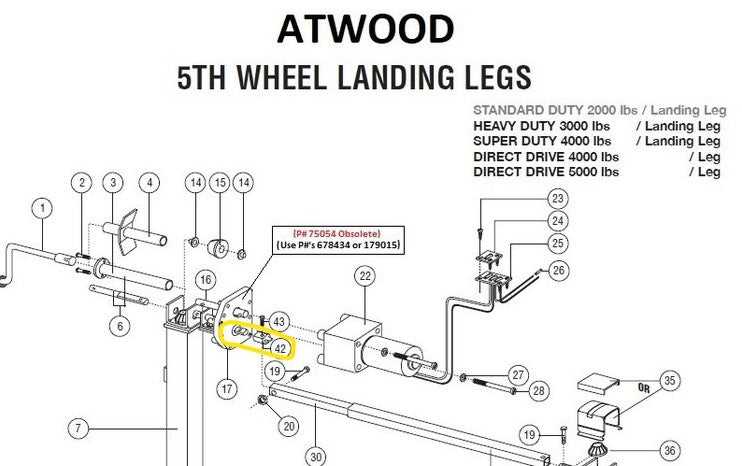

Comprehensive Diagram of Atwood Landing Gear Parts

When it comes to ensuring the stability and functionality of recreational vehicles, a thorough comprehension of critical elements is paramount. These components play a vital role in maintaining balance and facilitating smooth operation. Whether you are an enthusiast or a seasoned expert, familiarity with these intricate mechanisms enhances both performance and safety.

Visual representation of these mechanisms offers insights into their structure and interrelationships. By dissecting the various sections, one can appreciate the complexity involved in their design. This exploration allows for a deeper understanding of how each piece contributes to the overall efficiency and reliability of the system.

As we delve into the specifics, we will uncover the ultimate assembly that supports your vehicle. Grasping the layout and function of each component empowers users to make informed decisions regarding maintenance and upgrades, ultimately leading to a more enjoyable experience on the road.

Overview of Atwood Landing Gear

This section provides a comprehensive look at essential components designed to support and stabilize various vehicles when stationary. Understanding the structure and functionality of these elements is crucial for maintenance and efficiency in their operation.

| Component | Description |

|---|---|

| Support Frame | Primary structure that bears the weight and ensures stability. |

| Adjustment Mechanism | Allows for height modification to accommodate uneven surfaces. |

| Wheel Assembly | Facilitates movement when repositioning the unit. |

| Locking System | Secures components in place during use to prevent movement. |

Importance of Landing Gear Components

The structural elements that support aircraft during takeoff, landing, and taxiing play a crucial role in overall flight safety and performance. These components must work in harmony to ensure a smooth transition between ground and air. Their reliability directly impacts operational efficiency and the safety of both crew and passengers.

Key Functions of Support Structures

Each element of the undercarriage serves a specific function, contributing to the aircraft’s stability and handling characteristics. Understanding these roles helps in maintaining the aircraft and ensuring it performs optimally throughout its service life.

Impact on Aircraft Performance

The integrity of the supporting structures affects various aspects of aviation, from weight distribution to shock absorption. Any failure or malfunction in these elements can lead to serious consequences during critical phases of flight. Regular inspection and maintenance are essential to prevent potential hazards.

| Component | Function |

|---|---|

| Strut | Provides support and absorbs shocks during landing. |

| Wheel | Facilitates movement on the ground and supports weight. |

| Brake System | Ensures safe deceleration and stopping capabilities. |

| Shock Absorber | Reduces the impact forces during landing. |

Detailed Parts List for Atwood Gear

This section provides an exhaustive inventory of components essential for the operation and maintenance of your equipment. Understanding each element’s function and relationship with others is crucial for ensuring optimal performance and reliability.

The primary components include the actuator, which is responsible for the movement, and the base assembly that serves as the foundation. Additionally, there are several linkages and fasteners that connect various elements, ensuring stability during operation.

Moreover, the support arms play a significant role in distributing weight and providing balance. Don’t overlook the electronic control unit, which facilitates user interaction and automates functions.

Lastly, a complete list should also encompass seals and gaskets, which prevent leaks and protect internal mechanisms from environmental factors. Each of these elements is vital for the seamless functionality of the system.

Visual Diagram of Landing Gear

This section provides an insightful representation of critical components that ensure the stability and safety of aircraft during ground operations. Understanding these elements is essential for maintenance and operation efficiency.

Key Elements: Each component plays a vital role in the overall functionality, contributing to smooth transitions from air to ground. The illustration highlights the intricate design and arrangement of these features, allowing for a comprehensive understanding.

Importance of Clarity: A clear visual representation aids technicians and engineers in identifying specific areas for inspection and repair, enhancing operational readiness and safety standards.

Functionality of Each Component

This section explores the essential roles played by various elements in the operational system, emphasizing their importance in ensuring efficiency and reliability. Each component contributes to the overall functionality, working in unison to achieve optimal performance during usage.

Key Elements and Their Roles

Understanding the specific functions of each part allows for better maintenance and troubleshooting. The following table outlines the critical components and their respective functionalities.

| Component | Functionality |

|---|---|

| Frame | Provides structural integrity and supports other elements. |

| Actuator | Facilitates movement by converting energy into mechanical action. |

| Connector | Ensures secure attachment and seamless communication between components. |

| Locking Mechanism | Holds components in place to prevent unintended movements. |

| Spring | Provides elasticity and absorbs shock to enhance stability. |

Importance of Regular Maintenance

Regular inspection and maintenance of each element are crucial for ensuring long-lasting performance. By understanding the specific roles of these components, users can better appreciate the need for careful monitoring and prompt repairs when necessary.

Common Issues with Landing Gear

Various challenges can arise in the assembly that ensures safe ground operations for aircraft. Understanding these common problems is crucial for maintaining optimal performance and safety during takeoff and landing. Below are some frequent issues encountered in this critical system.

Mechanical Failures

- Hydraulic Leaks: Loss of fluid can lead to a failure in retraction and extension.

- Worn Components: Regular wear can affect the reliability and efficiency of the mechanisms.

- Locking Mechanism Malfunctions: Issues in the locking system can prevent secure positioning during operations.

Environmental Effects

- Corrosion: Exposure to moisture and salt can deteriorate materials over time.

- Debris Accumulation: Foreign objects can hinder movement and function.

- Temperature Variations: Extreme heat or cold can affect material integrity and fluid properties.

Regular inspections and maintenance are essential to mitigate these issues and ensure safety and reliability in aviation operations.

Maintenance Tips for Longevity

Ensuring the durability and reliability of essential equipment requires consistent care and attention. By following specific maintenance practices, users can significantly extend the lifespan of their mechanisms, minimizing downtime and costly repairs.

Regular Inspections: Conduct frequent checks to identify any wear or damage. Early detection of issues can prevent more extensive problems down the line.

Proper Cleaning: Keep components free from dirt and debris. Use appropriate cleaning agents that won’t cause corrosion or deterioration. Regular cleaning helps maintain optimal performance.

Lubrication: Apply suitable lubricants to moving parts to reduce friction and prevent overheating. This simple step can enhance efficiency and prevent premature wear.

Environment Considerations: Store equipment in a controlled environment, avoiding extreme temperatures and humidity levels. Proper storage conditions protect materials from degradation.

Follow Manufacturer Guidelines: Adhere to the recommendations provided by the manufacturer regarding maintenance schedules and procedures. This ensures that the equipment functions correctly and safely.

Replacement of Worn Components: Timely replacement of any damaged or worn-out items is crucial. Using high-quality replacements can help maintain the overall integrity of the system.

Implementing these strategies can lead to better performance and longevity, ensuring that your equipment remains reliable for years to come.

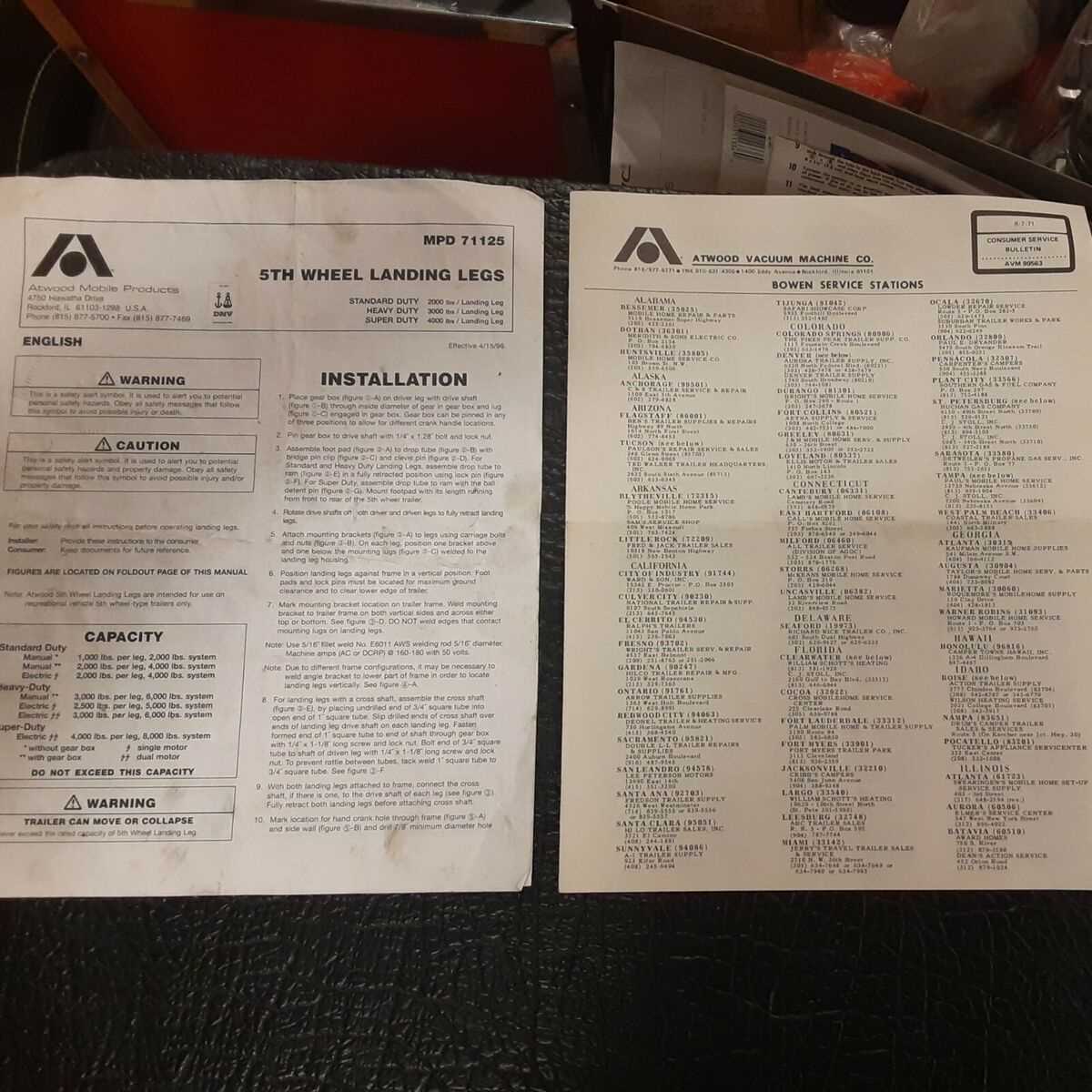

Installation Process Explained

This section outlines the essential steps for effectively integrating components into a system, ensuring optimal functionality and safety. A systematic approach not only facilitates efficiency but also enhances the longevity of the assembly.

Preparation Steps

Prior to beginning the installation, gather all necessary tools and materials. Ensure that the work area is clean and organized to prevent any complications during the process. It is also vital to review the manufacturer’s instructions thoroughly.

Installation Steps

Begin by positioning the primary structure securely. Align the elements according to the specified guidelines, utilizing appropriate fastening techniques. After assembly, conduct a thorough inspection to confirm that all components are securely attached.

| Step | Description |

|---|---|

| 1 | Gather tools and materials |

| 2 | Prepare the workspace |

| 3 | Follow assembly guidelines |

| 4 | Secure all components |

| 5 | Conduct final inspection |

Comparing Atwood to Other Brands

This section explores the distinctions and similarities between a prominent manufacturer and its competitors in the recreational equipment market. By examining various aspects such as performance, durability, and cost-effectiveness, users can make informed choices tailored to their specific needs.

Performance Analysis

- Efficiency under varying conditions

- Response time and reliability

- Compatibility with other equipment

Cost and Value

- Initial purchase price

- Long-term maintenance expenses

- Resale value and warranty options

Upgrading Your Landing Gear Parts

Enhancing the components that support and stabilize your vehicle is essential for improving overall performance and safety. This process not only involves replacing outdated elements but also integrating advanced technology to ensure reliability and efficiency. Upgrading these critical systems can lead to a smoother experience and greater peace of mind during operation.

Benefits of Component Enhancement

Investing in new technology can significantly reduce wear and tear, leading to lower maintenance costs in the long run. Improved materials and designs often provide greater durability, ensuring that your vehicle performs optimally in various conditions. Additionally, modern enhancements can lead to better responsiveness and stability, greatly benefiting your driving experience.

Choosing the Right Upgrades

When considering upgrades, it’s important to assess compatibility with your existing systems. Research various options and consult experts to determine which enhancements best suit your needs. Focus on reputable manufacturers known for their quality and innovation to ensure you’re making a worthwhile investment.

Safety Considerations When Operating

Ensuring a secure environment during operation is crucial for the well-being of both personnel and equipment. Proper precautions must be taken to minimize risks and promote effective functioning. This section outlines essential safety measures that should be adhered to when engaging with machinery or systems.

Pre-Operational Checks

Before initiating any procedures, it is vital to perform thorough inspections. The following steps should be taken:

- Examine all components for signs of wear or damage.

- Verify that all safety mechanisms are in place and functioning.

- Ensure that the operational area is clear of obstacles and hazards.

- Review the operational manual for specific instructions and safety warnings.

During Operation

While in operation, adherence to safety protocols is essential. Key practices include:

- Maintain a safe distance from moving parts and machinery.

- Use appropriate personal protective equipment (PPE) at all times.

- Communicate clearly with team members to ensure everyone is aware of tasks and potential hazards.

- Monitor the equipment for unusual noises or behaviors that may indicate a malfunction.

By following these guidelines, operators can significantly reduce the risk of accidents and ensure a safer working environment.

Customer Reviews and Experiences

This section focuses on the feedback and insights shared by users regarding their interactions with various components essential for vehicle stability and support. Understanding customer perspectives can illuminate the quality, reliability, and overall satisfaction associated with these crucial items.

Positive Feedback

Many users have expressed satisfaction with the durability and ease of installation of these components. Customers appreciate the clear instructions provided, which enhance the overall experience and confidence in handling repairs or upgrades.

Challenges Encountered

Some users have reported difficulties related to compatibility with certain vehicle models. While the majority found the components effective, a few noted issues that arose during installation, highlighting the importance of thorough research before purchase.

Resources for Further Learning

This section aims to provide valuable materials and references for those seeking to expand their knowledge in the field of mechanical components and their functionalities. Whether you are a beginner or an expert, these resources will enhance your understanding and practical skills.

Books and Manuals

- Mechanical Systems: A Comprehensive Guide – An in-depth exploration of mechanical systems.

- Fundamentals of Mechanical Design – A foundational text covering essential design principles.

- Maintenance and Troubleshooting Techniques – Practical strategies for effective upkeep.

Online Courses and Tutorials

- Coursera – Mechanical Engineering Basics – An introductory course for beginners.

- edX – Advanced Mechanics – For those looking to delve deeper into complex topics.

- YouTube – DIY Repair Videos – Visual guides for hands-on learning.

Utilizing these resources will support your journey toward mastering the intricacies of mechanical systems and their applications.