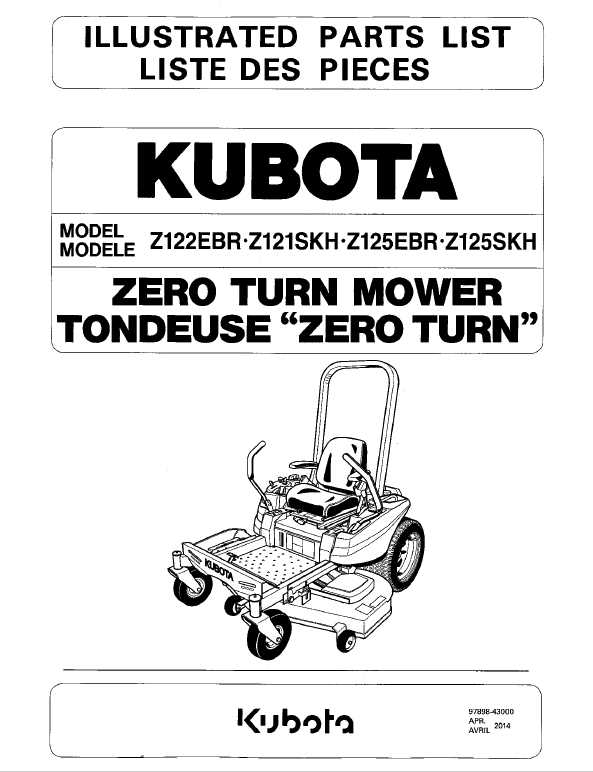

Kubota T1880 Parts Diagram Overview

In the realm of outdoor machinery, comprehending the intricate relationships between various elements is essential for effective maintenance and repair. A well-structured overview of these components not only enhances operational efficiency but also prolongs the lifespan of your machinery. Having a clear visual reference can serve as a vital tool for both novice and experienced operators alike.

Exploring the intricate layout of these crucial elements offers insights into their functionalities and interactions. This knowledge empowers users to tackle issues proactively, ensuring that each segment operates harmoniously within the system. By delving into the specific arrangements, operators can easily identify potential areas of concern and address them promptly.

Furthermore, a detailed representation of these components aids in the procurement of necessary replacements. Understanding the configuration allows for informed decisions when sourcing new items, ultimately saving time and resources. Whether you are looking to enhance performance or simply maintain your equipment, having a solid grasp of its inner workings is indispensable.

Understanding the Kubota T1880 Overview

This section aims to provide a comprehensive look at a specific model known for its efficiency and versatility in outdoor maintenance tasks. The focus will be on the features, functionalities, and components that contribute to its performance, making it a valuable asset for both residential and commercial users.

Key Features

The machine is designed with user-friendly controls and an ergonomic layout, ensuring ease of operation. Its powerful engine and robust build allow for reliable performance across various terrains. Additionally, the inclusion of advanced technologies enhances its efficiency, making maintenance tasks quicker and more effective.

Component Breakdown

Understanding the structure of this equipment can aid users in identifying necessary replacements and performing maintenance efficiently. Below is a table summarizing the main components and their functions:

| Component | Function |

|---|---|

| Engine | Powers the machine, providing necessary torque and speed. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

| Deck | Houses the cutting blades, essential for trimming grass and other vegetation. |

| Wheels | Facilitate mobility across different surfaces. |

| Control Panel | Allows the operator to manage speed, direction, and other settings. |

This overview serves as a foundation for understanding the intricate workings of this model, highlighting the importance of each part in achieving optimal performance.

Essential Components of Kubota T1880

Understanding the vital elements of this robust machine is crucial for ensuring its efficient operation and longevity. Each component plays a significant role in the overall functionality, contributing to the seamless performance expected from high-quality lawn equipment.

Engine: At the heart of the machinery lies the power source, which provides the necessary energy to drive all operations. A well-maintained engine is essential for optimal performance and reliability.

Transmission: This component is responsible for transferring power from the engine to the wheels. A smooth transmission ensures that the vehicle moves efficiently, allowing for easy navigation across various terrains.

Cutting Deck: The cutting deck is critical for maintaining a neat and well-manicured lawn. Its design impacts the quality of the cut, making it vital for achieving professional results.

Wheels and Tires: The wheels provide stability and traction, which are essential for maneuverability. Choosing the right tires enhances grip and performance on different surfaces.

Steering System: This system allows the operator to control the direction of the machine effectively. Precision in steering ensures that the equipment can navigate tight spaces with ease.

By familiarizing oneself with these key components, users can enhance their understanding of maintenance practices, leading to improved performance and a longer lifespan for the equipment.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They serve as essential tools for understanding the structure and functionality of equipment, allowing users to identify individual elements and their interconnections. This clarity is vital for efficient troubleshooting and ensuring proper assembly.

Benefits of Visual Guides

- Enhanced Understanding: Diagrams simplify complex systems, making it easier for users to grasp how different elements work together.

- Efficient Troubleshooting: Quick identification of faulty components accelerates the repair process, reducing downtime.

- Accurate Assembly: Clear illustrations prevent mistakes during reassembly, ensuring all parts are correctly positioned.

Best Practices for Using Visual References

- Always refer to the latest version of the illustration to ensure accuracy.

- Use markers or notes to highlight areas of concern or required replacements.

- Cross-reference with manuals or guides for comprehensive understanding.

In summary, visual references are invaluable for anyone involved in the upkeep of machinery. They not only streamline the maintenance process but also enhance overall efficiency and reliability.

Where to Find Kubota T1880 Diagrams

Locating accurate schematics for machinery can significantly enhance maintenance and repair efforts. These illustrations serve as vital resources, offering insights into component arrangements and system functions. Understanding where to access these visuals is crucial for effective troubleshooting and part replacement.

Online Resources

The internet hosts a wealth of platforms dedicated to machinery support. Here are some notable sources:

- Manufacturer’s Website: The official site often provides downloadable manuals and schematics.

- Forums and Community Sites: Enthusiast communities frequently share resources and experiences that can lead to valuable finds.

- Online Marketplaces: Websites that specialize in equipment sales may also feature manuals as part of their product listings.

Physical Resources

In addition to digital options, consider these traditional avenues:

- Local Dealerships: Authorized dealers can provide printed manuals and expert advice.

- Library Resources: Public and university libraries may offer access to technical manuals or subscriptions to databases.

- Workshops and Repair Shops: Local mechanics often have access to comprehensive guides and can assist in finding specific schematics.

Common Issues with T1880 Parts

When dealing with machinery components, several challenges can arise that may affect performance and longevity. Understanding these common problems is essential for effective maintenance and troubleshooting. Various factors, including wear and tear, improper installation, and environmental conditions, can contribute to these issues.

Frequent Problems

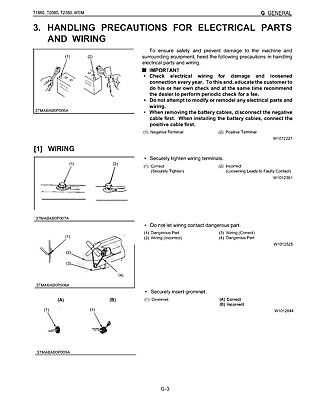

Among the most typical concerns are the degradation of seals, misalignment of gears, and electrical failures. Regular inspections can help identify these issues early, preventing more severe damage.

Impact of Neglect

Neglecting regular maintenance can exacerbate existing issues, leading to increased operational costs and downtime. It is crucial to monitor the condition of essential components and address any signs of wear promptly.

| Issue | Description | Recommended Action |

|---|---|---|

| Seal Degradation | Worn or cracked seals can lead to leaks. | Replace seals regularly to maintain integrity. |

| Gear Misalignment | Improperly aligned gears can cause excessive noise and wear. | Realign gears as needed and ensure proper installation. |

| Electrical Failures | Faulty wiring or connections may disrupt operation. | Inspect electrical systems and replace damaged components. |

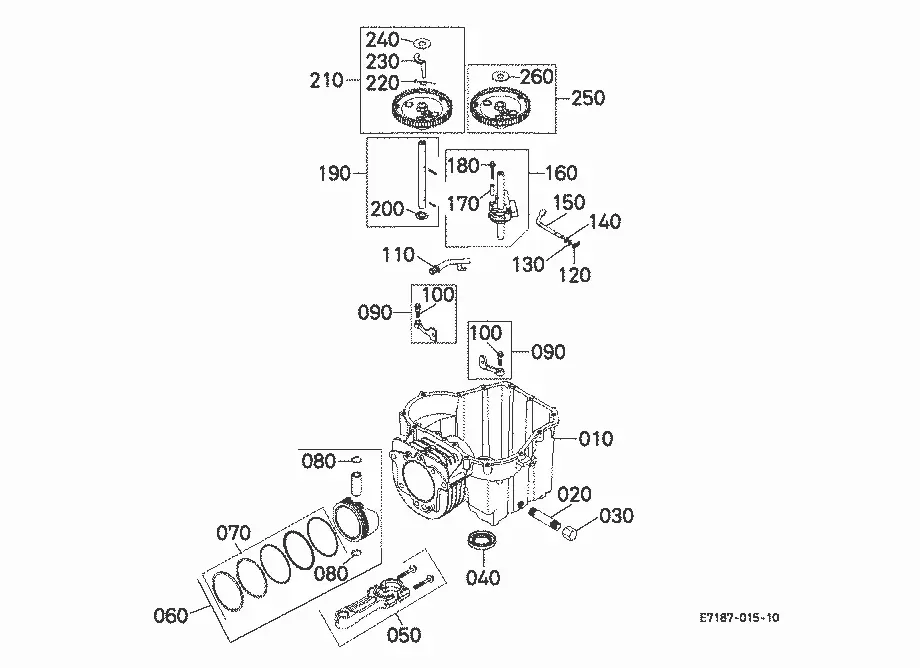

How to Interpret Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a guide, offering insights into how different elements fit together and function as a whole. Grasping the layout and labeling of these visuals can significantly enhance your troubleshooting skills and streamline your repair processes.

Decoding Symbols and Labels

Every visual representation includes various symbols and annotations that indicate specific elements and their functions. Familiarize yourself with common notations, as they often convey critical information such as part numbers, assembly instructions, and connection points. Pay close attention to these details, as they are essential for accurately identifying the components you need.

Following the Flow of Assembly

These illustrations usually follow a logical sequence, depicting how components connect and interact. Observe the pathways that guide you through the assembly, as this can help you understand the operational relationships between parts. By following these connections, you can more easily identify potential issues and ensure that your repairs are performed correctly and efficiently.

Maintaining Your Kubota T1880

Regular upkeep of your outdoor machinery is essential for optimal performance and longevity. By following a structured maintenance routine, you can ensure that your equipment runs smoothly, reducing the risk of unexpected breakdowns and costly repairs.

Essential Maintenance Tasks

- Check and replace the oil regularly to keep the engine running efficiently.

- Inspect air filters and clean or replace them as needed to maintain airflow.

- Sharpen or replace the blades to ensure effective cutting performance.

- Examine belts and cables for wear and tear to prevent operational failures.

- Keep tires properly inflated to improve traction and reduce wear.

Seasonal Considerations

- Spring: Inspect all systems after winter storage; replace any worn parts.

- Summer: Monitor engine temperature and cooling system; clean debris from fins.

- Fall: Prepare for winter by cleaning and storing equipment properly.

- Winter: Consider using a cover to protect machinery from harsh weather conditions.

By adhering to these maintenance practices, you can extend the life of your machinery and ensure reliable performance throughout the seasons.

Identifying Genuine Kubota Parts

Ensuring the longevity and efficiency of machinery relies heavily on the use of authentic components. These original items are crafted to meet precise specifications, providing reliability and performance that imitations cannot match. Recognizing these genuine articles is essential for maintaining operational integrity.

Key Features of Authentic Components

When evaluating components, several distinguishing traits can help identify the real deal. Look for quality materials, precise fit, and thorough documentation that accompanies the product. Authentic items typically feature specific markings or labels that indicate their origin and authenticity.

Comparison Table of Genuine vs. Imitation

| Feature | Genuine Component | Imitation Component |

|---|---|---|

| Material Quality | High-grade materials | Inferior quality |

| Fit and Finish | Precision engineered | May not fit properly |

| Documentation | Includes certification | Often lacks proof |

| Performance | Reliable and efficient | Inconsistent performance |

By understanding these characteristics, users can make informed decisions, ensuring that their equipment operates optimally for years to come.

Tools Needed for T1880 Repairs

When undertaking maintenance or fixing machinery, having the right tools is essential for efficiency and effectiveness. Proper equipment not only facilitates smoother operations but also ensures that tasks are performed safely and accurately.

Basic Hand Tools: A set of reliable hand tools, including wrenches, screwdrivers, and pliers, is fundamental. These instruments are crucial for loosening or tightening components and making minor adjustments.

Socket Set: A comprehensive socket set is invaluable for working on various fasteners. It allows for better torque application and easier access to hard-to-reach areas, enhancing overall repair efficiency.

Torque Wrench: Maintaining the correct torque specifications is vital for machinery longevity. A torque wrench ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage and promoting safety.

Diagnostic Tools: Utilizing diagnostic equipment, such as multimeters and pressure gauges, can help identify underlying issues swiftly. These tools are critical for troubleshooting electrical systems and hydraulic components.

Safety Gear: Personal protective equipment (PPE) such as gloves, goggles, and masks is essential when performing repairs. Safety should always be a priority to prevent injuries while working on machinery.

In conclusion, being well-equipped with the right tools enhances the repair process, ensuring that each task is completed effectively and safely. Investing in quality equipment pays off in the long run, leading to better performance and reliability of the machinery.

Upgrading Components for Better Performance

Enhancing the functionality of your machinery can significantly boost its efficiency and longevity. By focusing on specific elements, operators can achieve a remarkable increase in performance, allowing for smoother operation and reduced wear and tear. This approach not only improves output but also enhances overall user satisfaction.

One effective strategy involves replacing standard parts with high-performance alternatives. Upgrading components such as filters, belts, and blades can lead to improved power delivery and more consistent results. For example, opting for a premium air filter can enhance airflow, resulting in better combustion and increased engine responsiveness.

Another important aspect is the compatibility of new components with existing systems. It is crucial to ensure that any upgrades seamlessly integrate with your current setup. Conducting thorough research and consulting with experts can help in selecting the most suitable enhancements for your needs.

Regular maintenance paired with strategic upgrades creates a synergistic effect, allowing the equipment to perform at its best. This not only extends the life of the machine but also minimizes the likelihood of unexpected breakdowns, ultimately leading to cost savings and increased productivity.