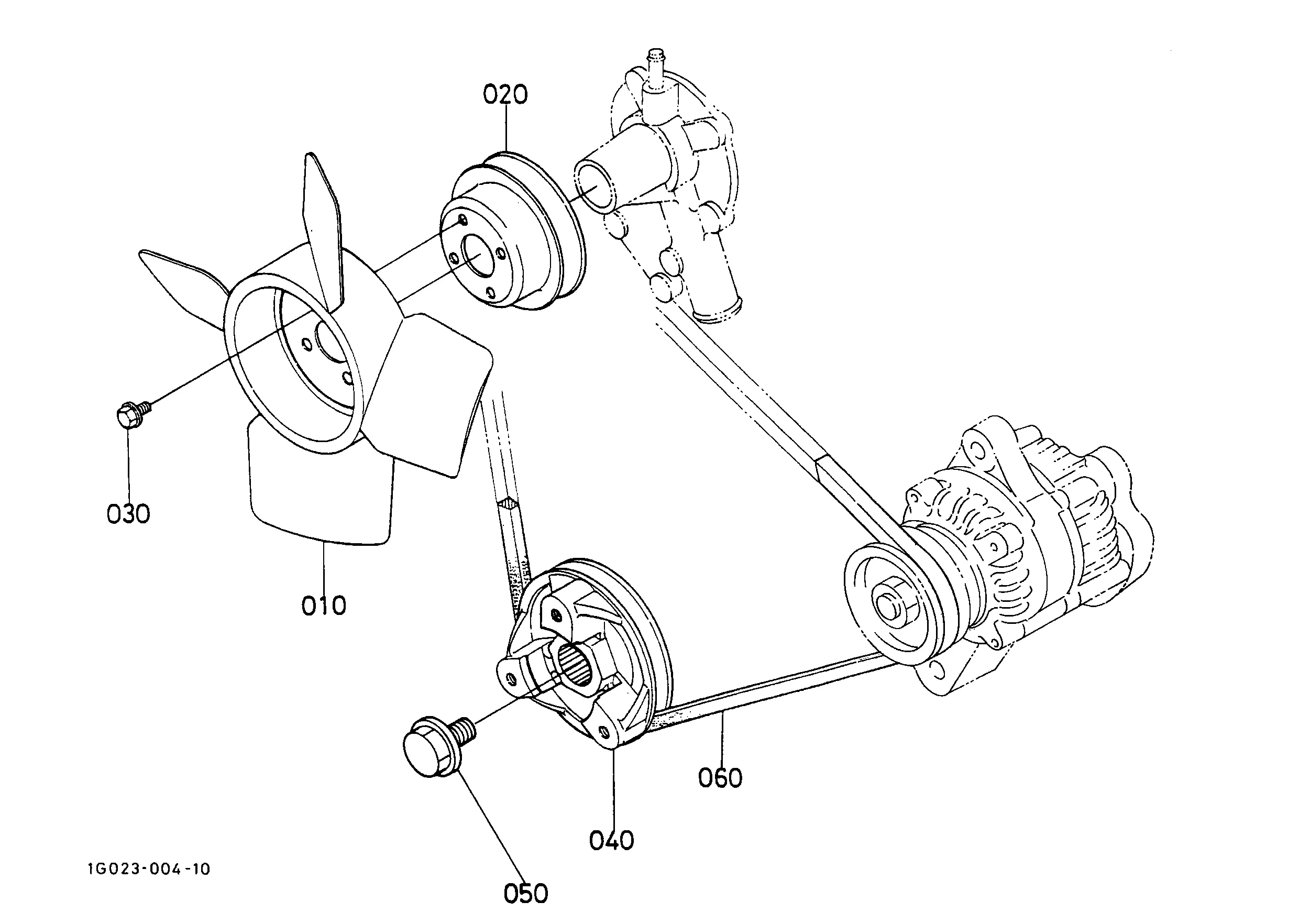

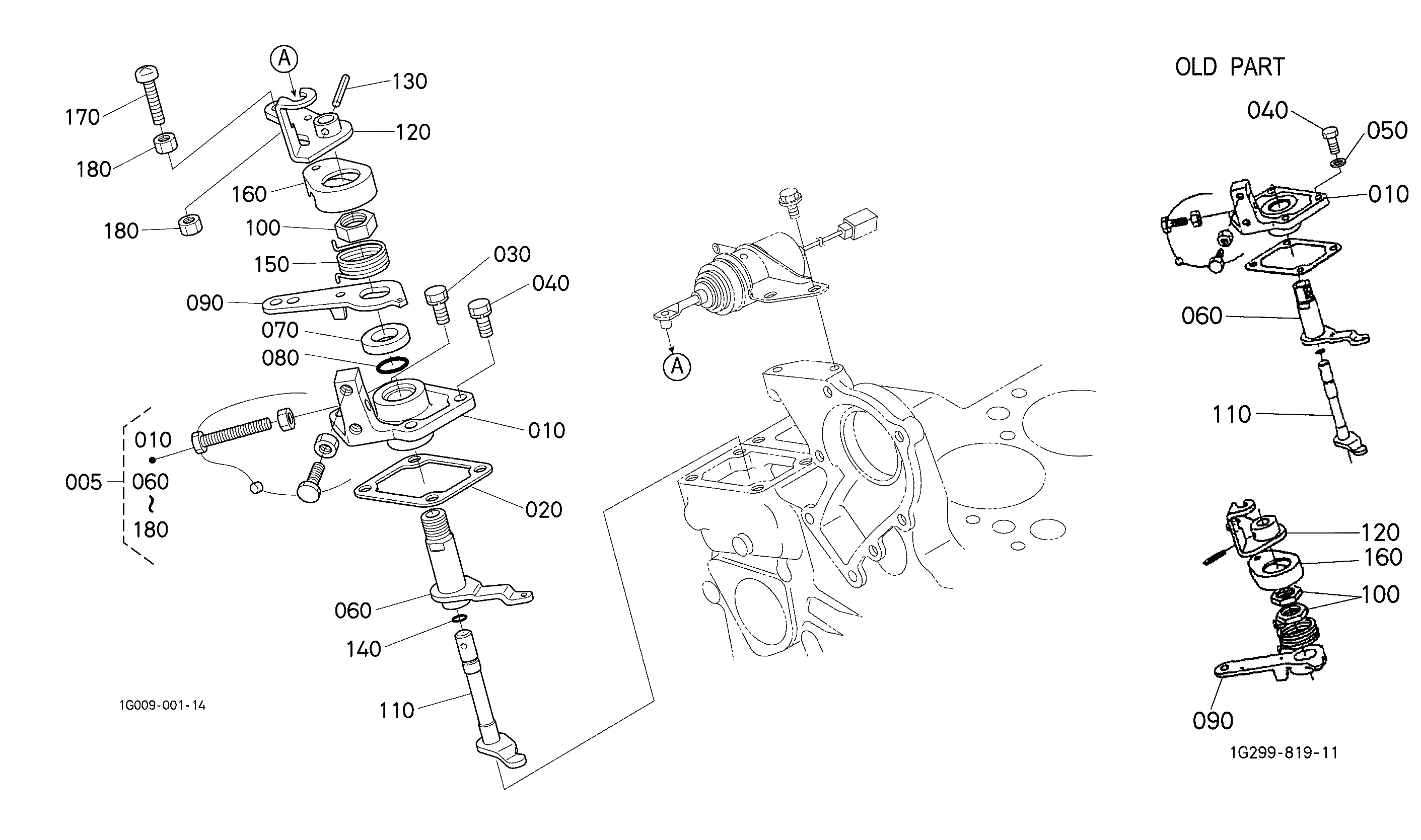

Kubota TG1860 Parts Diagram Overview

When it comes to maintaining and repairing your machinery, having a clear understanding of its various elements is essential. Each component plays a vital role in ensuring optimal performance and longevity. Familiarizing yourself with these parts can help streamline maintenance tasks and troubleshoot any issues that may arise.

In this section, we will explore an organized representation of the intricate network of components that make up your equipment. By visualizing how these pieces fit together, you will gain valuable insights into their functions and interactions. This knowledge will empower you to make informed decisions regarding repairs and replacements, ultimately enhancing the efficiency of your machinery.

Whether you are a seasoned operator or a newcomer to the field, grasping the layout of your equipment’s essential elements can simplify your maintenance routine. A thorough understanding of each part’s location and role can save time and reduce frustration, ensuring your machinery operates smoothly and effectively.

Kubota TG1860 Overview

This section provides a comprehensive look at a specific model known for its efficiency and reliability in various outdoor tasks. Designed for both residential and commercial applications, this machine stands out due to its robust features and user-friendly operation.

Key Features

- Powerful engine delivering consistent performance

- Ergonomic controls for enhanced user comfort

- Durable construction ensuring longevity

- Versatile attachments for different tasks

Applications

- Maintaining lawns and gardens

- Efficiently clearing debris

- Handling various landscaping projects

- Support for light agricultural work

Understanding Parts Diagrams

Comprehending visual representations of components is essential for effective maintenance and repair. These illustrations serve as valuable tools for identifying each element within a machine, facilitating troubleshooting and restoration efforts.

Key benefits of utilizing such visual aids include:

- Clarity: They provide a clear view of where each component fits within the assembly.

- Efficiency: Quickly locating necessary items can save time during repairs.

- Accuracy: Ensuring the correct parts are used reduces the likelihood of errors.

When analyzing these visuals, consider the following aspects:

- Labels: Pay attention to numbered items and descriptions for easy identification.

- Sections: Break down the illustration into manageable parts to understand each function.

- Relationships: Observe how components interact and support one another within the system.

Familiarity with these representations can enhance your repair skills and lead to better outcomes in machinery upkeep.

Key Components of Kubota TG1860

The intricate design of this garden machine features several essential elements that work in harmony to ensure optimal performance. Each component plays a crucial role in delivering efficiency and reliability, making the equipment suitable for a variety of outdoor tasks.

Engine: The powerhouse of the machine, responsible for providing the necessary energy for all operations. It is engineered for durability and efficiency, ensuring smooth functionality even under demanding conditions.

Transmission: This element facilitates the transfer of power from the engine to the wheels. Its design allows for seamless gear changes, enhancing maneuverability and control during operation.

Chassis: The framework that supports all components, contributing to the overall stability and strength of the machine. A robust chassis is vital for withstanding the rigors of regular use in various terrains.

Deck: The cutting mechanism, designed to provide a clean and precise cut. Its innovative design ensures that grass is evenly trimmed, promoting a healthy lawn appearance.

Steering System: This feature allows the operator to navigate the machine with ease. An efficient steering system enhances agility, making it simpler to maneuver around obstacles in the yard.

Understanding these key components not only aids in proper maintenance but also helps users appreciate the sophisticated engineering behind the equipment. Each part is meticulously crafted to deliver performance and reliability, ensuring satisfaction for users in their outdoor endeavors.

How to Read a Parts Diagram

Understanding a schematic representation of components can significantly enhance your ability to maintain and repair machinery. Familiarity with these illustrations allows users to identify and locate individual elements, making troubleshooting and replacement tasks more efficient.

To effectively interpret these visuals, follow these guidelines:

- Familiarize Yourself with Symbols:

- Each symbol represents a specific component.

- Learn the common symbols used in your equipment’s manuals.

- Identify Key Sections:

- Look for clusters of related parts grouped together.

- Note the labels or numbers that correspond to parts lists.

- Cross-Reference with Manuals:

- Use the accompanying literature to find detailed descriptions.

- This will help you understand the function of each component.

- Pay Attention to Orientation:

- Observe how parts are oriented in relation to each other.

- This can indicate assembly directions and connections.

By mastering these techniques, you’ll be better equipped to navigate component schematics, making your maintenance and repair tasks much more manageable.

Common Issues with Kubota TG1860

Understanding the frequent challenges that users face with their equipment can help in maintaining optimal performance. Certain mechanical devices often exhibit recurring problems that can affect their efficiency and longevity. Identifying these issues early on is crucial for timely intervention and repairs.

Frequent Mechanical Problems

Many operators report specific mechanical failures that can hinder operation. These typically include issues with the engine, drive system, and electrical components. Addressing these concerns promptly can prevent more significant complications.

Maintenance and Repair Tips

Regular upkeep is vital for any machinery. Ensuring routine checks and timely replacements can mitigate most problems. Operators are encouraged to follow maintenance schedules diligently and consult manuals for specific repair guidance.

| Issue | Description | Solution |

|---|---|---|

| Engine Overheating | Excessive heat can lead to performance drops. | Check coolant levels and inspect the radiator. |

| Electrical Failures | Inconsistent power can cause operational interruptions. | Examine wiring and connections for damage. |

| Transmission Problems | Shifting difficulties can affect maneuverability. | Inspect fluid levels and replace worn components. |

Essential Maintenance Tips

Regular upkeep of your machinery is crucial for optimal performance and longevity. By following a systematic approach, you can ensure that your equipment operates efficiently, minimizing the risk of unexpected breakdowns and costly repairs.

Routine Checks

Implementing a schedule for routine inspections is vital. Focus on the following areas:

- Fluid levels: Regularly check oil, coolant, and hydraulic fluids.

- Filters: Inspect and replace air, fuel, and oil filters as necessary.

- Tires: Ensure proper inflation and examine for wear and tear.

- Belts and hoses: Look for signs of cracking or fraying.

Seasonal Maintenance

Adapting maintenance practices according to the season can enhance performance:

- Spring: Clean the equipment and check all components for winter wear.

- Summer: Monitor cooling systems and keep vents clear of debris.

- Autumn: Prepare the machinery for colder temperatures by changing fluids.

- Winter: Store equipment properly, ensuring it is protected from harsh conditions.

Where to Find Replacement Parts

Locating suitable components for machinery maintenance can be a straightforward process with the right resources. Whether you’re looking for a specific item or a variety of options, understanding where to search can save time and ensure efficiency.

Authorized Dealers: One of the most reliable sources is authorized dealers. They typically offer a wide selection of original components, ensuring quality and compatibility. It’s advisable to check the official website for a list of local distributors.

Online Marketplaces: Numerous online platforms specialize in selling machinery components. Websites like eBay or Amazon often have listings from various sellers, which can be a great way to compare prices and availability. Be sure to read reviews to gauge the reliability of the sellers.

Aftermarket Suppliers: If original parts are too costly, consider aftermarket suppliers. These companies provide alternatives that often come at a lower price without sacrificing performance. Researching reputable aftermarket options can yield significant savings.

Local Repair Shops: Local repair shops can also be an excellent resource. They might have spare components on hand or can help you locate them through their networks. Additionally, they can offer valuable insights into which parts are the best fit for your needs.

Online Forums and Communities: Engaging with online forums and communities dedicated to machinery enthusiasts can provide leads on where to find components. Members often share their experiences and recommendations, which can guide you to the best resources.

Benefits of Genuine Kubota Parts

Using authentic components for your machinery offers numerous advantages that enhance performance, longevity, and reliability. When it comes to maintaining equipment, opting for original supplies ensures that every part functions harmoniously, ultimately leading to improved efficiency and reduced downtime.

Quality Assurance

One of the primary benefits of utilizing original components is the assurance of quality. These supplies are manufactured to meet the highest standards, ensuring they perform optimally. Here are some key points regarding quality:

- Designed specifically for your machine’s model.

- Tested for durability and performance under various conditions.

- Manufactured using superior materials to withstand wear and tear.

Enhanced Performance

When equipment operates with genuine components, it can achieve superior performance levels. This translates to better productivity and operational efficiency. Consider the following benefits:

- Improved compatibility with existing machinery.

- Consistent performance over time without unexpected failures.

- Lower risk of breakdowns, leading to reduced maintenance costs.

Tools Required for Repairs

When undertaking maintenance or repair tasks on machinery, having the right tools is essential for efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also ensures that the job is done correctly, minimizing the risk of damage and prolonging the lifespan of the equipment.

Essential Tools

- Wrenches: Adjustable and socket wrenches are crucial for loosening and tightening bolts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help with different fasteners.

- Pliers: Needle-nose and standard pliers are useful for gripping and bending materials.

- Hammer: A good hammer aids in driving nails and adjusting parts that may be misaligned.

- Torque Wrench: Ensures bolts are tightened to the correct specifications to prevent damage.

Specialized Equipment

- Multimeter: For electrical diagnostics, helping to identify wiring issues.

- Oil Filter Wrench: Essential for changing filters during maintenance.

- Jack Stands: Provide stability and safety when working underneath the machinery.

- Diagnostic Tools: Specialized devices can aid in troubleshooting complex issues.

Understanding the Warranty Policy

When purchasing machinery, it is crucial to be aware of the protection offered by the manufacturer in the event of defects or issues. A well-defined warranty policy ensures peace of mind, covering repairs and replacements within specified limits. Understanding the terms can help you make informed decisions and protect your investment.

Key aspects of a typical warranty policy include:

- Coverage Duration: The length of time the warranty is valid, usually starting from the date of purchase.

- Inclusions: Specific components or services that are covered under the warranty.

- Exclusions: Parts or conditions that are not covered, such as damage from misuse or lack of maintenance.

- Claim Process: The steps you need to take to file a warranty claim, including necessary documentation.

- Transferability: Whether the warranty can be transferred to a new owner if the equipment is sold.

Understanding these elements helps you navigate potential issues and ensures that you are fully aware of your rights and responsibilities. Always keep the warranty documentation accessible and familiarize yourself with the specific terms to maximize the benefits of your purchase.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your equipment can lead to significant gains in productivity. By focusing on strategic enhancements, you can elevate performance levels, reduce operational downtime, and increase the longevity of your machinery. Below are some effective upgrades to consider.

- Engine Tuning: Adjusting the engine parameters can optimize fuel efficiency and power output.

- Upgraded Filters: Implementing high-performance air and fuel filters ensures cleaner operation, which can prolong engine life.

- Improved Tires: Switching to high-traction tires can enhance stability and maneuverability on various terrains.

- Hydraulic System Enhancements: Upgrading hydraulic components can lead to faster response times and greater lifting capacity.

- Lighting Upgrades: Installing advanced lighting solutions can improve visibility during low-light operations, ensuring safety and efficiency.

These enhancements not only boost performance but also provide a more reliable and enjoyable user experience. Careful consideration of each upgrade will help you achieve optimal results and maximize your investment.

Customer Reviews and Feedback

Customer experiences play a crucial role in understanding the quality and performance of any machinery. Feedback from users provides invaluable insights into the reliability, usability, and overall satisfaction associated with various components and models. This section highlights the sentiments and observations shared by individuals who have interacted with these products.

Positive Experiences: Many users express high levels of satisfaction, often highlighting the durability and efficiency of their equipment. Comments frequently mention how easy the machinery is to operate and maintain, making it a preferred choice for both professionals and enthusiasts alike.

Areas for Improvement: While the majority of feedback is favorable, some reviews indicate room for enhancement. Users occasionally note that certain parts could benefit from better design or materials, which could improve overall performance and longevity.

Overall Sentiment: The collective feedback showcases a balanced view, where the strengths of the equipment often outweigh its shortcomings. Regular updates and responsiveness from manufacturers in addressing concerns contribute positively to customer loyalty and satisfaction.