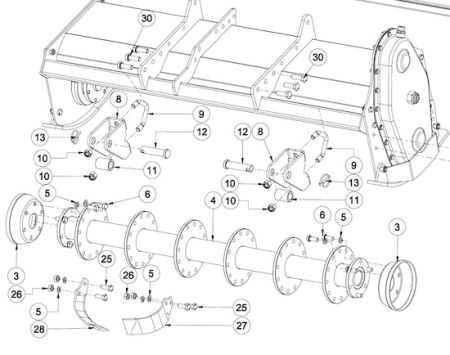

Land Pride Tiller Parts Diagram for Easy Reference

When it comes to maintaining and optimizing the performance of farming machinery, knowing the intricate details of its construction is essential. Each piece plays a crucial role in ensuring efficient operation, and understanding how they fit together can lead to better upkeep and smoother functionality. Whether you are a seasoned professional or a novice, having a clear overview of these tools’ structural elements is invaluable.

Identifying the key elements of these agricultural devices allows you to troubleshoot any issues that may arise. From the blades that rotate and cut into the soil to the frame that holds everything together, each component has its function. By familiarizing yourself with these vital pieces, you can address wear and tear, replace damaged sections, and ultimately extend the life of the machine.

In this section, we will explore the layout of these tools, breaking down each segment to provide a comprehensive guide for users. Whether you’re looking to repair or upgrade your equipment, a well-detailed view of the assembly will make all the difference.

Essential Components of Land Pride Tiller

When working with agricultural equipment designed for soil preparation, several key elements ensure its efficient operation. Each machine consists of different functional units that contribute to its performance. Understanding these core elements is crucial for proper maintenance and optimal use in the field.

The most critical sections of this machinery include the cutting tools, drive system, and structural frame. These components work in unison to till the soil, break up compacted earth, and provide a smooth finish. Without any of these essential units, the machine cannot function as intended, leading to poor results and potential damage.

| Component | Function |

|---|---|

| Cutting Blades | These are responsible for slicing through the soil to break it up into finer pieces, promoting better aeration. |

| Gearbox | Transfers power from the engine to the cutting blades, ensuring that the machine operates smoothly. |

| Frame | Supports all other components, providing stability and durability under heavy conditions. |

| Drive Belts | Transmit motion from the engine to the rotating parts, facilitating the tilling process. |

Understanding the Tiller Drive Mechanism

The drive system of a cultivation machine plays a crucial role in its overall performance, enabling efficient movement and operation. The mechanism responsible for transferring power from the engine to the working components is fundamental in achieving optimal efficiency. By understanding how each element of this system works, operators can better maintain and troubleshoot the equipment to ensure long-term functionality.

Key Components of the Drive System

- Engine: The source of power, converting fuel into mechanical energy.

- Transmission: Responsible for controlling the speed and direction of the machine.

- Gears: Integral for transferring the motion from the engine to the working parts.

- Belts and Chains: These components help connect the transmission to other elements, ensuring smooth movement.

- Control Levers: Allow the operator to adjust speed and functionality during use.

How the Drive System Works

- The engine generates power, which is transferred to the transmission system.

- The transmission adjusts the power flow, directing it to the gears or belts.

- Gears or belts then transfer this motion to the working components, ensuring the desired action.

- Control levers allow the operator to fine-tune the system, ensuring appropriate operation for the task.

Exploring the Tillage Blade Assembly

The tillage blade assembly plays a critical role in the effectiveness of soil preparation. This component is designed to cut, churn, and incorporate soil for optimal planting conditions. Understanding the construction and function of this assembly ensures proper maintenance and performance over time.

- Blade Functionality: The blades are engineered to efficiently break up compacted soil, allowing for better air and water circulation, which is crucial for plant growth.

- Durability: Made from robust materials, these blades must withstand repeated contact with hard soil and debris. Their strength is vital for maintaining performance under challenging conditions.

- Assembly Components: The blade assembly typically includes the cutting edges, support brackets, and attachment points. Each element is crucial to the overall function of the system.

By focusing on the blade system, operators can enhance the efficiency of their equipment and prolong its lifespan, ensuring that it continues to deliver consistent results throughout its operational life.

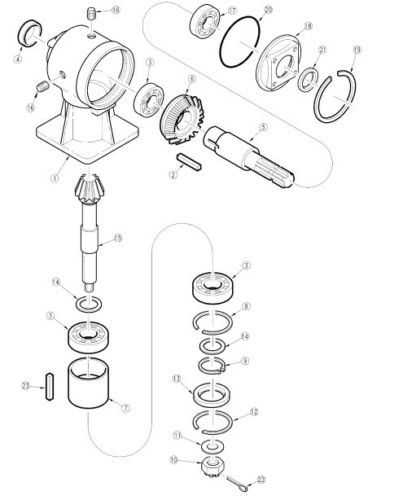

How the Gearbox Operates in Tilling

The gearbox plays a crucial role in the overall function of soil cultivation machinery. Its main task is to transfer power from the engine to the rotating components, allowing the machine to break up soil effectively. This mechanical unit ensures that energy is efficiently distributed and utilized, optimizing the performance of the equipment. By converting engine speed into usable torque, it enables the ground-working elements to rotate at appropriate speeds for efficient tilling operations.

Function of the Gearbox

- Converts engine power into mechanical energy.

- Adjusts the speed and torque to suit the soil conditions.

- Ensures smooth rotation of the working components.

Key Components of the Gearbox

- Input Shaft: The part that receives power from the engine.

- Gears: These adjust the speed and torque for the working parts.

- Output Shaft: Delivers the transferred power to the rotating elements of the machinery.

Functions of the Tiller Hitch and Frame

The hitch and frame of agricultural equipment serve as essential components that facilitate the connection between the machine and the tractor. They provide the necessary support and structure, ensuring that the implement functions efficiently and remains stable during operation. This section explores the key roles of these components, focusing on how they contribute to the overall performance of the equipment.

Hitch Functions

The hitch mechanism is responsible for attaching the equipment to the tractor, enabling power transmission and control. It must be robust enough to withstand the stresses encountered during use, providing secure attachment while allowing for easy adjustments. Proper alignment and flexibility are critical to ensure smooth operation in varying terrain and conditions.

Frame Functions

The frame provides structural integrity and distributes the forces exerted during tilling. It supports the implement’s working components and allows for adjustments in height and width. A well-designed frame enhances the balance and maneuverability of the machine, improving efficiency and reducing wear on both the implement and the tractor.

| Component | Primary Function | Impact on Operation |

|---|---|---|

| Hitch | Attachment point between machine and tractor | Ensures secure connection and control |

| Frame | Structural support for working parts | Improves balance, stability, and durability |

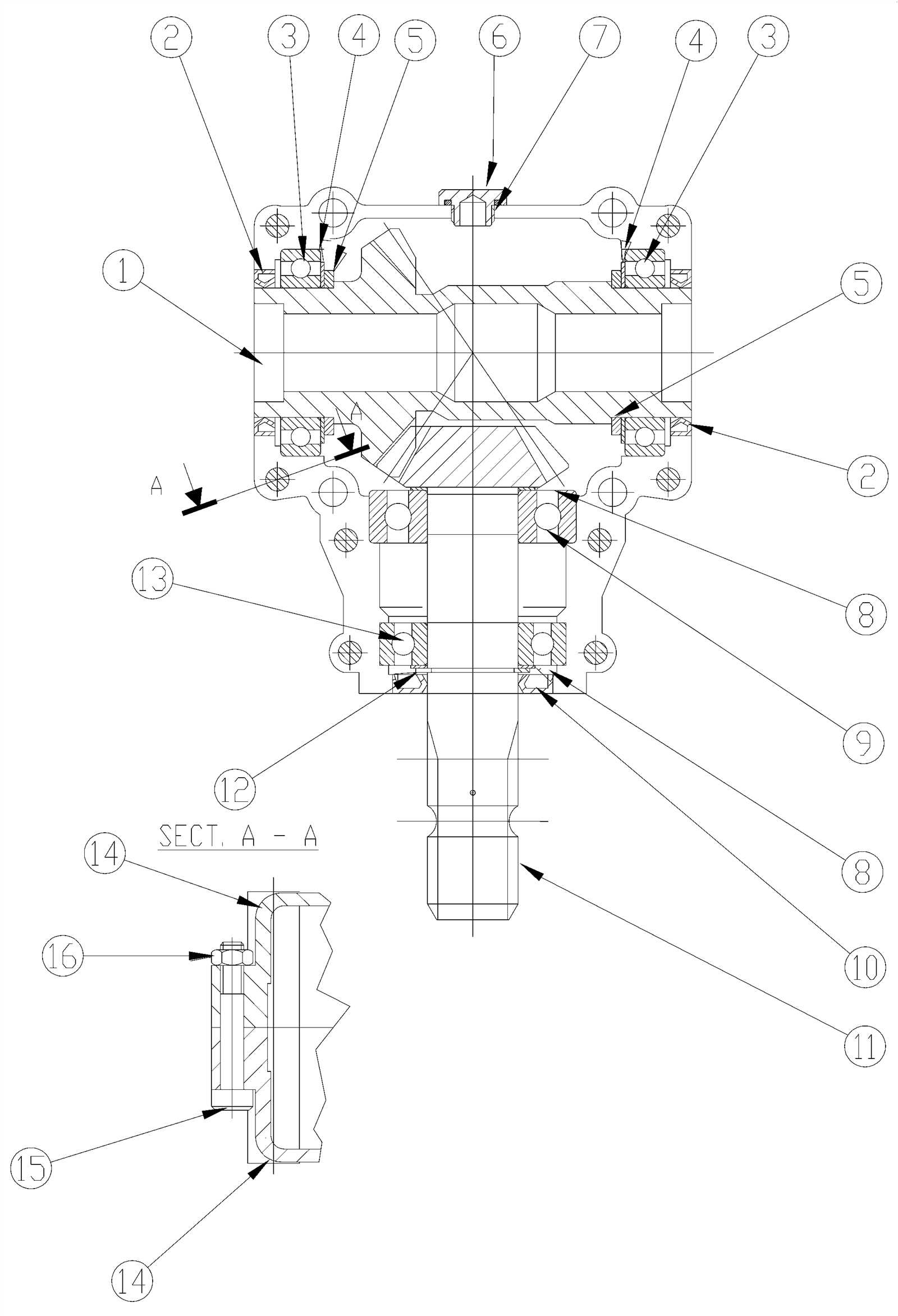

Identifying the Tiller Shaft and Bearings

Understanding the key components of a soil cultivation tool is essential for proper maintenance and operation. Among these, the central rod and its supporting elements play a crucial role in transferring mechanical power and ensuring smooth movement. Recognizing these elements is important for anyone who needs to replace or inspect them, as they are critical for the machine’s performance and longevity.

The central rod, typically cylindrical, connects various rotating components and ensures that motion is evenly distributed throughout the mechanism. It is mounted on bearings, which help reduce friction and provide stability during operation. These bearings are located at key points where the rod is secured and are vital for maintaining smooth, efficient function. When inspecting the system, check for any signs of wear, such as unusual noise, excessive movement, or lubrication issues, as these may indicate that the bearings or the shaft itself need attention.

Bearings are often found at the ends of the shaft or within housing units that keep the rod in place. They are responsible for allowing the shaft to rotate freely while absorbing forces exerted during use. Over time, these components may degrade, leading to inefficiency or even damage to the entire mechanism. Regularly examining these parts for any damage or wear can help extend the lifespan of your equipment.

Land Pride Tiller Belt System Overview

The belt mechanism is an essential component of modern agricultural equipment, ensuring smooth power transfer between various moving elements. This system plays a pivotal role in optimizing the efficiency of the machine’s functions, offering both flexibility and reliability. Understanding how the belts interact within the machinery can significantly aid in maintenance and troubleshooting processes.

- Provides consistent motion from the engine to the working components.

- Ensures synchronization of different moving parts for effective operation.

- Helps protect the system by allowing for slippage in case of overload.

- Requires regular inspection and maintenance for long-term performance.

Proper alignment and tension of the belt system are key to its overall performance. A misaligned or loose belt can cause unnecessary wear, inefficient power transmission, or even damage other components. Regularly replacing worn-out belts is crucial to maintaining optimal functionality and preventing breakdowns.

- Check belt tension and alignment regularly to prevent slippage.

- Use correct replacement belts to maintain factory specifications.

- Monitor wear and tear, especially if unusual noises or vibrations occur during operation.

Efficient functioning of the belt system will enhance the machine’s productivity, ensuring that it performs at peak capacity. Regular maintenance and attention to these details will prolong the life of the equipment and reduce the need for costly repairs.

The Role of the Chain Drive System

The chain drive mechanism plays a vital role in transferring motion and power between different components of agricultural machinery. This system ensures smooth operation by linking the main drive shaft to various working parts, thereby maintaining efficiency and performance during field tasks.

In this type of setup, the chain serves as a reliable medium for power transmission, allowing components to work in harmony with each other. It connects the engine’s output to the rotating elements that perform the actual soil processing. The efficiency of this system directly impacts the machine’s overall productivity and lifespan.

- Power Transmission: The chain drive ensures consistent and effective power delivery from the engine to the working blades.

- Durability: Chains are designed to withstand tough working conditions, offering long-lasting performance even under heavy use.

- Maintenance: Regular checks and proper lubrication are essential to maintaining the system’s reliability and preventing wear and tear.

- Efficiency: The chain drive reduces energy loss and optimizes the performance of the equipment during operation.

Maintenance Tips for Tiller Components

Keeping your soil preparation equipment in top condition is crucial for ensuring its longevity and performance. Regular upkeep of the various mechanical elements can prevent major breakdowns and optimize functionality. Below are some practical suggestions to maintain the key components effectively and extend their useful life.

Check and Replace Worn Blades

The cutting elements of the machine endure significant wear with every use, especially when working on tougher soil. Regularly inspect them for signs of damage, wear, or dullness. Sharp blades ensure efficient digging and can reduce the strain on the machine’s engine. Replacing or sharpening the blades when necessary can prevent poor soil performance and increased fuel consumption.

Lubrication and Gear Maintenance

The mechanical parts, such as gears and shafts, must be adequately lubricated to ensure smooth operation. Failing to maintain proper lubrication can lead to overheating and excessive wear. Be sure to follow the manufacturer’s guidelines for the appropriate type of lubricant and intervals for applying it.

| Component | Recommended Maintenance | Maintenance Frequency |

|---|---|---|

| Blades | Check for wear, replace or sharpen if needed | Every 10-15 hours of operation |

| Belts | Inspect for cracks and tension, replace if worn | Every 20-25 hours of operation |

| Gears and Shafts | Lubricate to prevent rust and friction | Every 25-30 hours of operation |

| Air Filters | Clean or replace to prevent clogging | Every 50-60 hours of operation |

How to Replace Worn Tiller Parts

Over time, components of your soil cultivation equipment may become worn and need to be replaced to ensure efficient operation. Replacing these components can restore performance, prevent further damage, and enhance the longevity of your machine. Understanding the basic steps and tools required for this process is essential for maintaining optimal functionality.

Step 1: Identify the Damaged Components

The first step is to carefully inspect the machine. Look for any signs of wear, such as cracks, rust, or bent pieces. Common areas of concern include the rotating elements, cutting blades, and any mechanisms that come into contact with the soil. Once identified, note the specific parts that require replacement and ensure you have the correct replacements on hand.

Step 2: Remove and Replace the Worn Components

Start by using the appropriate tools, such as wrenches or screwdrivers, to carefully detach the worn components. Keep track of any fasteners, as these may need to be reused during the reassembly process. Once the damaged items are removed, align the new pieces with the machine’s assembly and secure them properly. Double-check that all components are tightly fastened to prevent any operational issues.

Tip: Always consult your machine’s user manual for specific instructions regarding the replacement process and compatible parts.

Note: Replacing worn-out components promptly will help maintain the machine’s efficiency and reduce the risk of more serious damage over time.

Common Issues with Tiller Parts

When operating a soil cultivation machine, several components may experience wear and tear, resulting in performance issues. Identifying and addressing these common malfunctions is essential for maintaining efficiency and prolonging the life of the equipment. Frequent problems can stem from incorrect assembly, inadequate lubrication, or general deterioration due to extensive use. In this section, we will explore the most typical issues encountered with the key components of these machines.

Component Misalignment

Misalignment of machine components can cause uneven soil processing and increase the strain on other parts. This often leads to excessive vibration, uneven performance, and premature damage. Common signs of misalignment include erratic motion, noise, and uneven wear patterns on the components.

Wear and Corrosion

Components exposed to harsh conditions such as moisture or abrasive soil can deteriorate over time. Wear and corrosion can weaken the material, leading to failure during use. Regular inspection and proper maintenance, including cleaning and lubrication, are necessary to prevent such issues.

| Component | Common Issue | Symptoms | Possible Solution |

|---|---|---|---|

| Drive Belt | Fraying | Slipping, noise | Replace belt |

| Shovels | Cracking | Inconsistent tilling, uneven ground | Replace damaged shovels |

| Axle | Misalignment | Vibration, uneven motion | Realign and secure axle |

Upgrading Your Tiller for Better Performance

Enhancing the efficiency of your cultivating equipment can lead to smoother operations and better results. Whether you are looking to improve its power, durability, or ease of use, various upgrades can make a significant difference. By focusing on key components, you can ensure that your machine runs optimally, handling tougher soil conditions with ease and saving time during large gardening or farming tasks.

Key Components to Consider

To achieve noticeable improvements in your equipment’s performance, it is important to focus on specific areas. Upgrading key components such as the blades, drive belts, and engine will ensure that the machine operates efficiently. Additionally, choosing durable materials for replacement parts can extend the life of your equipment, reducing the frequency of repairs.

| Component | Suggested Upgrade | Benefits |

|---|---|---|

| Blades | High-carbon steel or reinforced blades | Increased durability and cutting efficiency |

| Drive Belts | Kevlar-reinforced belts | Enhanced resistance to wear and heat, longer lifespan |

| Engine | Upgraded horsepower engine | Improved power output for tough soils |

Maintaining Upgraded Equipment

Regular maintenance of upgraded components is essential to ensure long-term performance. Routine checks and timely replacements will help to prevent downtime and preserve the efficiency gains from your upgrades. Be sure to clean and inspect each part, making adjustments as needed to keep everything running smoothly.

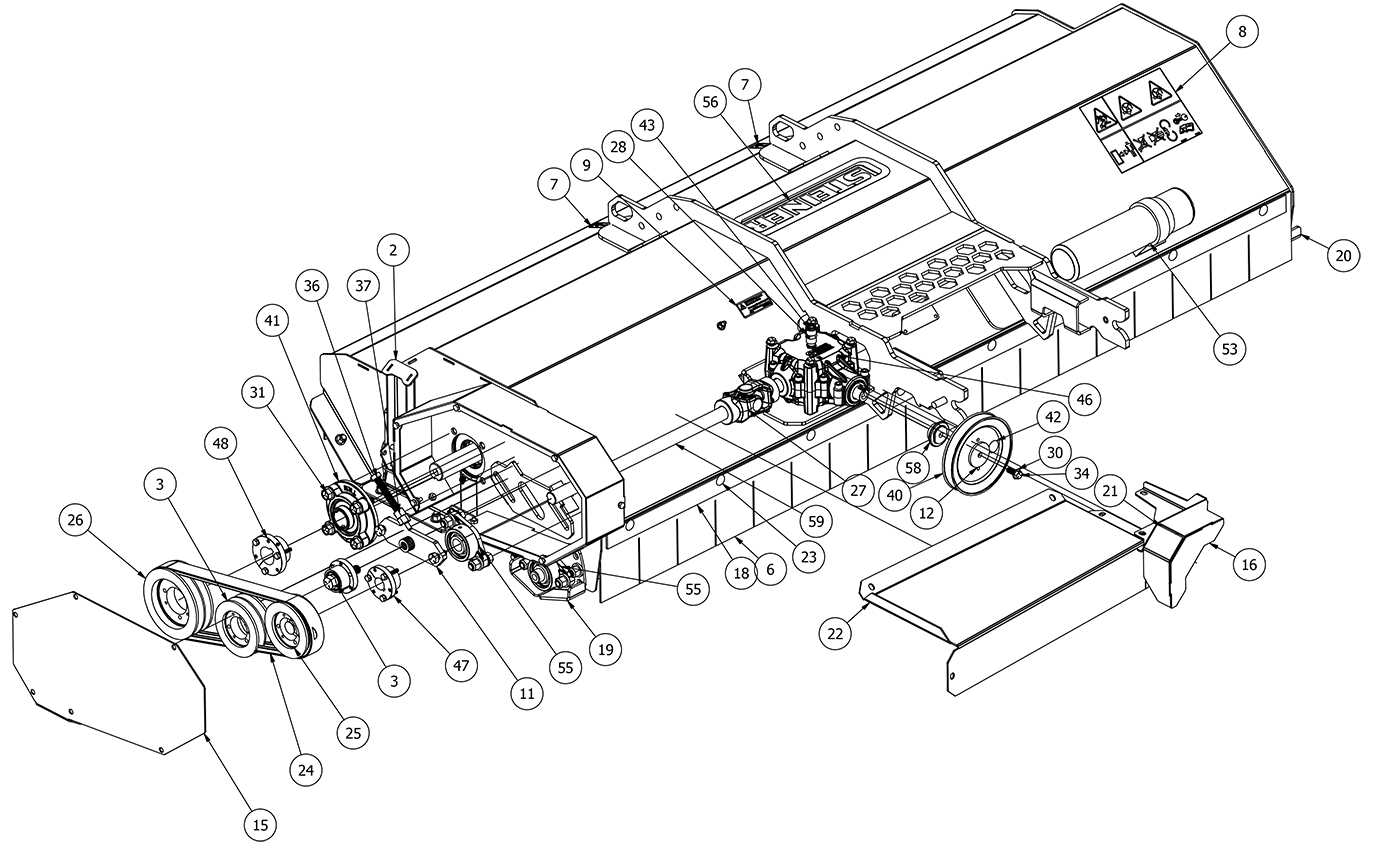

How to Use the Parts Diagram Effectively

Understanding how to interpret a machinery blueprint is essential for successful maintenance and repair. This visual guide provides clarity on the various components that make up the equipment and how they fit together. By following these illustrations, users can identify individual elements and their functions, ensuring efficient assembly or disassembly processes.

Familiarize Yourself with Key Sections

- Start by identifying the major sections, typically broken down into categories such as drive systems, operational mechanisms, and attachments.

- Focus on the reference numbers and labels provided, which will help in locating the correct part when searching for replacements.

- Check for any notes or specifications that may indicate particular maintenance or assembly tips for specific components.

Step-by-Step Approach

- Compare the visual guide with your equipment, paying close attention to the layout of each element.

- Identify the parts that need attention, whether for repair, replacement, or adjustment.

- Utilize the part numbers and descriptions to cross-reference with supplier catalogs or manuals to find accurate matches.

- Ensure that you follow the order of assembly or disassembly as indicated to avoid confusion or incorrect handling.