:

- Help new users familiarize themselves with machinery.

- Support advanced training for skilled operators.

- Encourage a deeper understanding of mechanical systems.

Top Kubota Models Explained

When it comes to compact machinery, several models stand out for their exceptional performance and versatility. These machines are designed to handle a variety of tasks, making them indispensable in various industries, from construction to landscaping.

Model A is renowned for its compact size and powerful engine, making it ideal for tight spaces while still delivering robust performance. Its ergonomic design enhances operator comfort, allowing for extended use without fatigue.

Model B, on the other hand, boasts advanced features that improve efficiency. With its enhanced hydraulic system, this model can tackle heavy loads with ease, making it a favorite among professionals who require reliability and strength.

Model C is notable for its adaptability, with a range of attachments that allow it to perform various tasks seamlessly. Whether it’s digging, lifting, or grading, this machine excels in diverse environments.

Understanding the unique capabilities of these models helps operators choose the right equipment for their specific needs, ensuring optimal productivity and performance in every project.

How to Read a Parts Diagram

Understanding a schematic representation of components can greatly enhance your ability to identify and replace various elements of machinery. These visual guides serve as an invaluable resource, providing clarity on how different pieces interact and fit together. Mastering this skill can save time and effort when performing maintenance or repairs.

Start by Familiarizing Yourself with Symbols: Each illustration often uses specific icons or labels to represent various components. Take a moment to decode these symbols to understand what each part signifies.

Follow the Flow: Many illustrations are designed to show the order of assembly or the path of operation. Observing how elements connect can give insights into the function and placement of each item.

Refer to the Key: Most schematics include a legend or key that explains the symbols and color codes used. This reference is crucial for accurate interpretation, ensuring you can correctly identify each part.

Check for Annotations: Additional notes or comments may accompany certain components, offering helpful tips or installation instructions. Pay attention to these details, as they can provide guidance on best practices.

Practice with Real Examples: The best way to become proficient is through experience. Examine actual schematics related to your machinery, applying your knowledge to real-world scenarios for improved understanding.

Aftermarket vs. OEM Parts

The choice between alternative and original components is crucial for maintaining machinery performance and longevity. Each option comes with its own set of advantages and considerations, impacting both cost and reliability. Understanding these differences can help users make informed decisions when servicing their equipment.

Advantages of OEM Components

- Guaranteed compatibility with the specific model.

- Often backed by a warranty from the manufacturer.

- Manufactured to the original specifications, ensuring optimal performance.

Benefits of Alternative Components

- Typically lower in cost, providing budget-friendly options.

- A broader selection may be available, including upgraded features.

- Possibility of faster availability through various suppliers.

Ultimately, the decision between original and alternative options should be based on individual needs, usage patterns, and financial considerations. Evaluating both choices carefully can lead to better outcomes for your machinery’s maintenance and overall efficiency.

Tools for Maintenance and Repairs

Effective upkeep and repairs require a selection of essential instruments that ensure efficiency and precision. Whether addressing minor adjustments or major overhauls, having the right tools on hand can significantly impact the quality of work and longevity of equipment.

Essential Tools

Among the most crucial instruments for maintenance are wrenches, screwdrivers, and pliers. Each of these tools serves a specific purpose, allowing for quick fixes and thorough inspections.

Additional Equipment

In addition to hand tools, certain power tools can enhance the repair process. Items like drills and impact wrenches can save time and effort, making complex tasks more manageable.

| Tool Type | Function |

|---|---|

| Wrenches | Loosening and tightening bolts |

| Screwdrivers | Fastening screws |

| Pliers | Gripping and bending materials |

| Drills | Creating holes |

| Impact Wrenches | Removing stubborn fasteners |

Resources for Parts and Manuals

Accessing reliable information is essential for maintaining and repairing heavy machinery. Numerous resources provide valuable insights, schematics, and documentation to assist users in understanding their equipment’s components and operations.

Online Manuals and Schematics

Many websites host digital manuals and detailed schematics, enabling easy reference for both new and seasoned operators. These resources often include comprehensive guides and troubleshooting tips.

Authorized Dealers and Service Centers

Visiting authorized dealers ensures access to genuine components and expert advice. Service centers can provide personalized assistance and may have manuals available for consultation.

| Resource Type | Examples |

|---|---|

| Online Manuals | Manufacturer’s website, Equipment forums |

| Authorized Dealers | Local dealerships, Service centers |

| Community Forums | Discussion boards, Social media groups |