Understanding the Lincoln Ranger 8 Parts Diagram

In the realm of automotive mechanics, grasping the intricacies of a vehicle’s composition is essential for maintenance and repair. This section delves into the intricate details that outline the arrangement and interaction of various components, providing a clear visual guide to enhance comprehension for both enthusiasts and professionals alike.

Comprehension of a vehicle’s layout empowers individuals to troubleshoot issues effectively and undertake necessary modifications with confidence. By examining how each element fits within the overall structure, one gains valuable insights that can lead to improved performance and longevity of the machine.

Moreover, visual representations serve as invaluable resources, facilitating a deeper understanding of complex systems. By breaking down the assembly into manageable sections, one can appreciate the function and significance of each constituent, fostering a more informed approach to vehicle care and enhancement.

Understanding the Lincoln Ranger 8

This section delves into the essential aspects of a well-known portable welding machine. It highlights the key features and components that contribute to its functionality and performance in various applications. Grasping the intricacies of this equipment is crucial for both beginners and seasoned professionals in the welding industry.

Manufactured for efficiency, this device is particularly valued for its robustness and versatility. Its design allows for seamless operation in diverse environments, making it a popular choice among welders. Understanding its structure not only enhances operational skills but also aids in maintenance and troubleshooting.

| Feature | Description |

|---|---|

| Power Source | Reliable and strong, ensuring consistent performance. |

| Portability | Compact and lightweight, ideal for on-site jobs. |

| Control Settings | Easy-to-use dials for precise adjustments. |

| Cooling System | Effective mechanism to prevent overheating during operation. |

| Durability | Built with high-quality materials to withstand harsh conditions. |

By familiarizing oneself with these fundamental elements, users can optimize their experience and achieve superior results in their welding projects. Knowledge of the machine’s configuration not only boosts productivity but also enhances safety measures during operation.

Essential Components of the Ranger 8

Understanding the crucial elements of this welding machine is key to optimizing its performance and longevity. Each component plays a significant role in ensuring efficient operation, safety, and ease of maintenance. A thorough grasp of these features can enhance the user experience and facilitate troubleshooting.

Power Source: The heart of the device, the power source converts energy into the necessary form for effective welding. Its reliability directly impacts the quality of the welds produced.

Control Panel: This interface allows users to adjust settings such as voltage and amperage. A well-designed control panel enhances usability, making it easier to customize operations according to specific tasks.

Cooling System: Essential for maintaining optimal operating temperatures, the cooling mechanism prevents overheating. Efficient heat management prolongs the lifespan of the machine and ensures consistent performance.

Electrode Holder: A crucial attachment, the electrode holder securely grips the welding rod, providing stability during operation. Its design affects the ease of use and comfort for the operator.

Ground Clamp: This component ensures a stable electrical connection to the workpiece, minimizing resistance. A secure ground is vital for effective welding and reduces the risk of defects in the final product.

Welding Gun: The welding gun directs the welding arc to the workpiece. Its ergonomic design and efficiency significantly influence the ease of handling and precision of the welds.

Familiarity with these key elements empowers users to maximize their equipment’s potential and maintain optimal functionality throughout its lifespan.

Importance of a Parts Diagram

A visual representation of components is essential for anyone working on machinery or equipment. It serves as a crucial tool that enhances understanding, enabling users to identify individual elements and their functions. By providing clarity, it helps both novices and experienced individuals navigate complex assemblies with ease.

Moreover, such illustrations facilitate efficient maintenance and repair processes. When issues arise, having access to a comprehensive visual guide allows for quicker diagnostics and troubleshooting. This not only saves time but also reduces the risk of errors during assembly or disassembly.

Additionally, these schematics promote effective communication among technicians and engineers. A shared reference point fosters collaboration and ensures that all parties involved are on the same page, ultimately leading to more successful outcomes in repair and maintenance tasks.

In conclusion, a detailed illustration of machine components is invaluable. It streamlines operations, enhances understanding, and improves collaboration, making it an indispensable resource for anyone involved in equipment management.

Common Issues with Lincoln Ranger 8

Welders, like any mechanical device, can experience a range of problems over time. Understanding these common issues can help users maintain optimal performance and extend the lifespan of their equipment. Below are some frequently encountered challenges and tips for addressing them.

Electrical Problems

Electrical issues can significantly hinder operation. Common symptoms include:

- Poor or inconsistent arc performance

- Failure to start or unexpected shutdowns

- Burnt fuses or tripped breakers

To troubleshoot, check connections, inspect cables for damage, and ensure all components are functioning properly. Regular maintenance can help prevent these electrical failures.

Gas and Fuel Concerns

Fuel and gas-related complications can lead to performance issues. Typical problems include:

- Gas leaks or improper gas flow

- Fuel contamination or evaporation

- Inefficient combustion

For resolution, inspect all lines for leaks, replace filters regularly, and ensure the correct fuel type is being used. Keeping the fuel system clean is essential for reliable operation.

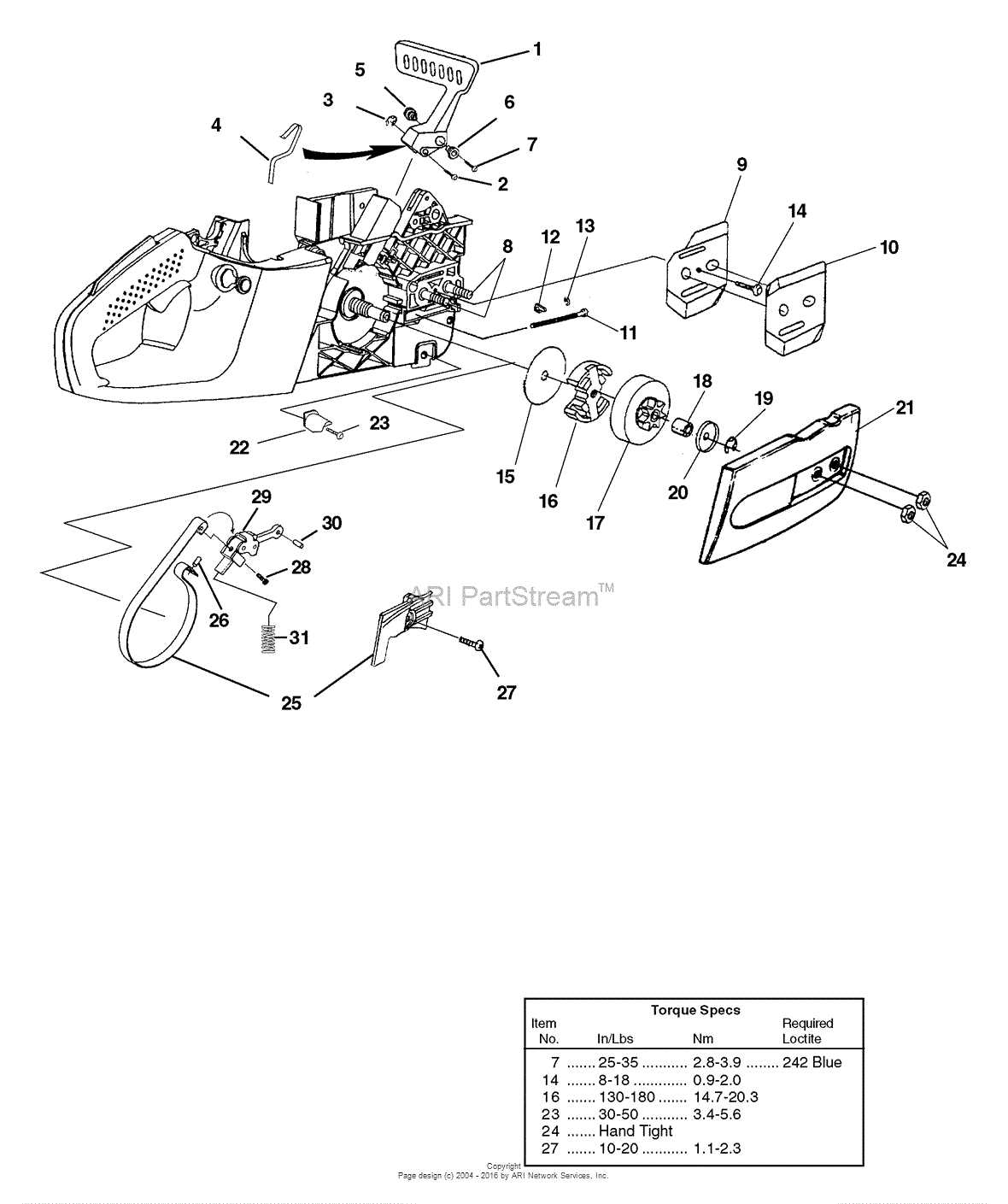

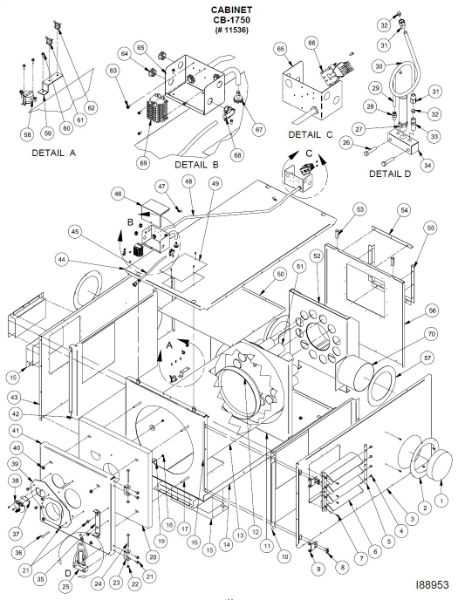

How to Read the Parts Diagram

Understanding the Overview

Reading a visual representation of components can be an essential skill for anyone involved in maintenance or repair tasks. Such illustrations provide a comprehensive view of various elements, showcasing how they interconnect and function together. By familiarizing yourself with these graphics, you can enhance your ability to identify and source specific components as needed.

Familiarizing with Symbols

Each illustration typically uses a unique set of symbols and markings to represent different items. It’s crucial to take the time to understand what each symbol signifies, as this knowledge will streamline the process of locating parts. Look for a legend or key, as it often accompanies the illustration, explaining the various symbols and their meanings.

Identifying Key Components

Once you understand the symbols, focus on identifying key components within the illustration. Components may be labeled with numbers or letters, allowing for easy reference. Cross-referencing these labels with accompanying documentation can clarify the function of each part, making troubleshooting more efficient.

Utilizing the Layout

The arrangement of items in the graphic is often intentional, reflecting their physical relationship in the system. Pay attention to how components are grouped, as this can indicate their functionality and interactions. Understanding this layout can be invaluable when attempting repairs or upgrades.

Conclusion

In summary, effectively interpreting these visual aids requires practice and attention to detail. By understanding the symbols, identifying components, and utilizing the layout, you can significantly improve your skills in maintenance and repairs. With this knowledge, you will be better equipped to tackle any challenges that arise.

Where to Find Replacement Parts

When it comes to maintaining your equipment, locating suitable components is crucial for ensuring optimal performance. Whether you are conducting routine maintenance or addressing a specific issue, having access to reliable sources for essential items can save both time and effort.

One effective method is to explore authorized dealers who specialize in equipment-related accessories. These professionals often provide genuine items that guarantee compatibility and quality. Additionally, visiting their online platforms can offer a broader selection, along with detailed information regarding availability and pricing.

Another excellent avenue is specialty retailers that focus on the specific type of machinery you are working with. These establishments typically stock a wide range of alternatives and can provide valuable advice on the best options for your needs. Furthermore, engaging with online marketplaces allows you to compare different sellers, making it easier to find competitive prices.

For those looking to save costs, exploring second-hand options through classified ads or auction sites can be beneficial. However, it is essential to verify the condition and compatibility of these components to avoid potential issues down the line.

Lastly, don’t underestimate the power of community forums and user groups. Connecting with fellow enthusiasts can lead to recommendations for reliable suppliers and even direct access to unused or surplus items. Networking within these communities often proves invaluable for finding the exact components you require.

Maintenance Tips for Lincoln Ranger 8

Proper upkeep of your equipment is crucial for ensuring longevity and optimal performance. Regular maintenance not only helps prevent breakdowns but also enhances efficiency, allowing you to get the most out of your investment. Following a systematic approach to care can lead to improved functionality and reduced repair costs.

Start by routinely checking all fluid levels, including oil and coolant. Keeping these at recommended levels helps prevent overheating and ensures smooth operation. Additionally, inspect filters regularly to ensure they are clean and free from debris, as this contributes to better performance and reduces wear on internal components.

Examine electrical connections and wiring for any signs of corrosion or damage. Clean connections can help maintain reliable power delivery. Furthermore, pay attention to any unusual noises or vibrations during operation; these can indicate underlying issues that require immediate attention.

Regularly inspect hoses and belts for signs of wear, such as cracks or fraying. Replacing these components as needed will prevent more significant problems down the line. Lastly, ensure that all moving parts are adequately lubricated, as this minimizes friction and prolongs the life of the machinery.

Upgrades for Enhanced Performance

Improving the efficiency and capabilities of your equipment can significantly enhance its overall functionality. By implementing various enhancements, users can experience better output, increased reliability, and a longer lifespan for their machinery. This section explores several effective modifications that can elevate performance to new heights.

Power and Efficiency Enhancements

One of the most impactful upgrades involves boosting power delivery. Consider installing a high-performance engine component that optimizes fuel efficiency and maximizes torque. Additionally, enhancing the exhaust system can facilitate improved airflow, which contributes to more effective combustion and overall energy output.

Durability and Reliability Improvements

To ensure longevity, investing in high-quality materials is essential. Upgrading to reinforced components can reduce wear and tear, thereby minimizing maintenance costs. Furthermore, implementing advanced cooling systems can prevent overheating, ensuring that your equipment operates at peak performance under demanding conditions.

In summary, strategic enhancements can lead to substantial gains in performance, efficiency, and durability. Exploring these options can empower users to achieve their desired outcomes with confidence.

DIY Repairs: A Step-by-Step Guide

Engaging in do-it-yourself maintenance can be both rewarding and cost-effective. This guide will provide you with a systematic approach to troubleshoot and resolve common issues effectively. By following these steps, you can enhance your skills and ensure the longevity of your equipment.

Before you begin, gather the necessary tools and materials:

- Basic hand tools (screwdrivers, wrenches, pliers)

- Replacement components (if applicable)

- Cleaning supplies (rags, solvents)

- Safety gear (gloves, goggles)

Here’s a simple step-by-step process to tackle your repair:

- Identify the Problem: Observe the equipment carefully to pinpoint any unusual noises, leaks, or performance issues.

- Refer to the Manual: Consult the user manual or repair guide for specific troubleshooting tips related to your model.

- Disassemble as Needed: If necessary, carefully take apart the components involved, keeping track of each piece for reassembly.

- Clean the Area: Remove any dirt, debris, or corrosion that may affect functionality.

- Replace Components: Swap out any damaged parts with new or refurbished ones, ensuring a proper fit.

- Reassemble: Carefully put everything back together, following your initial disassembly order.

- Test Your Work: Run the equipment to ensure everything functions correctly. Listen for any irregular sounds and check for leaks.

By following this guide, you can gain confidence in handling repairs, saving both time and money while maintaining your equipment in optimal condition.

Safety Precautions When Repairing

When undertaking any maintenance or repair work, it is crucial to prioritize safety to prevent accidents and ensure a secure working environment. Proper precautions not only protect the individual performing the tasks but also contribute to a more efficient repair process. Adhering to established safety protocols is essential for anyone involved in mechanical or electrical repairs.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots.

- Ensure the workspace is clean and organized to minimize hazards.

- Disconnect power sources before starting any repairs to prevent electric shock.

- Use tools that are in good condition and suitable for the task at hand.

- Maintain proper ventilation, especially when working with chemicals or in enclosed spaces.

Specific Safety Measures

- Read and understand the manufacturer’s instructions before beginning any repair work.

- Have a first aid kit readily available in case of accidents.

- Be aware of your surroundings and ensure that no one is in the immediate area while you are working.

- Properly dispose of any hazardous materials in accordance with local regulations.

- Take regular breaks to avoid fatigue, which can lead to mistakes and accidents.

Customer Reviews and Experiences

This section delves into the thoughts and reflections of users who have interacted with a particular range of equipment. Their insights provide valuable perspectives on performance, durability, and overall satisfaction. By sharing their personal stories, customers help others make informed decisions and highlight areas of improvement.

Many users praise the reliability and efficiency of their machinery, noting how it seamlessly integrates into their workflows. Several reviewers emphasize the ease of operation, which allows both novices and seasoned professionals to achieve desired results without extensive training.

On the other hand, some experiences highlight challenges, particularly related to maintenance and repair. Users frequently share tips on sourcing compatible components and navigating repair processes. These shared experiences foster a sense of community among users, encouraging them to support one another in overcoming obstacles.

Overall, customer feedback serves as a critical resource for potential buyers, showcasing the strengths and weaknesses of the equipment. By considering these reviews, individuals can better understand what to expect and make choices that align with their needs.