Understanding the Land Pride FDR2572 Parts Diagram for Effective Maintenance

In the realm of machinery and agricultural implements, comprehending the intricate details of each element is essential for efficient operation and maintenance. This understanding not only enhances the lifespan of the equipment but also ensures optimal performance in various tasks. By exploring the structure and function of different components, operators can troubleshoot issues and make informed decisions regarding repairs and replacements.

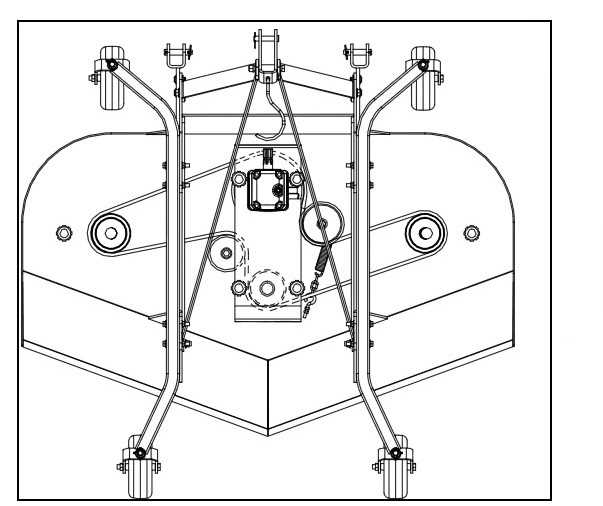

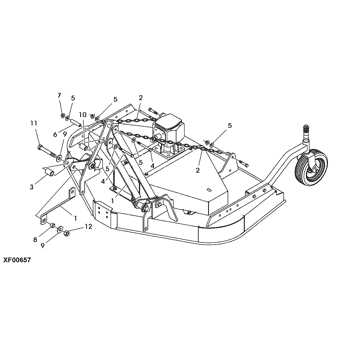

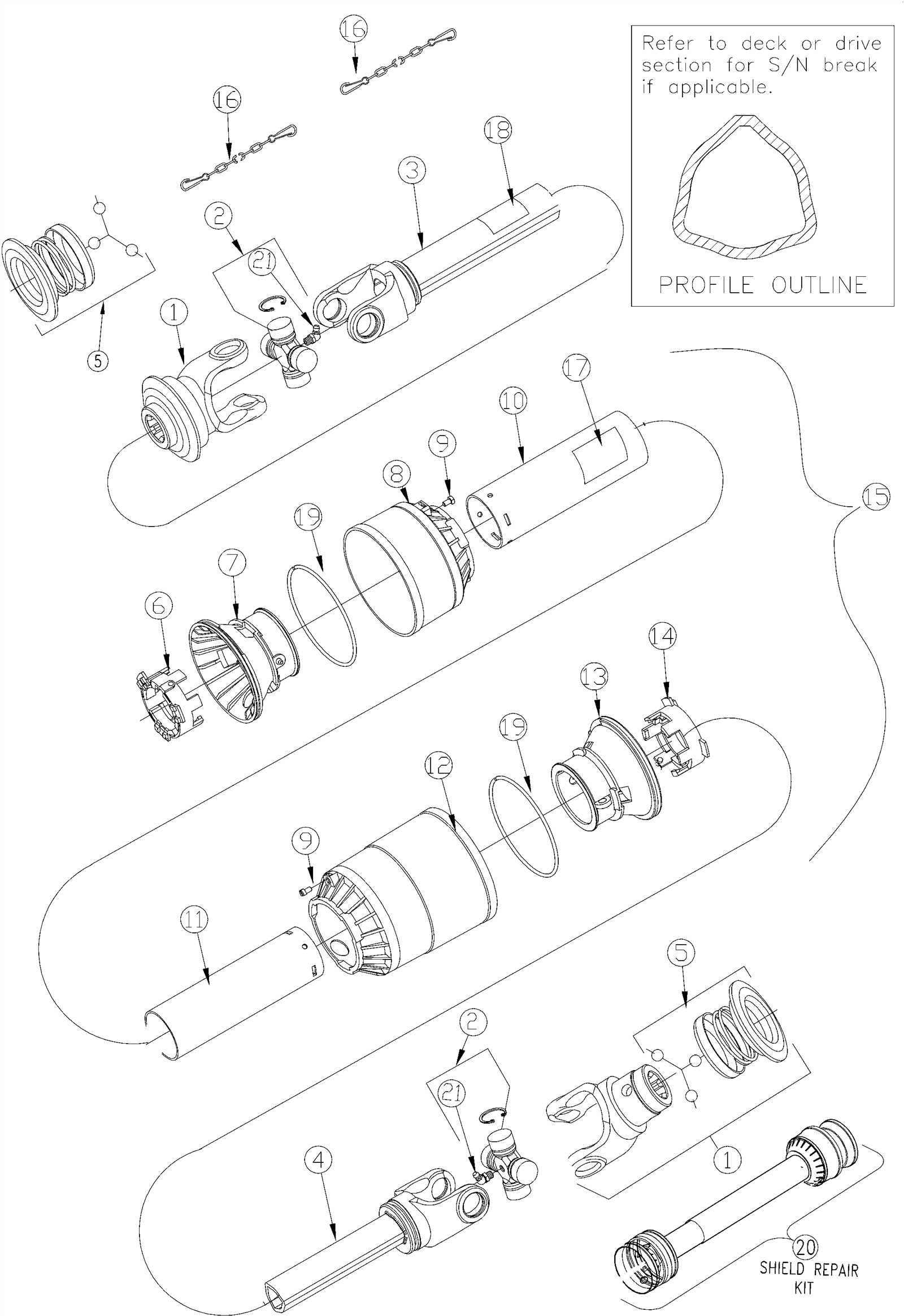

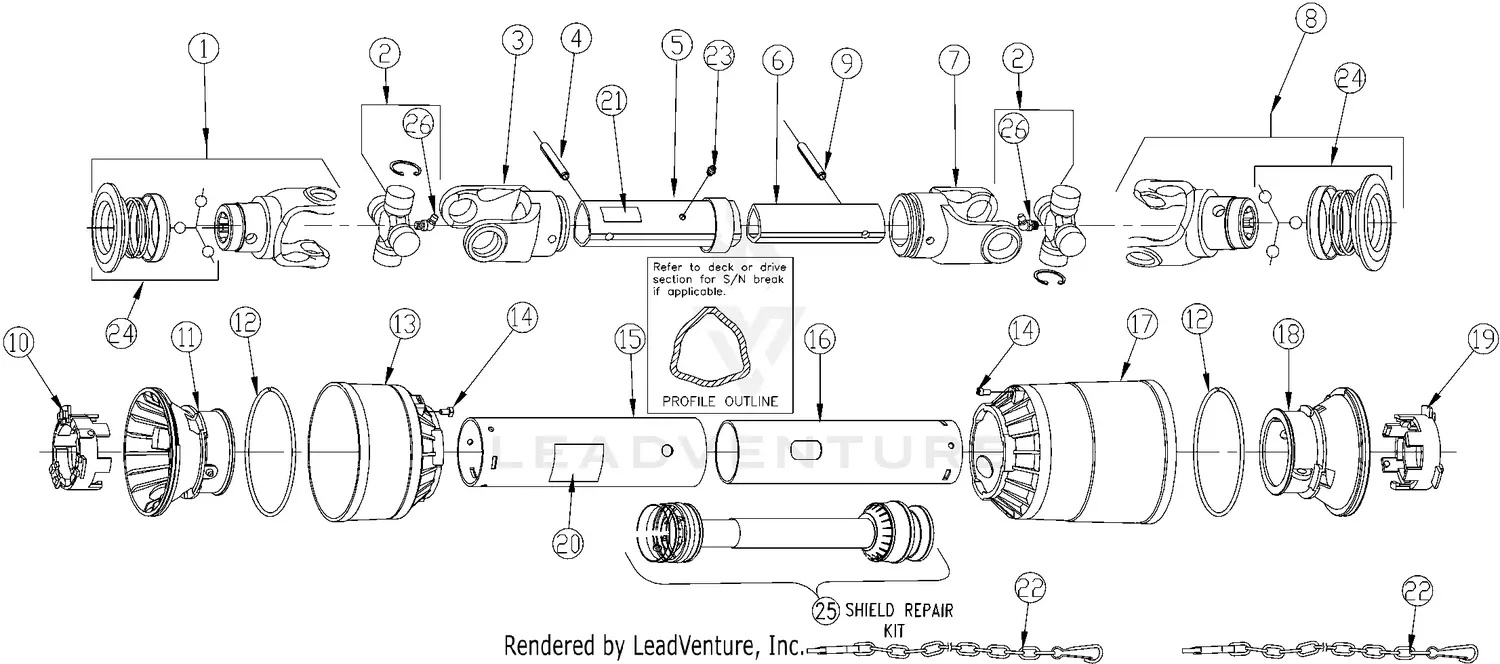

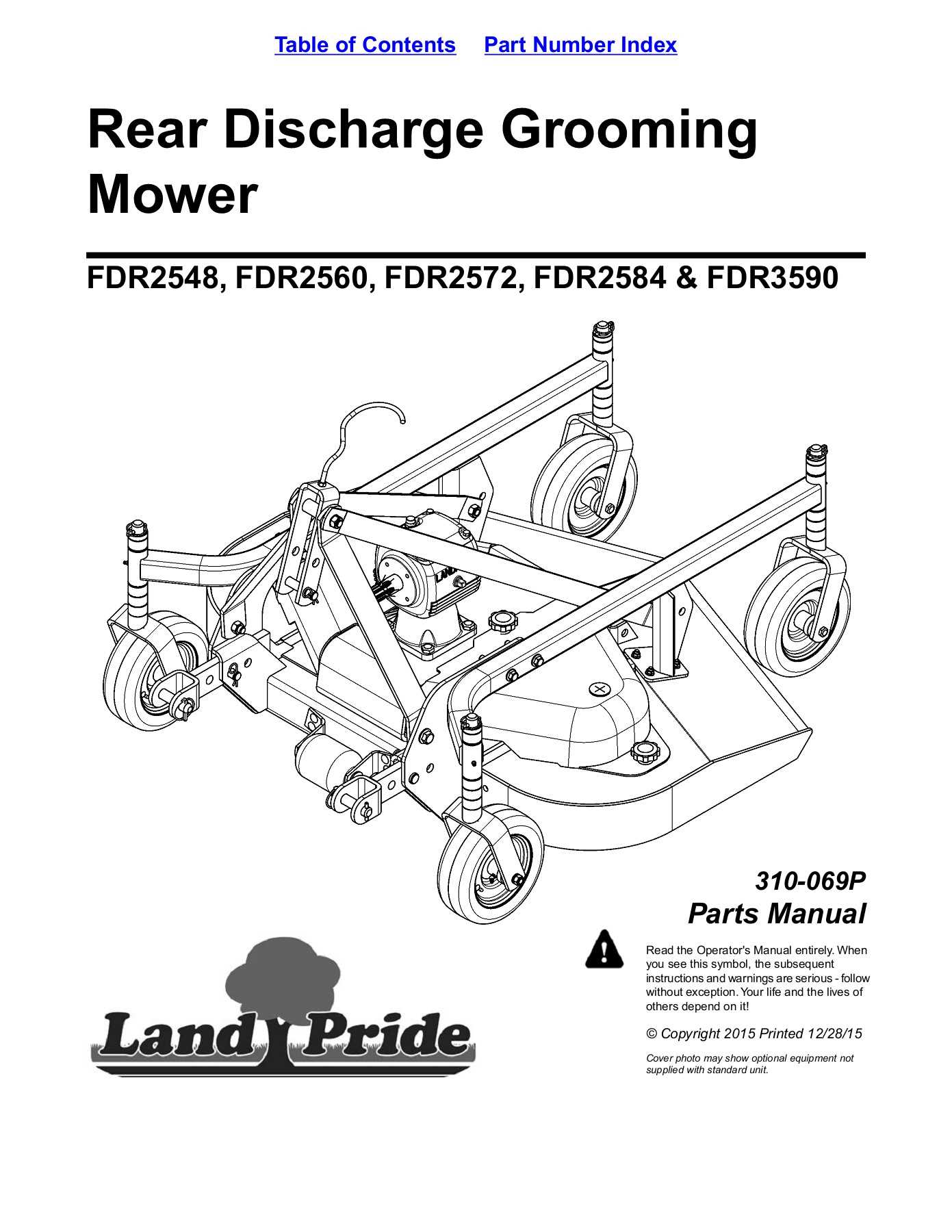

Having a visual representation of the various elements within a machine facilitates a deeper grasp of its workings. Such illustrations can serve as valuable resources for technicians and operators alike, providing clarity on assembly and disassembly processes. Additionally, they enable users to identify specific parts swiftly, which is crucial during maintenance or upgrades.

Moreover, a thorough exploration of component relationships enhances the operator’s ability to diagnose problems effectively. This knowledge is paramount, as it fosters a proactive approach to equipment care. By recognizing the interplay between various parts, users can anticipate potential malfunctions and address them before they escalate, ultimately leading to increased productivity and reduced downtime.

Understanding Land Pride FDR2572

This section delves into the features and components of a specific type of agricultural machinery designed for various land management tasks. Familiarity with its structure and functionality is essential for operators to ensure optimal performance and maintenance.

Key aspects to consider include:

- Design and engineering principles that enhance usability.

- Functionality tailored for efficiency in field operations.

- Components that contribute to durability and reliability.

For effective operation, it’s crucial to recognize the role of each element within the system:

- Frame: Provides stability and support during use.

- Blades: Essential for cutting and tilling soil.

- Hitch: Facilitates attachment to various tractors.

- Wheels: Enable mobility and transport across different terrains.

Understanding these features will enhance the operator’s ability to manage equipment effectively, leading to improved agricultural outcomes.

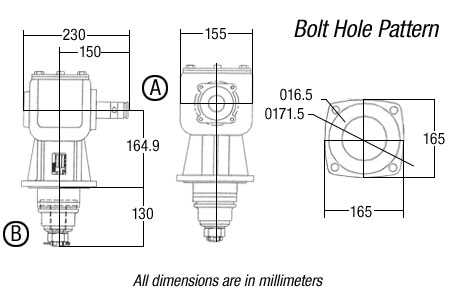

Overview of FDR2572 Features

This section presents a comprehensive look at the distinctive attributes of the FDR2572 model, showcasing its design and functionality that enhance efficiency and performance in various applications.

Key Characteristics

The FDR2572 is equipped with advanced components that contribute to its robust operation. These features are specifically engineered to optimize user experience and facilitate seamless functionality in demanding environments.

Technical Specifications

| Feature | Description |

|---|---|

| Durability | Constructed with high-quality materials for long-lasting use. |

| Efficiency | Optimized performance to maximize productivity. |

| Ease of Use | User-friendly interface designed for quick operation. |

| Versatility | Adaptable to a variety of tasks and conditions. |

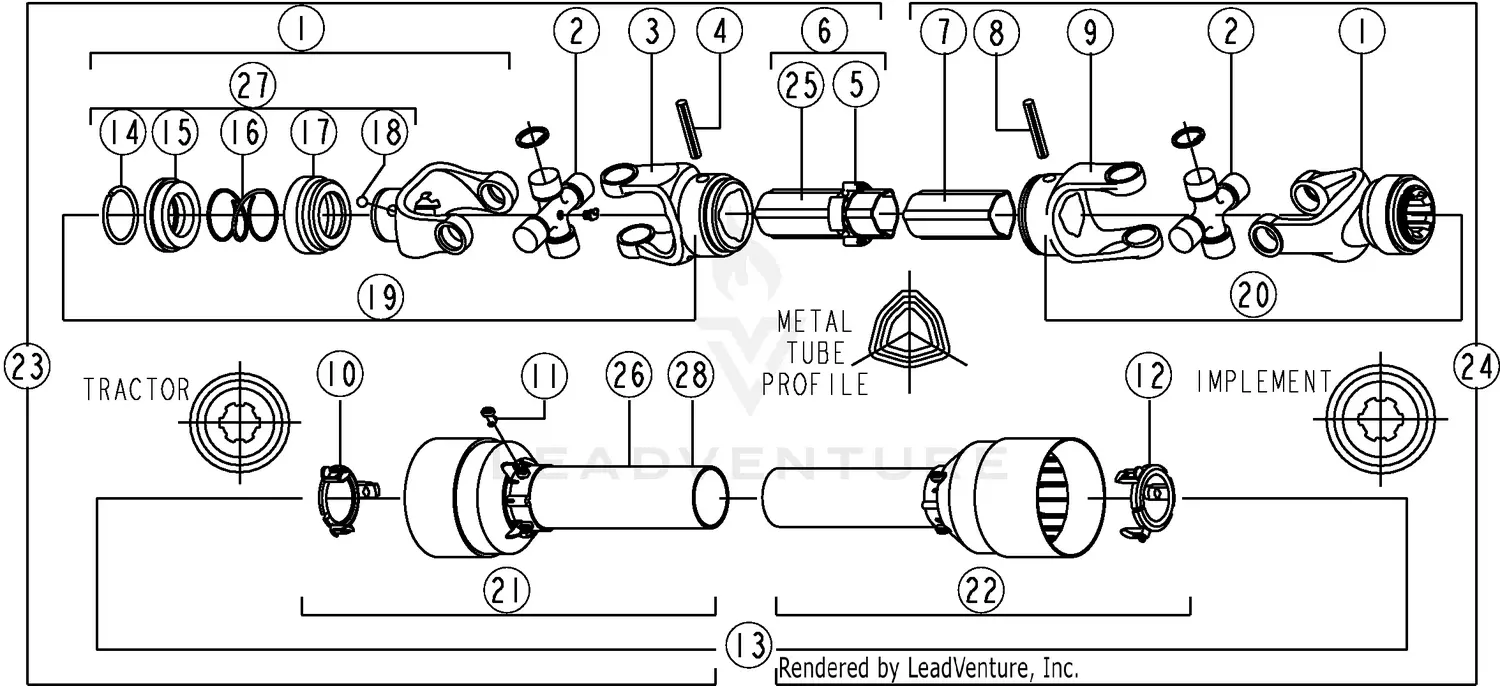

Key Components Explained

This section delves into the essential elements that constitute a typical assembly, highlighting their functions and interconnections. Understanding these components is vital for effective maintenance and operation, ensuring optimal performance and longevity of the machinery.

Core Elements

The primary constituents serve crucial roles in the overall functionality of the unit. Each part is designed to work harmoniously with others, creating a cohesive system that delivers reliable results.

| Component | Function |

|---|---|

| Motor | Drives the entire assembly, providing necessary power. |

| Frame | Offers structural integrity, supporting all attached components. |

| Hydraulic System | Facilitates movement and operation through fluid dynamics. |

| Control Unit | Regulates and manages the performance of the assembly. |

Supportive Mechanisms

In addition to the core elements, various supportive mechanisms enhance efficiency and safety. These auxiliary components are designed to improve user experience and maintain the durability of the system.

| Supportive Mechanism | Purpose |

|---|---|

| Safety Guards | Protect operators from potential hazards during operation. |

| Lubrication System | Reduces friction and wear, extending the life of moving parts. |

| Feedback Sensors | Provide real-time data for better control and adjustments. |

Importance of Maintenance

Regular upkeep of machinery and equipment is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to unexpected breakdowns, increased operational costs, and a decrease in overall efficiency. By prioritizing maintenance, users can prevent minor issues from escalating into significant problems, ultimately saving time and resources.

Benefits of Routine Care

Implementing a schedule for routine care provides several advantages. First and foremost, it helps in identifying potential issues before they develop into major failures. Timely inspections can uncover wear and tear, allowing for early intervention. Additionally, well-maintained equipment typically operates more efficiently, leading to reduced energy consumption and lower costs.

Impact on Safety and Reliability

Regular maintenance also enhances safety and reliability. Equipment that is consistently cared for is less likely to malfunction, which minimizes the risk of accidents in the workplace. Ensuring that all components are functioning correctly not only protects personnel but also promotes a smoother workflow. A commitment to maintenance reflects a responsible approach to operational integrity.

Common Issues and Solutions

When dealing with machinery, it’s not uncommon to encounter a range of challenges that can affect performance and efficiency. Understanding these potential problems and their remedies is essential for maintaining optimal functionality. This section highlights typical complications and offers effective solutions to address them.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Excessive heat can lead to component failure and reduced performance. | Ensure proper lubrication and check coolant levels regularly. |

| Noisy Operation | Unusual sounds may indicate wear or damage in moving parts. | Inspect for loose components and replace worn parts as needed. |

| Poor Performance | Decreased efficiency can stem from various mechanical issues. | Perform a thorough inspection and address any identified faults. |

| Electrical Failures | Malfunctions in electrical systems can disrupt operation. | Check wiring connections and test electrical components for integrity. |

| Fluid Leaks | Leaks can lead to insufficient lubrication and overheating. | Identify the source of the leak and replace any damaged seals or hoses. |

Parts Availability and Sources

Access to essential components is crucial for maintaining and enhancing equipment performance. Understanding where to find reliable sources can significantly impact operational efficiency and longevity.

There are various avenues for acquiring necessary items, ranging from authorized dealers to online marketplaces. Each source offers unique benefits, including warranty options, competitive pricing, and immediate availability.

| Source Type | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official retailers offering manufacturer-certified components. | Quality assurance and warranty coverage. |

| Online Marketplaces | Web platforms that connect buyers with various suppliers. | Wide selection and often lower prices. |

| Local Distributors | Regional suppliers that provide quick access to inventory. | Immediate availability and personalized service. |

| Aftermarket Suppliers | Third-party vendors offering compatible alternatives. | Cost savings and diverse options. |

By exploring these options, users can ensure they obtain high-quality items tailored to their specific needs, thus optimizing their machinery’s functionality.

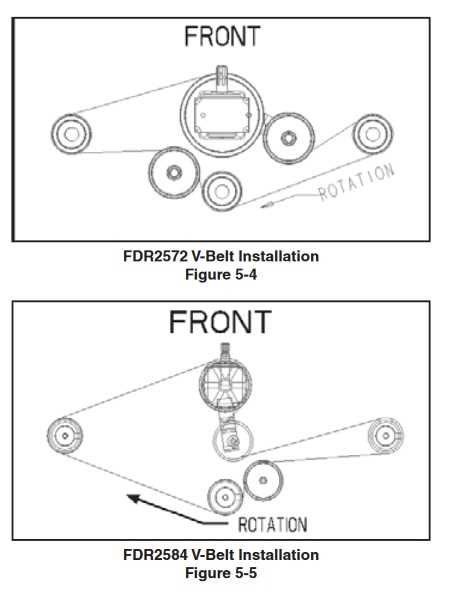

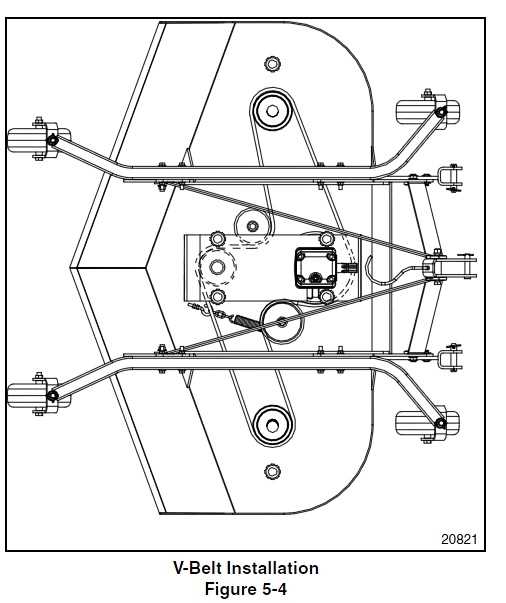

Assembly Instructions for Users

This section provides a comprehensive guide for individuals looking to piece together their equipment effectively. Following these instructions will ensure a smooth assembly process, enhancing functionality and durability.

Before starting, gather all necessary components and tools. Ensure you have a clean workspace to avoid misplacing any items. Here are the steps to follow:

- Review the provided components list to confirm you have everything needed.

- Begin with the main structure, aligning each segment according to the provided orientation.

- Secure each section with the appropriate fasteners, ensuring they are tightened adequately.

- Proceed to attach additional features, making sure to follow the sequence for optimal assembly.

- Double-check all connections to verify stability and correctness.

It is beneficial to consult any visual aids included with your product for clarity. In case of uncertainties, reaching out to customer support can provide additional assistance.

Finally, ensure the equipment is tested in a controlled manner to confirm proper functionality before full use.

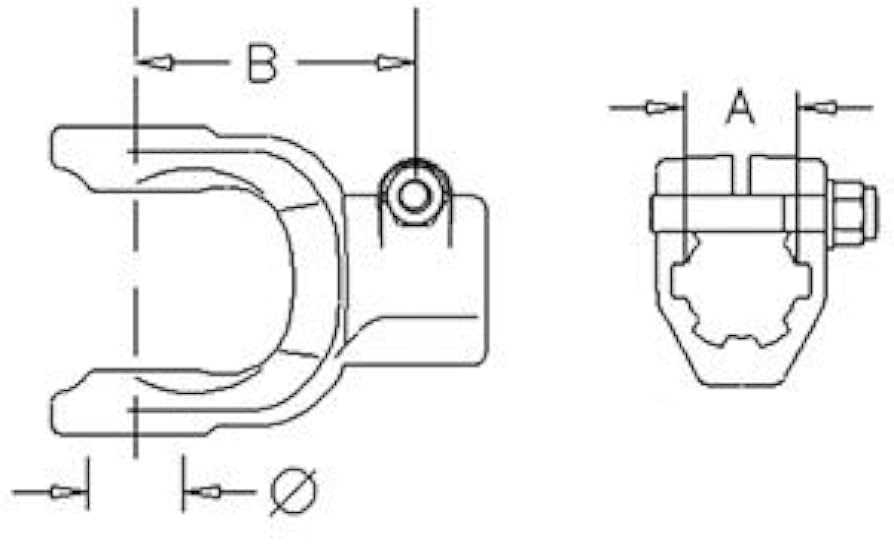

Diagram Interpretation Techniques

Understanding visual representations of complex systems is crucial for effective analysis and application. This section explores methods to decode and utilize graphical illustrations efficiently, enhancing comprehension and practical implementation.

Key Strategies for Effective Analysis

To interpret visuals accurately, one can employ several techniques. First, identify the main components and their relationships. Next, examine the flow of information, which can provide insights into functionality. Lastly, consider the context in which these visuals are used to gain a deeper understanding of their significance.

Common Symbols and Notations

Familiarity with standard symbols can greatly facilitate interpretation. The following table outlines some frequently encountered representations and their meanings:

| Symbol | Description |

|---|---|

| Circle | Represents a connection point or node. |

| Arrow | Indicates direction or flow of processes. |

| Rectangle | Denotes a process or action to be taken. |

Safety Precautions During Use

Ensuring safety during operation is crucial to prevent accidents and injuries. Proper guidelines should be followed meticulously to create a secure working environment.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE).

- Conduct a thorough inspection before use.

- Ensure all safety guards are in place and functioning.

Operational Best Practices

- Maintain a clear workspace to avoid tripping hazards.

- Follow the manufacturer’s instructions for operation.

- Keep bystanders at a safe distance during use.

Optimal Operating Conditions

Creating the ideal environment for equipment functionality is crucial for maximizing performance and longevity. Understanding the specific requirements for optimal operation allows users to ensure that machinery runs efficiently, minimizing wear and potential failures.

Temperature plays a vital role; machinery typically operates best within a designated range. Excessive heat can lead to overheating, while cold conditions may hinder performance. Maintaining appropriate levels is essential for achieving peak efficiency.

Additionally, lubrication is fundamental to reducing friction and wear. Regularly checking and replenishing lubrication not only enhances functionality but also extends the lifespan of components. Implementing a routine maintenance schedule can significantly impact overall performance.

Furthermore, ensuring proper alignment and calibration of parts is necessary to avoid unnecessary strain. Regular inspections can help identify any misalignments early, allowing for timely corrections and preventing long-term damage.

Ultimately, adhering to these optimal conditions fosters a reliable and efficient operating environment, enhancing productivity and reducing costs over time.

Comparing with Similar Models

This section aims to explore the similarities and differences between various comparable equipment within the same category. By analyzing key features and functionalities, users can make informed decisions when selecting machinery that best suits their needs.

Key Features to Consider

- Performance specifications

- Durability and build quality

- Ease of maintenance

- Compatibility with attachments

- Cost-effectiveness

Popular Alternatives

- Model A: Known for its robust performance in tough conditions.

- Model B: Offers advanced technology for enhanced efficiency.

- Model C: A budget-friendly option with reliable features.

By examining these alternatives, users can delve into the ultimate choice that aligns with their operational requirements and budget constraints.

User Experiences and Testimonials

In this section, we delve into the firsthand accounts and feedback from individuals who have utilized various components for their machinery. These insights provide valuable information about reliability, performance, and overall satisfaction. Hearing from users can significantly influence potential buyers in their decision-making process.

| User Name | Experience Summary | Rating (out of 5) |

|---|---|---|

| John D. | Had a great experience with the components; they exceeded my expectations in durability and efficiency. | 5 |

| Mary S. | The installation was straightforward, and the performance improved significantly. Highly recommended! | 4 |

| Tom H. | Reliable parts that have held up well under heavy use. A solid investment for my equipment. | 4.5 |

| Emily R. | Customer service was helpful when I had questions, and the product quality was impressive. | 5 |

| Sam K. | While the performance was good, I faced some challenges during installation. Overall, satisfied. | 3.5 |

Future Upgrades and Modifications

As technology continues to advance, the potential for enhancing existing machinery becomes increasingly significant. Upgrades can improve efficiency, extend the lifespan, and adapt equipment to new tasks or environments. By exploring various modification options, users can ensure their systems remain competitive and effective in a rapidly evolving market.

Integrating advanced sensors can provide real-time data, enhancing operational capabilities. Additionally, retrofitting with more efficient components can reduce energy consumption and maintenance costs. Customization options, such as improved ergonomics or automation features, can also enhance user experience and productivity.

Considering future developments, it’s essential to evaluate compatibility with existing systems to facilitate seamless integration. Ongoing research into innovative technologies may reveal additional opportunities for enhancements, ensuring that equipment remains relevant and capable of meeting changing demands.