Kubota T1670 Parts Diagram for Easy Maintenance

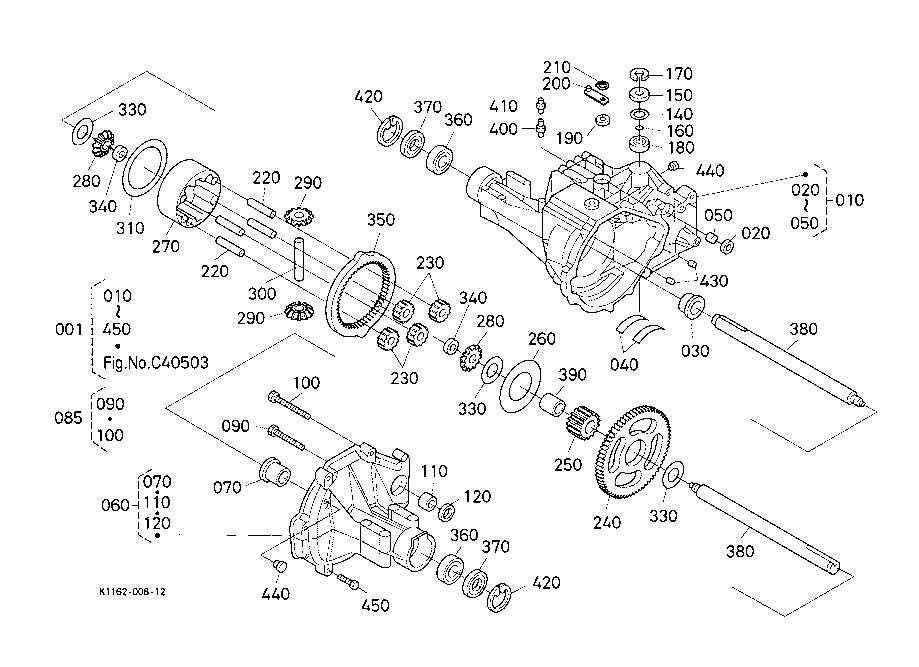

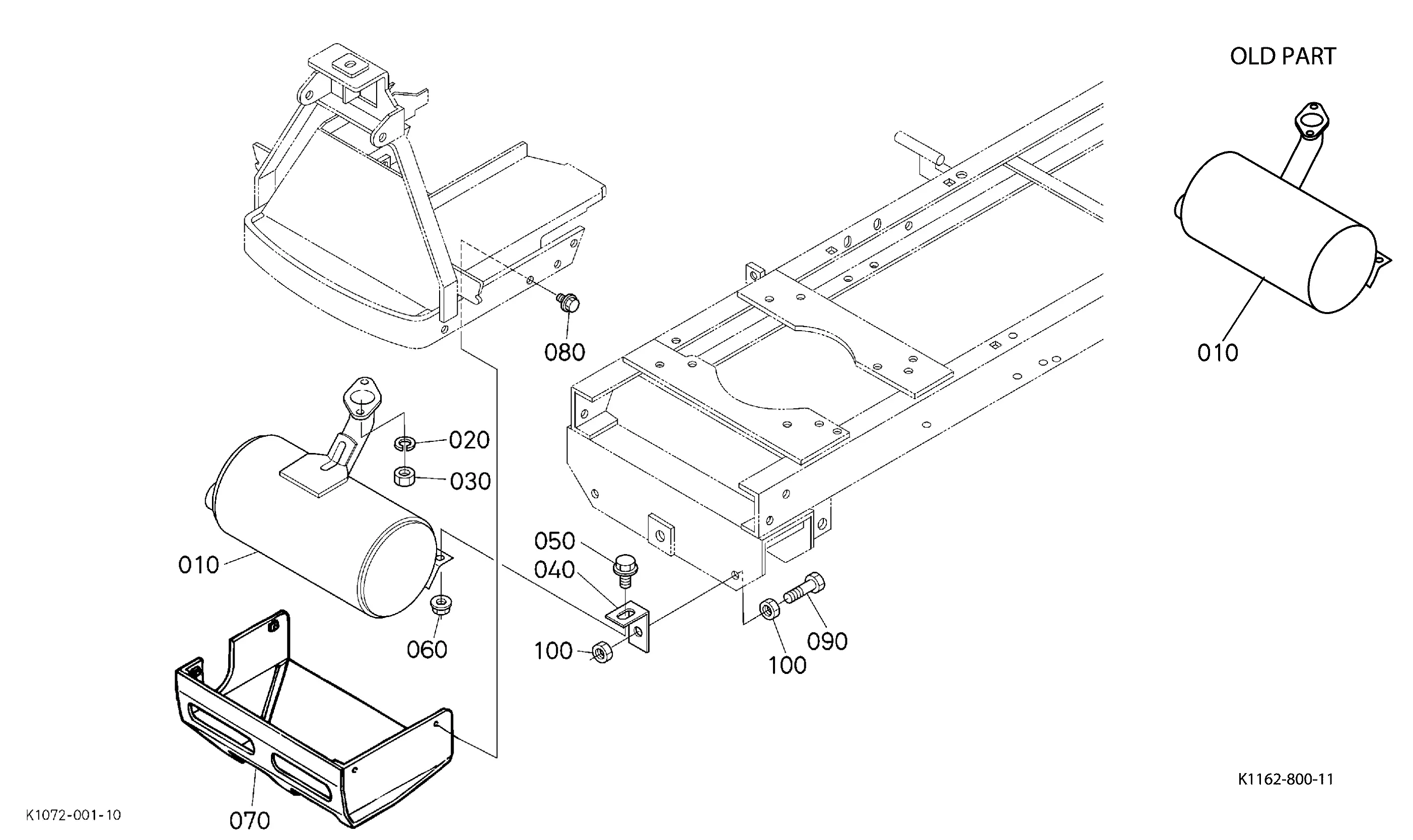

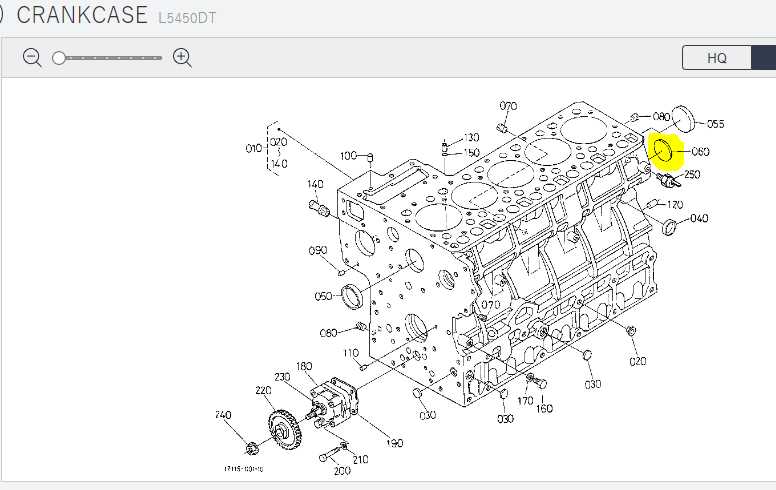

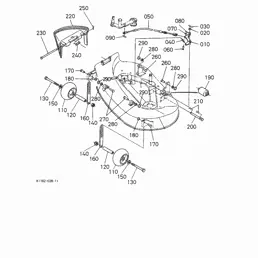

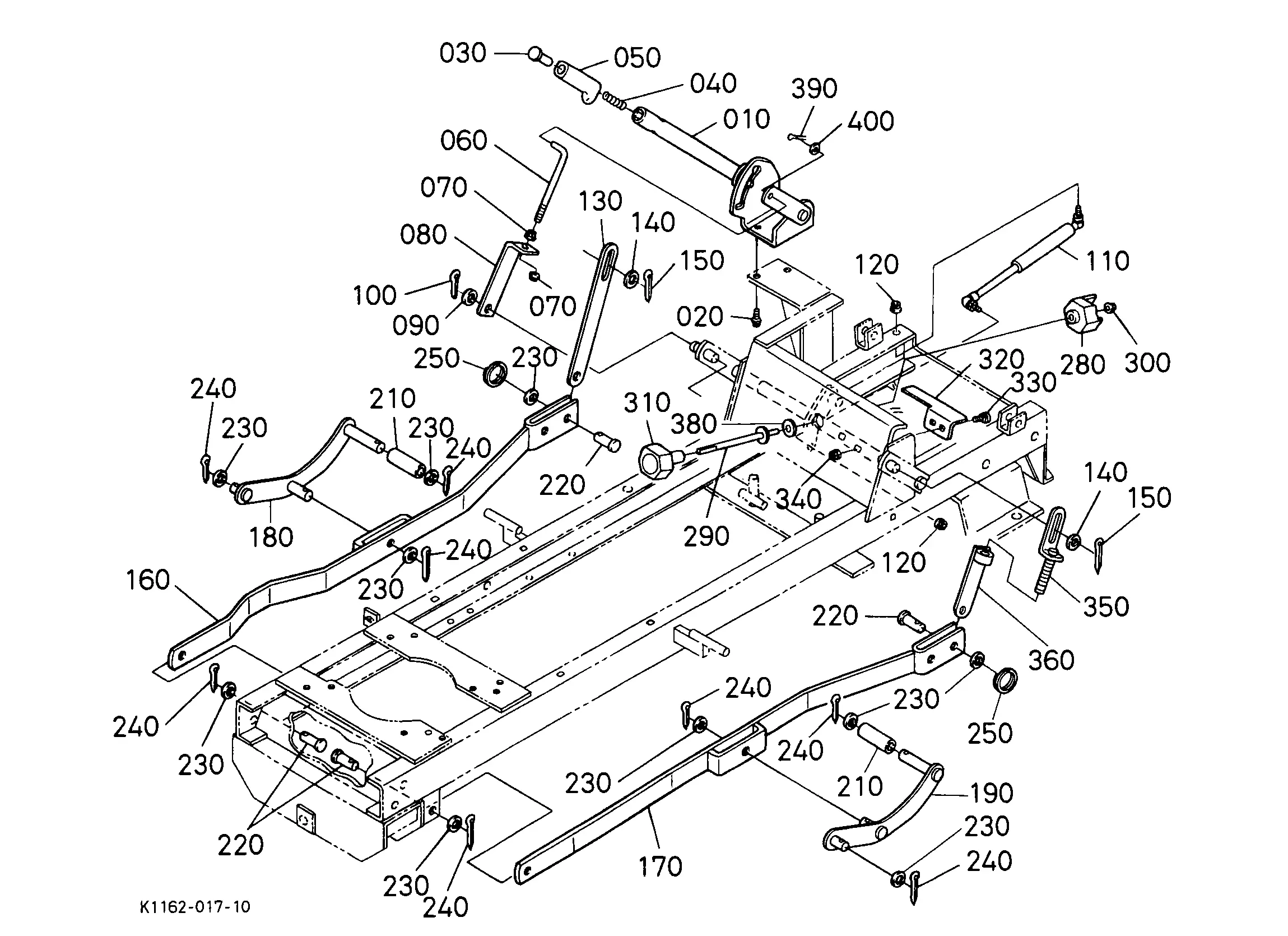

In the realm of outdoor equipment maintenance, having a clear representation of machinery components is crucial. This ensures that operators and technicians can effectively identify and access essential elements for repairs and upkeep. A detailed schematic serves as a visual guide, simplifying the complex assembly of various parts.

When working with engines and related devices, familiarity with the arrangement of each individual piece enhances troubleshooting efficiency. Recognizing how components interconnect and function together is vital for optimal performance. Additionally, having an accurate layout aids in ensuring that replacements or repairs are executed correctly, minimizing downtime and maximizing productivity.

Moreover, understanding the intricacies of these diagrams empowers users to perform regular maintenance with confidence. This knowledge not only prolongs the life of the machinery but also ensures safety during operation. By delving into the specifics of component placement, operators can cultivate a more intuitive grasp of their equipment, leading to improved handling and care.

Kubota T1670 Overview

This section provides a comprehensive look at a popular model designed for efficiency and versatility in outdoor maintenance tasks. With a focus on user-friendly features and robust performance, this machine caters to a wide range of landscaping and agricultural needs.

Key characteristics include:

- Reliable engine performance for various terrains

- Ergonomic design enhancing user comfort during operation

- Efficient cutting system for effective grass management

- Durability, ensuring long-lasting use under tough conditions

Designed for ease of use, this equipment includes intuitive controls that simplify operation, making it accessible for both seasoned operators and novices alike.

Maintenance and serviceability are also prioritized, allowing for straightforward upkeep to ensure optimal performance over time.

Overall, this model stands out in the market due to its combination of reliability, efficiency, and user-centric design, making it a valuable asset for any property owner or professional landscaper.

Key Features of Kubota T1670

This compact riding machine is designed for efficiency and ease of use, making it an ideal choice for homeowners and professionals alike. Its thoughtful engineering ensures optimal performance across various tasks, providing users with reliable service throughout the seasons.

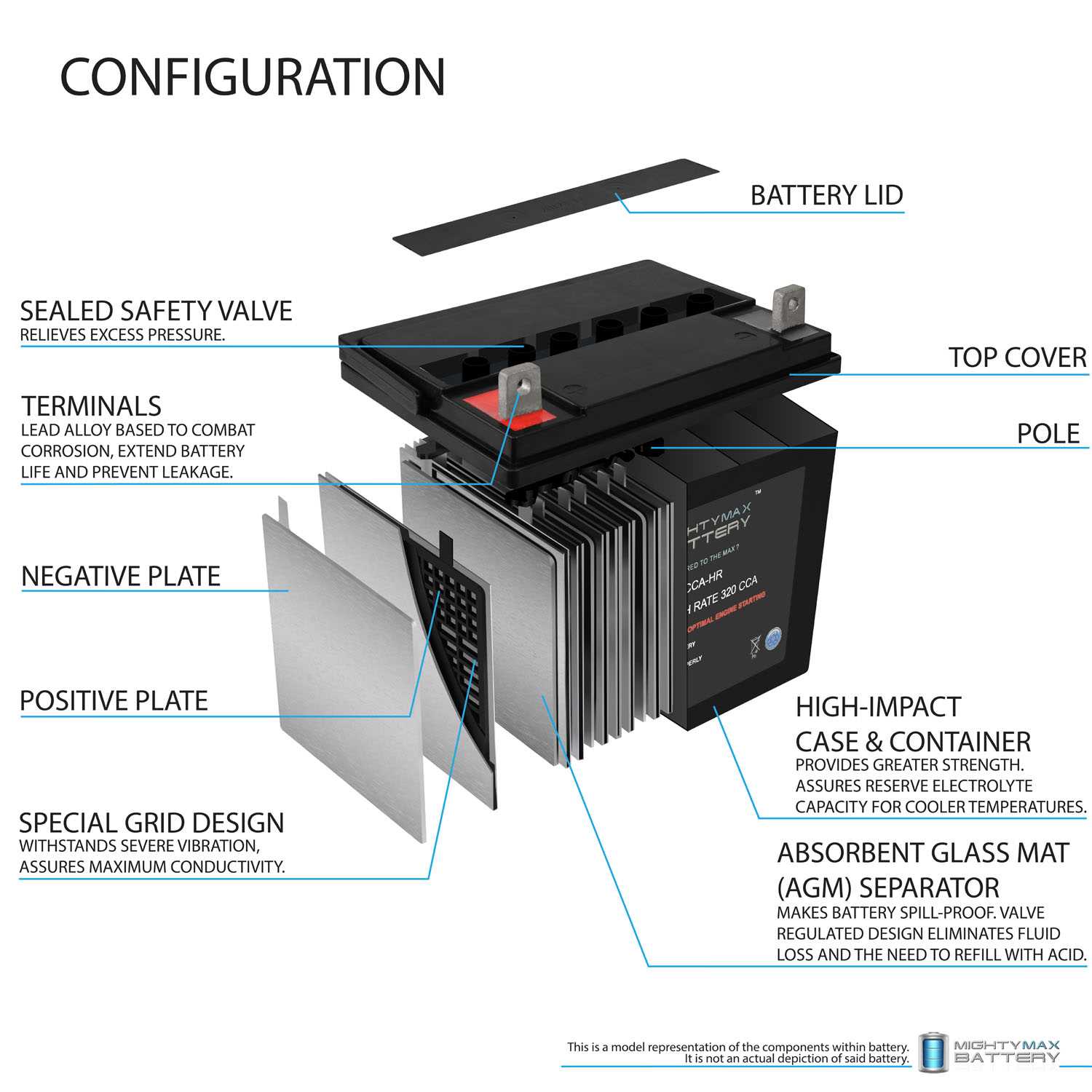

Powerful Engine: Equipped with a robust motor, this unit delivers exceptional torque and acceleration, enabling smooth operation on diverse terrains. The engine’s efficiency contributes to reduced fuel consumption, ensuring longer working hours without frequent refueling.

Superior Maneuverability: Featuring a tight turning radius, this model excels in navigating around obstacles and tight spaces. Its compact design allows for easy handling, making it perfect for landscaped areas and smaller yards.

Comfortable Operation: The ergonomic seating and intuitive controls enhance the user experience. With adjustable features, operators can customize their setup for maximum comfort during extended use, minimizing fatigue.

Durable Construction: Built with high-quality materials, this equipment withstands the rigors of outdoor work. Its sturdy frame and reliable components ensure longevity, providing peace of mind for those who rely on it for various tasks.

Versatile Attachments: The ability to connect various implements adds to the versatility of this machine. Whether for mowing, hauling, or snow removal, users can adapt it to meet their specific needs throughout the year.

Overall, this riding machine combines power, agility, and comfort, making it a valuable asset for anyone looking to maintain their outdoor spaces effectively.

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations that break down components play a crucial role in this process. They serve as valuable tools that enhance comprehension, streamline repairs, and ensure proper assembly.

Clarity and Precision are paramount when dealing with complex equipment. Visual aids provide a clear overview of individual elements, allowing users to easily identify and locate each piece. This clarity reduces the likelihood of errors during repairs, ensuring that all necessary components are accounted for.

Efficiency in Repair is significantly improved when one has access to these visual guides. Mechanics can quickly refer to the illustrations to understand how parts fit together, saving time and minimizing frustration. With a comprehensive view, repairs can be completed swiftly and accurately.

Moreover, these resources facilitate effective communication among technicians and customers. When discussing issues or solutions, visual representations provide a common language, helping to bridge gaps in understanding. This fosters collaboration and confidence in the maintenance process.

In conclusion, visual aids are indispensable in the realm of machinery maintenance. They enhance understanding, streamline processes, and promote efficient communication, ultimately leading to better outcomes and prolonged equipment lifespan.

Understanding Kubota T1670 Components

Grasping the intricate details of machine elements is crucial for efficient operation and maintenance. Each component plays a vital role, contributing to overall functionality and performance. A thorough comprehension of these elements enables users to troubleshoot issues effectively and optimize usage.

Core Elements of the System

At the heart of any equipment lies a series of essential components that work in unison. From the engine to the transmission, each part must function seamlessly to ensure reliability. Familiarity with these core elements aids in identifying potential problems and implementing timely repairs.

Maintenance and Repair Considerations

Regular upkeep is paramount for prolonging the lifespan of machinery. Understanding how each piece fits within the larger assembly allows for more informed maintenance decisions. Recognizing wear patterns and knowing when to replace specific components can significantly enhance performance and prevent costly breakdowns.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components can greatly enhance maintenance and repair efforts. These resources provide invaluable insights into the assembly and function of various parts, ensuring that users can efficiently address issues as they arise.

One of the best places to start is the official manufacturer’s website. Often, these sites offer downloadable resources or online tools that allow you to view and print illustrations directly related to your equipment.

In addition, many specialized online retailers provide access to visual guides. These platforms not only sell replacement items but also include comprehensive charts that detail the components, making it easier to identify what you need.

Community forums and dedicated online groups are also excellent sources. Enthusiasts and experts share their knowledge, often posting links to diagrams and offering advice on sourcing specific components.

Finally, consider consulting service manuals or repair guides. These documents frequently contain the necessary visual references, along with step-by-step instructions, which can be extremely helpful during troubleshooting or maintenance tasks.

Common Issues with T1670 Parts

Maintaining machinery often brings challenges, particularly when it comes to specific components. Users frequently encounter various problems that can affect performance and reliability. Understanding these issues can lead to more efficient troubleshooting and prolonged equipment lifespan.

Frequent Problems

- Wear and Tear: Components can degrade over time due to regular use, leading to decreased efficiency.

- Corrosion: Exposure to moisture and elements can cause rust and deterioration, particularly in metallic parts.

- Alignment Issues: Improper installation or adjustment can result in misalignment, affecting overall functionality.

- Loose Connections: Vibration during operation may lead to loosened bolts or connections, creating operational hazards.

Signs of Trouble

- Unusual noises during operation, indicating potential malfunction.

- Decreased power or performance, suggesting possible internal issues.

- Visible damage or cracks on external components, which can compromise safety.

- Frequent need for repairs, signaling ongoing underlying problems.

Addressing these common challenges promptly can help ensure smoother operation and enhance the longevity of your machinery.

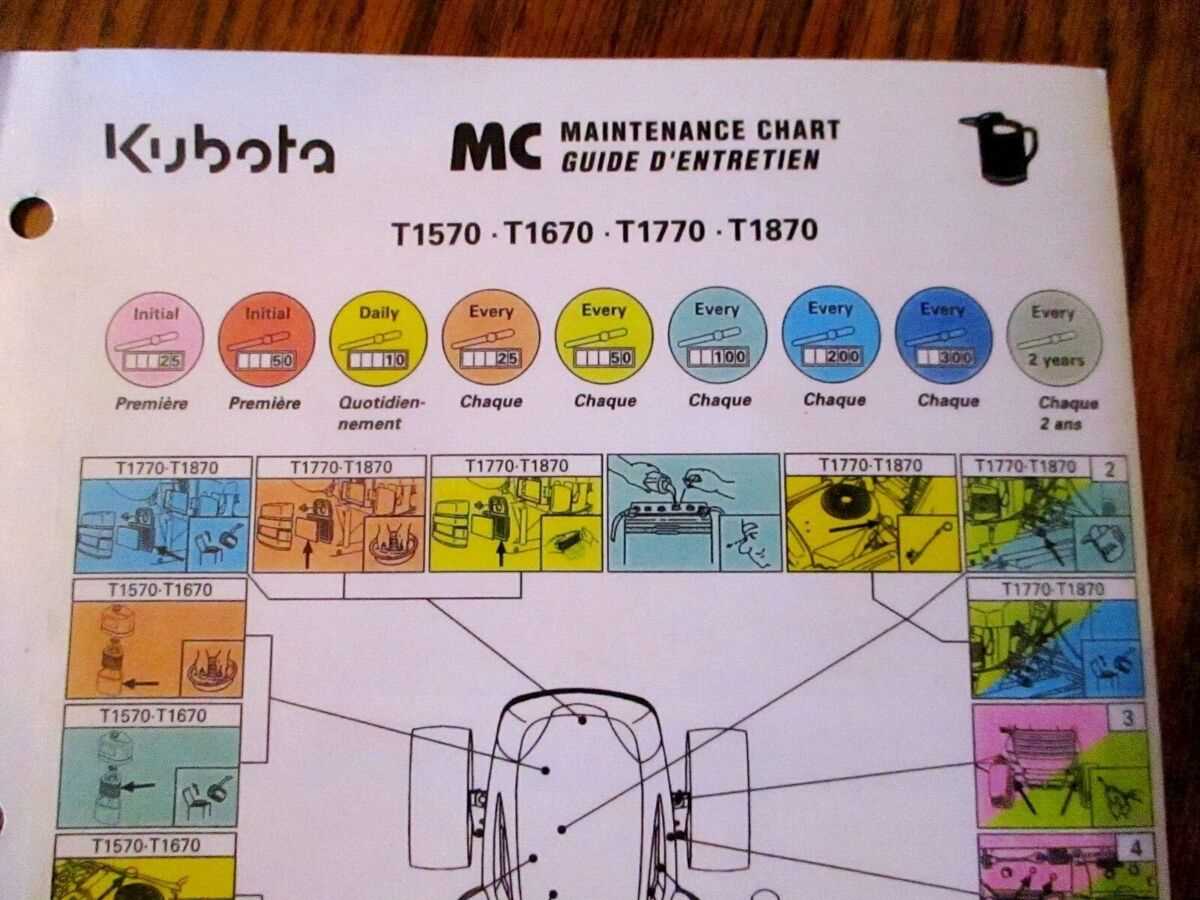

Maintenance Tips for Kubota T1670

Proper upkeep of your equipment ensures longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents potential issues that could lead to costly repairs. Following a consistent care routine will keep your machinery in excellent condition.

Start by routinely checking and changing the oil. Clean oil is vital for the engine’s health, so adhere to the manufacturer’s recommendations for intervals. Additionally, inspect and replace air filters to ensure proper airflow and reduce strain on the engine.

Maintaining the blades is crucial for effective operation. Regular sharpening and inspection for damage can make a significant difference in performance. Ensure that any debris is cleared from the cutting deck to prevent buildup that can affect functionality.

It’s important to monitor tire pressure and tread wear. Properly inflated tires provide better traction and control, while worn tires can lead to instability. Make sure to clean the tires to remove dirt and debris that can accumulate during use.

Lastly, always store the equipment in a dry, sheltered area when not in use. This practice protects it from the elements and extends its lifespan. Keeping a maintenance log can also help track service dates and future needs.

Comparing Parts with Other Models

When examining the components of different machinery, it’s essential to identify similarities and differences across various models. This analysis not only aids in understanding compatibility but also enhances maintenance strategies. By comparing various elements, operators can optimize their equipment for better performance and longevity.

Key Component Comparisons

Identifying critical components that may be interchangeable or unique can save time and resources during repairs. This section highlights a few essential elements to consider when comparing models.

| Component | Model A | Model B | Model C |

|---|---|---|---|

| Engine Type | Single Cylinder | Single Cylinder | V-Twin |

| Transmission | Hydrostatic | Gear Drive | Hydrostatic |

| Deck Width | 42 inches | 48 inches | 42 inches |

| Wheel Size | 20 inches | 18 inches | 20 inches |

Benefits of Component Analysis

Conducting a thorough examination of machinery components across various models provides several advantages. It enables owners to make informed decisions regarding upgrades and replacements, ensuring efficiency and functionality. Additionally, understanding these comparisons can facilitate better inventory management and cost savings in the long run.

Ordering Replacement Parts Online

In today’s digital age, acquiring necessary components for machinery has become more accessible than ever. The internet offers a plethora of options for sourcing high-quality items efficiently. Understanding the process can save time and ensure that you receive exactly what you need to keep your equipment running smoothly.

When looking to purchase components online, it’s important to follow a few key steps to ensure a successful transaction:

| Step | Description |

|---|---|

| 1. Identify the Component | Gather the model number and any relevant specifications to ensure compatibility. |

| 2. Research Vendors | Look for reputable online retailers or manufacturers with positive reviews. |

| 3. Compare Prices | Check different sites to find competitive pricing and available options. |

| 4. Verify Authenticity | Ensure that the products are genuine and meet industry standards. |

| 5. Place Your Order | Follow the vendor’s instructions for completing the purchase, paying attention to shipping details. |

By following these steps, you can confidently navigate the online marketplace for machinery components, ensuring you find the right items to maintain performance and reliability.

Tips for DIY Repairs and Upgrades

Engaging in do-it-yourself repairs and enhancements can be a rewarding experience, allowing you to save money and gain a deeper understanding of your equipment. With the right approach, even those with minimal experience can tackle various tasks effectively. This section provides essential tips to ensure your projects are successful and satisfying.

First, always start with thorough research. Gather information about the specific components and functions you intend to work on. This knowledge will help you identify potential challenges and the best methods for tackling them. Utilize online resources, forums, and instructional videos to expand your understanding.

Next, ensure you have the appropriate tools and safety gear. Investing in quality tools can make a significant difference in the ease and efficiency of your work. Additionally, wearing protective equipment is crucial to prevent injuries during repairs.

When disassembling any machinery, take the time to document the process. Use photographs or notes to keep track of the order of components, which can be invaluable when reassembling. Organizing small parts in labeled containers can also help avoid confusion later.

Lastly, don’t hesitate to seek advice from experienced individuals. Joining online communities or local groups can provide valuable insights and support. Collaborating with others can enhance your skills and confidence in handling repairs and upgrades.