Comprehensive Guide to Roper Rally Lawn Mower Parts Diagram

Maintaining small engines requires a thorough comprehension of their components and how they interact. By grasping the intricacies of each element, enthusiasts and professionals alike can ensure optimal performance and longevity. This understanding is essential for troubleshooting common issues and facilitating repairs effectively.

Visual aids play a crucial role in this learning process. Diagrams provide clear representations of various assemblies, enabling users to identify and locate specific components easily. This resource can be invaluable for anyone seeking to enhance their mechanical skills and tackle maintenance tasks with confidence.

Whether you are a seasoned technician or a novice, familiarity with these visual tools can streamline your repair processes. By integrating this knowledge into your routine, you can enhance the functionality and reliability of your machinery, ultimately leading to a more efficient and enjoyable experience in your outdoor activities.

Understanding Roper Rally Lawn Mowers

This section explores the essential components and mechanisms behind these popular outdoor maintenance machines. By grasping their functionality, users can optimize their performance and longevity.

Key Features

- Powerful engine options

- User-friendly controls

- Durable construction

- Efficient cutting systems

Maintenance Tips

- Regularly check and change the oil.

- Inspect the blades for sharpness and damage.

- Clean the chassis to prevent rust.

- Store in a dry, sheltered location.

Key Components of Lawn Mowers

Understanding the essential elements that contribute to the functionality of grass cutting machines is vital for both maintenance and operation. Each component plays a significant role in ensuring efficiency and performance while achieving the desired results in turf care.

Engine: The heart of any cutting machine, the engine powers the device and dictates its overall performance. A reliable engine is crucial for consistent operation, influencing both speed and cutting efficiency.

Blades: Sharp and well-maintained blades are fundamental for achieving a clean cut. The design and material of the blades impact how effectively they slice through grass, making regular inspection and sharpening essential for optimal results.

Deck: The deck houses the blades and serves as the primary structure of the machine. Its design affects the maneuverability and stability during use, ensuring that the device can handle various terrains without difficulty.

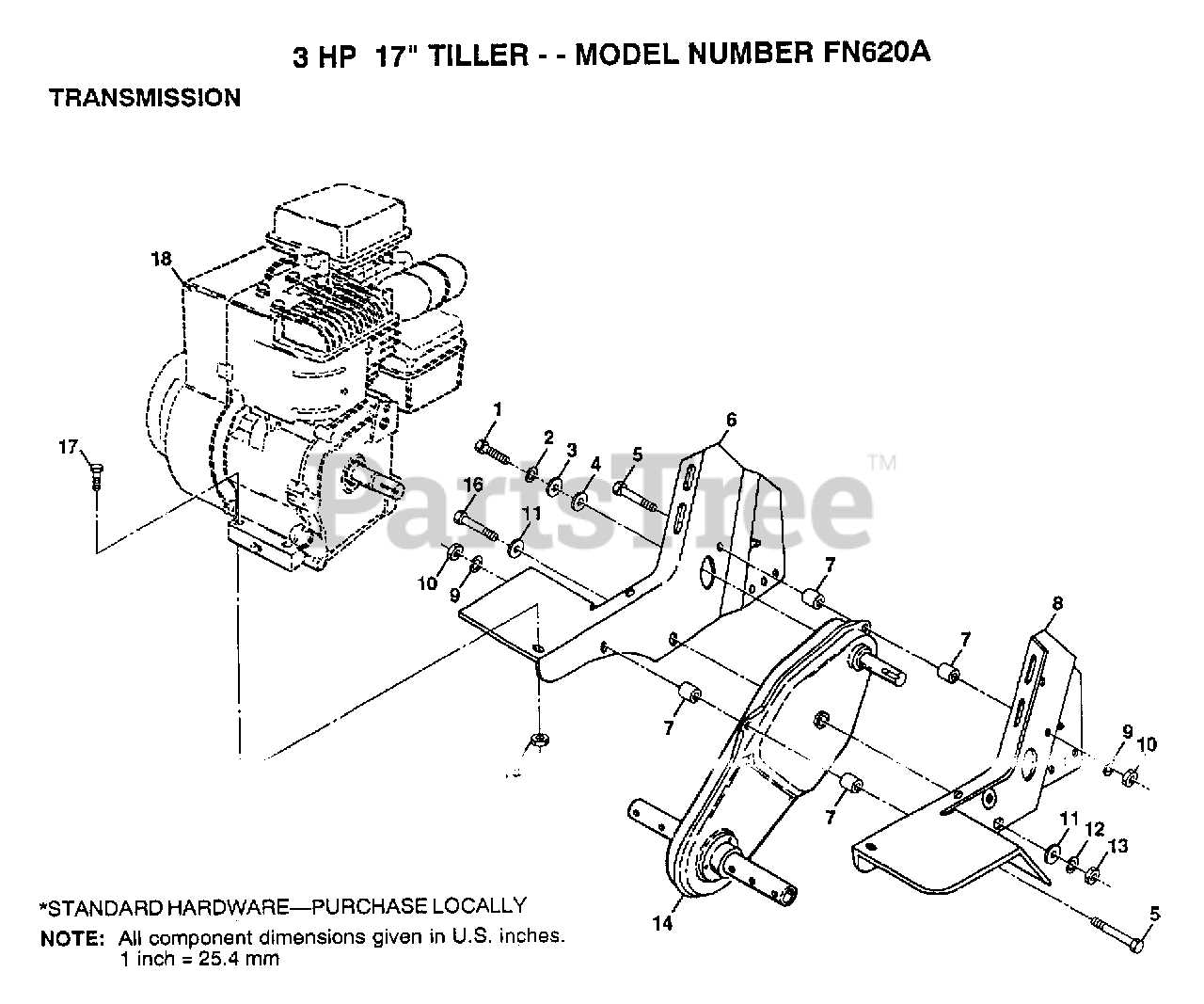

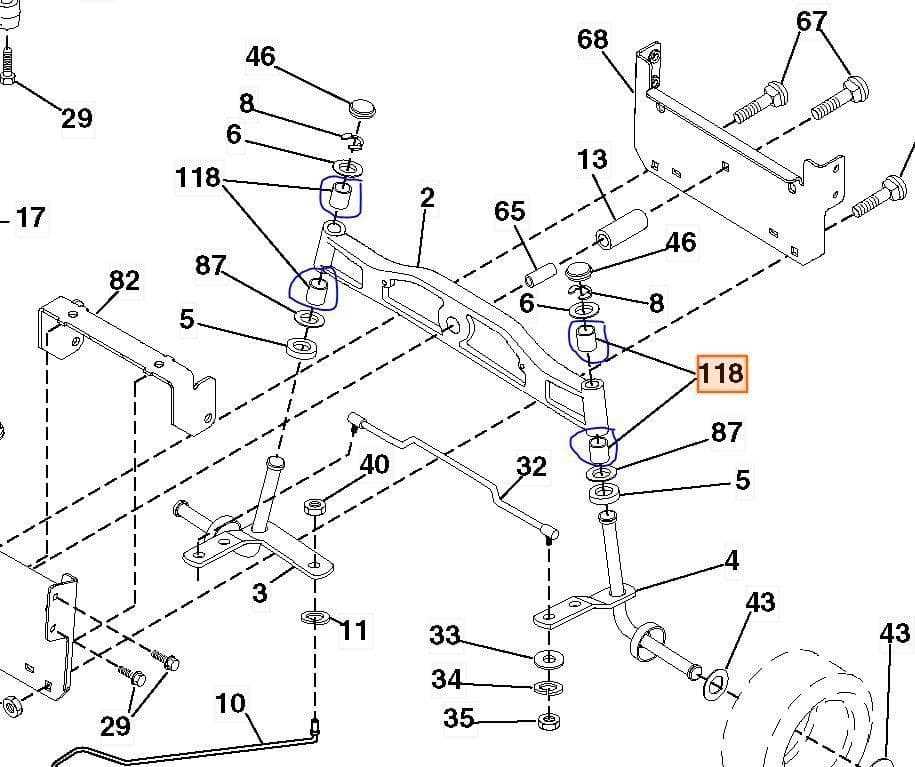

Transmission: This component transmits power from the engine to the wheels, allowing for smooth movement. A well-functioning transmission is critical for ease of handling and control, particularly on slopes and uneven ground.

Wheels: The wheels provide mobility and stability. Their size and tread pattern can greatly influence traction and maneuverability, making them an important factor in performance, especially in challenging conditions.

Fuel System: This system is responsible for delivering the necessary fuel to the engine. Proper maintenance ensures that the engine runs efficiently, preventing issues that could hinder performance.

By familiarizing oneself with these key components, users can better maintain their equipment, ensuring long-lasting performance and enhanced functionality.

Importance of Accurate Parts Diagrams

Clear and precise illustrations of components play a crucial role in the maintenance and repair processes. They provide essential guidance for users, ensuring that each piece is identified correctly and facilitating efficient assembly or replacement. Accurate representations help in minimizing errors and improving the overall effectiveness of repairs.

Moreover, these visuals contribute to a deeper understanding of how various elements interact, which can enhance the user’s ability to troubleshoot issues effectively. An accurate schematic not only saves time but also reduces the risk of damage during repairs.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids provide clear identification of each component. |

| Reduced Errors | Minimizing mistakes during repairs leads to better outcomes. |

| Improved Troubleshooting | A deeper understanding of interactions among parts aids in diagnostics. |

Common Issues with Roper Mowers

When it comes to outdoor machinery, various challenges can arise that may hinder performance and efficiency. Understanding these frequent problems can help users maintain their equipment effectively and extend its lifespan.

- Engine Difficulties: Starting issues are common, often caused by stale fuel or a dead battery.

- Cutting Problems: Inconsistent trimming may result from dull blades or improper deck height settings.

- Transmission Failures: Slipping gears or difficulty in shifting can indicate worn-out components.

- Electrical Malfunctions: Faulty wiring or blown fuses often lead to power outages or unreliable operation.

Regular maintenance is key to preventing these issues. Here are some maintenance tips:

- Change the oil and filters regularly.

- Sharpen or replace blades as needed.

- Inspect belts and cables for wear.

- Clean the air filter to ensure optimal airflow.

By being proactive and addressing these common challenges, users can ensure their outdoor equipment remains in good working condition for years to come.

How to Identify Lawn Mower Parts

Understanding the components of your grass-cutting machine is essential for effective maintenance and repair. Recognizing various elements will empower you to address issues more efficiently and prolong the life of your equipment.

Start by examining the user manual. This document usually includes a labeled guide, making it easier to locate each section. Familiarize yourself with the common components such as the engine, transmission, and cutting blades.

Next, utilize online resources. Websites dedicated to outdoor machinery often offer detailed illustrations and descriptions. These visual aids can help you pinpoint specific areas and understand their functions.

Finally, observe the machine in action. Watching how different elements interact during operation can clarify their roles and importance, providing a deeper understanding of your equipment.

Tools Needed for Maintenance

Proper upkeep of outdoor equipment is essential for optimal performance and longevity. Utilizing the right instruments ensures efficiency during servicing tasks and contributes to the overall health of the machine.

Essential Instruments

Basic tools like wrenches and screwdrivers are fundamental for any maintenance job. Replacing worn components often requires specific sizes, so having a comprehensive set is crucial.

Advanced Equipment

For in-depth care, consider investing in diagnostic tools. These devices allow you to assess functionality and identify underlying issues, making your maintenance efforts more effective.

Replacing Worn Out Components

Over time, various elements of your equipment may degrade, impacting performance and efficiency. Regular maintenance and timely replacement of these components are crucial to ensure longevity and optimal functionality. This section explores the process and considerations for identifying and substituting these essential parts.

Signs of Deterioration

It’s important to recognize when components need to be replaced. Common indicators include unusual noises, decreased performance, and visible wear. Addressing these issues promptly can prevent further damage.

Replacement Process

When you’ve identified worn elements, follow these steps for replacement:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and new components. |

| 2 | Disconnect power source for safety. |

| 3 | Carefully remove the old component. |

| 4 | Install the new part, ensuring a secure fit. |

| 5 | Reconnect the power source and test functionality. |

Where to Find Genuine Parts

When seeking authentic components for your outdoor equipment, it’s essential to know the best sources to ensure quality and reliability. Genuine pieces not only enhance performance but also extend the lifespan of your machinery.

Authorized Dealers

One of the most reliable options is to visit authorized dealers. They offer a wide selection of original items, often backed by warranties. These establishments typically have knowledgeable staff who can assist you in finding exactly what you need.

Online Retailers

Many reputable online platforms specialize in outdoor equipment supplies. Look for websites that guarantee authenticity and offer customer reviews. Utilizing these resources can help you delve into the ultimate options available for your machinery.

Benefits of Using OEM Parts

Opting for original components ensures optimal performance and longevity of your equipment. These parts are specifically designed to meet the manufacturer’s standards, leading to enhanced reliability and efficiency.

Quality Assurance

Original components undergo rigorous testing and quality checks, guaranteeing that they fit perfectly and function as intended. This reduces the likelihood of failures and costly repairs in the long run.

Enhanced Performance

Using genuine components allows your machinery to operate at its best, maximizing efficiency and reducing wear. This ultimately translates to a smoother user experience and extended lifespan for your equipment.

Understanding Warranty Coverage

Warranty coverage serves as a critical safety net for consumers, ensuring that products function as intended for a specified duration. This protection can vary widely, encompassing everything from manufacturing defects to specific service stipulations.

Types of Warranty Coverage

- Limited Warranty: Offers coverage for specific parts or conditions, often excluding certain damages.

- Full Warranty: Provides comprehensive protection, generally covering repairs or replacements without charge.

- Extended Warranty: An option to prolong coverage beyond the standard period, often at an additional cost.

Key Considerations

- Check the duration of the warranty and what it covers.

- Understand the claims process and any documentation required.

- Be aware of any exclusions that may apply to your coverage.

Safety Tips for Lawn Care

Maintaining your outdoor space can be a rewarding experience, but it’s essential to prioritize safety while working with various equipment and tools. By following key guidelines, you can protect yourself and ensure a smooth process while enhancing the beauty of your surroundings.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) when engaging in outdoor maintenance activities. This includes sturdy footwear, gloves, and eye protection to shield against debris. Additionally, consider using hearing protection if operating noisy machinery for extended periods.

Equipment Handling

Proper handling of tools and machinery is crucial to avoid accidents. Before use, inspect all equipment for any defects or damage. Familiarize yourself with the operational instructions, and ensure that safety features are functioning correctly. When finished, store all equipment safely and out of reach of children and pets.

Upgrading Your Roper Mower

Enhancing the performance and longevity of your outdoor equipment can significantly transform your mowing experience. By focusing on key components and innovative upgrades, you can ensure that your machine operates at its ultimate efficiency while also meeting your specific needs.

Key Improvements

Consider upgrading the engine for better power and fuel efficiency. A high-quality replacement can lead to a smoother operation and reduced maintenance costs. Additionally, enhancing the cutting mechanism can provide a cleaner and more precise cut, elevating the overall quality of your lawn care.

Maintenance Tips

Regular maintenance is crucial to maximize the benefits of any upgrades. Ensure that all components are clean and well-lubricated. Replacing worn-out elements promptly can prevent larger issues down the line. Delve into your machine’s manual to identify parts that may require attention or enhancement.

Maintenance Schedule for Longevity

Establishing a regular upkeep routine is crucial for extending the lifespan of your equipment. Consistent attention to essential tasks can enhance performance, reduce the likelihood of breakdowns, and ensure optimal efficiency over time.

Routine Tasks

- Check and replace the oil at regular intervals.

- Inspect and clean air filters to prevent clogging.

- Sharpen blades to maintain cutting efficiency.

Seasonal Care

- Before winter storage, clean and cover the machine.

- In spring, inspect belts and cables for wear.

- Lubricate moving parts to reduce friction.