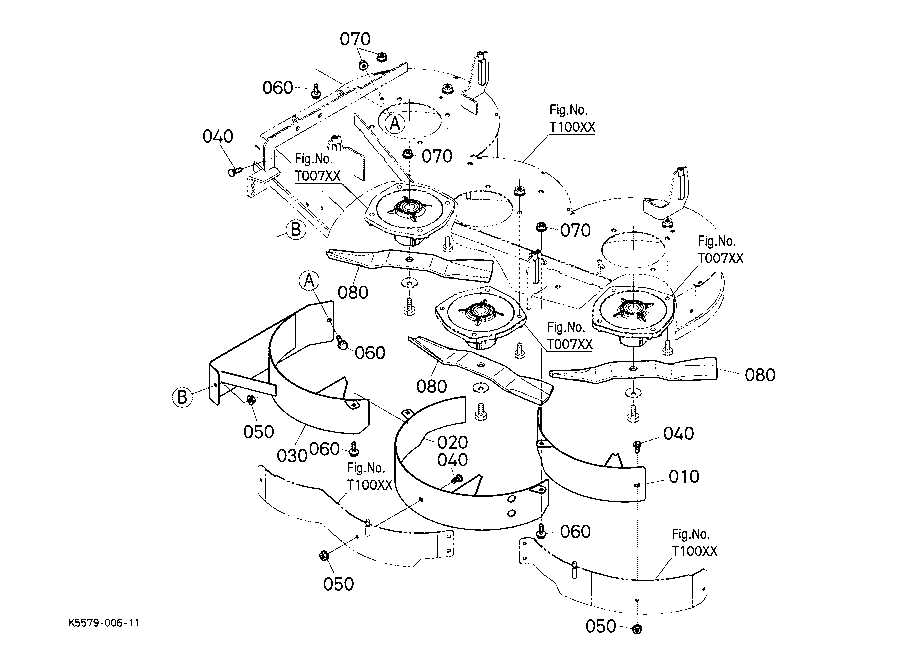

Kubota Z122EBR-48 Parts Diagram Overview

When maintaining or repairing machinery, having a comprehensive understanding of its internal structure is essential. This knowledge enables operators to identify components effectively and streamline the maintenance process. An in-depth exploration of each segment ensures that all aspects are addressed, minimizing downtime and enhancing performance.

The focus here is on a specific model renowned for its efficiency and reliability. By examining its assembly, we can uncover the relationships between various elements, providing insights into how they function together. This approach not only facilitates repairs but also aids in troubleshooting, ensuring that users can address any issues that arise swiftly.

Utilizing a visual representation of the machinery’s composition can significantly simplify the identification of parts. Such illustrations serve as a valuable resource for both seasoned professionals and newcomers, fostering a deeper understanding of the equipment. Whether for routine maintenance or complex repairs, this guide will illuminate the essential components that keep the machine running smoothly.

Kubota Z122EBR-48 Overview

This compact mower is designed to provide exceptional performance and ease of use for homeowners and landscape professionals alike. Its robust construction and advanced features make it an ideal choice for maintaining small to medium-sized lawns efficiently. The combination of power and agility allows users to navigate tight spaces with precision while ensuring a clean cut.

Key Features

One of the standout characteristics of this model is its powerful engine, which delivers impressive torque and speed. Additionally, the innovative design includes ergonomic controls, enhancing user comfort during operation. The cutting deck is engineered for optimal grass management, promoting healthy lawn growth.

Maintenance and Support

Regular upkeep is essential to prolong the life of this equipment. Access to quality replacement components and technical support ensures that users can maintain peak performance. Understanding the layout of the machine’s components aids in efficient servicing and troubleshooting, allowing owners to keep their mower in top condition.

Understanding Parts Diagrams

Visual representations of components serve as essential tools in the maintenance and repair of machinery. They provide an organized layout that helps users identify and understand the various elements that comprise a system. By breaking down complex machinery into manageable sections, these illustrations facilitate better comprehension and streamline the process of locating specific items.

Benefits of Visual Representations

- Enhanced clarity in identifying individual components.

- Streamlined repair and maintenance procedures.

- Improved communication between technicians and suppliers.

- Facilitation of ordering the correct replacements.

How to Use These Illustrations Effectively

- Familiarize yourself with the layout and labeling conventions used.

- Cross-reference components with your machine’s manual for accuracy.

- Keep a list of frequently replaced items for easy reference.

- Use these visuals to troubleshoot issues by locating related parts.

By leveraging the advantages of these visual guides, users can enhance their understanding and efficiency in managing their equipment.

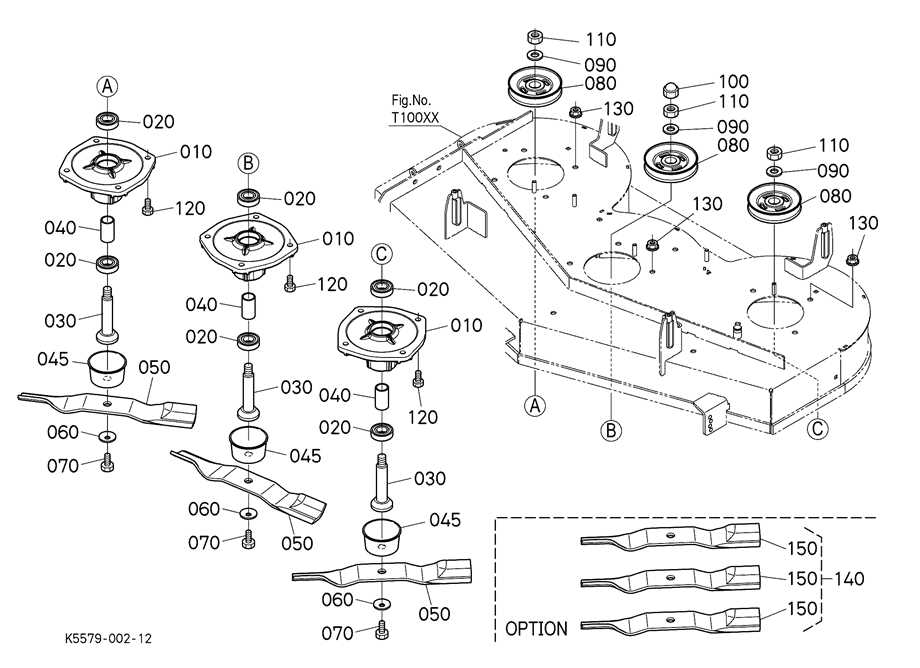

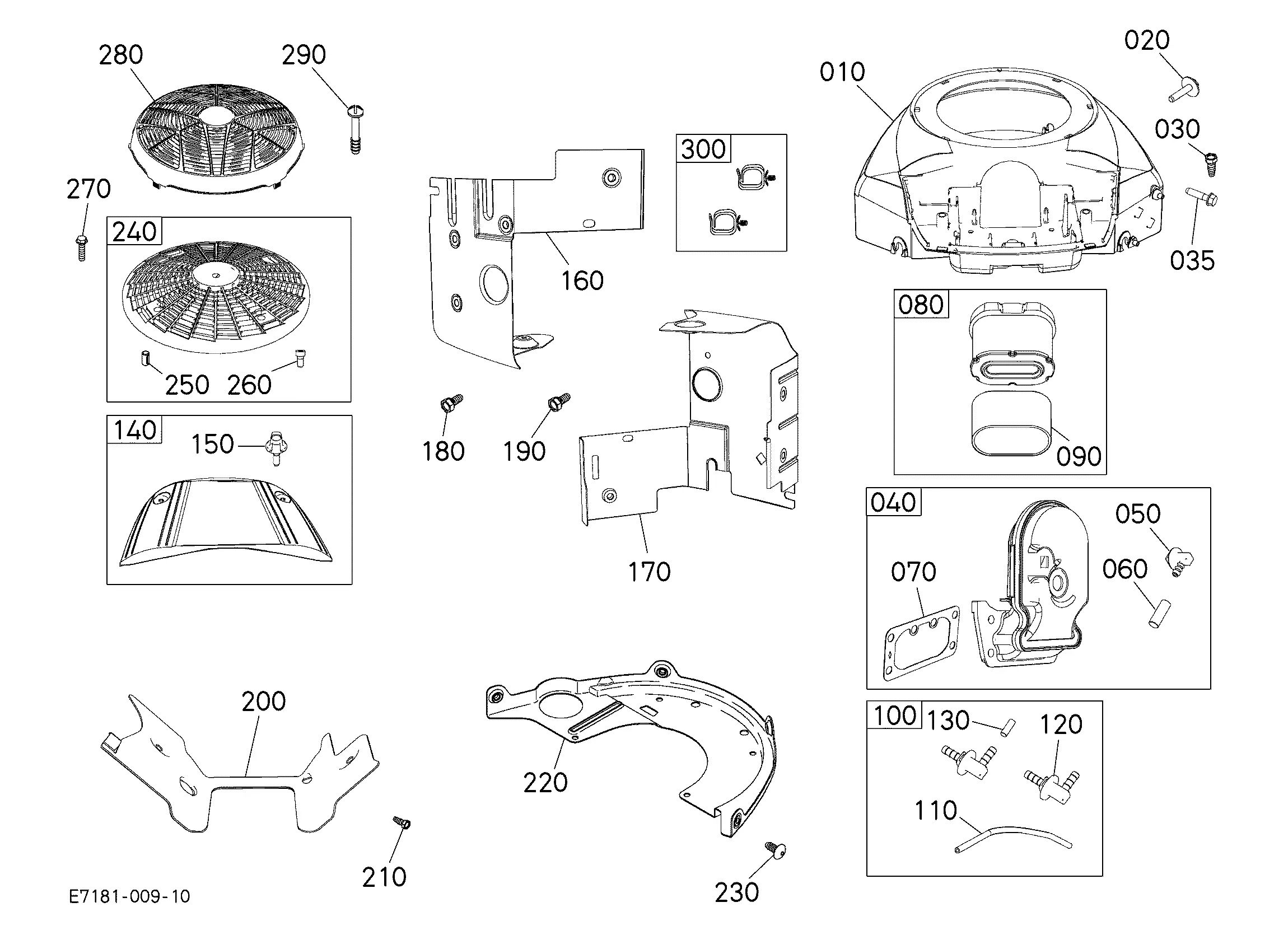

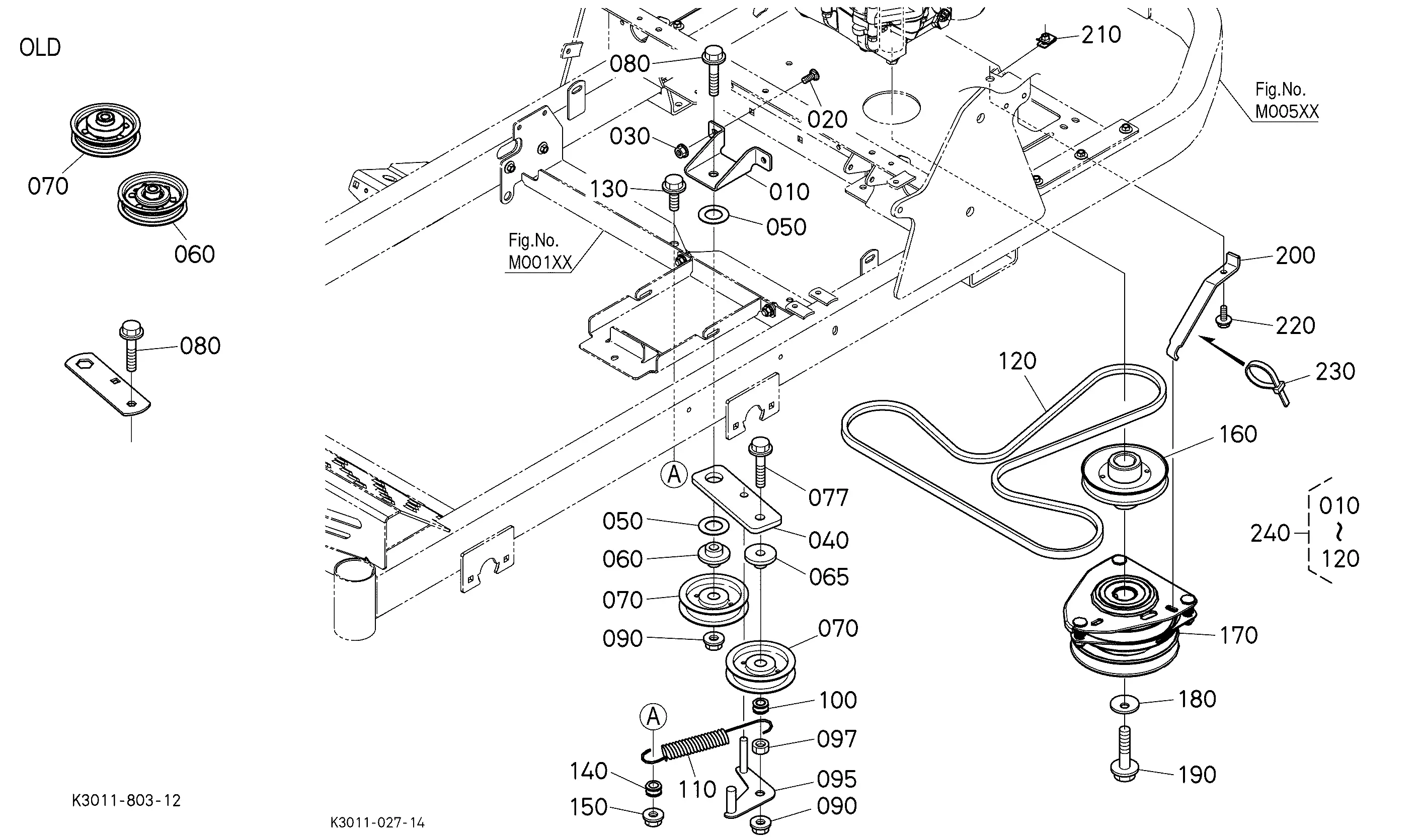

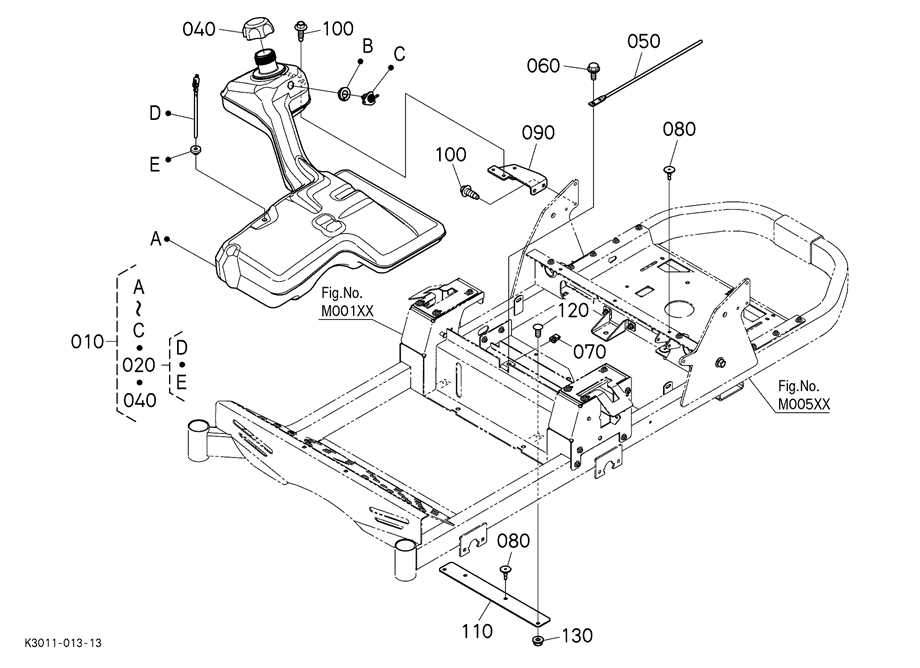

Key Components of Kubota Z122EBR-48

This section delves into the essential elements that constitute a reliable and efficient mowing machine. Understanding these crucial parts helps users maintain optimal performance and ensure longevity.

Main Structure

- Chassis: The frame provides stability and supports various components.

- Engine: The powerhouse that drives the entire system, contributing to cutting efficiency.

- Transmission: This element facilitates smooth gear changes, enhancing maneuverability.

Cutting System

- Blades: Sharp and durable, these are essential for a clean cut.

- Deck: The protective cover that houses the cutting mechanism and ensures even grass trimming.

- Height Adjustment Mechanism: Allows users to modify cutting heights for different grass types.

Recognizing these components empowers operators to perform maintenance and troubleshoot effectively, ensuring their equipment remains in top condition.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the maintenance and repair of complex machinery. These visual aids provide essential information, guiding users through the intricacies of assembly and disassembly. Accurate representations ensure that components are correctly identified and handled, which significantly enhances efficiency and reduces the likelihood of errors.

Having reliable visuals not only streamlines the repair process but also extends the lifespan of equipment. By clearly depicting each element, users can better understand how parts interact, leading to more informed decisions during maintenance. This understanding can prevent costly mistakes and minimize downtime.

| Benefit | Description |

|---|---|

| Enhanced Efficiency | Clear visuals help technicians perform tasks quickly and correctly. |

| Reduced Errors | Accurate representations lower the chances of mistakes during repairs. |

| Informed Decision-Making | Understanding the relationship between components leads to better maintenance choices. |

| Increased Longevity | Proper handling and assembly result in a longer lifespan for the machinery. |

In summary, the significance of reliable illustrations cannot be overstated. They serve as essential tools for both novices and experienced technicians, ensuring that maintenance tasks are carried out effectively and safely.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visuals provide a comprehensive overview of components and their relationships, allowing users to identify necessary items and their placement within a system.

When analyzing such illustrations, follow these steps:

| Step | Description |

|---|---|

| 1 | Examine the overall layout to grasp the configuration of elements. |

| 2 | Identify specific segments or groups for focused inspection. |

| 3 | Refer to accompanying labels or keys that explain each element. |

| 4 | Cross-reference with a list of items for clarification and verification. |

By following these guidelines, users can effectively navigate technical visuals to support their repair and maintenance tasks.

Common Replacement Parts Explained

In the realm of machinery maintenance, understanding key components that frequently require replacement is essential for optimal performance. Identifying these vital elements can enhance longevity and efficiency, ensuring smooth operation.

Key Components

- Blades: Essential for cutting, they need regular inspection and sharpening to maintain effectiveness.

- Filters: Air and oil filters play a crucial role in keeping the engine clean and preventing wear.

- Batteries: Regular checks and replacements are necessary to avoid starting issues.

- Belts: Often wear out due to constant movement and require timely replacement to prevent malfunction.

Maintenance Tips

- Regularly inspect all components for signs of wear.

- Keep a log of replaced items to track maintenance history.

- Use quality replacements to ensure compatibility and durability.

Maintaining Your Kubota Mower

Proper upkeep of your lawn care equipment is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents costly repairs. Understanding key aspects of maintenance will ensure your mower remains in peak condition throughout its life.

Routine Checks

Regular inspections are crucial. Begin with checking the oil level and quality; clean oil is vital for engine health. Inspect the air filter to prevent debris buildup that can hinder performance. Additionally, ensure that the blades are sharp and free of damage, as this affects cutting quality and efficiency.

Seasonal Maintenance

At the start of each season, perform a thorough checkup. Change the oil and filter to maintain engine integrity. Replace spark plugs and inspect belts for wear and tear. Also, clean the underside of the mower to remove grass clippings and debris that can affect performance. This proactive approach will help you enjoy a well-functioning machine for years to come.

Where to Find Parts Diagrams

Accessing visual representations of components is crucial for efficient maintenance and repair. These resources can provide detailed insights into assembly and disassembly processes, ensuring that you have the right information at your fingertips.

Online Resources

The internet offers a plethora of platforms dedicated to machinery support. Websites often host extensive libraries featuring illustrations and manuals, which can be searched by model number or type. Utilizing these online databases can greatly enhance your repair experience.

Manufacturer Support

Reaching out to the original equipment maker can yield authoritative resources. Many manufacturers provide downloadable guides and technical documents directly on their official sites. Engaging with customer service may also lead to obtaining specialized diagrams tailored to your specific machinery needs.

Benefits of Using OEM Parts

Utilizing original manufacturer components is essential for maintaining the performance and reliability of equipment. These products are designed specifically to fit and function seamlessly within the machinery, ensuring optimal operation. Choosing such items provides peace of mind, knowing that they meet the stringent quality standards set by the manufacturer.

Quality Assurance

OEM products undergo rigorous testing and quality control processes. This ensures that each component meets the exact specifications required for proper function. As a result, using these parts can lead to enhanced durability and longevity, reducing the likelihood of premature failures and costly repairs.

Perfect Compatibility

One of the significant advantages of selecting original components is their guaranteed compatibility. These items are engineered to work harmoniously with existing systems, minimizing the risk of issues that can arise from using aftermarket alternatives. Investing in OEM parts ensures that your equipment continues to perform at its best without unexpected disruptions.

Steps for Ordering Replacement Parts

Replacing components in machinery requires a systematic approach to ensure compatibility and efficiency. By following a few essential steps, you can streamline the process of obtaining the necessary elements for repairs or upgrades.

Start by identifying the specific item you need. Gather information such as model numbers and descriptions to avoid confusion. Next, consult your machinery’s manual or an online resource to verify compatibility. Once you have the required details, choose a reputable supplier that offers quality products.

When placing your order, ensure that you double-check all details, including quantity and specifications. After submitting your request, keep track of the shipping status to anticipate delivery. Finally, upon receiving the new component, inspect it carefully before installation to confirm that it meets your requirements.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular care and attention. By following a few essential maintenance practices, you can significantly extend the lifespan of your machinery and keep it running efficiently. Below are some key tips to help you maintain optimal performance.

Regular Inspections

- Check for any signs of wear or damage on all components.

- Inspect fluid levels regularly to prevent overheating or mechanical failures.

- Ensure that filters are clean and replace them as necessary.

Proper Cleaning

- Clean the exterior to prevent rust and corrosion.

- Remove debris from moving parts to avoid blockages and malfunctions.

- Use appropriate cleaning solutions to avoid damaging surfaces.

By adhering to these practices, you can help ensure that your equipment remains in top condition for many years to come.

Troubleshooting Common Issues

When operating machinery, encountering issues is a common occurrence. Understanding how to diagnose and resolve these problems can enhance performance and extend the lifespan of your equipment. This section outlines frequent complications and offers practical solutions to help you maintain optimal functionality.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Dead battery, faulty ignition, or fuel issues | Check battery connections, replace the battery if needed, and ensure fuel is reaching the engine. |

| Overheating | Low coolant levels, blocked radiator, or malfunctioning thermostat | Inspect coolant levels, clear any obstructions in the radiator, and replace the thermostat if necessary. |

| Poor Cutting Performance | Dull blades, incorrect height settings, or engine power loss | Sharpen or replace blades, adjust height settings, and check for engine performance issues. |

| Unusual Noises | Loose parts, worn bearings, or debris in the mechanism | Tighten loose components, inspect and replace worn parts, and clean any foreign objects from the machinery. |

| Fluid Leaks | Worn seals, damaged hoses, or loose fittings | Examine seals for wear, replace any damaged hoses, and ensure fittings are properly tightened. |

Connecting with Kubota Support

Engaging with customer assistance is vital for ensuring optimal performance and longevity of your machinery. Whether you require technical guidance, parts replacement, or general inquiries, accessing support can enhance your experience and resolve any issues efficiently.

Contact Methods

There are various ways to reach out for help, including phone support, online chat, and email. Each option offers unique advantages, allowing you to choose what suits your needs best.

Resource Availability

In addition to direct communication, a wealth of online resources is available, including FAQs, troubleshooting guides, and user manuals. Utilizing these materials can often provide quick answers to common concerns.